Composition for low downforce chemically mechanical polishing of coppers in ULSI (Ultra Large Scale Integrated Circuit) multi-layered copper wiring

A polishing composition and chemical-mechanical technology, applied in polishing compositions containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as affecting production capacity, achieve elimination of negative effects, balance chemical corrosion, Balance the effect of strong oxidative corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

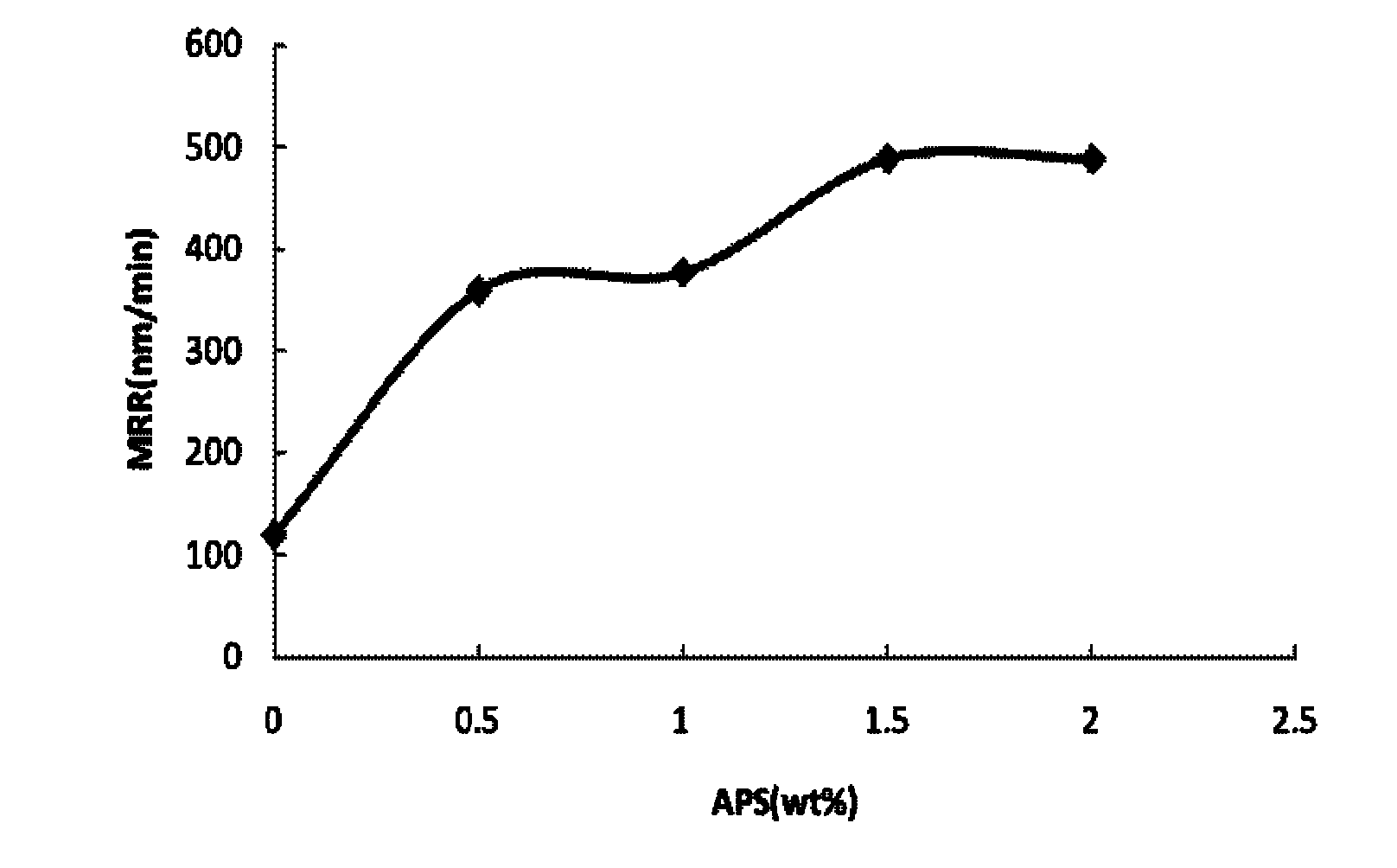

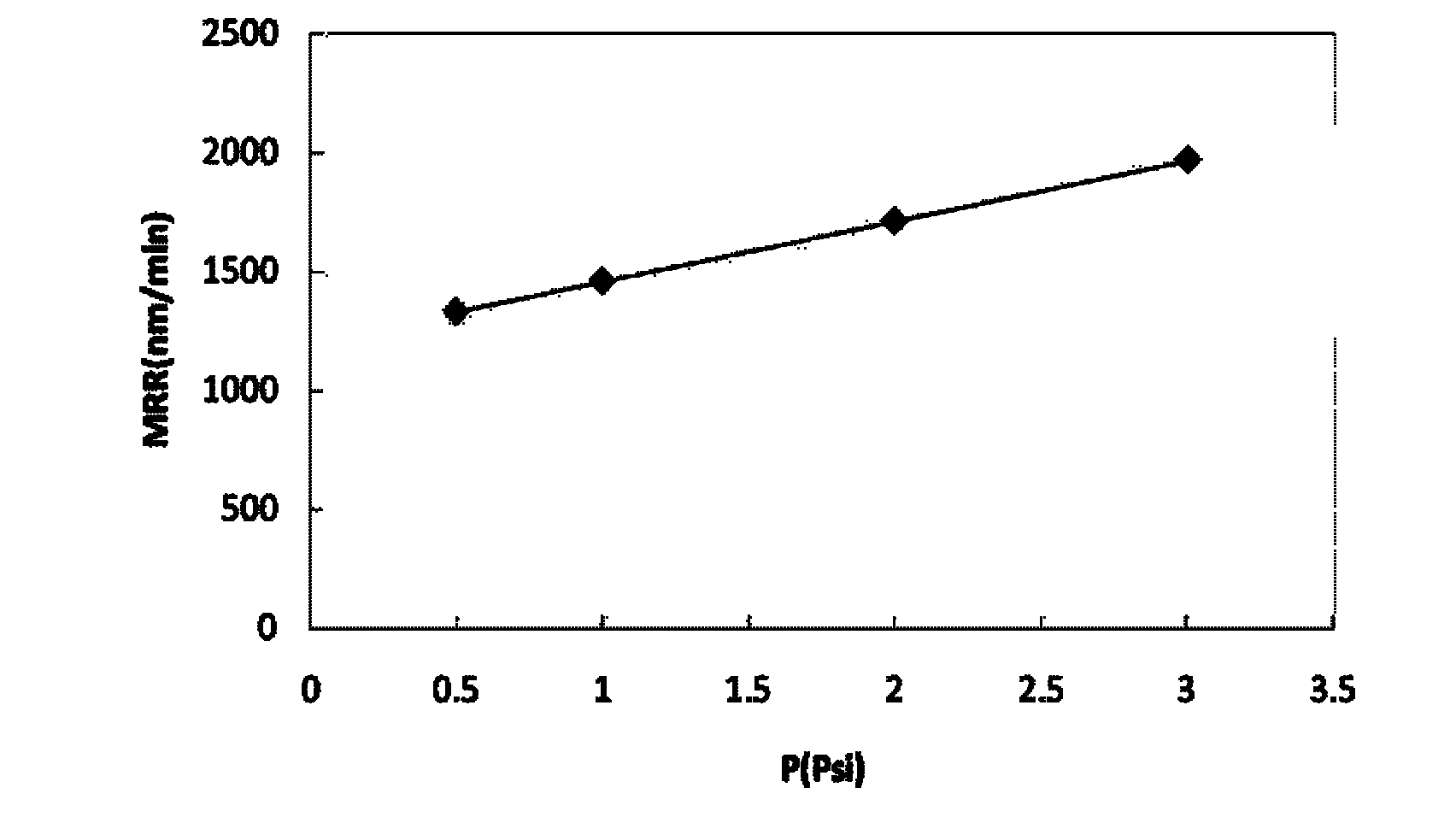

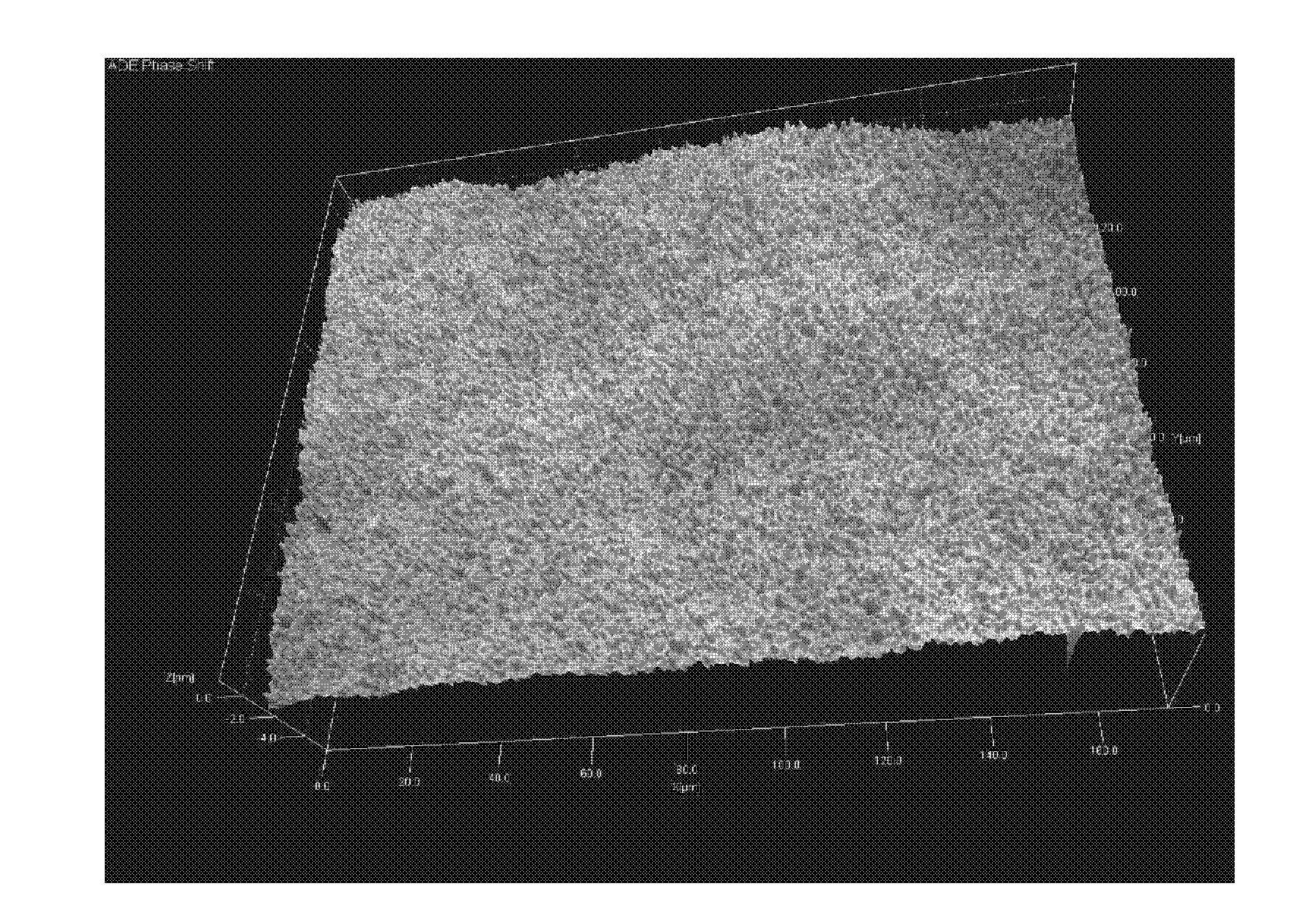

[0036] Prepare 1000 grams of copper polishing solution: Add 10 grams of glycine, 5 grams of ammonium persulfate and 0.1 grams of benzotriazole into 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of 30% 50 nanometer disulfide Silicon oxide hydrosol, before polishing, add 30 grams of 30% oxidant hydrogen peroxide solution, use KOH to calibrate the pH value to 10.0, and finally add water to make up 1000 grams and stir evenly, then perform copper polishing with a pressure of 0.5Psi, and the polishing removal rate The MRR is 358.1nm / min, and the surface roughness Sa is 5.73nm.

Embodiment 2

[0038] Prepare 1000 grams of copper polishing solution: Add 10 grams of glycine, 10 grams of ammonium persulfate and 0.1 grams of benzotriazole to 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of 30% 50 nanometer disulfide Silicon oxide hydrosol, before polishing, add 30 grams of 30% oxidant hydrogen peroxide solution, use KOH to calibrate the pH value to 10.0, and finally add water to make up 1000 grams and stir evenly, then perform copper polishing with a pressure of 0.5Psi, and the polishing removal rate The MRR is 376.0nm / min, and the surface roughness Sa is 5.80nm.

Embodiment 3

[0040] Prepare 1000 grams of copper polishing solution: add 10 grams of glycine, 20 grams of ammonium persulfate and 0.1 grams of benzotriazole to 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of 30% 50 nanometer two Silicon oxide hydrosol, before polishing, add 30 grams of 30% oxidant hydrogen peroxide solution, use KOH to calibrate the pH value to 10.0, and finally add water to make up 1000 grams and stir evenly, then perform copper polishing with a pressure of 0.5Psi, and the polishing removal rate The MRR is 487.6nm / min, and the surface roughness Sa is 4.07nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com