Base plate cutting cutter wheel device and base plate cutting method

A cutting knife and substrate technology, applied to glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass debris splashing, etc., and achieve the effects of reducing wear, preventing foreign matter, and cutting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

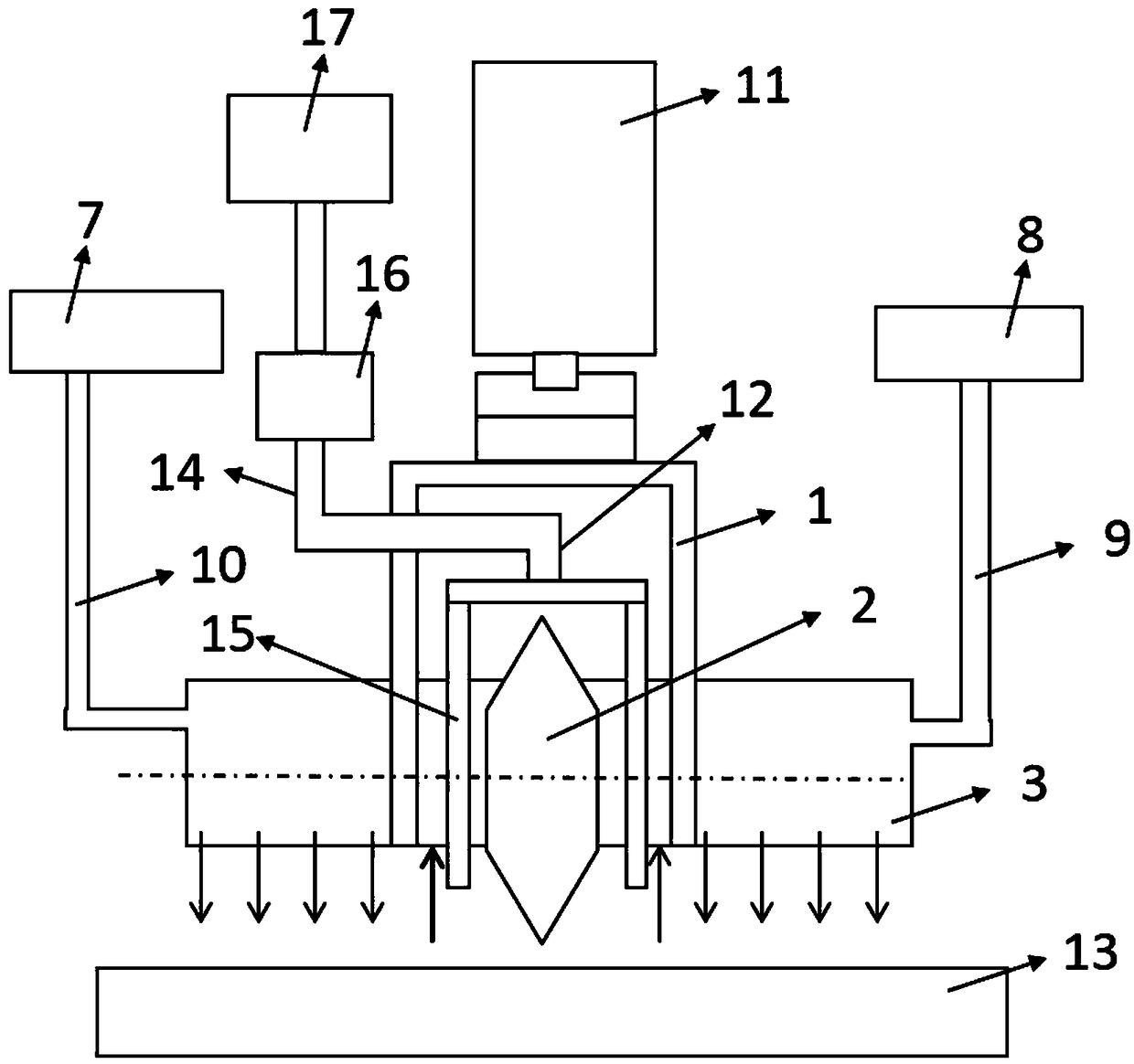

[0038] figure 2 It is a structural schematic diagram of the present invention, such as figure 2 As shown, a substrate cutting cutter wheel device includes: a mounting frame 1, a cutter wheel 2 and a motor 11 arranged on the mounting frame 1, an air flotation platform 3, a positive pressure pipeline 9 connected to the air flotation platform 3 and a negative The pressure pipeline 10, the positive pressure solenoid valve 8 connected to the positive pressure pipeline 9, the negative pressure solenoid valve 7 connected to the negative pressure pipeline 10, and the dust collecting devices 12 arranged on both sides of the cutter wheel 2.

[0039] Wherein, the negative pressure pipeline 10 is a vacuum interface, which can inhale air; the positive pressure pipeline 9 is a CDA interface, which can be blown up.

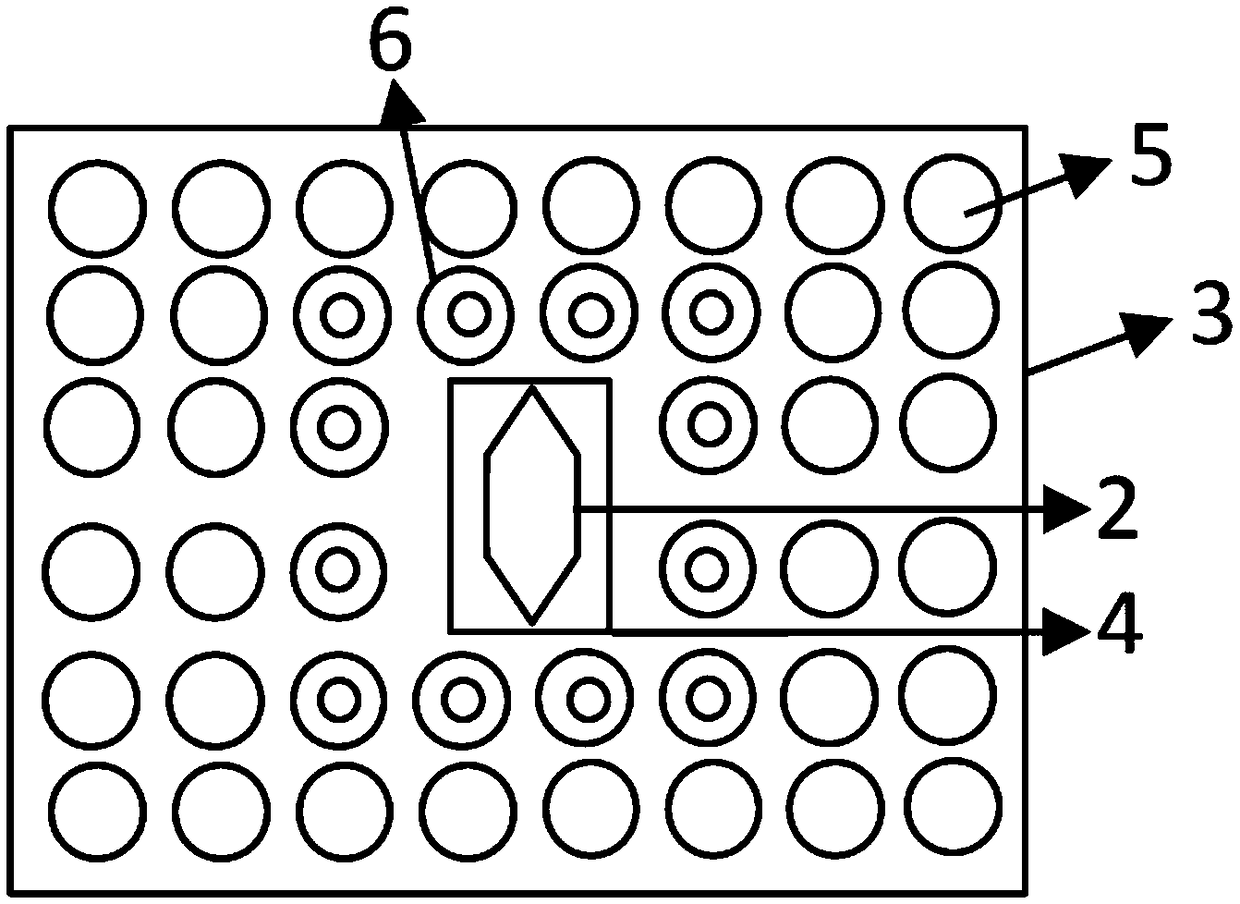

[0040] Such as image 3 Shown is a schematic structural view of the air bearing platform 3 of the present invention, the air bearing platform 3 includes a cutter wheel place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com