Materials composition and processing method for composite fiber

A technology of composite fibers and processing methods, applied in fiber processing, chemical instruments and methods, lamination, etc., can solve problems such as loss of characteristics and functions, non-waterproof, loss of application value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

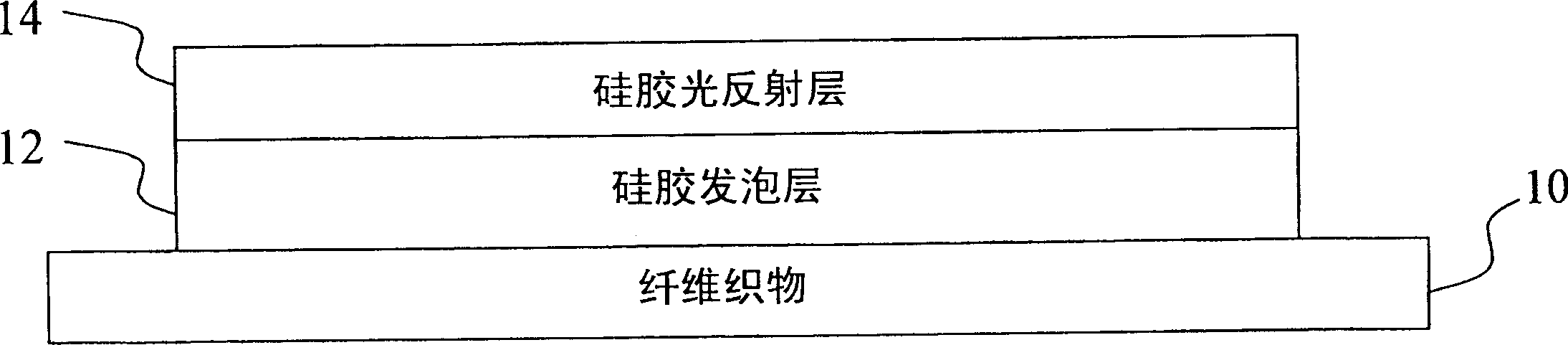

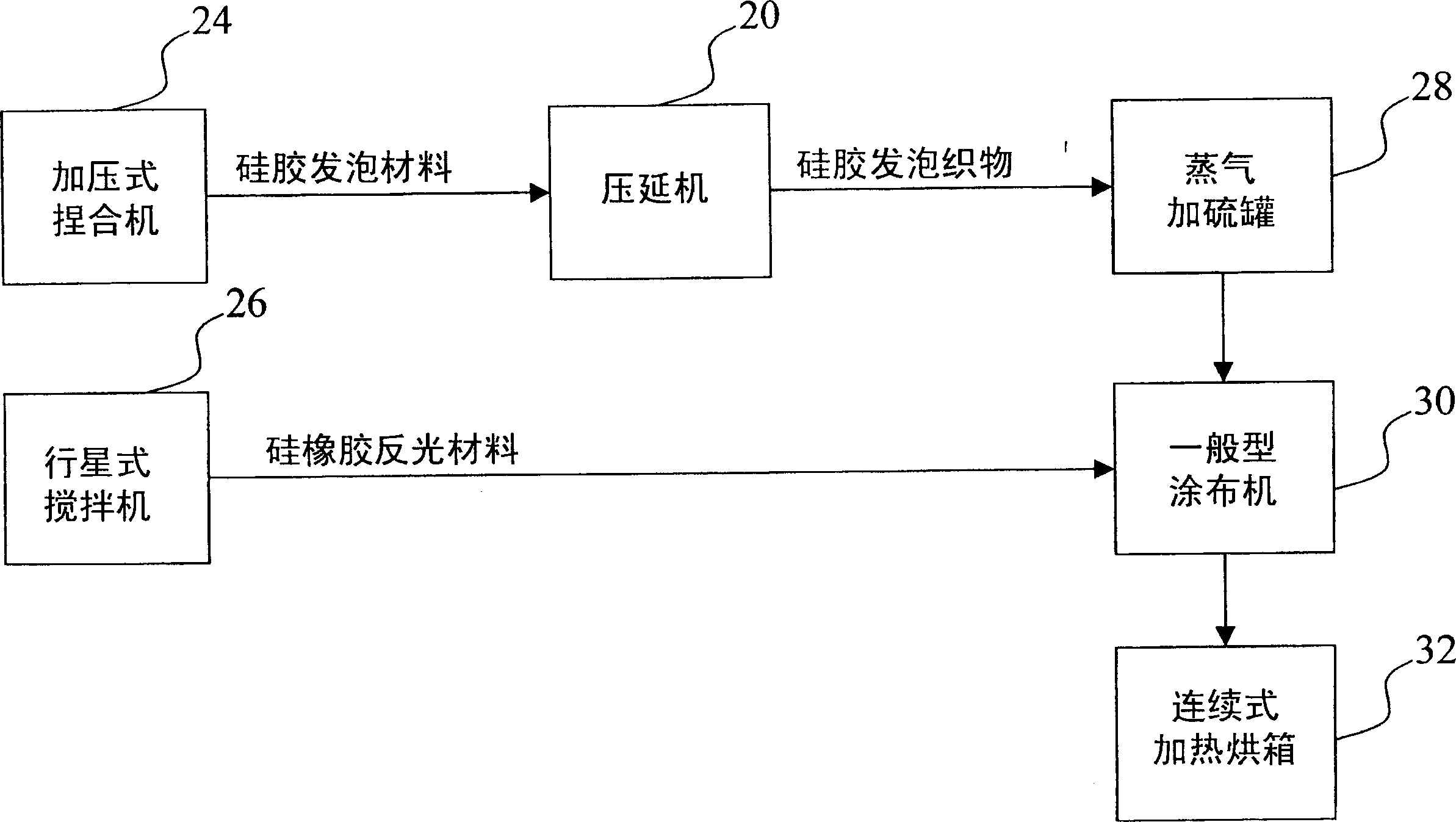

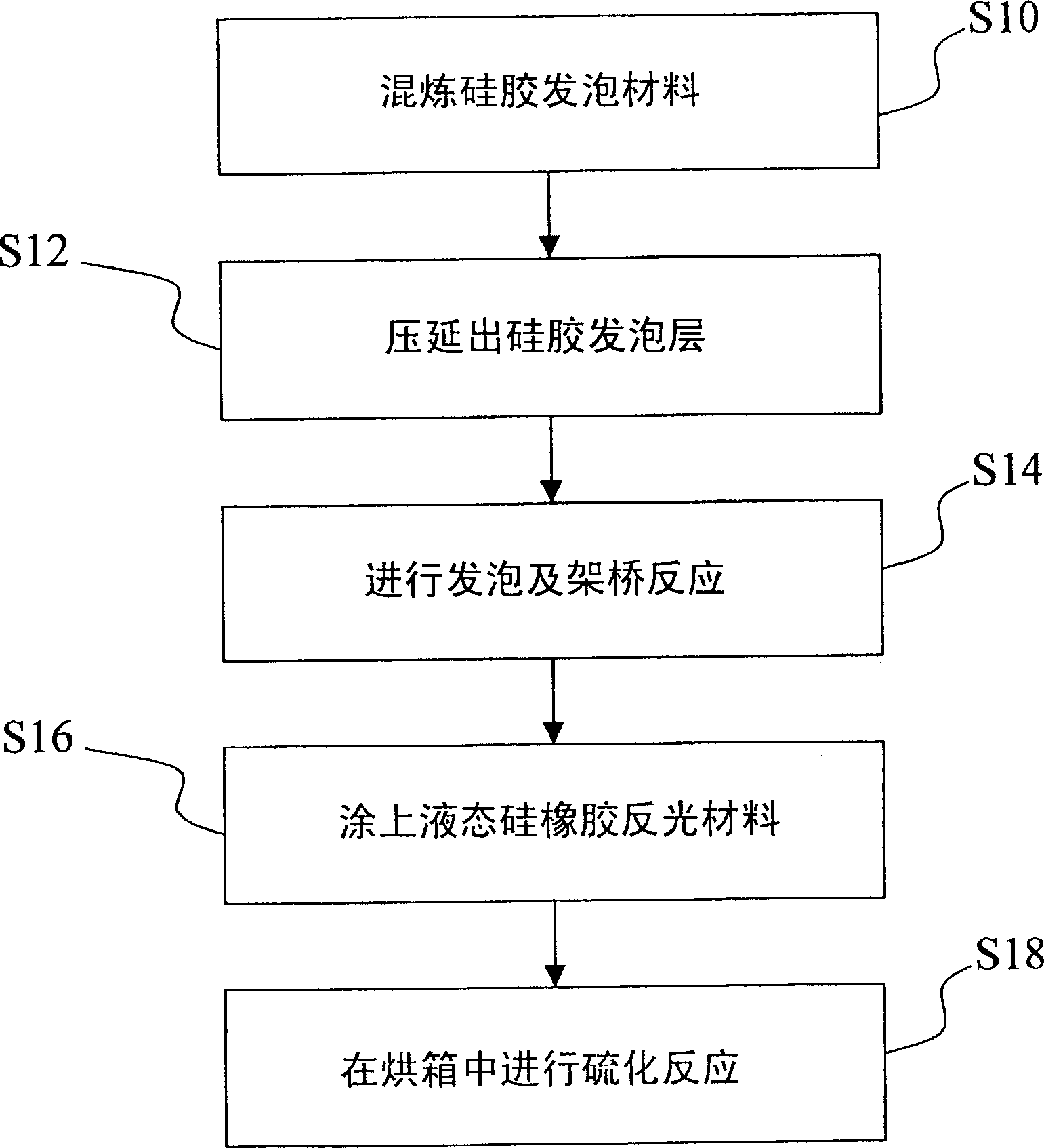

[0028] The present invention provides a material composition and processing method of a composite fiber, the composite fiber is such as figure 1 The structure shown is that a silicone foam layer 12 with thermal insulation effect and a silicone light reflection layer 14 that can enhance the function of heat insulation and radiation resistance are laminated on the fiber fabric 10, wherein the silicone foam layer 12 is mainly Contains high-temperature silicone rubber, organosilane, calcium carbonate, bridging agent, foaming agent, and reinforcing filler. The silica gel light reflective layer 14 mainly includes liquid silicone rubber and reflective filler.

[0029] The composition of the silicone foam layer 12 is: 100 parts by weight (PHR) of polysiloxane, and its chemical structure is as follows:

[0030]

[0031] Wherein R1 can be methyl, hydroxyl or vinyl, R2 or R3 can be methyl, vinyl or phenyl, y / (x+y) = 0.001 to 0.003, and the molecular weight ranges from 300,000 to 800,000; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com