Overheating protection button switch

A technology of overheating protection and buttons, which is applied to thermal switch parts and other directions, can solve the problems of easy burnout of button switches, affecting the swing accuracy of conductive seesaw, and poor reliability of buttons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

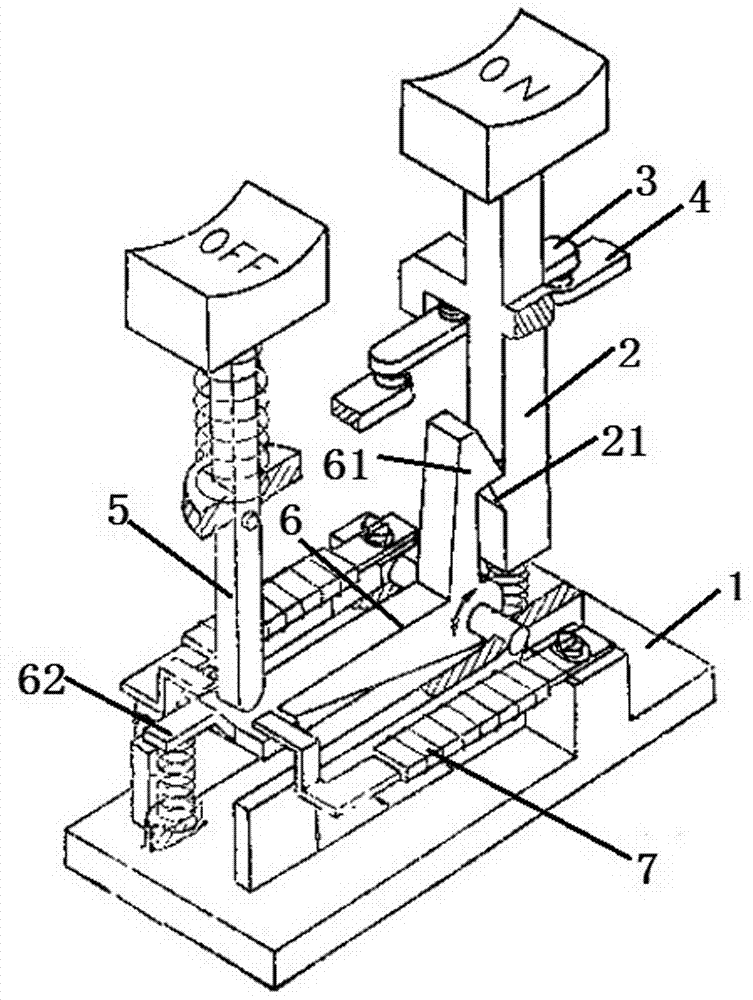

[0011] Such as figure 1 Shown: Overheat protection button switch, including base body 1, on button and off button. The on button consists of a button cap, a connecting rod 2, a movable contact 3 and a fixed contact 4 from top to bottom. The movable contact 3 is installed on the connecting rod 2, and when the connecting rod 2 moves downward, Contact with the fixed contact 4 in order to complete the circuit. The front end of the connecting rod 2 is a chuck 21 with the tip facing upward. The disconnect button comprises a disconnect button cap, a disconnect lever 5 and a return spring. After the disconnect button is pressed, the disconnect button cap and the disconnect lever 5 can return to their original positions under the action of the return spring.

[0012] A claw lever 6 is installed on the seat body 1 along the straight line where the disconnecting lever 5 and the connecting lever 2 are located. The claw lever 6 is hinged on the seat body through the claw lever shaft. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com