Chemico-mechanical polishing solution

A technology of chemical mechanics and polishing liquid, which is applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve the problems of reducing the removal rate of polysilicon, and achieve the effect of increasing the removal rate

Inactive Publication Date: 2009-08-05

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF5 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hydrophobic groups of the polymer are thought to be adsorbed on the polysilicon surface, forming a passivation layer that reduces the polysilicon removal rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

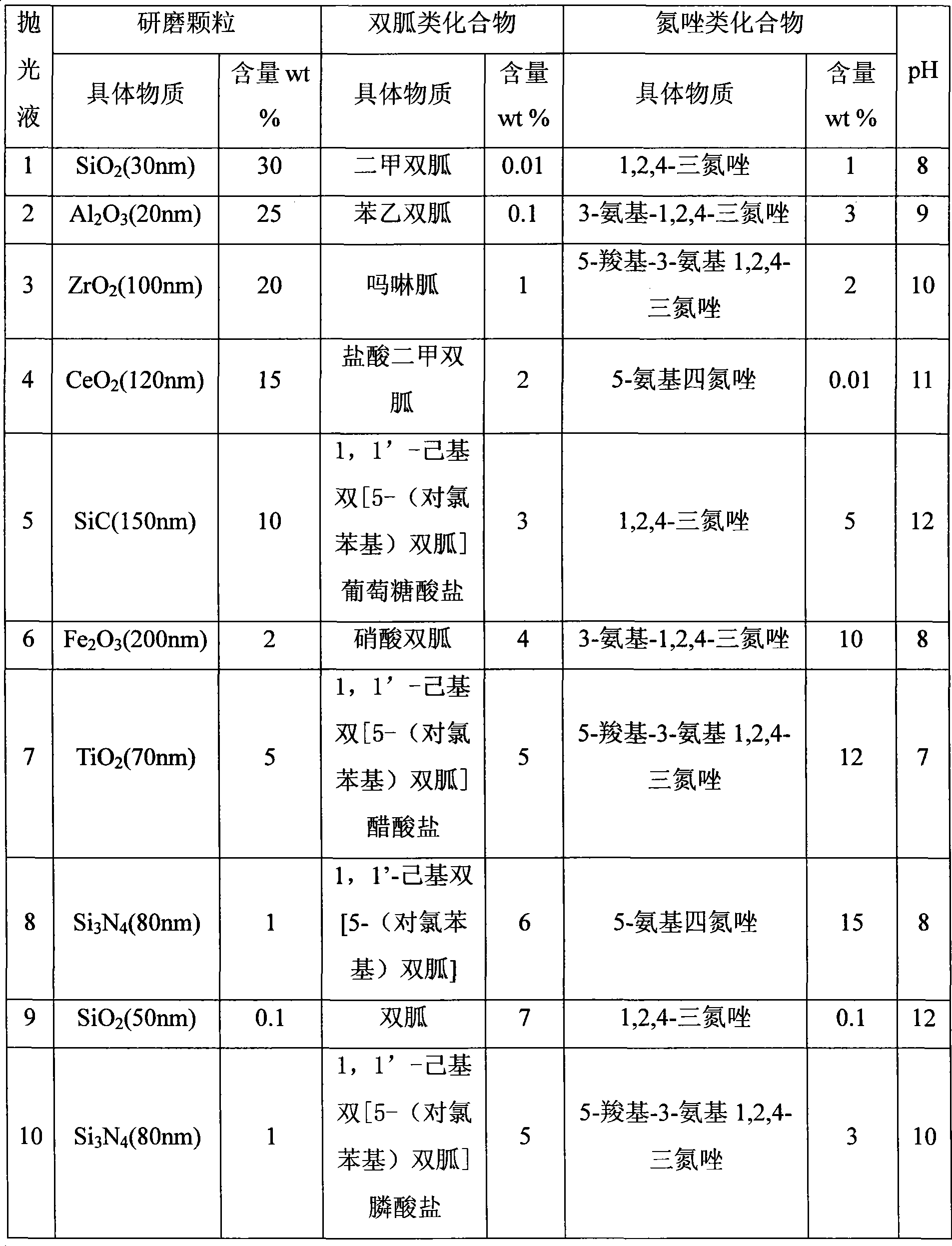

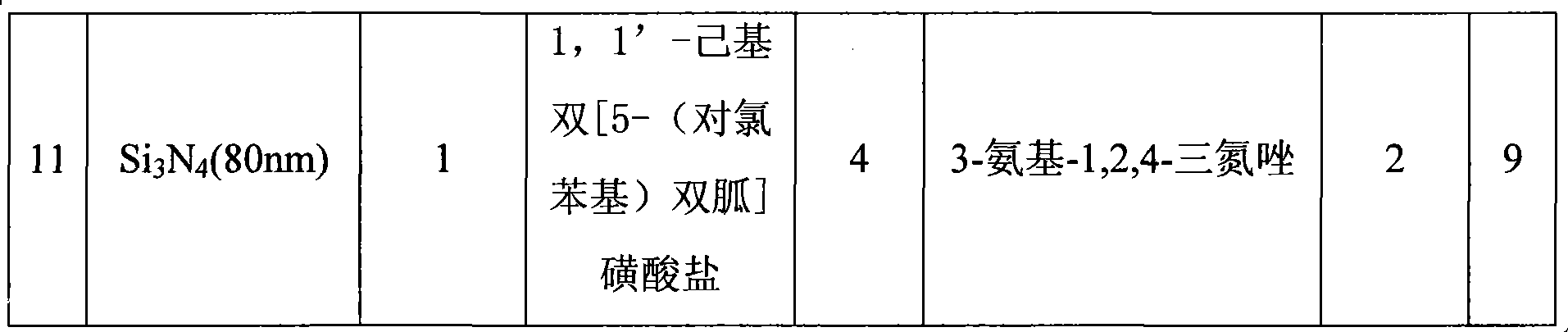

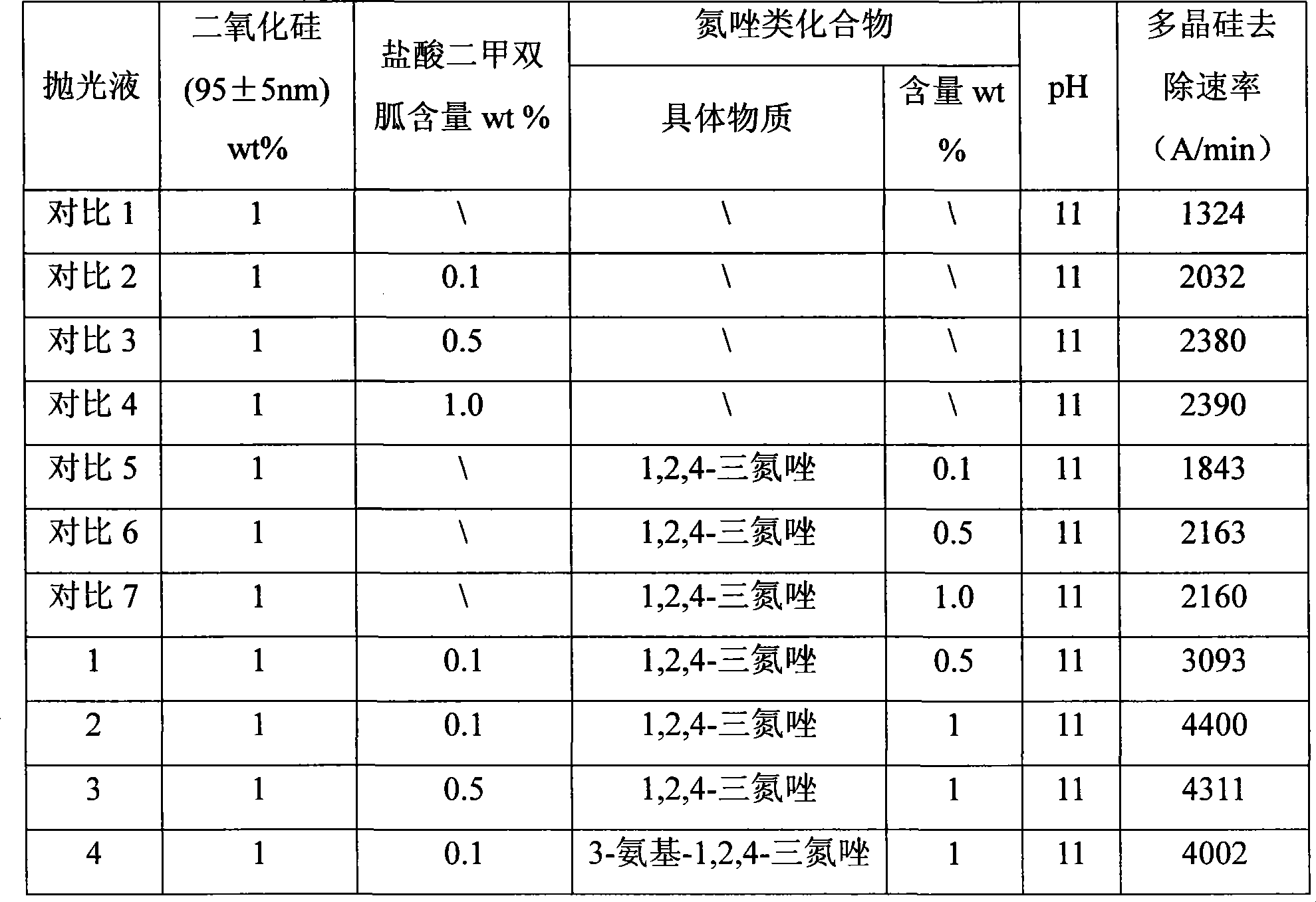

Embodiment 1~11

[0022] Table 1 shows polishing fluids 1 to 11 of the present invention. According to the formula in the table, each component is simply mixed evenly, and the balance is water, adjusted to a suitable pH value with a pH regulator, and left to stand for 30 minutes to obtain each polishing solution. Polishing fluid.

[0023] Table 1 Polishing liquid embodiment 1~11 formula of the present invention

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a chemical-mechanical polishing solution. The chemical-mechanical polishing solution contains ground particles and water and also contains biguanide compound and nitrogen and azole compound, wherein the biguanide compound and the nitrogen and azole compound have synergistic effect and can remarkably improve the elimination rate of polysilicon.

Description

technical field [0001] The invention relates to a chemical mechanical polishing liquid in semiconductor manufacturing process. Background technique [0002] With the continuous development of semiconductor technology and the continuous increase of interconnection layers in large-scale integrated circuits, the planarization technology of conductive layers and insulating dielectric layers has become particularly critical. The chemical mechanical polishing (CMP) technology pioneered by IBM in the 1980s is considered to be the most effective method for global planarization. [0003] Chemical mechanical polishing (CMP) is composed of chemical action and mechanical action and the combination of the two actions. Its equipment usually consists of a polishing table with a polishing pad (pad), and a polishing head (carrier) for carrying a chip (wafer). Among them, the grinding head fixes the chip, and then presses the front side of the chip on the grinding pad. When chemical mechan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02H01L21/304

CPCC09G1/02H01L21/3212C09K3/1463

Inventor 王晨荆建芬杨春晓

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com