Weeding and obstacle avoiding mechanism and weeding and obstacle avoiding robot

A technology of robots and obstacle avoidance sensors, which is applied to agricultural machinery and implements, manipulators, cutters, etc., can solve the problems of low intelligence level, manual removal, and high price, so as to improve weeding efficiency, reduce labor intensity, prevent damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

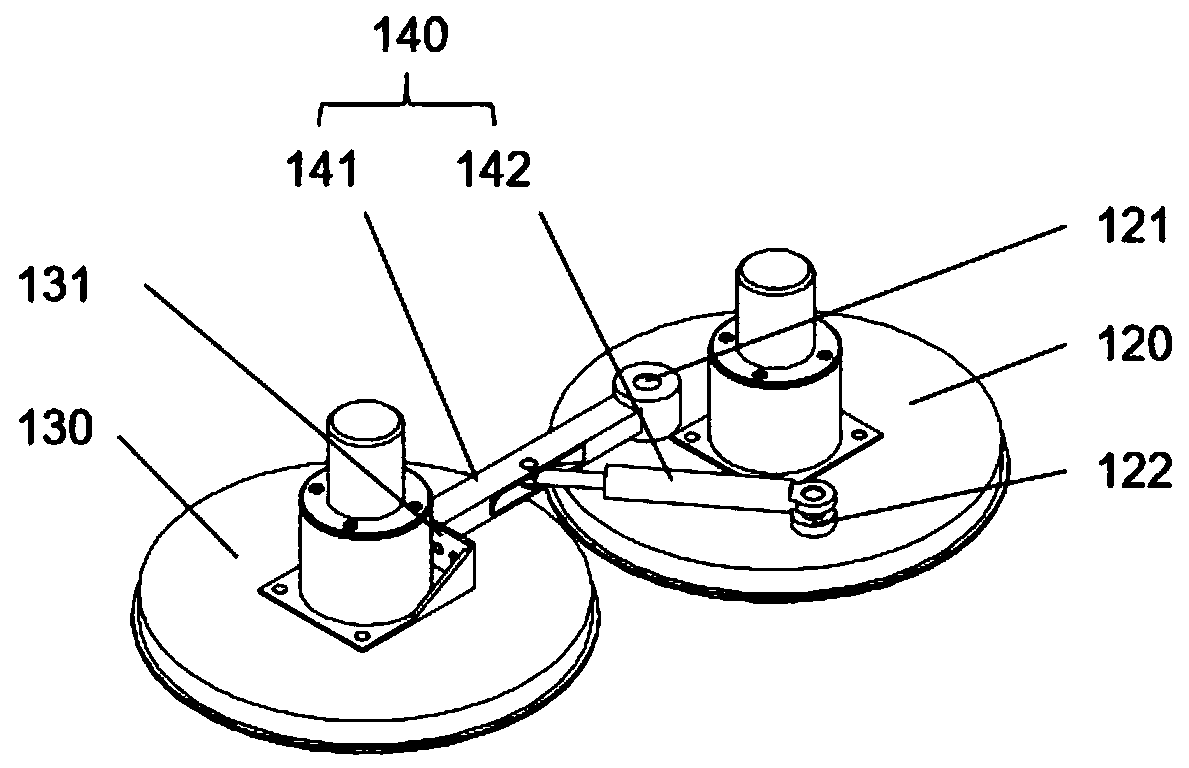

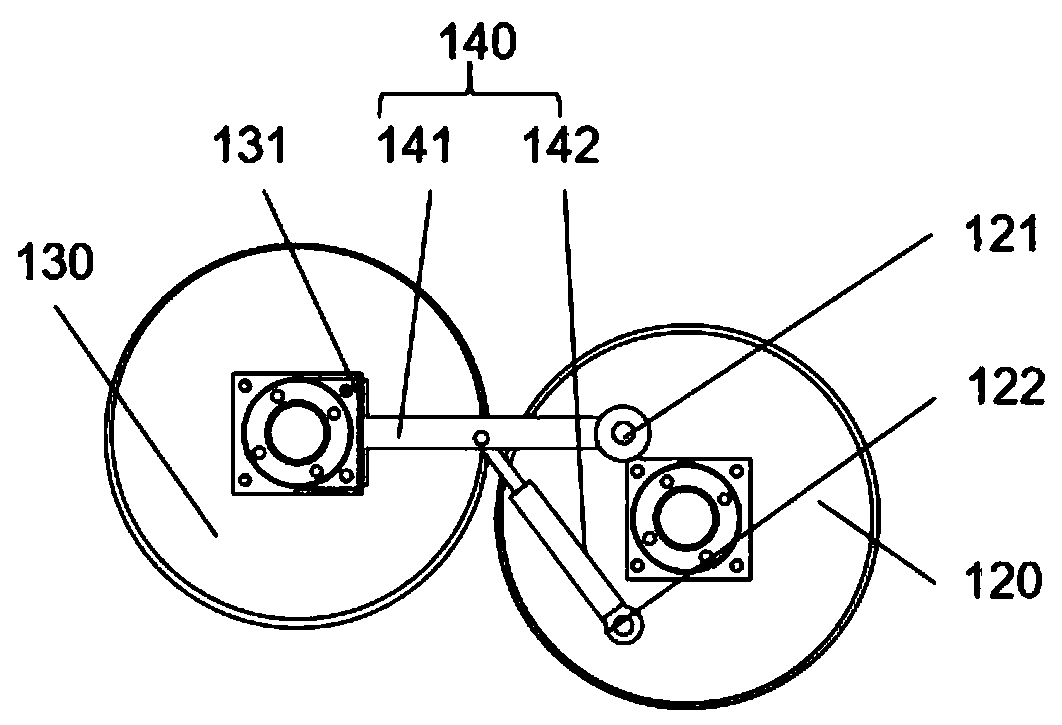

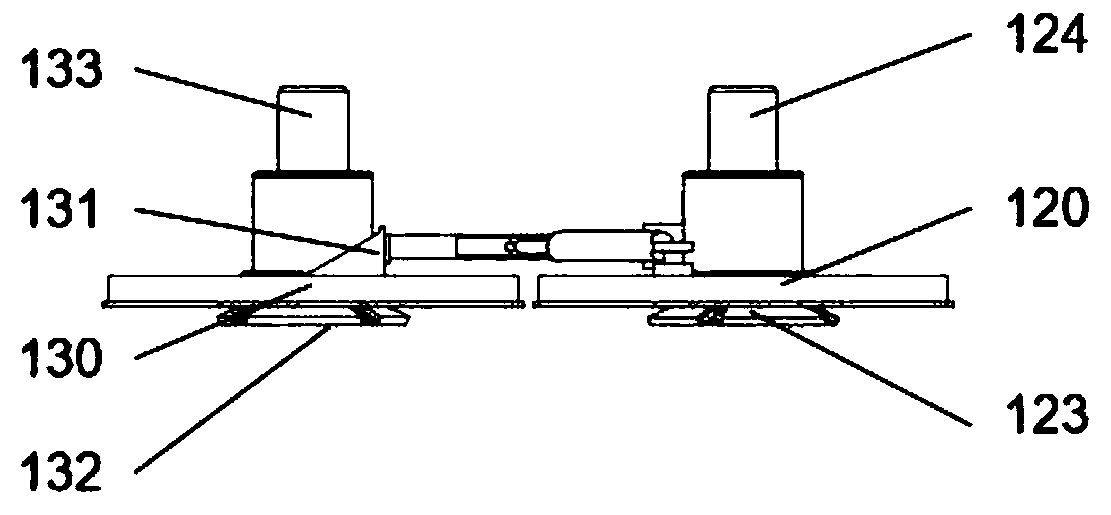

[0031] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-8 Specific embodiments of the present invention are described in detail.

[0032] See attached figure 1 and 2 , the present invention provides a weeding and obstacle avoidance mechanism 100, including a weeding structure 110 and an obstacle avoidance structure 140;

[0033] The weeding structure 110 includes a fixed cutter head cover 120 and a rotating cutter head cover 130;

[0034] The rotating cutterhead cover 130 is connected to the fixed cutterhead cover 120 through the obstacle avoidance structure 140;

[0035] The obstacle avoidance structure 140 includes a connecting rod 141 and a linear drive part 142;

[0036] The first end of the connecting rod 141 is rotatably connected to the fixed cutterhead cover 120, the second end of the connecting rod 141 is connected to the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com