Electrostatic spinning device for preparing coaxial nanofiber in batches

A coaxial electrospinning and nanofiber technology, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of low efficiency of coaxial electrospinning technology, and achieve increased width and production efficiency High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

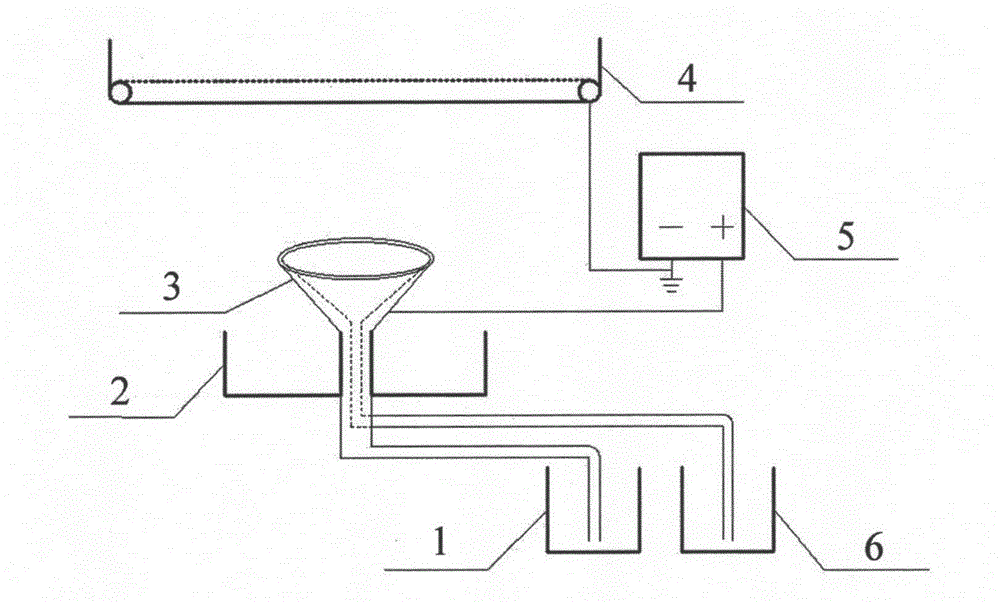

[0014] like figure 1 As shown, it is a schematic structural diagram of an electrospinning device for preparing coaxial nanofibers in batches. The electrospinning device for preparing coaxial nanofibers in batches includes a first liquid supply device 1, a second liquid supply device 6, a needle-free The coaxial electrospinning nozzle 3, the fiber collecting device 4 and the high voltage generator 5, the positive pole of the high voltage generator 5 is connected to the needleless coaxial electrospinning nozzle 3, the negative pole of the high voltage generator 5 is connected to the fiber collecting device 4, The fiber collecting device 4 is grounded. The needle-free coaxial electrospinning nozzle 3 comprises an outer layer solution spinneret and an inner layer solution spinneret located inside the outer layer solution spinneret, the inner layer solution spinneret and the outer layer solution spinneret The solution spinnerets are all trumpet-shaped, the inner layer solution spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com