Method for relieving anaerobic ammonium oxidation system salinity shock with betaine as additive

A technology of anaerobic ammonium oxidation and betaine, which is applied in the direction of anaerobic digestion treatment, etc., can solve the problem of time-consuming oxidation of sludge, and achieve the effect of saving capital investment and operating costs, saving time and cost, and avoiding huge waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

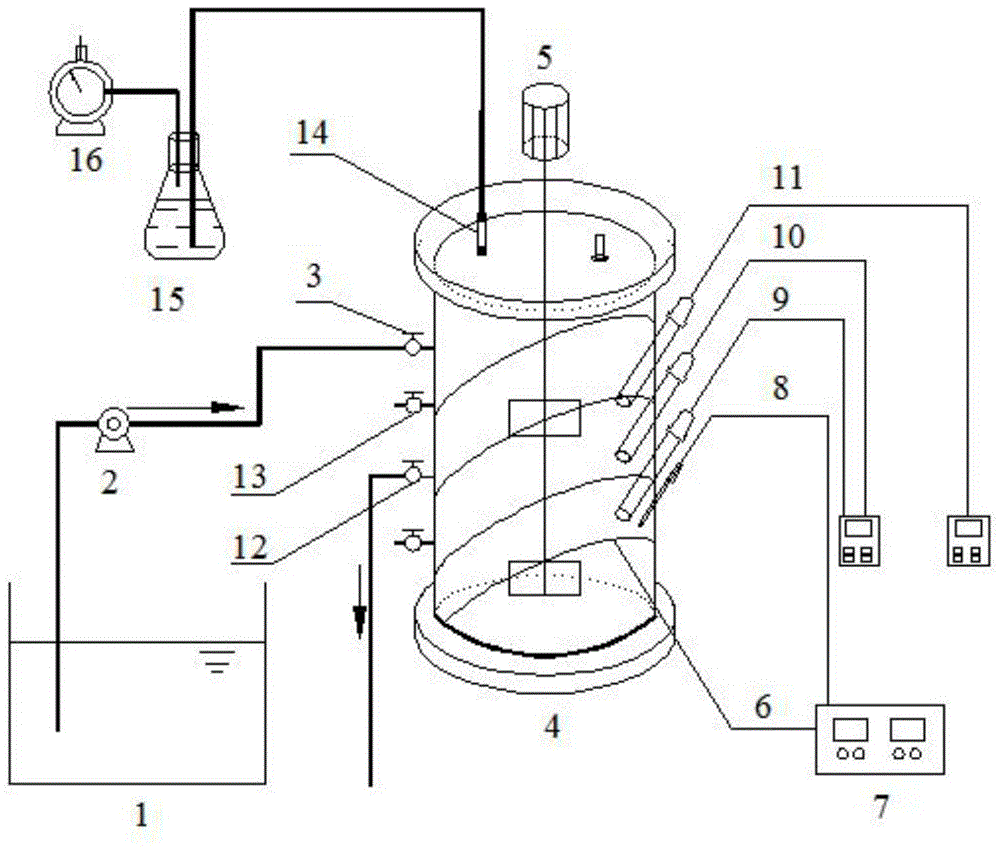

[0022] Now in conjunction with accompanying drawing and embodiment the present invention is further described:

[0023] like figure 1 As shown, the device consists of a raw water tank 1 and an SBR anaerobic ammonium oxidation reactor 4 connected in series. Raw water tank 1 is connected with SBR anaerobic ammonium oxidation reactor 4 through water inlet pipe and peristaltic pump 2; The lye bottle 15 and the gas flow meter 16 are connected, and further experiments can collect the gas produced by the SBR anammox reactor through the gas flow meter and analyze the gas composition. The SBR anaerobic ammonium oxidation reactor 4 is provided with a water inlet valve 3, a sampling valve 13, and a drain valve 12 from top to bottom. A temperature sensor 8 is arranged inside the reactor, and a temperature-controlled heating belt 6 is arranged on the periphery, which is connected with a temperature-controlled box 7 . The SBR anaerobic ammonium oxidation reactor is matched with a DO mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com