System and method for cultivation of aerobic particle sewage sludge and for treating organic waste water

A technology for aerobic granular sludge and organic wastewater, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. problems such as low activity, to achieve the effect of ensuring smooth progress and completion, shortening time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

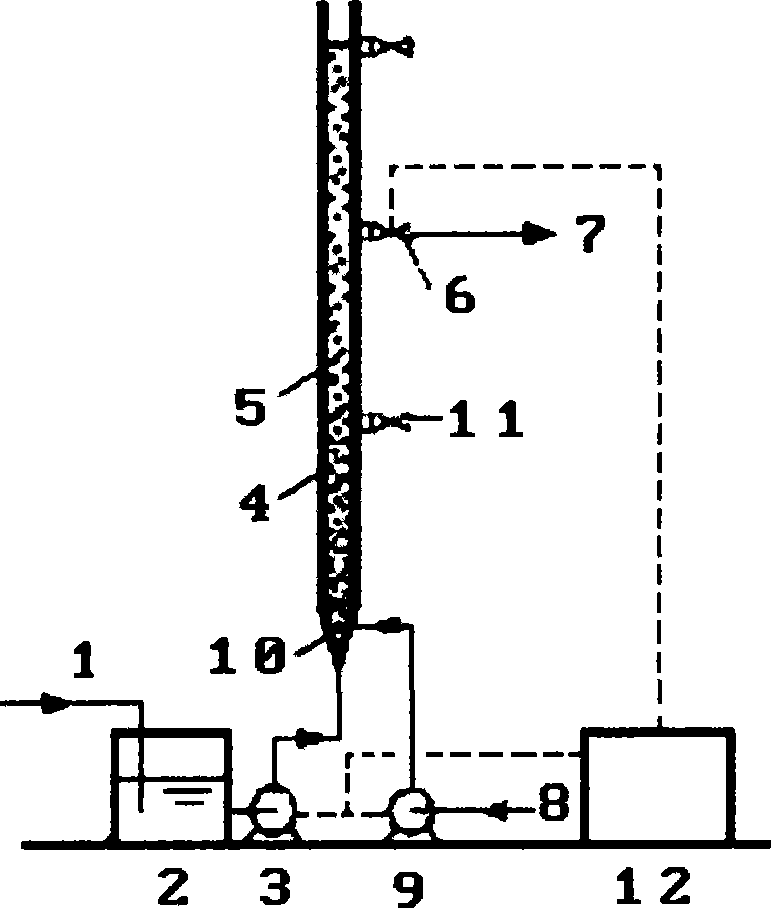

[0024] Embodiment 1: short cycle SBR cultivates aerobic granular sludge

[0025] The flocculent activated sludge is used to inoculate, and the sewage used for cultivation uses glucose as the carbon source, and the COD Cr Concentration 900mg / L, TN concentration 90mg / L, TP concentration 18mg / L, sodium bicarbonate 150-1200mg / L. The aspect ratio of the SBR main reactor is 16.7. The SBR operates in short cycle mode with a cycle time of 2.5h. Each cycle includes water intake time of 5 minutes, aeration starts at the same time of water intake, aeration time of 132-144 minutes, settling time decreases step by step from 15 minutes, 10 minutes, 6 minutes, 4 minutes to 3 minutes, and drainage time of 3 minutes. SBR drainage ratio is 1 / 3. The water temperature is controlled at room temperature, and the pH is controlled between 6.5-8.0. According to the process requirements, the sewage influent 1 is added to the water storage tank 2. After setting and starting the automatic control de...

Embodiment 2

[0026]Example 2: Treatment of low-concentration domestic sewage with aerobic granular sludge in short-cycle SBR

[0027] The aerobic granular sludge was cultivated according to the conditions and methods of Example 1, and the cultivated AGS was used to treat low-concentration domestic sewage in a short-cycle SBR. COD of Low Concentration Domestic Sewage Cr , ammonia nitrogen and TP concentration are about 400mg / L, 40mg / L and 8mg / L respectively.

[0028] The aspect ratio of the SBR main reactor is 16.7. The SBR operates in short cycle mode with a cycle time of 2.5h. Each cycle includes water inflow for 5 minutes, aeration starts at the same time as water inflow, aeration time is 144 minutes, settlement time is 3 minutes, and drainage time is 3 minutes. SBR drainage ratio is 1 / 3. The water temperature is controlled at room temperature. Dosing sodium bicarbonate 150mg / L, control the pH between 6.5-8.0.

[0029] According to the process requirements, the sewage influent 1 is...

Embodiment 3

[0031] Example 3: Treatment of medium-concentration sewage with aerobic granular sludge in short-cycle SBR

[0032] The aerobic granular sludge was cultivated according to the conditions and methods of Example 1, and the medium-concentration sewage was treated in a short-cycle SBR by using the cultivated AGS. COD of medium concentration sewage Cr , ammonia nitrogen and TP concentration are about 900mg / L, 120mg / L and 16mg / L respectively.

[0033] The aspect ratio of the SBR main reactor is 16.7. The SBR operates in short cycle mode with a cycle time of 2.5h. Each cycle includes water inflow for 5 minutes, aeration starts at the same time as water inflow, aeration time is 144 minutes, settlement time is 3 minutes, and drainage time is 3 minutes. SBR drainage ratio is 1 / 3. The water temperature is controlled at room temperature. Add sodium bicarbonate 600mg / L to control the pH between 6.5-8.0.

[0034] According to the process requirements, the sewage influent 1 is added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com