Tool for machining stone or concrete floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

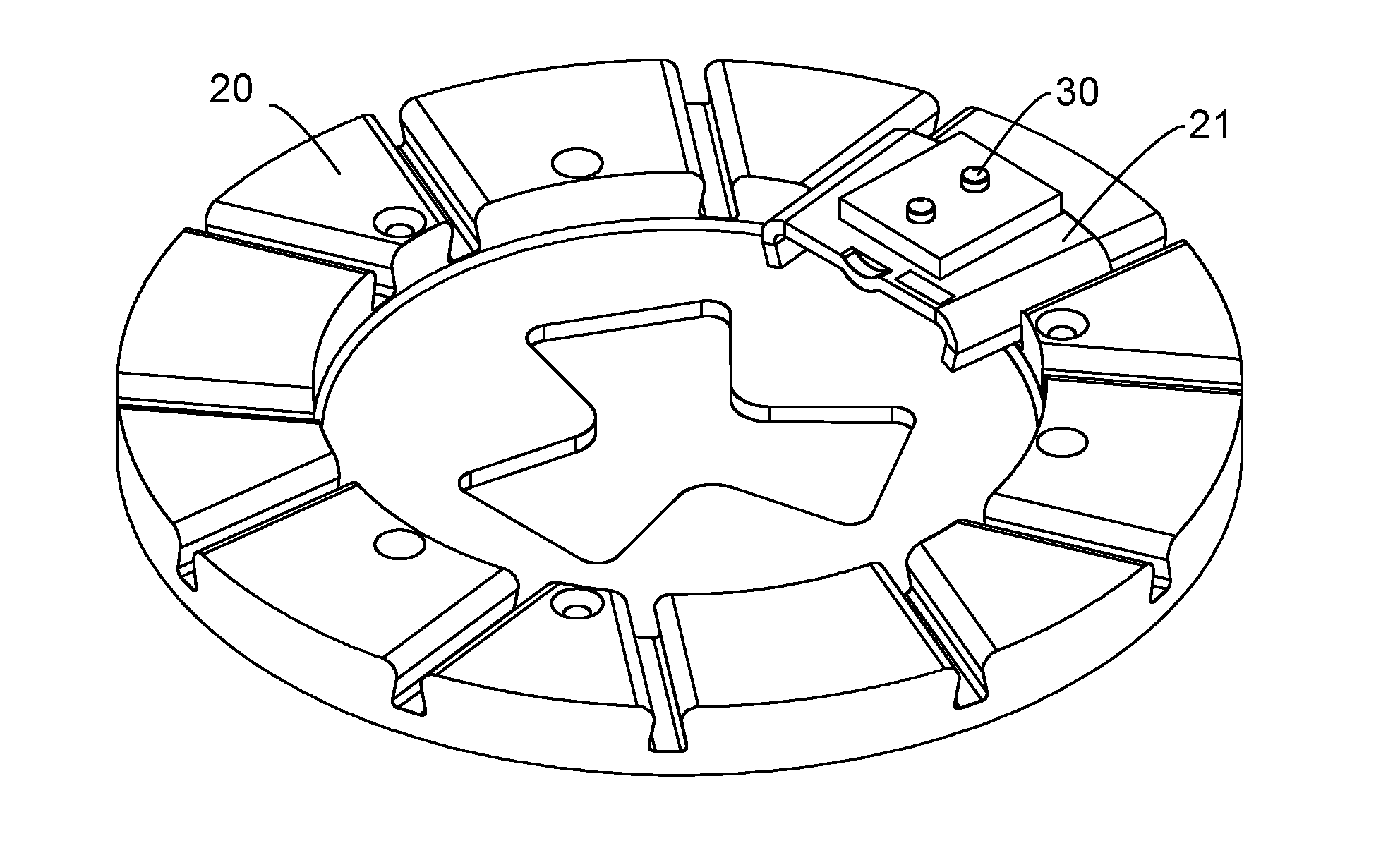

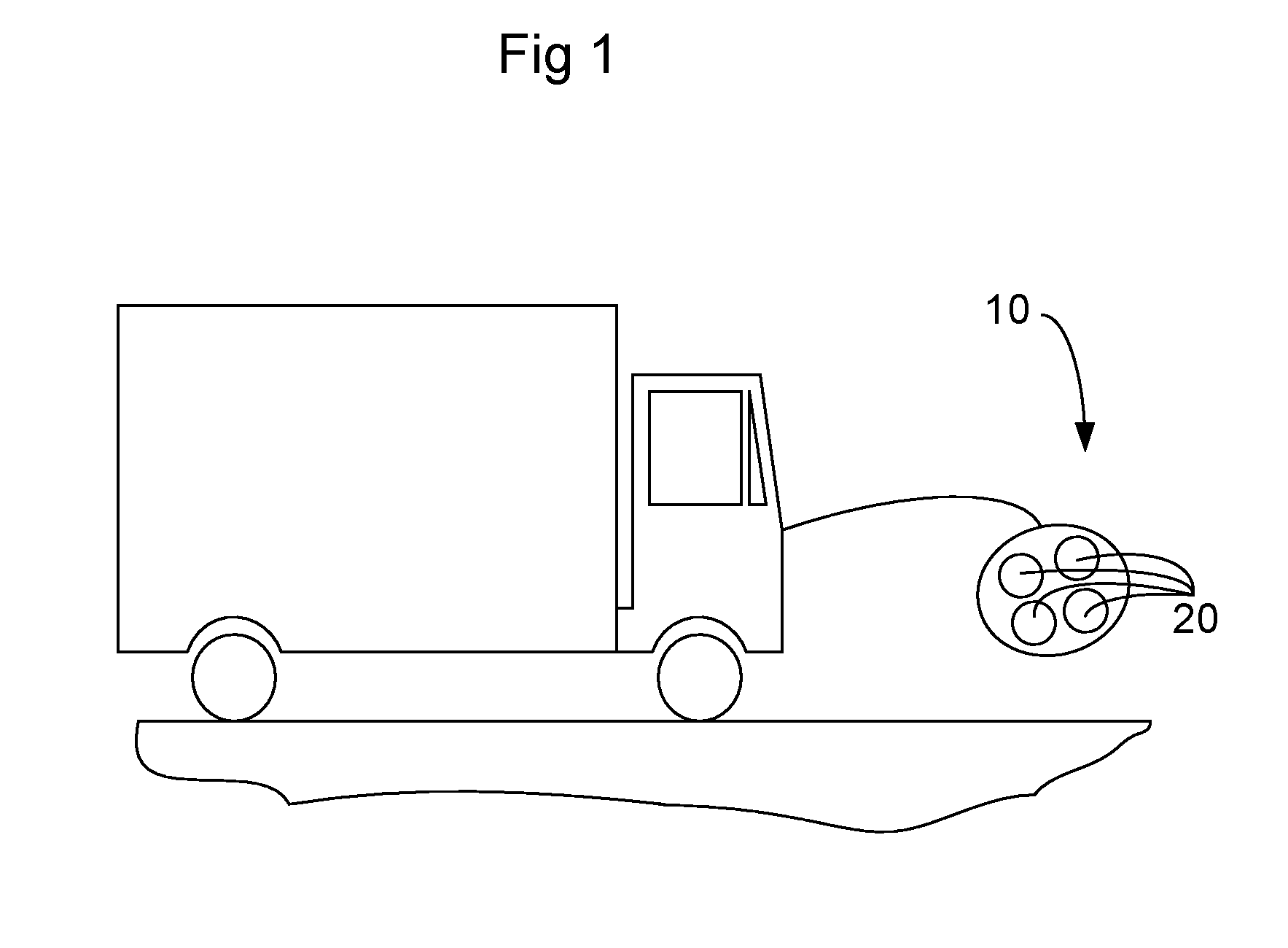

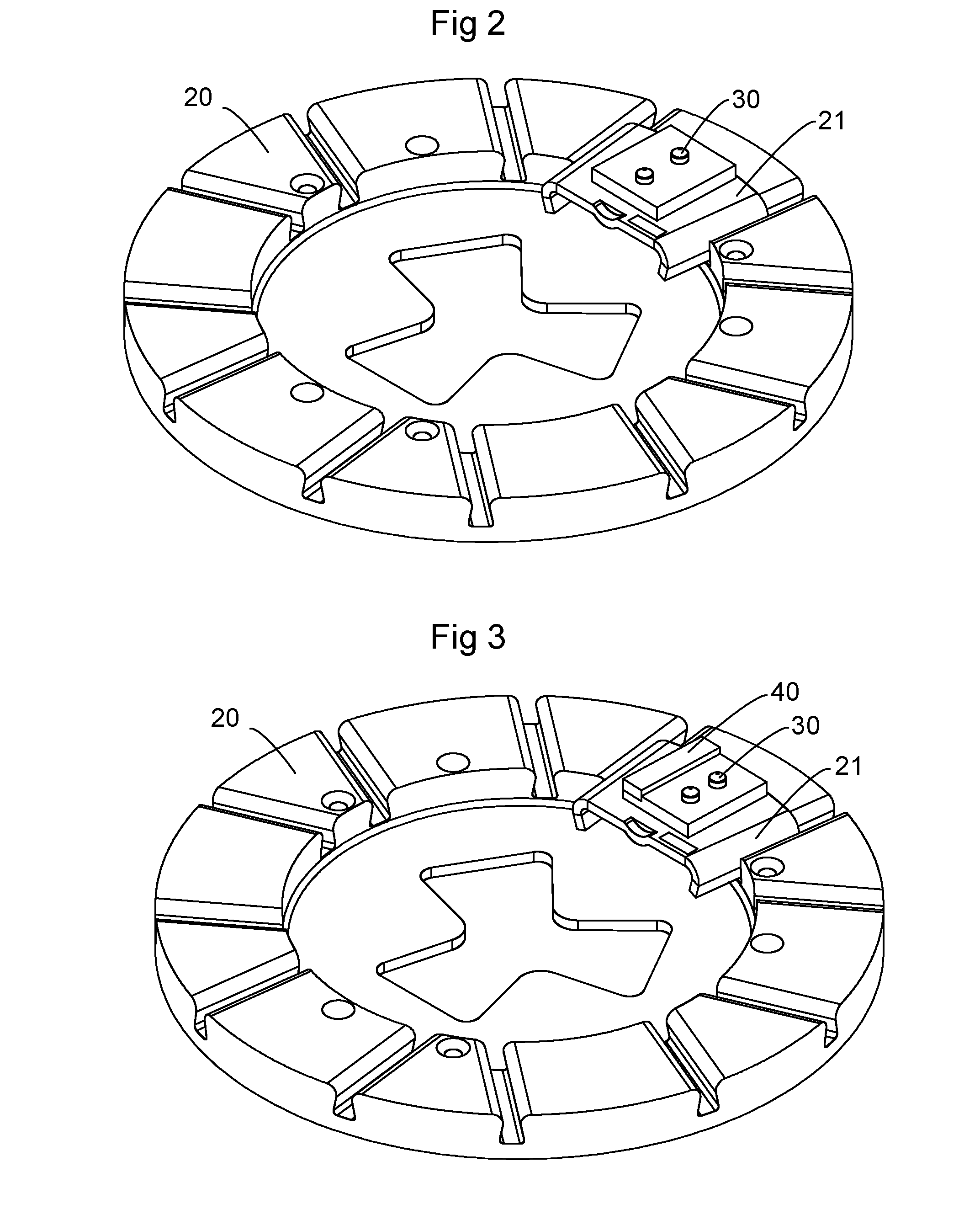

[0022]FIG. 1 indicates a machine for machining surfaces on floors and roads with an abrading or machining tool 10 with at least one rotating disc 20, which is mounted rotatably and for abrasion / machining of surfaces is driven by a motor as is explained in more detail in for example the patent publication WO 94 / 08752. The floor and / or road surfaces may be stone, concrete, different types of asphalt, or different types of coatings on these surfaces, e.g. epoxy lacquers / resins / adhesives, plastic materials (e.g. plastic mats), paint, lacquer, or any other type of coating. On the rotatable machining disc 20 a suitable number of carrier plates 21 may be detachably attached (only one plate is mounted in FIGS. 2-4) and positioned according to a predetermined pattern, i.e. a pattern suitable for the desired machining, at the periphery of the disc 20. The machining disc 20 is rotated substantially in a plane parallel to the surface in a known way and by means of known driver means. There may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com