Light filter manufacturing method and exposure mask plate

A manufacturing method and a technology of optical filters, which are applied in the direction of optical filters, microlithography exposure equipment, photolithography exposure devices, etc., can solve the problem of increased thickness and cost of optical filters, decreased light transmittance, increased processes and costs and other issues to achieve the effect of improving display performance, increasing flatness, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

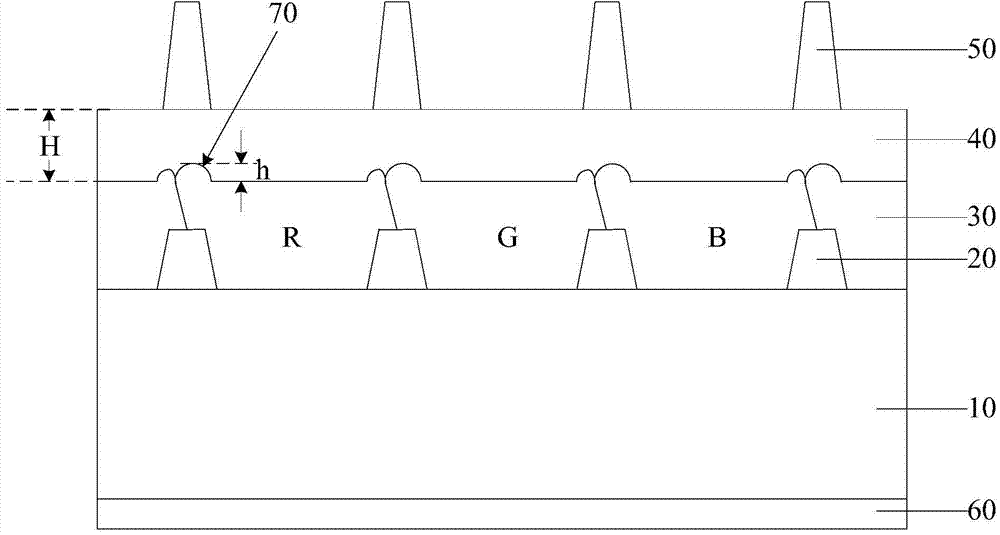

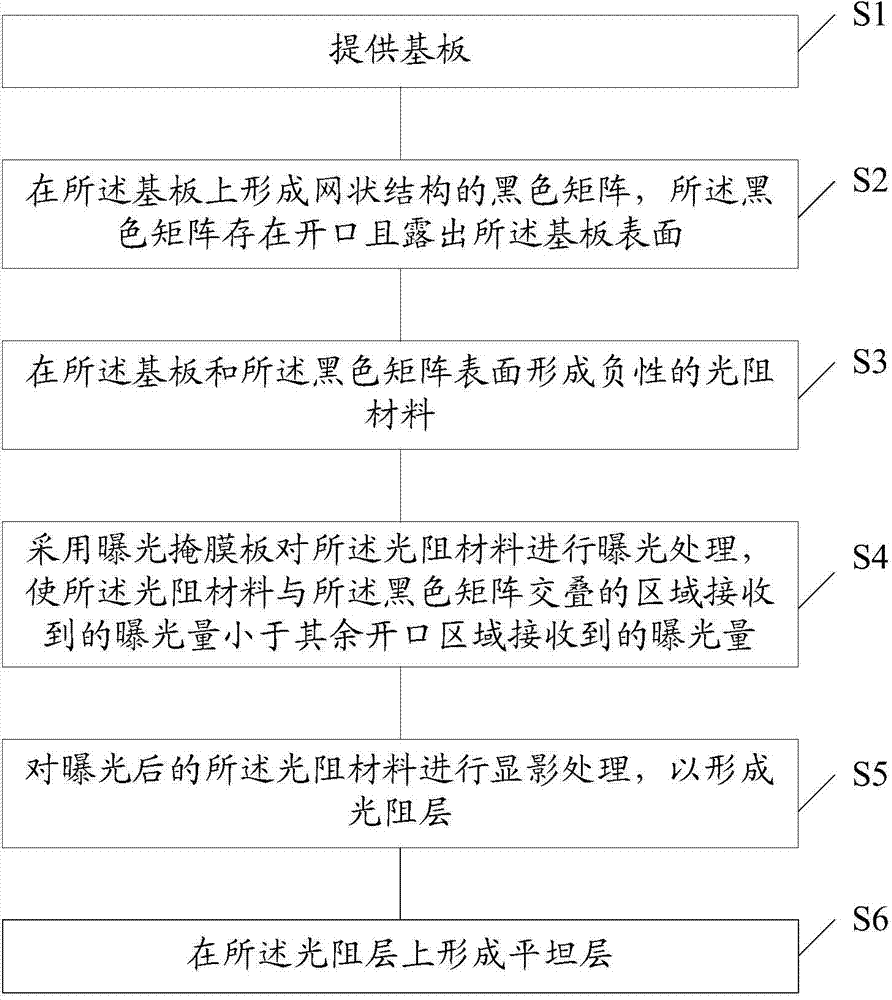

[0039] As mentioned in the background, in the prior art, horns are formed on the edge of the photoresist unit in contact with the black matrix, and the area where the horns are located will make the upper surface of the photoresist layer uneven, which ultimately affects the display performance of the liquid crystal display. Although this technical problem can be solved by forming a flat layer on the photoresist layer, considering that the greater the height of the horns, the worse the flatness of the photoresist layer, the greater the thickness of the flat layer, and the flatness requirements of the flat layer material The higher the value, the higher the cost of the filter, the lower the light transmittance, and the worse the color display effect.

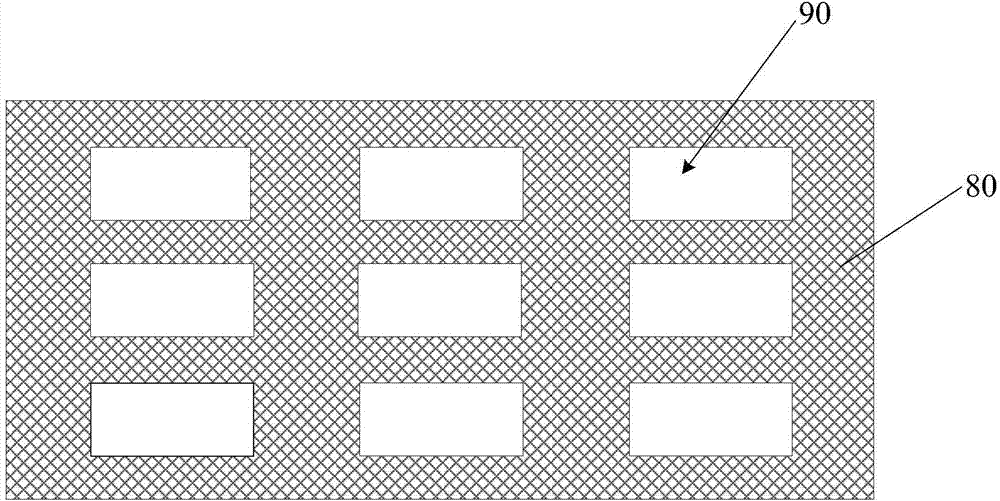

[0040] In view of the above technical problems, the present invention provides a method for manufacturing an optical filter. Since the photoresist layer is a negative photoresist material, the less exposure it receives during the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com