Docile non-bracket type windscreen wiper structure

A bracket type, wiper technology, applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of increased fuel consumption, damage to safety, increased power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

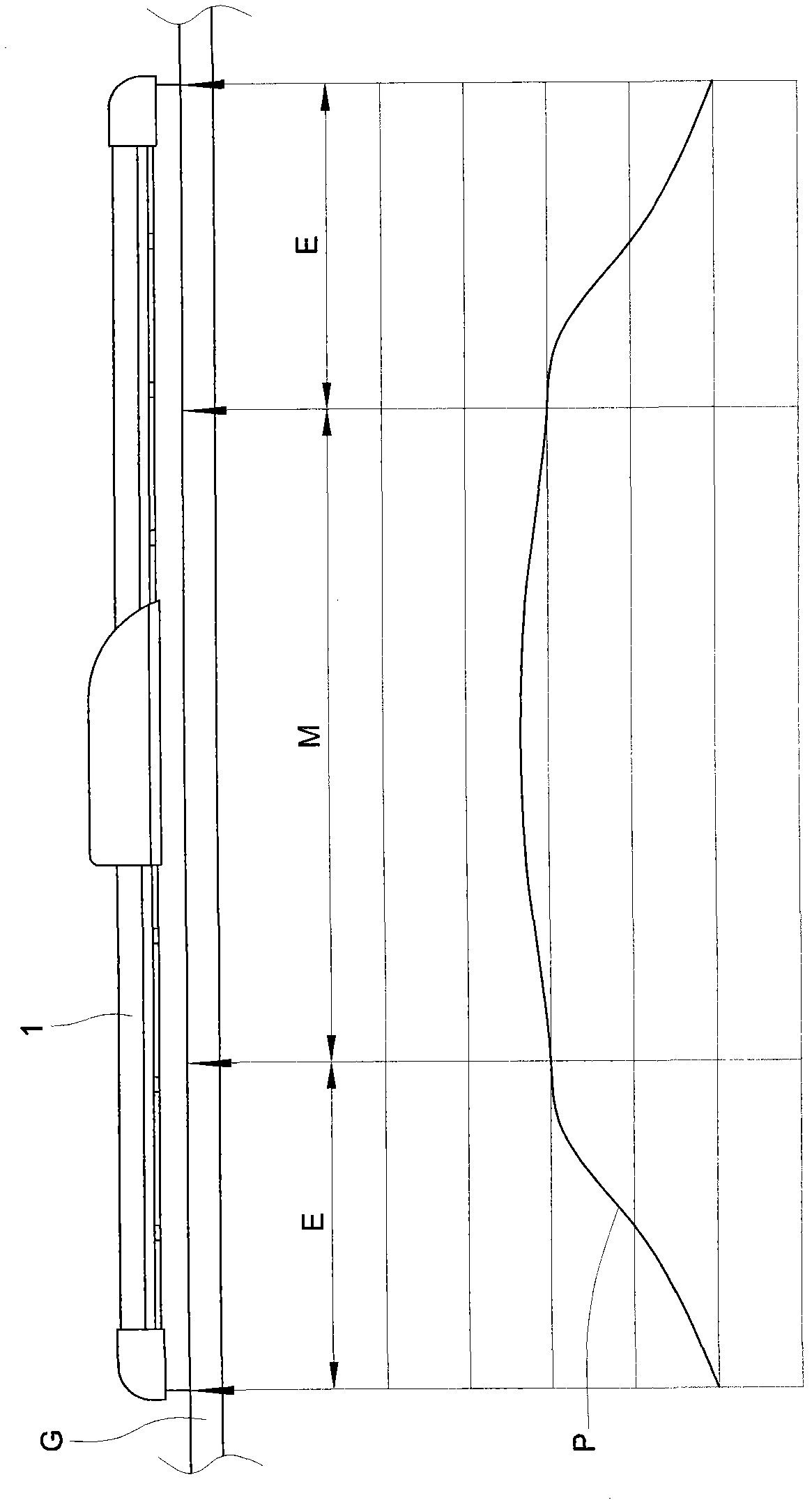

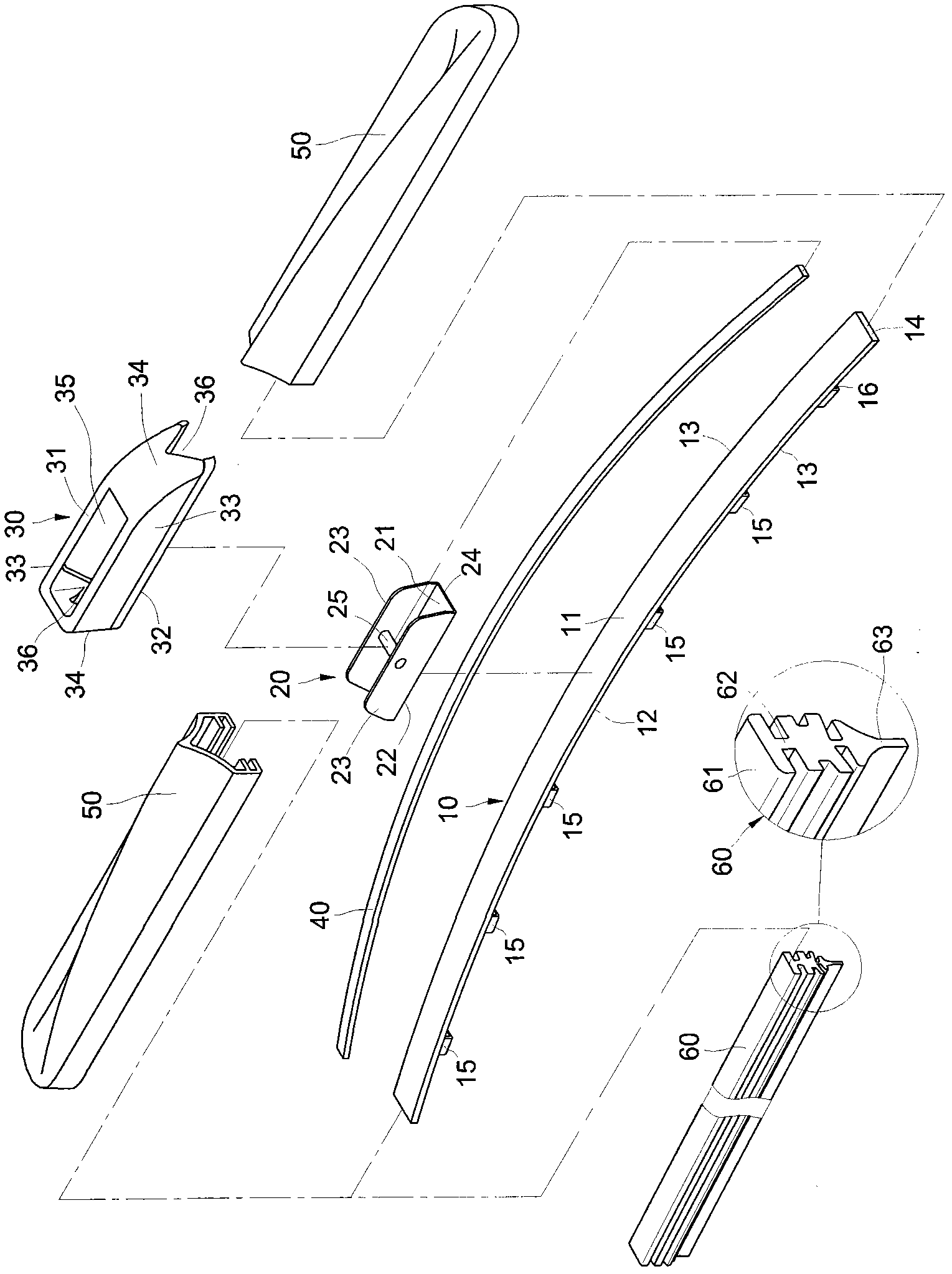

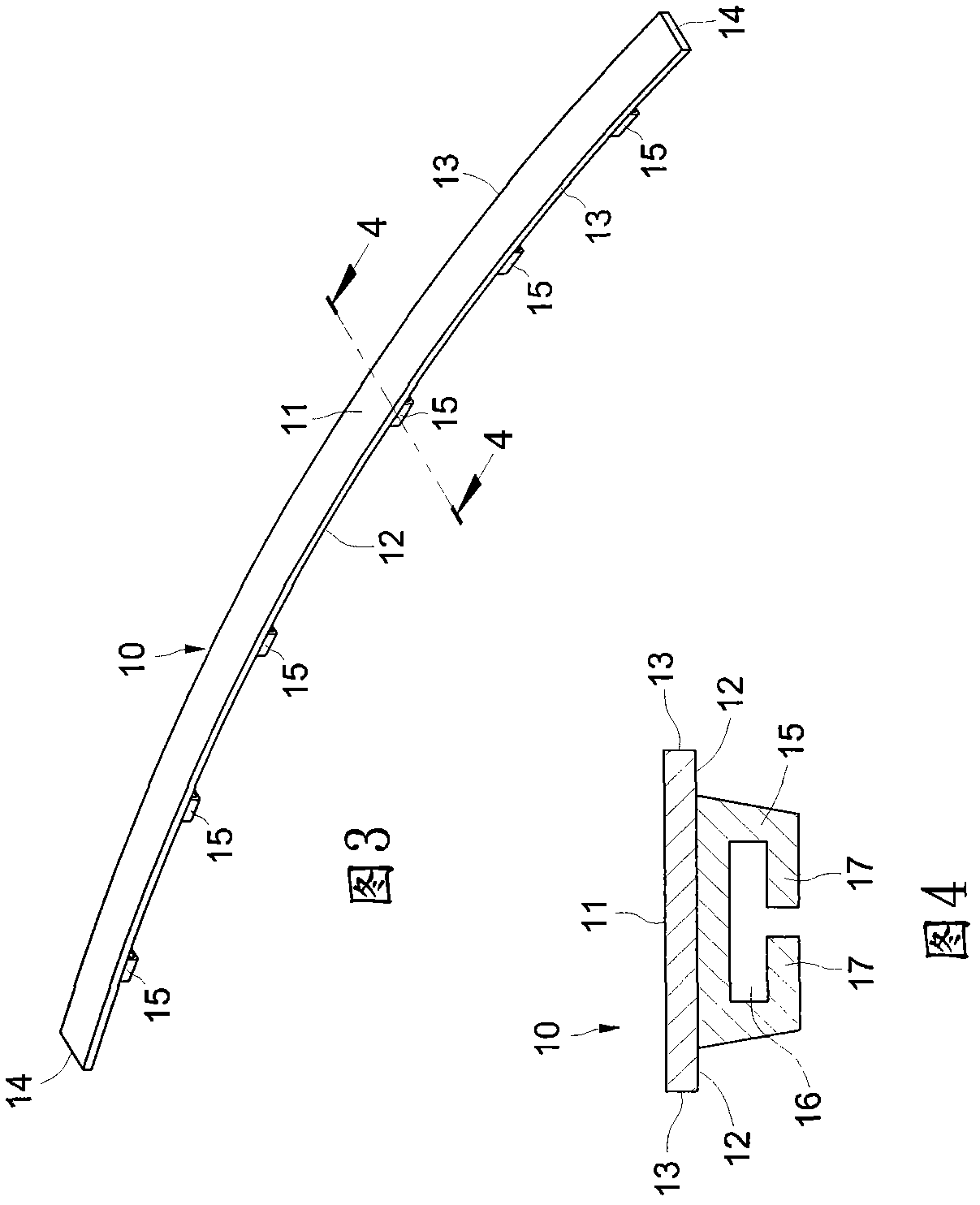

[0083] Please refer to Figure 2 to Figure 7 , Figure 19 and Figure 20 As shown, the non-support type wiper structure of the present invention includes:

[0084] The metal dome body 10 is made of a flexible metal material and is a flat rectangular strip that bends downwards. It has a top surface 11, a bottom surface 12, and two long sides 13 and two short sides 14 parallel to each other. The bottom surface 12 is convex There are several clamping seats 15 arranged at intervals, and the bottom surfaces of the clamping seats 15 are respectively bent inwardly to surround and form a hollow channel 16, and two horizontal clamping parts 17 (such as Figure 4 shown);

[0085] The receiving seat 20 is fixed at the center of the top surface 11 of the metal shrapnel body 10, and has a top surface 21, a bottom surface 22, two long sides 23 parallel to each other and two short sides 24, and a straddle between the two long sides 23 There is a support shaft 25, which can be connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com