Process and equipment for manufacturing wide-width magnesium alloy plate in coils

A magnesium alloy plate and magnesium alloy technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficult control of plate shape, high investment, unsuitable for continuous production of coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

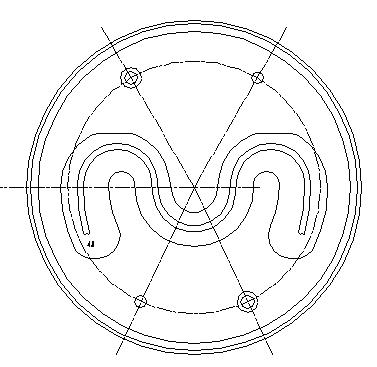

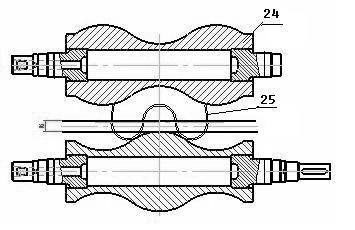

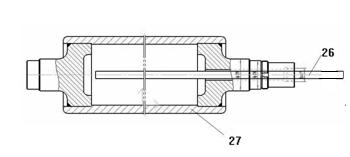

[0038] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11 show: a process for producing wide-width magnesium alloy plates in coils, which is to peel cast bars through milling—multiaxial forging— Mechanical processing - high temperature aging - bar heating - small tonnage extrusion machine extrusion - flattening - curling; the steps are as follows:

[0039] a. The as-cast magnesium alloy bar is milled and skinned to remove the surface casting cold layer; in the range of 230°C-350°C, 5 times of multi-axis forging are carried out, and the ¢600 round bar is machined;

[0040] b. Refine the microstructure of ¢600 round bar by 460°C high temperature aging to improve the extrusion performance and rolling performance of the material; make the magnesium alloy material undergo shrinkage porosity and shrinkage cavity, so that some small cracks are we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com