Polishing fluid for smoothing treatment of refined surface and use method thereof

A technology for smoothing and fine surface treatment, applied in the field of polishing liquid, it can solve the problems of small original particle size, irregular shape, depression, etc., and achieve the effect of improving the removal rate and excellent surface smoothing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

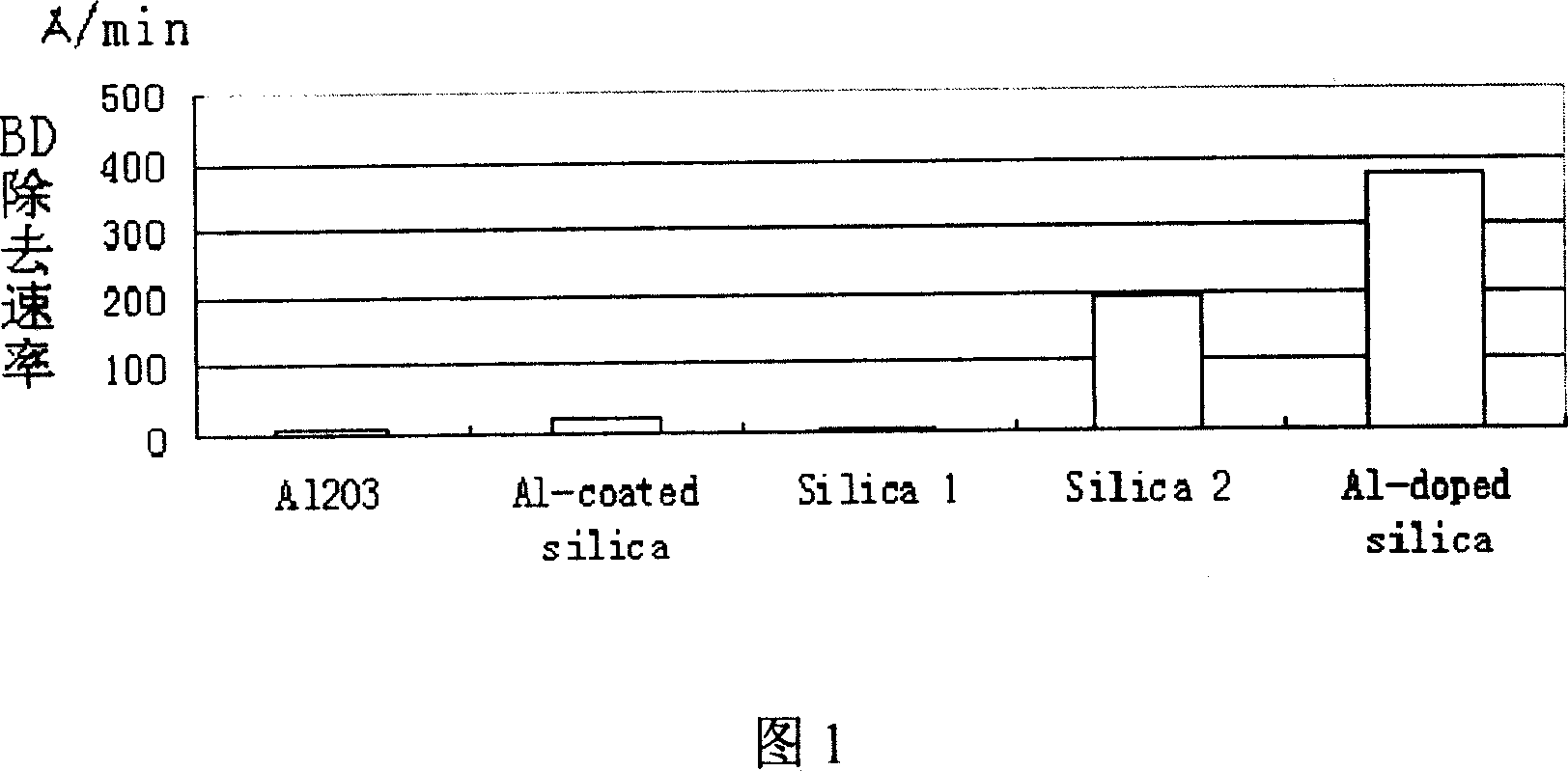

[0036] Embodiment 1 Various abrasives to the comparison of BD material removal rate

[0037] Comparative polishing liquid A: Al 2 o 3 Abrasive (particle size 100nm, specific surface area 50m 2 / g) 6wt%, water 94wt%, pH=3.0;

[0038] Comparative Polishing Fluid B: Coated with Al 2 o 3 SiO 2 (Al-coated silica) abrasive (particle size 15nm, specific surface area 190m 2 / g, Al 2 o 3 accounted for SiO 2 10% of) 6wt%, water 94wt%, pH=3.0;

[0039] Comparative Polishing Fluid C: SiO 2 (Silica 1) abrasive (particle size 70nm, specific surface area 75m 2 / g) 6wt%, water 94wt%, pH=3.0;

[0040] Comparative polishing liquid D: SiO 2 (Silica 2) abrasive (particle size 30nm, specific surface area 100m 2 / g) 6wt%, water 94wt%, pH=3.0;

[0041] Polishing liquid 1: Colloidal Al-doped silica (particle size: 50nm, specific surface area: 85m 2 / g, aluminum accounted for SiO 2 2wt%) 6wt%, water 94wt%, pH=3.0.

[0042] The comparative polishing solutions A to D and polishing solu...

Embodiment 2

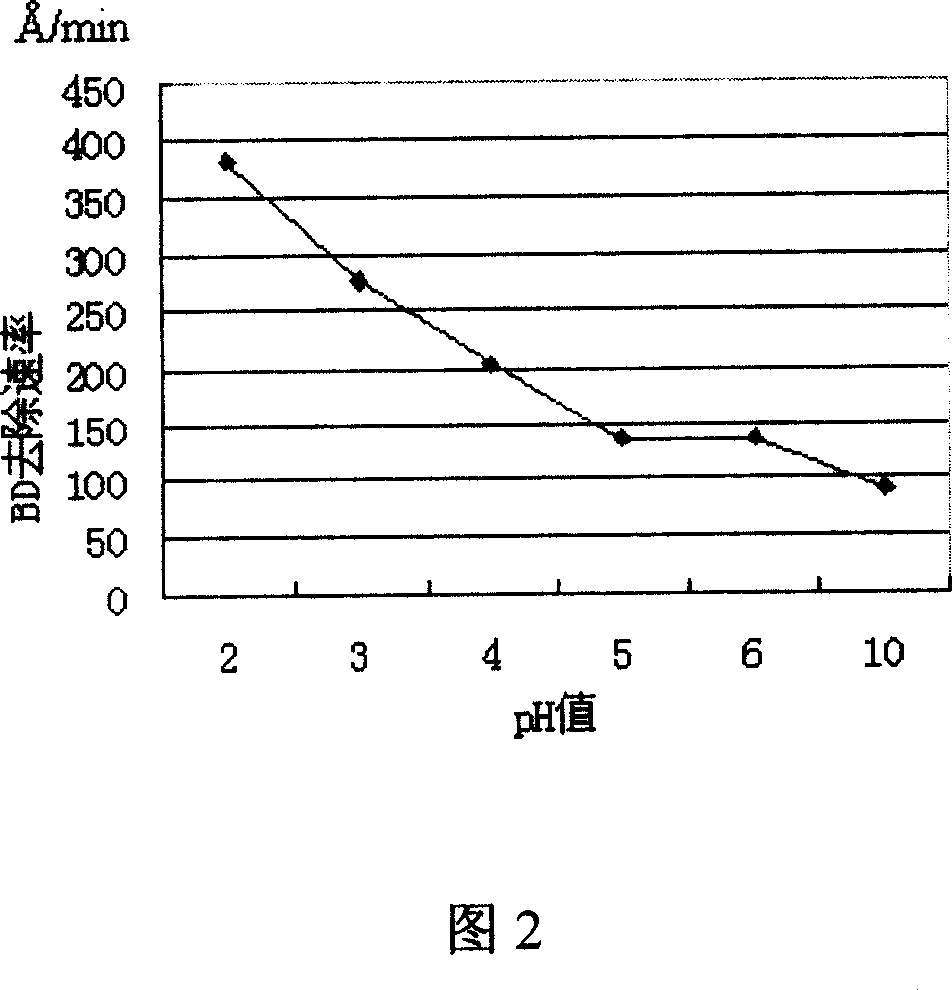

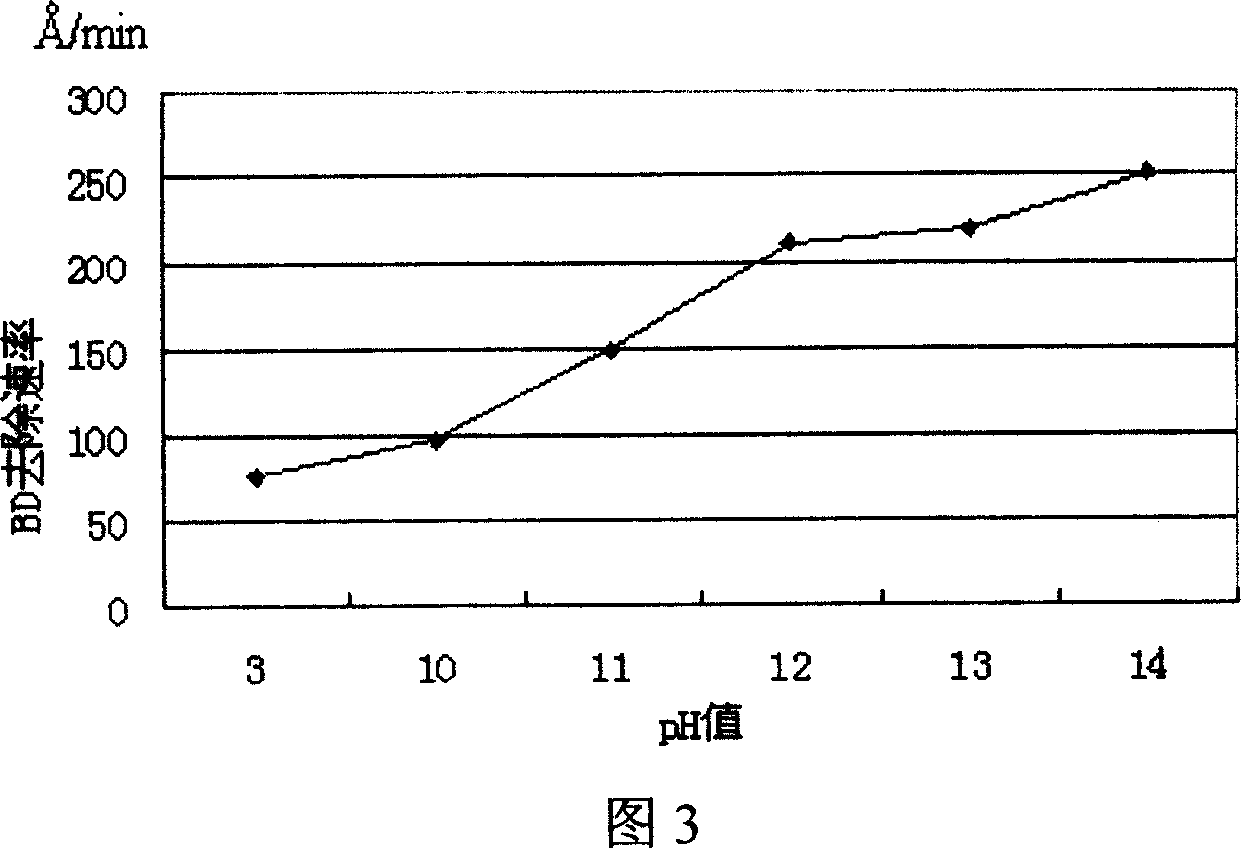

[0044] Example 2 The comparison of sol-type aluminum-doped silica abrasives to the removal rate of BD materials at different pH

[0045] Polishing solution E: sol-type aluminum-doped silica abrasive (particle size 50nm, aluminum accounted for SiO 2 2wt%) 5wt%, the balance is water, pH is regulated by acid and alkali etc.; Its polishing process parameter is: downward pressure 2psi, polishing desktop rotation speed 70rpm, Politex pad, Logitech PM5 Polisher.

[0046] Polishing fluid F: sol-type aluminum-doped silica abrasive (particle size 50nm, aluminum accounted for SiO 2 2wt%) 10wt%, the balance is water, the pH is adjusted by acid and alkali etc.; its polishing process parameters are: downward pressure 2psi, polishing table rotation speed 70rpm, IC1010 pad, Logitech PM5 Polisher.

[0047] Result: the removal rate of each abrasive in the polishing liquid E to the BD material is shown in Figure 2, as can be seen from Figure 2, on the soft polishing pad (for example, Politex pa...

Embodiment 3

[0048] Embodiment 3 The comparison of the concentration of sol-type aluminum-doped silica abrasive to the removal rate of BD material

[0049] Polishing liquid 2: sol-type aluminum-doped silica abrasive (particle size 30nm, specific surface area 100m 2 / g, aluminum accounted for SiO 2 2wt%) 2.5wt%, water 97.5wt%, pH=3.0;

[0050] Polishing liquid 3: sol-type aluminum-doped silica abrasive (particle size 30nm, specific surface area 100m 2 / g, aluminum accounted for SiO 2 2wt%) 5wt%, water 95wt%, pH=3.0;

[0051] Polishing liquid 4: sol-type aluminum-doped silica abrasive (particle size 30nm, specific surface area 100m 2 / g, aluminum accounted for SiO 2 2wt%) 7.5wt%, water 92.5wt%, pH=3.0;

[0052] Polishing liquid 5: sol-type aluminum-doped silica abrasive (particle size 30nm, specific surface area 100m 2 / g, aluminum accounted for SiO 2 2wt%) 10wt%, water 90wt%, pH=3.0;

[0053] Polishing liquid 6: sol-type aluminum-doped silica abrasive (particle size 30nm, specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com