Polishing solution containing ceric oxide powder/colloid silicon dioxide mixed abrasive and preparing process thereof

A technology of colloidal silica and ceria, which is applied in the direction of polishing compositions containing abrasives, can solve the problems of uneven size and shape of composite particles, complicated preparation methods, scratches and pits, etc., and achieves favorable Large-scale production, simple preparation process, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

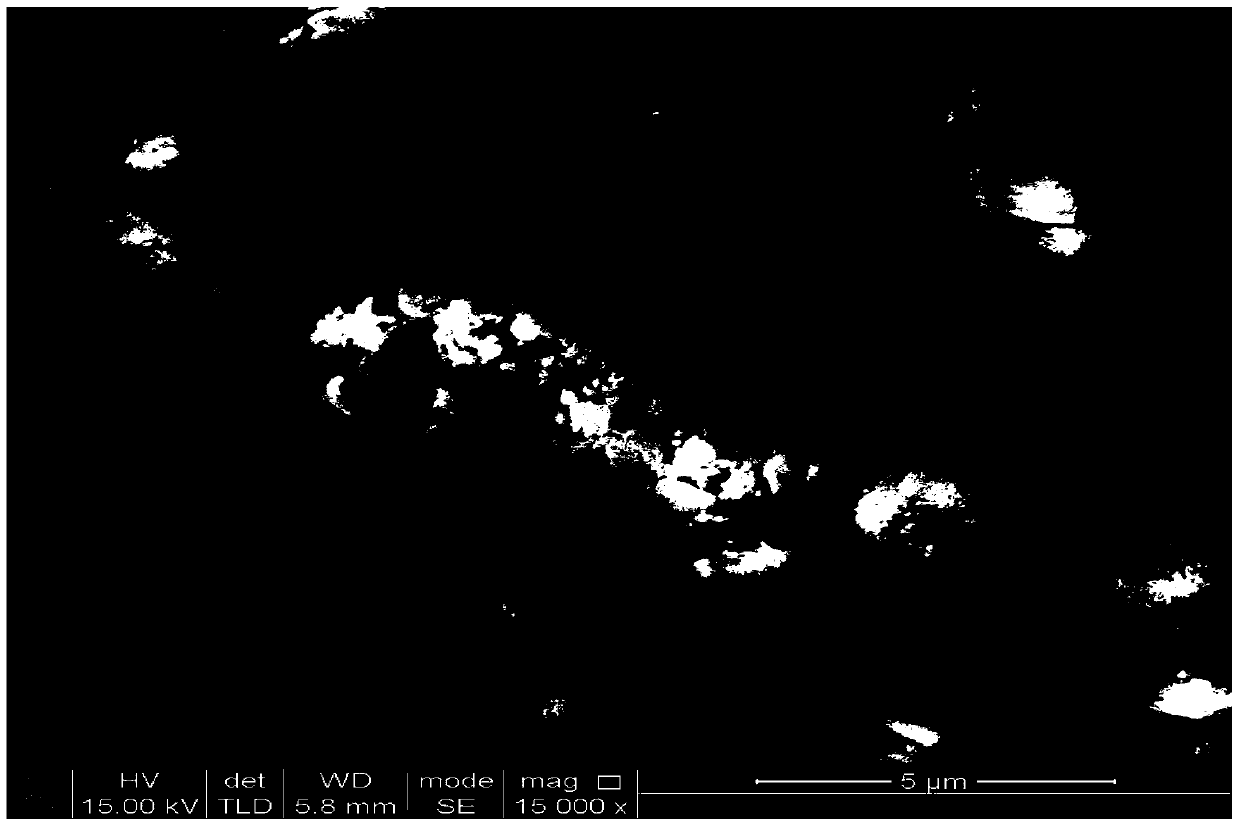

[0022] The polishing liquid containing ceria powder and colloidal silicon dioxide mixed abrasive uses cerium dioxide powder, colloidal silicon dioxide, dispersant and water as raw materials, and the weight percentage of each component is: cerium dioxide powder Colloid 3%-10%, colloidal silicon dioxide 5%-50%, dispersant 0.001%-0.5%, and the rest is water;

[0023] Wherein, the particle size of the ceria is 100-2000nm, and the particle size of the silicon dioxide is 10-200nm.

[0024] For the selected dispersant, sodium dodecylsulfonate, sodium dodecylbenzenesulfonate, Tween 80, polyethylene glycol 400, polyvinylpyrrolidone, carboxymethylcellulose, polyacrylamide , cetyltrimethylammonium bromide, polyethyleneimine, sodium hexametaphosphate, chlorododecylpyridinium, isopropanolamine, fatty alcohol polyoxyethylene ether phosphate or one or more Compositions.

[0025] There is also a pH regulator in the raw materials, the content of which ensures that the pH of the solution is c...

Embodiment 1

[0032] A polishing solution containing mixed abrasives of cerium dioxide powder and colloidal silicon dioxide, the weight percentage of each component is 3% of cerium dioxide powder with a particle size of 100nm, and 50% of colloidal particles with a particle size of 10nm Silicon dioxide (SiO 2 concentration is 35%), 0.001% of the dispersant is sodium dodecylbenzenesulfonate and polyethylene glycol 400, and the rest are water;

[0033] According to the amount of required polishing fluid, select an appropriate container (or storage equipment in actual production), and add 50% of colloidal silicon dioxide (SiO2) with a particle size of 10 nm to it. 2 Concentration is 35%), then add 3% cerium oxide powder with a particle size of 100nm and stir evenly, then add 0.001% of the composition of sodium dodecylbenzenesulfonate and polyethylene glycol 400 as a dispersant, Finally, add water to the required volume and stir evenly, add a pH adjuster, such as one or a mixture of ammonia, po...

Embodiment 2

[0036] A polishing solution containing mixed abrasives of cerium oxide powder and colloidal silicon dioxide, the weight percentage of each component is 5% of cerium oxide powder with a particle diameter of 600nm, and 45% of colloidal powder with a particle diameter of 80nm Silicon dioxide (SiO 2 Concentration is 35%), the composition of 0.008% sodium lauryl sulfonate and Tween 80 is used as dispersant, and all the other are water;

[0037] According to the amount of required polishing fluid, select an appropriate container (or storage equipment in actual production), and add 45% of colloidal silicon dioxide (SiO2) with a particle size of 80nm therein 2 Concentration is 35%), then add 5% cerium oxide powder with a particle size of 600nm and stir evenly, then add 0.008% sodium dodecylsulfonate and Tween 80 composition as a dispersant, finally add water to the required volume and stir evenly, add a pH adjuster, such as one or a mixture of ammonia, potassium hydroxide, and sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com