Imprinted water-permeable cement concrete ground structure with aggregate exposed on surface, and manufacturing method thereof

A technology of permeable cement and its production method, which can be applied to pavement details, cohesive pavement paved on site, roads, etc., which can solve the limitations of decorative and artistic effects, the inability to achieve realistic effects, and the inability to achieve water-permeable effects. Beautiful texture, reduce urban heat island effect, high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

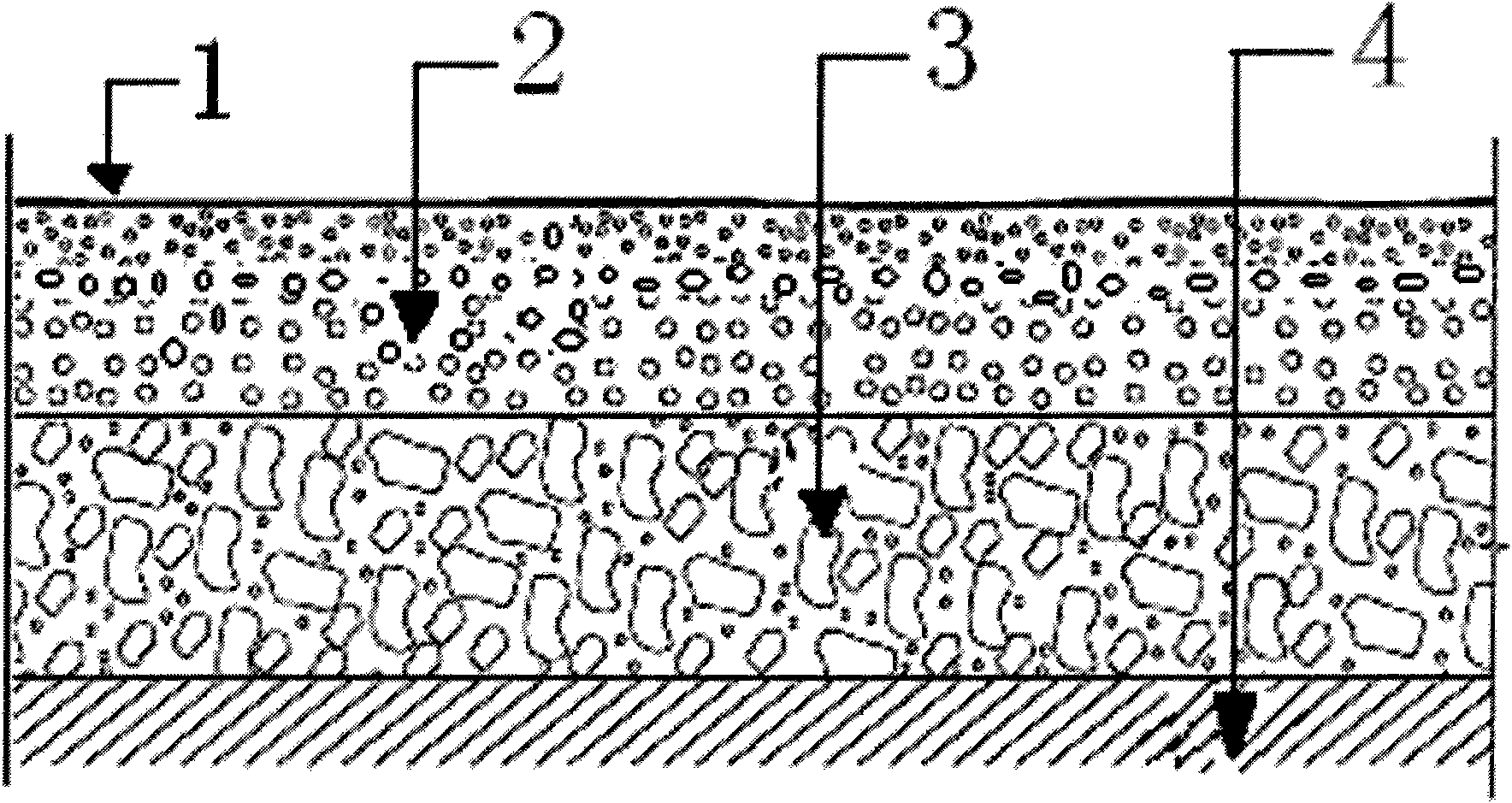

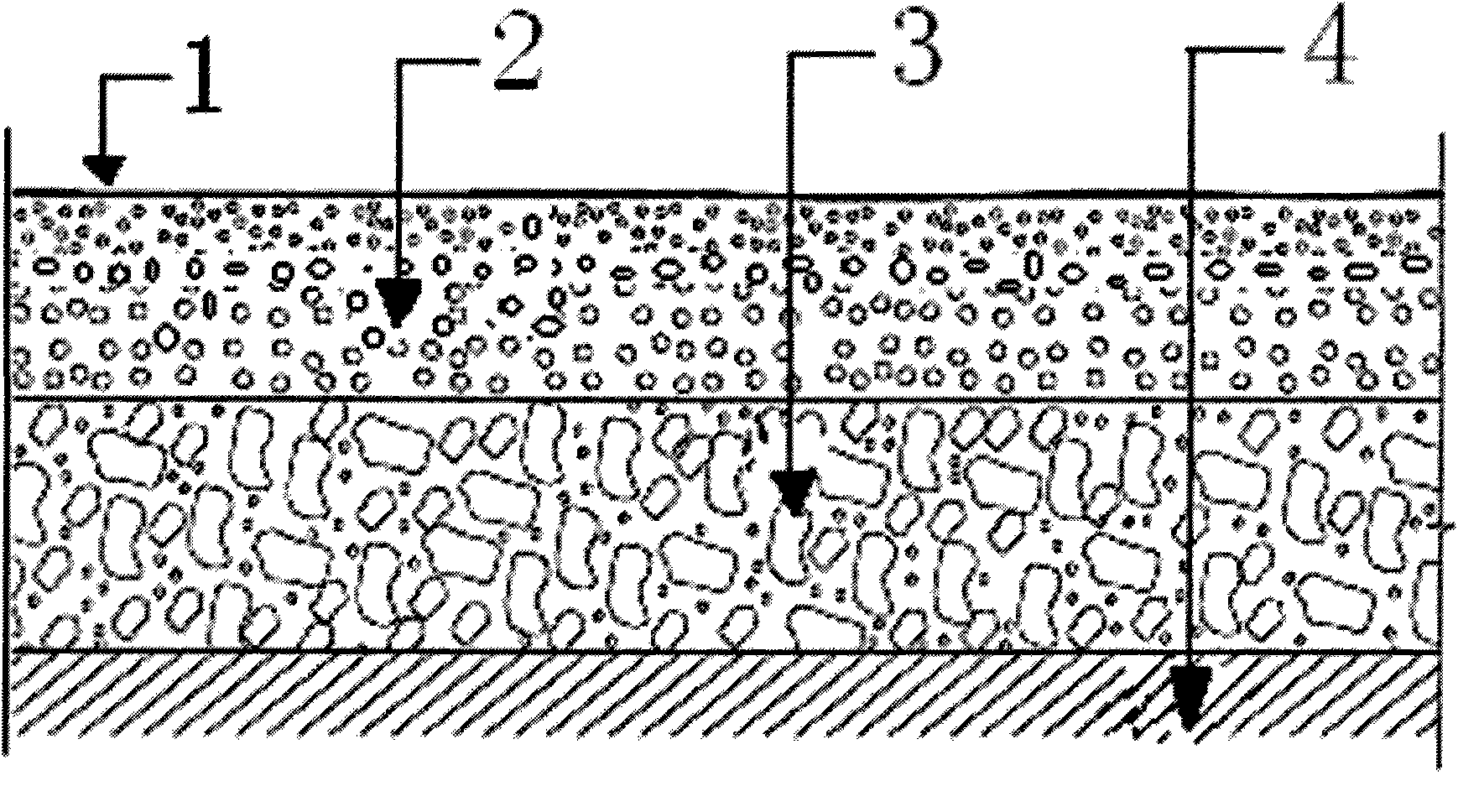

[0021] Below in conjunction with accompanying drawing, the present invention is specifically described, as figure 1 It is a schematic diagram of the exposed aggregate embossed permeable cement concrete ground structure according to the present invention. The pavement structure includes at least one cement permeable concrete layer (2), a cushion layer (3) and a base layer (4). Arranged sequentially from bottom to bottom, it is characterized in that the upper surface of the cement permeable concrete layer with the effect of exposed aggregate is formed with patterns and textures by embossing technology.

[0022] Wherein, the cement permeable concrete layer can be formed by stacking two or more layers of cement permeable concrete, the uppermost layer of permeable concrete is the surface layer, and the rest are the bottom layer. The protective layer (1) can be selectively sprayed on the outer surface of the outermost layer of permeable concrete according to requirements or the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com