Arc oscillation-based gas shielded welding arc tracking method

A technology of gas shielded welding and arc, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of welding current jump, influence on arc stability, spatter, etc. Flexible, reducing the effect of signal mutations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

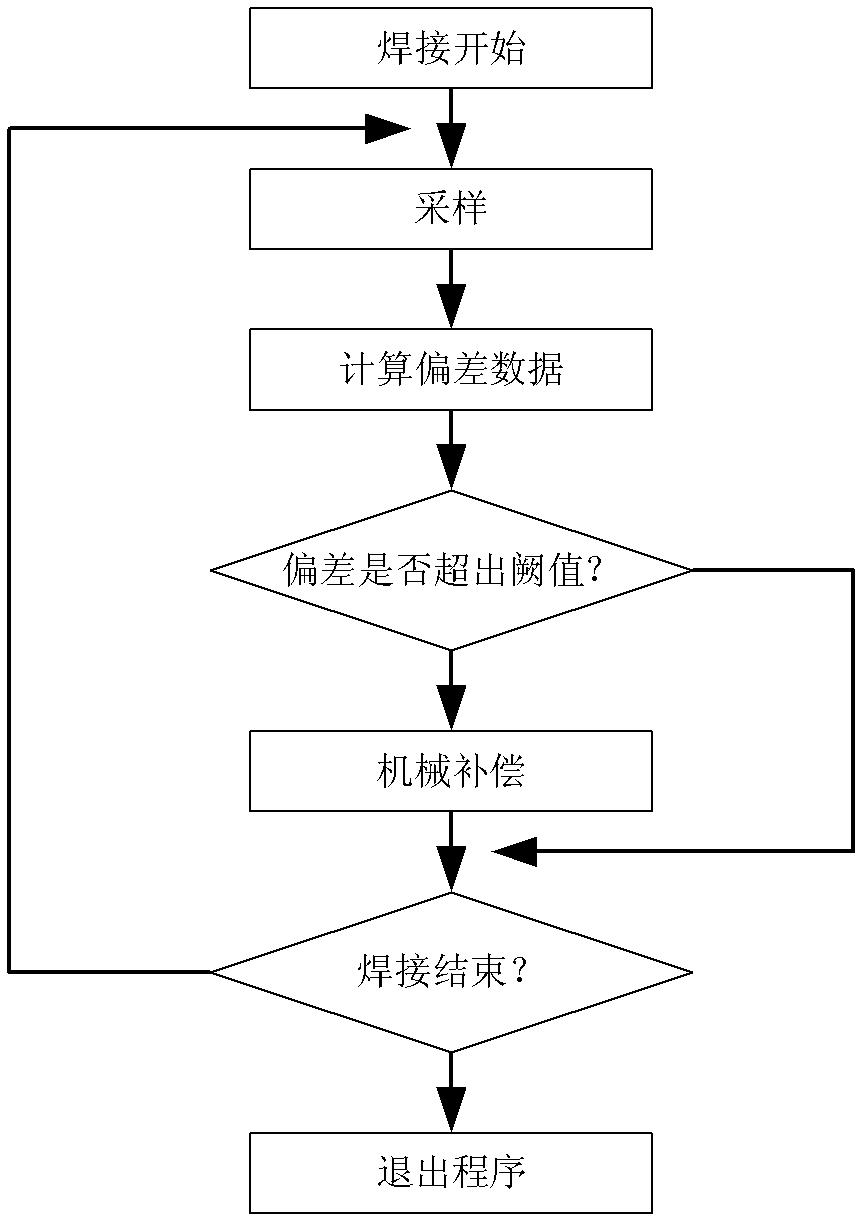

[0039] The present invention is a gas shielded welding arc tracking method based on arc swing, such as figure 1 shown, including the following steps:

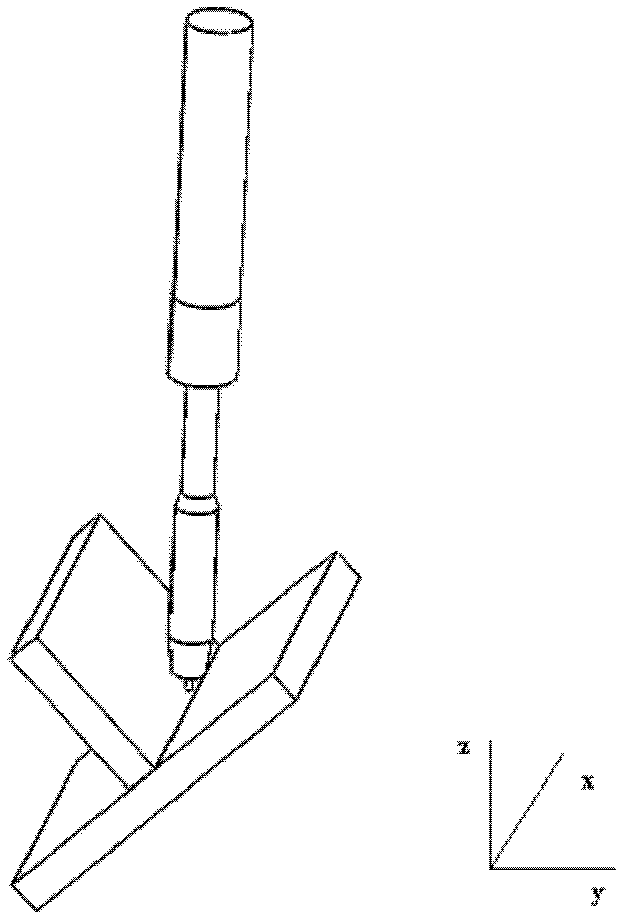

[0040] 1) After the welding starts, the welding torch starts to swing periodically in the direction perpendicular to the weld seam.

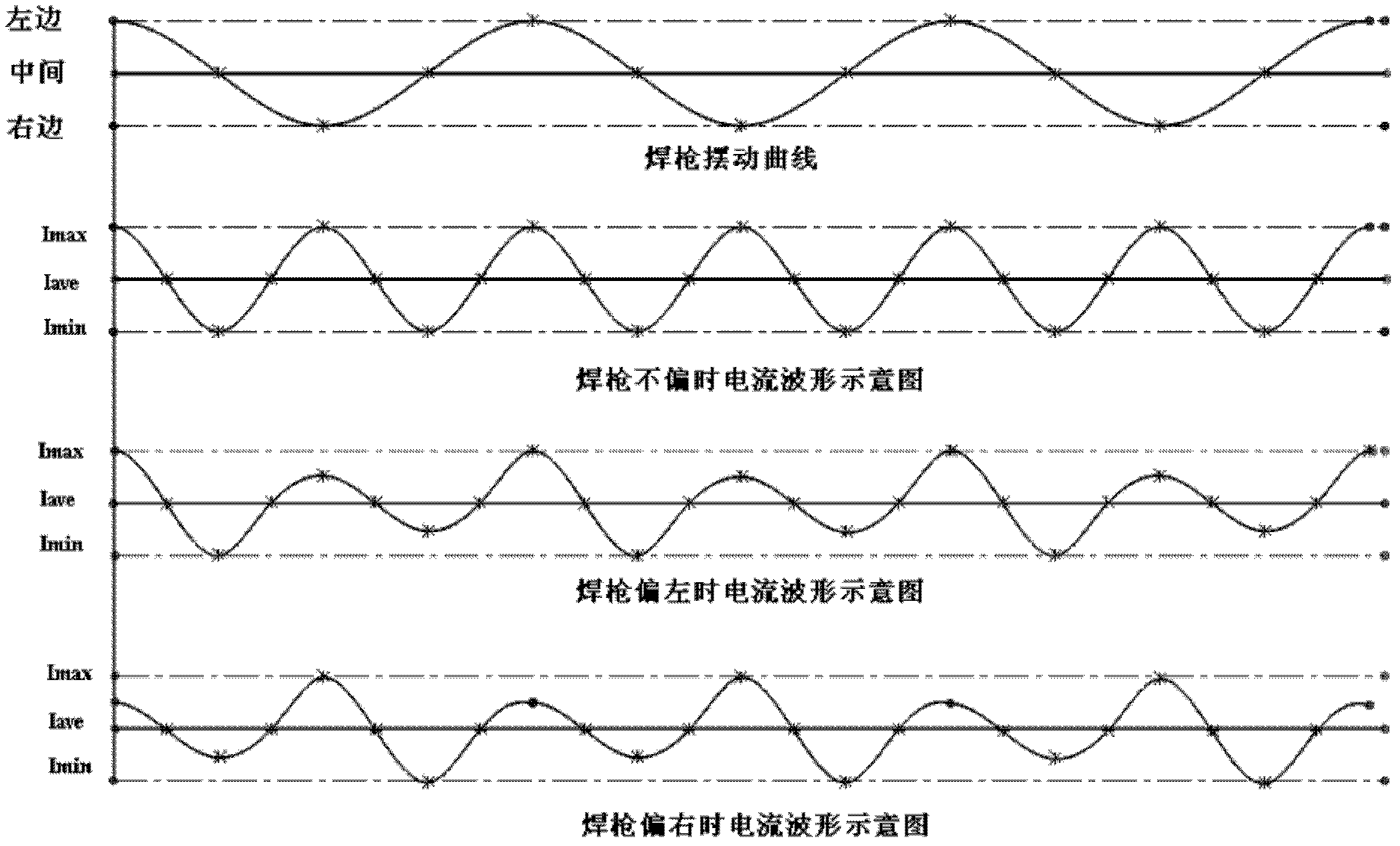

[0041] The trigger signal for the torch swing is controlled by the sampling process. The current sensor triggers the welding torch to swing in a specific direction (left or right) while sampling, so that the current change period can be synchronized with the swing direction of the welding torch, that is, the sampling of the welding current is performed synchronously with the swing of the arc. After a deviation occurs, the swing direction of the welding torch can be judged by the periodic coordinates, and the direction of the deviation can be determined in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com