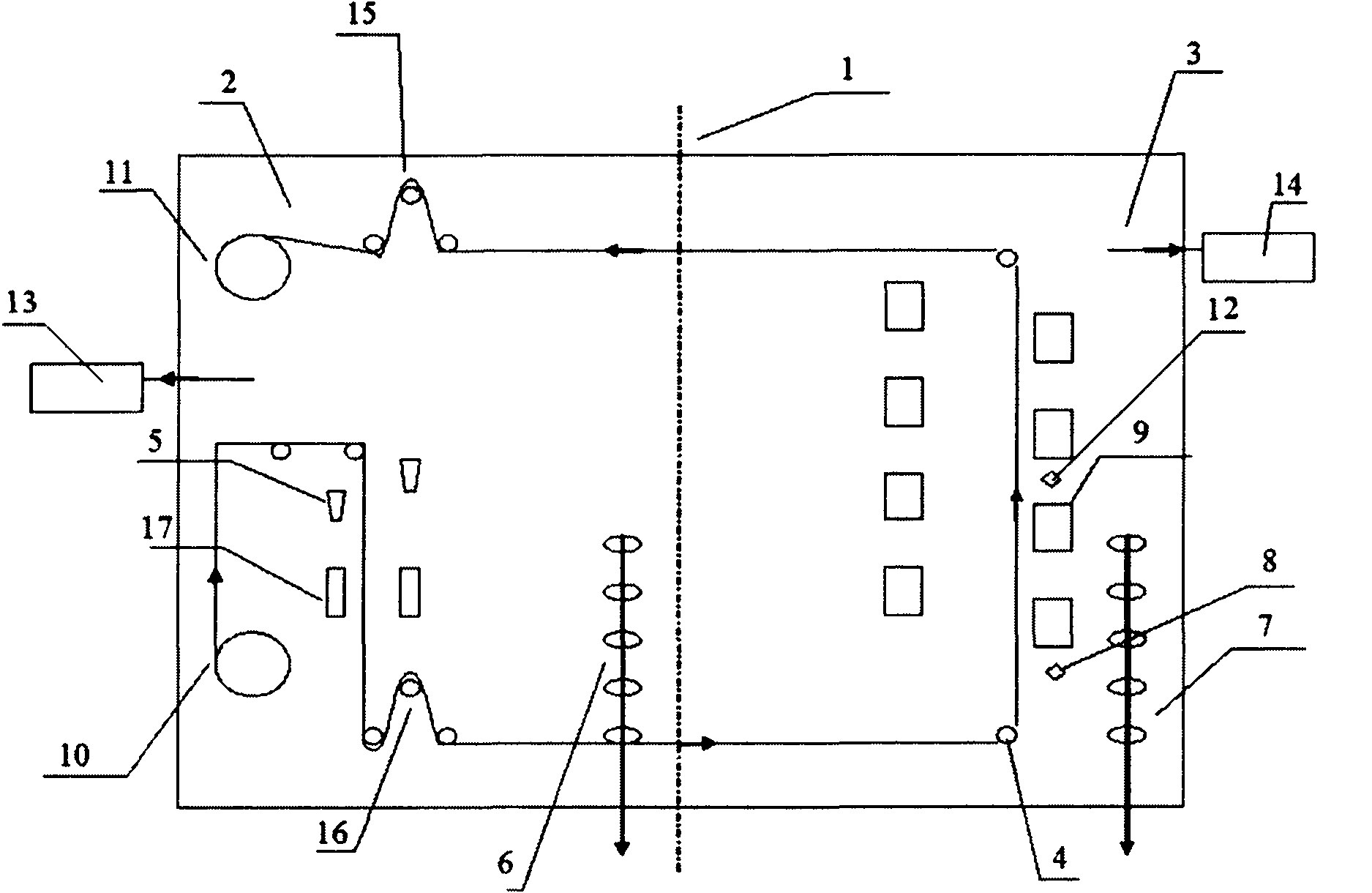

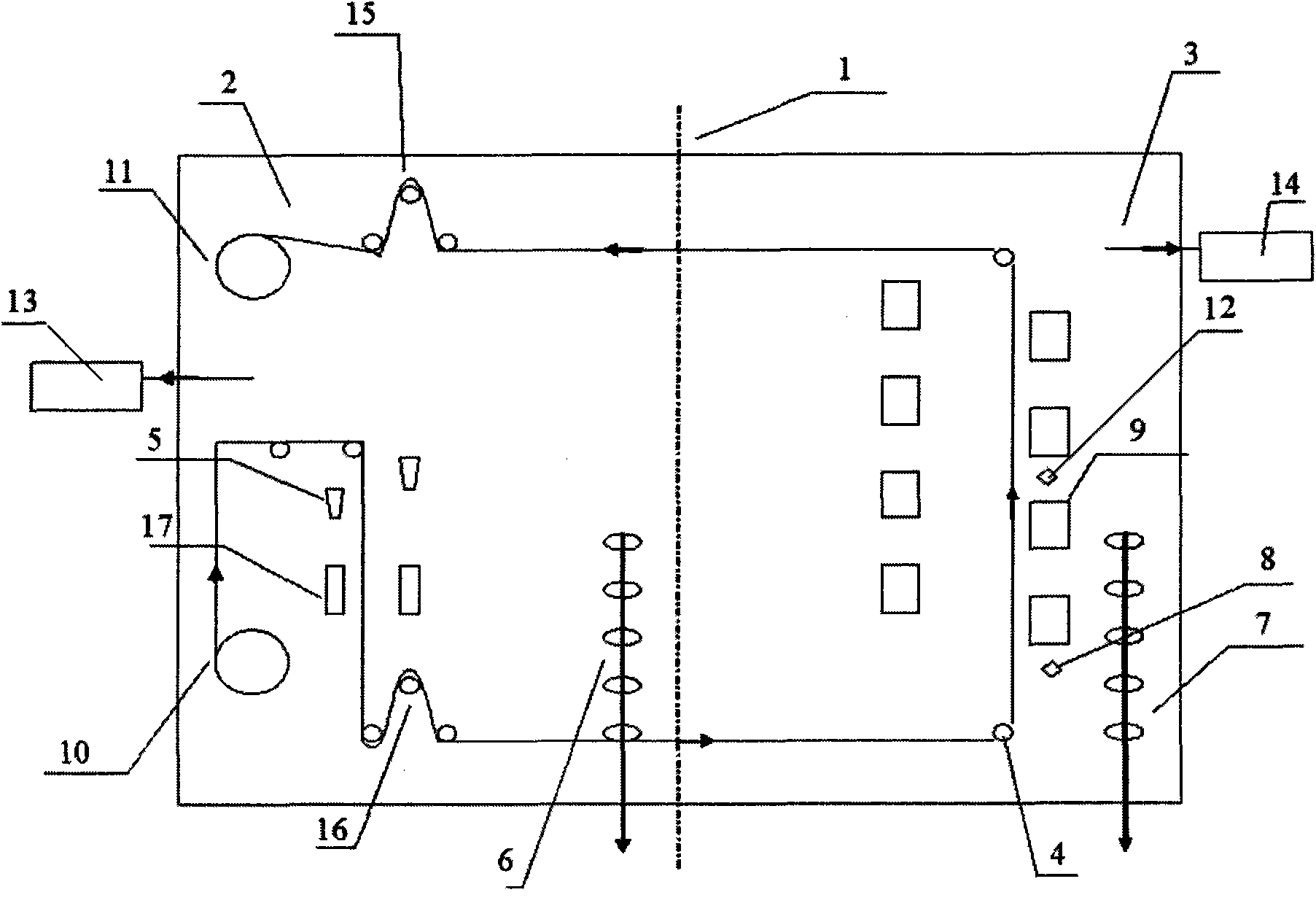

Manufacturing method and device of winding banded ITO conductive film

A technology of conductive film and production method, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem that sheet-type products cannot meet the requirements of large-scale products, many production processes, and poor product performance consistency and other problems, to achieve the effect of good product performance consistency, improved quality, and large width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The ITO conductive film is produced according to the following steps: first, the substrate is in the discharge chamber, and the surface of the substrate is treated by an infrared heater and an ion source in a vacuum state; secondly, it enters the sputtering chamber, and the substrate is sprayed Sputter silicon dioxide film on top; then, sputter indium tin oxide film on the silicon dioxide film; finally, leave the studio for cutting and packaging; among them, the power of linear ion source is 2kw; the power of infrared heater is 300W, the temperature 100°C; the vacuum degree of the sputtering chamber is 1×10 -3 pa, the sputtering atmosphere is formed by oxygen and argon with a mass ratio of 0.2:5; silicon dioxide film: the sputtering power is 200w, the sputtering target is quartz with a purity greater than 99.99%, and the sputtering power supply is radio frequency sputtering power supply; Indium tin oxide film: the sputtering power is 500w, the sputtering target is a cer...

Embodiment 2

[0017] The ITO conductive film is produced according to the following steps: first, the substrate is in the discharge chamber, and the surface of the substrate is treated by an infrared heater and an ion source in a vacuum state; secondly, it enters the sputtering chamber, and the substrate is sprayed sputtering silicon dioxide film on top; then, sputtering indium tin oxide film on the silicon dioxide film; finally, leaving the working room for cutting and packaging; among them, the power of the linear ion source is 6kw; the power of the infrared heater is 550W, and the temperature 115°C; the vacuum degree of the sputtering chamber is 3×10 -3 pa, the sputtering atmosphere is formed by oxygen and argon with a mass ratio of 0.2:5.5; silicon dioxide film: the sputtering power is 350w, the sputtering target is quartz with a purity greater than 99.99%, and the sputtering power supply is radio frequency sputtering power supply; Indium tin oxide film: the sputtering power is 650w, th...

Embodiment 3

[0019] The ITO conductive film is produced according to the following steps: first, the substrate is in the discharge chamber, and the surface of the substrate is treated by an infrared heater and an ion source in a vacuum state; secondly, it enters the sputtering chamber, and the substrate is sprayed Sputter silicon dioxide film on top; then, sputter indium tin oxide film on the silicon dioxide film; finally, leave the studio for cutting and packaging; among them, the power of linear ion source is 10kw; the power of infrared heater is 800W, the temperature 130°C; the vacuum degree of the sputtering chamber is 5×10 -3 pa, the sputtering atmosphere is formed by oxygen and argon with a mass ratio of 0.2:6; silicon dioxide film: the sputtering power is 500w, the sputtering target is quartz with a purity greater than 99.99%, and the sputtering power supply is radio frequency sputtering power supply; Indium tin oxide film: the sputtering power is 800w, the sputtering target is a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com