Snap on latch mechanism for a sash window

a latch mechanism and sash window technology, applied in the direction of mechanical devices, fastening means, carpet fasteners, etc., can solve the problems of difficult assembly of the ro-mai latch mechanism, difficult to mount the latch mechanism in the hollow sash, etc., and achieve the effect of wide tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

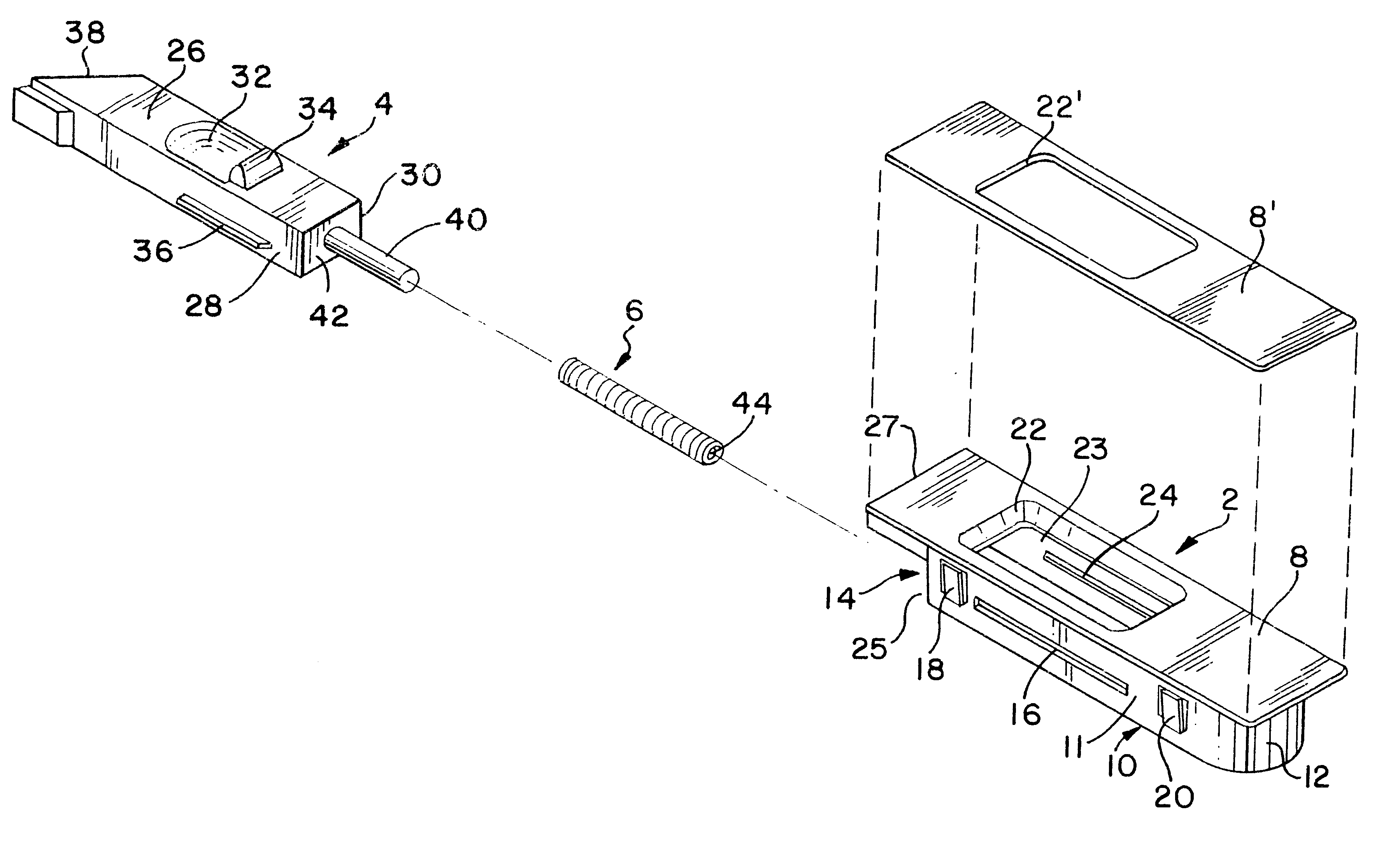

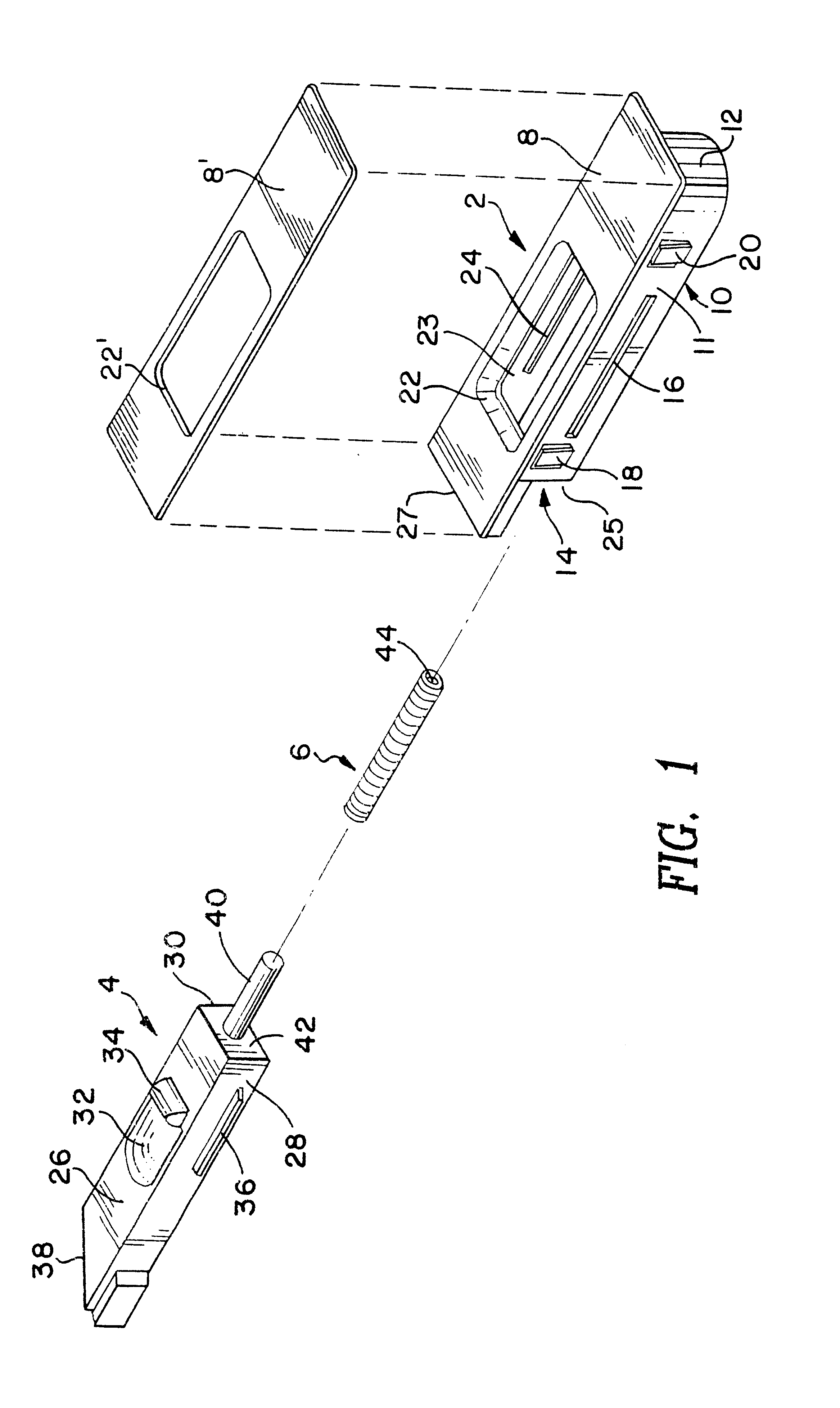

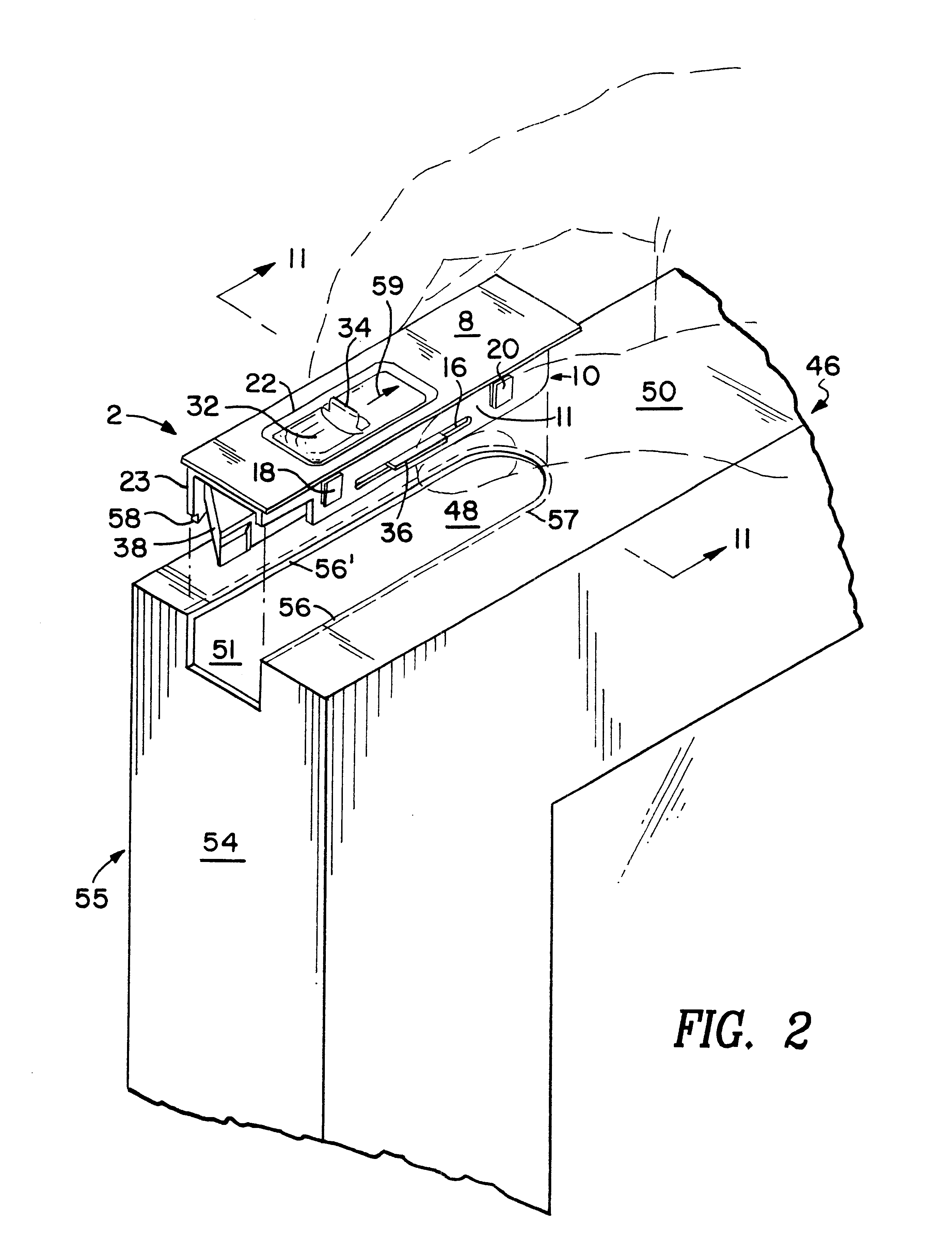

FIG. 1 is an exploded isometric view of a latching mechanism of the invention for use in the top left corner of a window that tilts toward the view about the bottom of its sash as viewed from the inside. It will be understood, however, that the latch mechanism may be mounted at different places and that it has other uses. Corresponding components are designated in the same way in all figures of the drawings.

The preferred latching mechanism is comprised of a housing 2, a bolt 4 and a longitudinal coiled compression spring 6. The housing 2 is comprised of a top plate 8 having a wall 10 depending therefrom at a slight distance from its periphery. Only one side wall 11 is seen in this view. One end 12 of the wall 10 is closed, and, although not shown in this view, its other end 14 is open. A slot 16 in the wall 11 is spaced from and runs parallel to the top plate 8, and tabs 18 and 20 that flare outwardly as the approach the top plate 8 are located adjacent opposite ends of the slot 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com