Method for manufacturing foamed polypropylene-resin particles

A technology of polypropylene-based resin and foamed particles, which is applied in the field of manufacturing polypropylene-based resin foamed particles, can solve problems such as the inability to realize the width of molding heating water vapor, and achieve wide width of molding heating water vapor, good formability, The effect of less decrease in physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] [Manufacture of polypropylene-based resin particles]

[0152] 0.05 parts by weight of talc, After 0.50 parts by weight of polyethylene glycol as a water-absorbing agent, melt-kneading was performed at a resin temperature of 220°C in a φ50mm single-screw extruder [manufactured by Osaka Seiki Works Co., Ltd., model 20VSE-50-28]. The obtained melt-kneaded resin was extruded into strands through a circular die, water-cooled, and then cut with a pelletizer to obtain cylindrical polypropylene-based resin particles with a weight of 1.2 mg / pellet.

[0153] [Manufacture of expanded polypropylene resin particles]

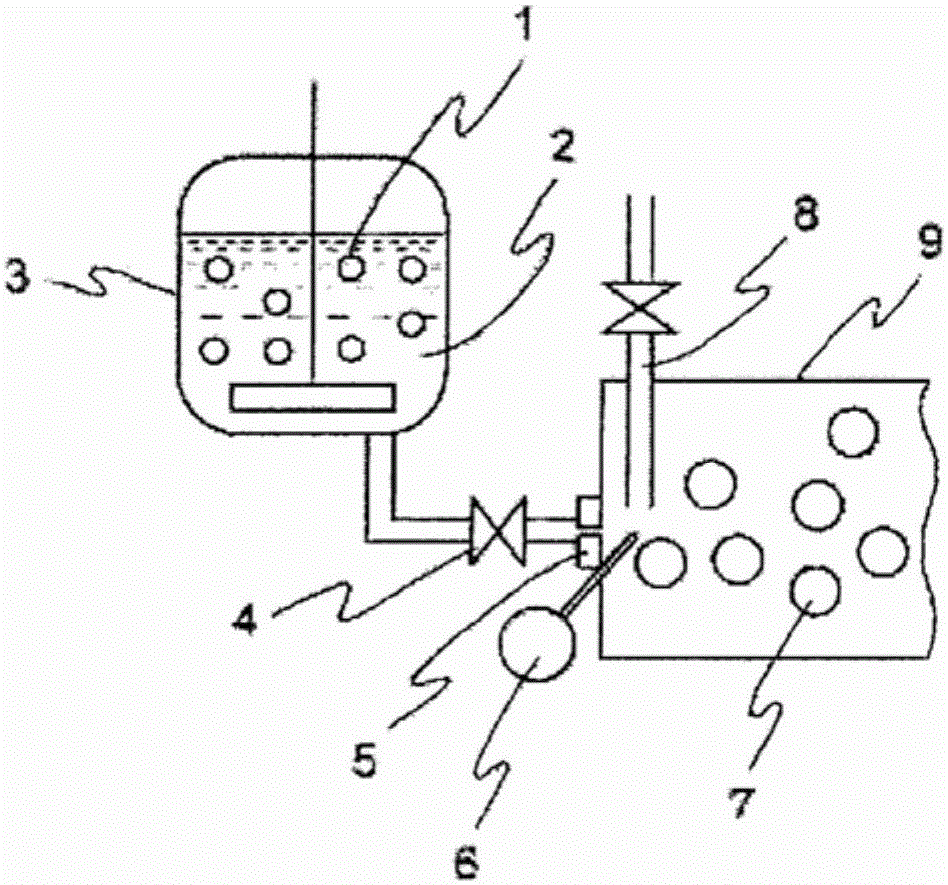

[0154] A pressure-resistant autoclave (pressure-resistant container 3) with a capacity of 10 L is used. image 3 The apparatus shown in the foaming tank 9 is used to produce expanded polypropylene-based resin particles.

[0155] In a pressure-resistant autoclave with a capacity of 10 L, 100 parts by weight of the obtained polypropylene-based resin particles, 170 par...

Embodiment 2

[0159] In [Manufacture of Polypropylene-based Resin Expanded Beads], except that the heating temperature (expansion temperature) of the contents of the autoclave was changed to 149° C., primary expanded bead and molded bead were obtained by the same operation as in Example 1. Inner foam molded body. The obtained primary expanded particles had an expansion ratio of 18 times, a DSC peak ratio of 29%, and a heat deformation rate of 0.0%. The minimum molding heating steam pressure is 0.22 MPa·G, and the fusion property, surface property, and 50% compressive strength are acceptable within the range of the entire heating water vapor pressure up to the high heating water vapor pressure of 0.32 MPa·G. The results are shown in Table 1.

Embodiment 3

[0161] [Manufacture of polypropylene-based resin particles]

[0162] 0.10 parts by weight of talc, Polypropylene-based resin particles were obtained in the same manner as in Example 1, except that polyethylene glycol was 0.50 parts by weight as a water absorbing agent.

[0163] [Manufacture of expanded polypropylene resin particles]

[0164] Using the obtained polypropylene-based resin particles, except that the heating temperature (foaming temperature) of the contents of the autoclave was changed to 136°C, primary expanded particles were obtained by the same operation as in Example 1, and in-mold foam molding body. The obtained primary expanded particles had an expansion ratio of 20 times, a DSC peak ratio of 20%, and a heat deformation rate of -1.0% at the melting point of the resin of 139-15=124°C.

[0165] [Manufacture of polypropylene-based resin in-mold foam molding]

[0166] In-mold foam molding was performed in the same manner as in Example 1, and the moldability a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com