Method of cryogenic surface activation direct bonding for preparation of quartz glass capillary tube

A quartz glass, direct bonding technology, applied in the field of materials, can solve the problems of small effective observation range of the device and rough inner wall of the channel, and achieve the effect of improving device performance, smooth inner wall, and controllable size rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

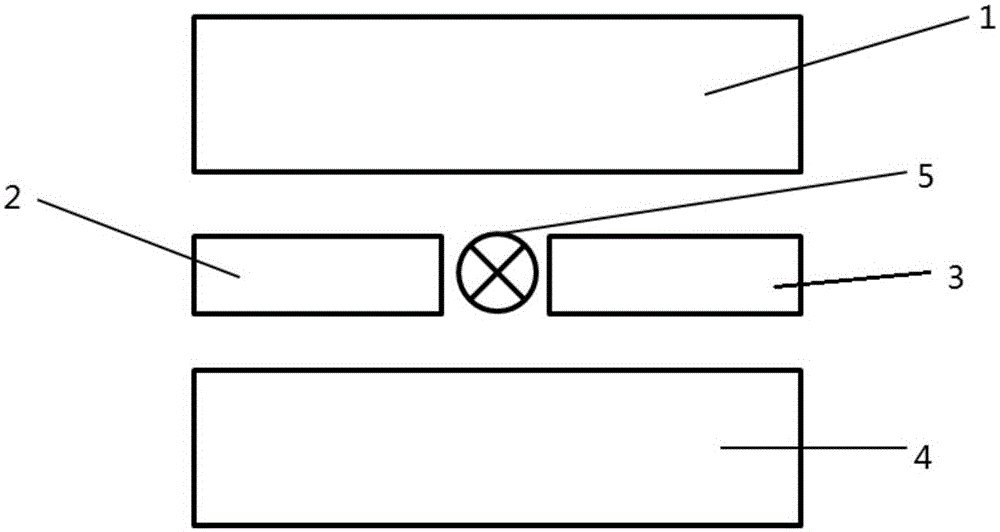

[0035] A method for preparing a quartz glass capillary by low-temperature surface activation and direct bonding, mainly comprising the following steps:

[0036] (S1), clean all the glass sheets, and remove all kinds of organic pollution;

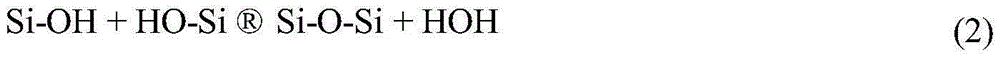

[0037] (S2), all glass sheets are treated in an oil bath with piranha lotion;

[0038] (S3), all glass sheets are cleaned by two-step RCA standard cleaning solution;

[0039] (S4), the glass sheet is immersed in an oil bath of activation solution;

[0040] (S5), after the glass sheet is rinsed with deionized water, it is transferred to a container filled with deionized water and bonded;

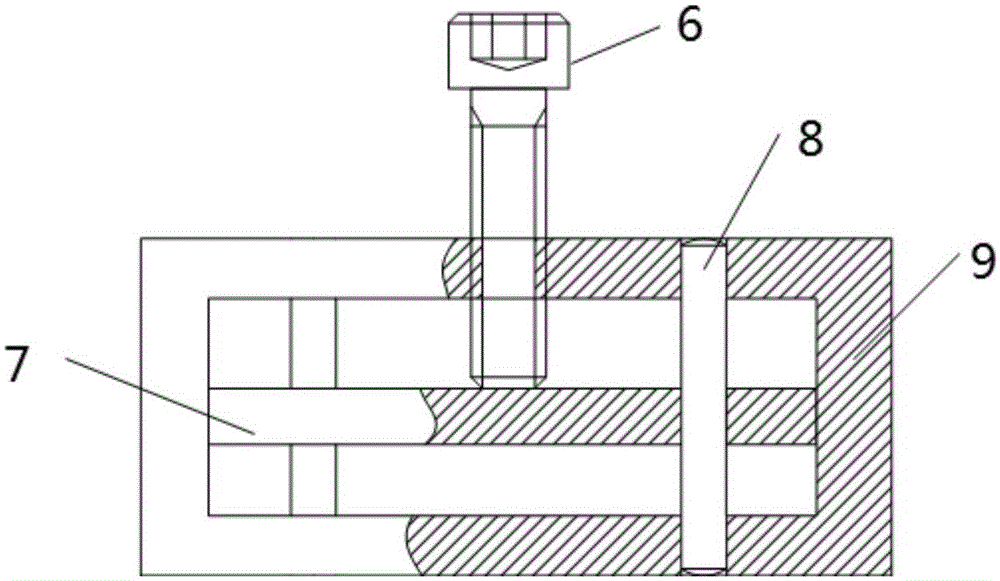

[0041] (S6), transfer the pre-bonded device to a stainless steel mold for pressure, keep it warm at a low temperature, and realize permanent bonding.

[0042] Among them, optical-grade quartz glass is preferably precision-processed into two sizes: 2.0mm×5.0mm×4.0mm and 0.2mm×2.0mm×5.0mm. The glass sheet is polished on 6 sides, the flatness f-number is N=1...

Embodiment 2

[0043] Embodiment 2: Preferable optical grade quartz glass is precision processed into two sizes: 10mm×10mm×2mm and 10mm×0.2mm×4.9mm. 10mm×10mm×2mm glass sheet is polished on both sides, 10mm×0.2mm×4.9mm is polished on 6 sides, the number of flatness apertures is N=1, and the surface roughness is required to be below 6nm. Two glass sheets of the above two different specifications are respectively taken. The glass slides were ultrasonically cleaned with methanol, acetone and deionized water for 5 minutes to remove various organic matter and dust pollution; then passed through piranha solution (H 2 SO 4 :H 2 o 2 Volume ratio=3:1) 120°C oil bath for 15 minutes. Then the glass piece is immersed in RCA1(NH 4 OH:H 2 o 2 :H 2 O volume ratio = 1:1:5) and RCA2 (NH 4 OH:HCl:H 2 (Volume ratio=1:1:5) were heated and boiled in an oil bath at 100°C for 15 minutes, followed by washing with deionized water for 5 minutes, and immersed in deionized water for later use. Then the glass...

Embodiment 3

[0044] Embodiment 3: Preferable optical grade quartz glass is precision processed into two sizes: 10mm×10mm×2mm and 10mm×0.3mm×4.85mm. 10mm×10mm×2mm glass sheet is polished on both sides, 10mm×0.3mm×4.85mm is polished on 6 sides, the number of flatness apertures is N=1, and the surface roughness is required to be below 6nm. The bonding conditions different from Example 2 are: the pre-bonding time at 100°C is 1.5 hours; steel needles with a diameter of 300 μm are used; pressure bonding is carried out in a vacuum oven at 150°C for 10 hours at low temperature. The rest of the steps are the same as in Example 2, and the peripheral dimensions of the finally prepared device are 10 mm×10 mm×4.3 mm, and the middle channel is a 300 μm square hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com