Method for manufacturing high-luminous-efficacy focusing solar Fresnel lens

A technology of Fresnel lens and concentrating solar energy, which is applied in the field of production of high-efficiency concentrating solar lens, can solve the problems of no Fresnel lens structure, etc., so as to improve light efficiency, service life, transparency and resistance The effect of aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

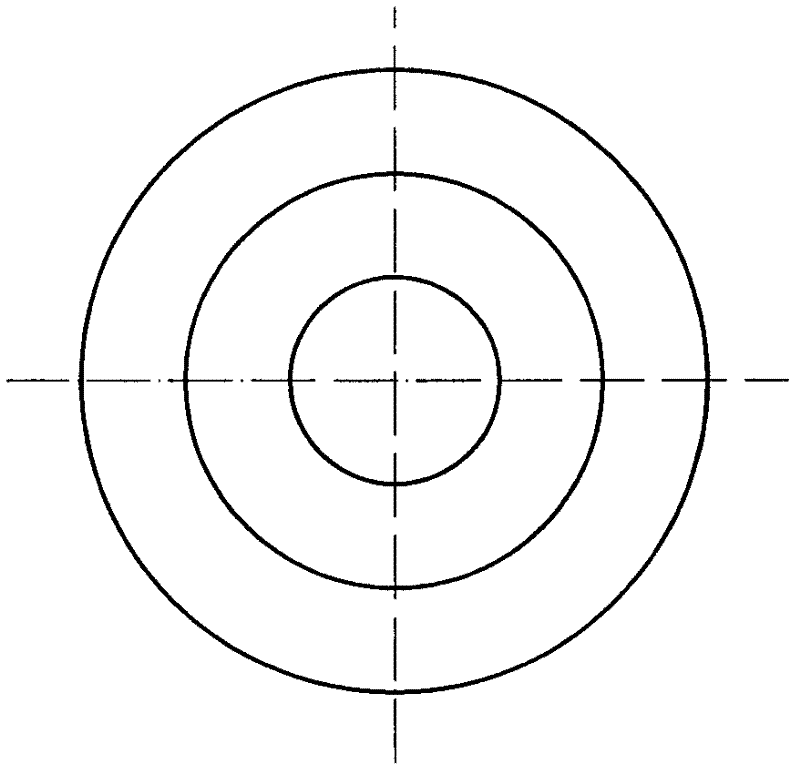

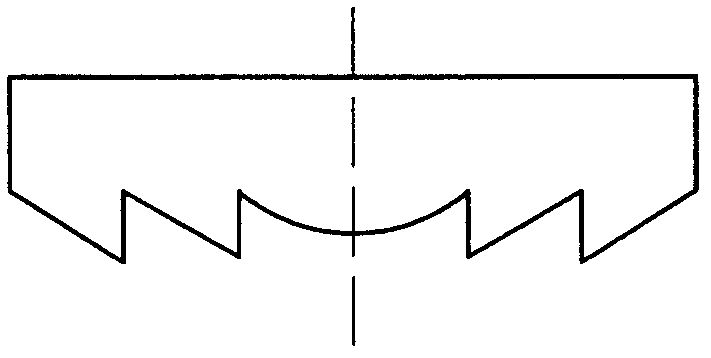

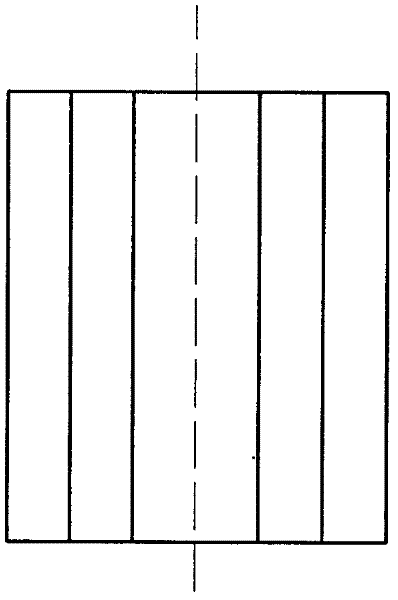

[0019] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing: Figure 1-4 The basic structure of the unimproved Fresnel lens is shown. Its bottom surface 2 is a plane, which is the light-receiving surface of the lens, and its backlight surface is a left-right symmetrical annular corrugated surface with the center point as the center (see figure 1 , 2 ) or a striped corrugated surface based on the center line (see image 3 , 4 ), the longitudinal section is symmetrical and saw-toothed. See Figure 7 , each corrugation has a refraction surface 1, a vertical surface 15, a corrugation top 10 and a corrugation bottom 6, and the structural characteristics of the latter three hinder the light effect of the Fresnel lens. see Figure 5 , changing the vertical surface to the inner slope 9 inclined toward the focal point, and changing the original circular groove bottom 6 to a narrow plane bottom, the incident li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com