Nano cerium oxide slurry for chemical mechanical polishing and preparation method thereof

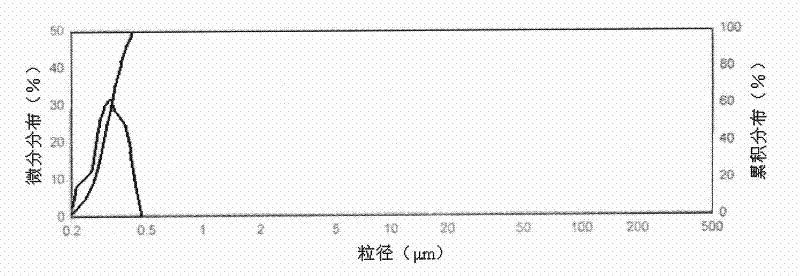

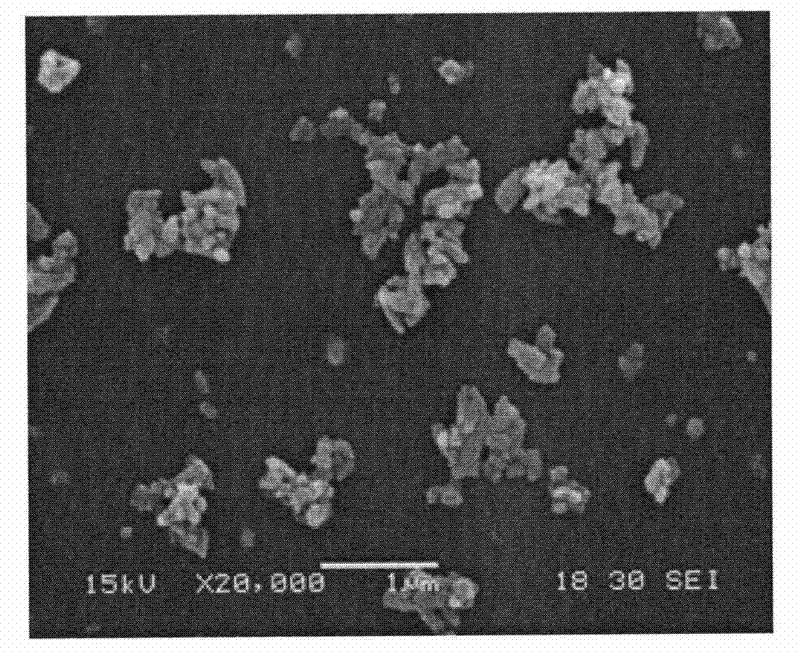

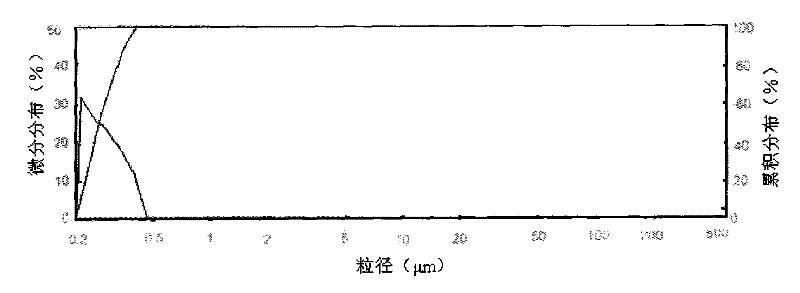

A nano-cerium oxide and chemical mechanical technology, which is applied in the field of chemical mechanical polishing slurry for semiconductors and its preparation, can solve problems such as inapplicability, and achieve the effects of high wear resistance, narrow particle size distribution range, and high polishing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of the 1st step nanometer cerium oxide powder

[0044] (1) Preparation of seed crystals: Heat 1L of oxalic acid solution with a concentration of 20g / L to a temperature of 70°C, add ammonia water with a weight concentration of 12.5% until the pH is 5.5, and then add 0.2L of a cerium chloride solution with a concentration of 50g / L , react at 70°C for 0.5h, age for 2h, filter and wash to obtain cerium oxalate crystal seeds;

[0045] (2) Precipitation: Add 2.5g of cerium oxalate seed crystals and 17.5g of cetyltrimethylammonium bromide to 1L of cerium chloride aqueous solution with a concentration of 50g / L, and add the weight concentration while stirring at 50°C. Be 25% ammonium bicarbonate aqueous solution, until the pH value is 6, obtain the cerium carbonate of precipitation;

[0046] (3) Roasting: filter and wash the cerium carbonate with a centrifuge, dry in an oven at 70° C. for 6 hours, and bake the dried cerium carbonate at 600° C. for 4 hours.

[004...

Embodiment 2

[0053] Preparation of the 1st step nanometer cerium oxide powder

[0054] (1) Preparation of seed crystals: Heat 1 L of oxalic acid solution with a concentration of 50 g / L to a temperature of 70° C., add ammonia water with a mass concentration of 12.5% until the pH is 4.5, and slowly add 0.15 L of cerium chloride with a concentration of 100 g / L Solution, react at 70°C for 1.5h, crystallize for 4h, filter and wash to obtain cerium oxalate crystal seeds;

[0055] (2) Precipitation: Add 22.5g cerium oxalate seed crystals in 1L concentration of 150g / L cerium nitrate aqueous solution, 15g polyethylene glycol 20000, under 70 ℃, add mass concentration while stirring and be 30% sodium bicarbonate and The mixed aqueous solution of sodium carbonate (the mass ratio of sodium bicarbonate and sodium carbonate is 5: 1), until pH value is 7, obtains the cerium carbonate of precipitation;

[0056] (3) Roasting: filter and wash the completed cerium carbonate with a centrifuge, dry at 120° C...

Embodiment 3

[0063] Preparation of the 1st step nanometer cerium oxide powder

[0064] (1) Preparation of seed crystals: Heat 1L of oxalic acid solution with a concentration of 20g / L to a temperature of 70°C, add ammonia water with a weight concentration of 12.5% until the pH is 5.5, and then add 0.2L of a cerium chloride solution with a concentration of 50g / L , react at 70°C for 0.5h, age for 2h, filter and wash to obtain cerium oxalate crystal seeds;

[0065] (2) Precipitation: Add 2.5 g of cerium oxalate seed crystals, 15.5 g of cetyltrimethylammonium bromide, and 5 g of polyvinyl alcohol 20000 in 1 L of 50 g / L cerium acetate aqueous solution, at 50 ° C, While stirring, adding an aqueous ammonium bicarbonate solution with a weight concentration of 25% until the pH value is 6 to obtain precipitated cerium carbonate;

[0066] (3) Roasting: filter and wash cerium carbonate with a centrifuge, dry in an oven at 90° C. for 4 hours, and bake the dried cerium carbonate at 500° C. for 5 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com