Patents

Literature

65results about How to "Reliable installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

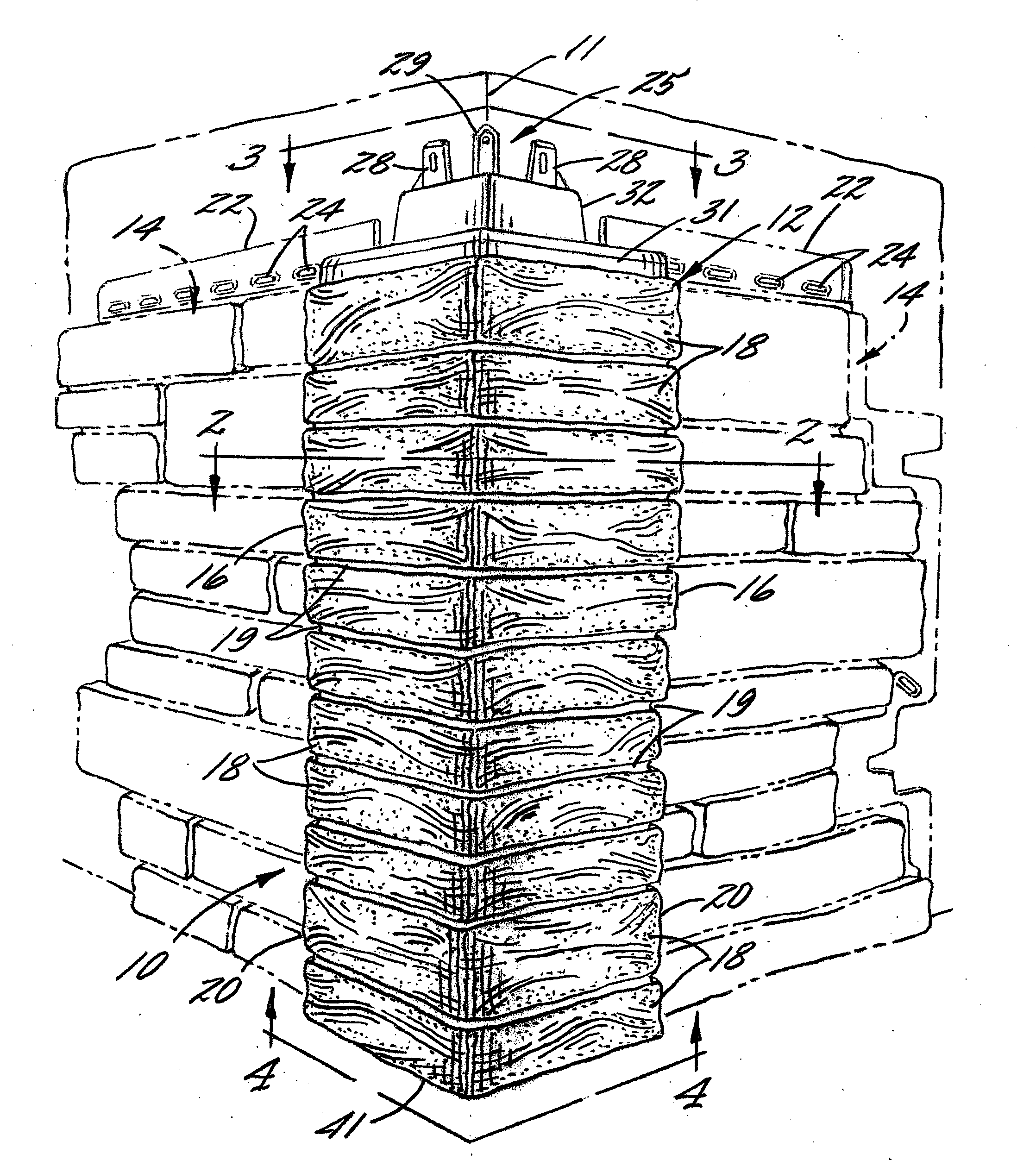

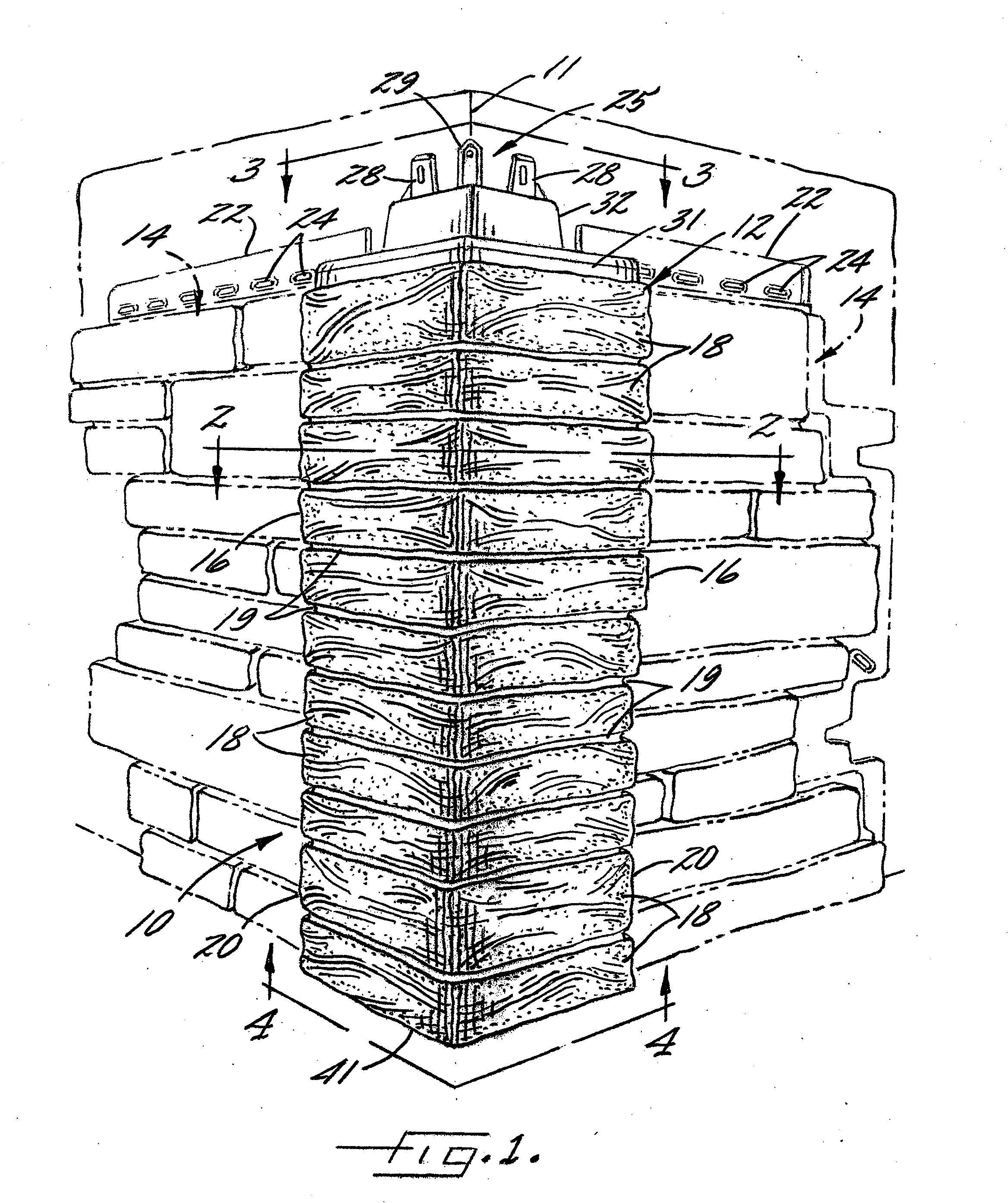

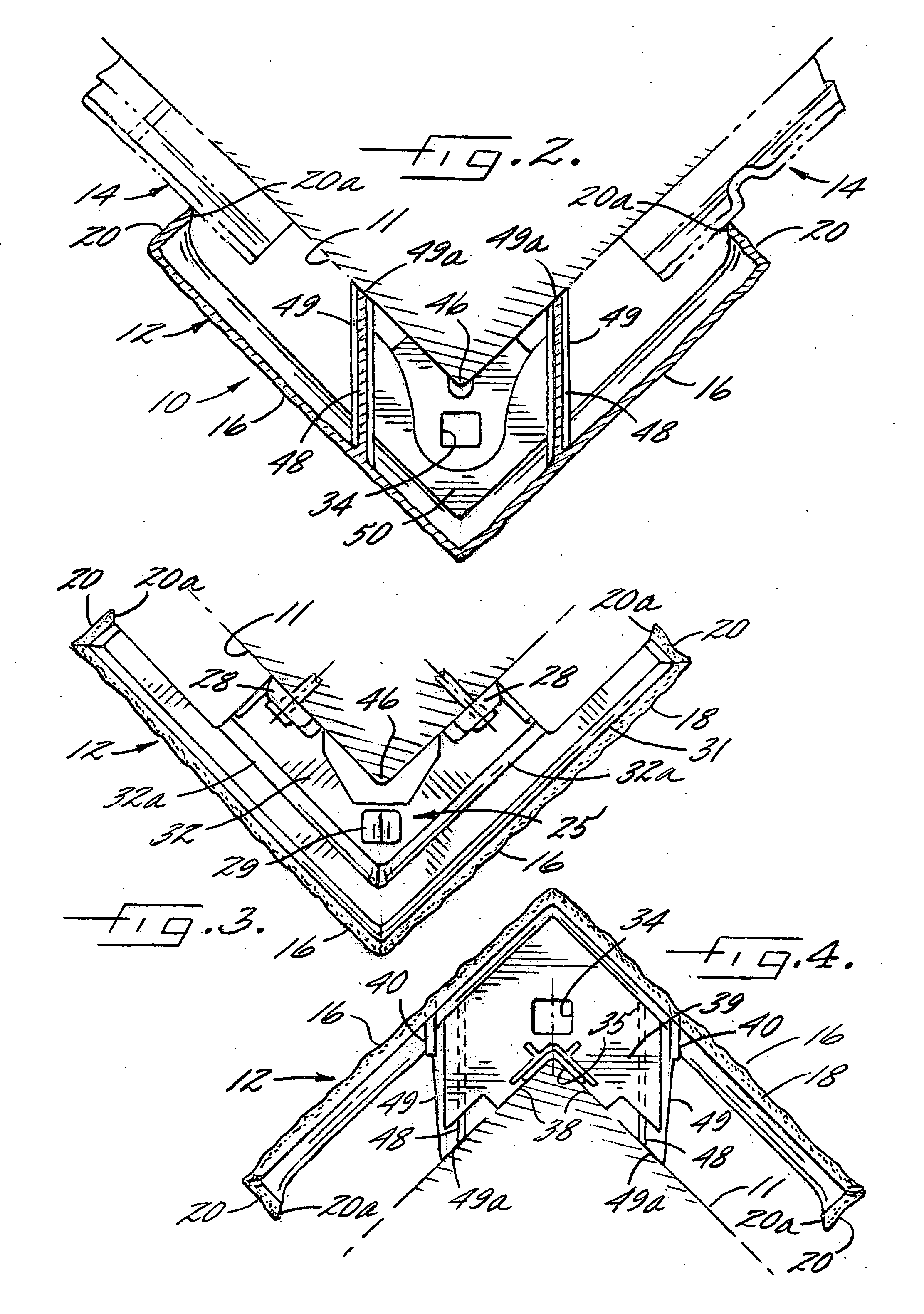

Roof and wall covering with improved corner construction

ActiveUS20100011690A1Reliable installationEasy to installCeilingsRoof covering using tiles/slatesEngineeringBuilding construction

A plastic molded wall covering that includes a plurality of one piece plastic molded corner moldings mounted in a vertically stacked array. The corner moldings each have a pair of front panels disposed at an angle to each other and formed with simulated building elements, such as hand laid stone. The corner moldings have respective upper and lower interlock devices and internal support and reinforcing walls extending rearwardly of the front panels in interconnecting relation to the interlock devices. The internal support and reinforcing walls have a curved serpentine configuration with a curved junction line with the respective front panels such that any plastic molded sink mark exposed on a front side of the front panels from the integrally formed internal walls similarly is undulating so as to blend into the simulated building elements and not detract from its natural appearance.

Owner:NOVIK INC

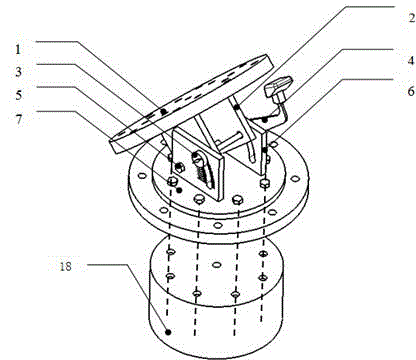

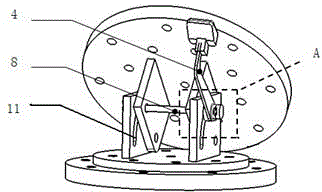

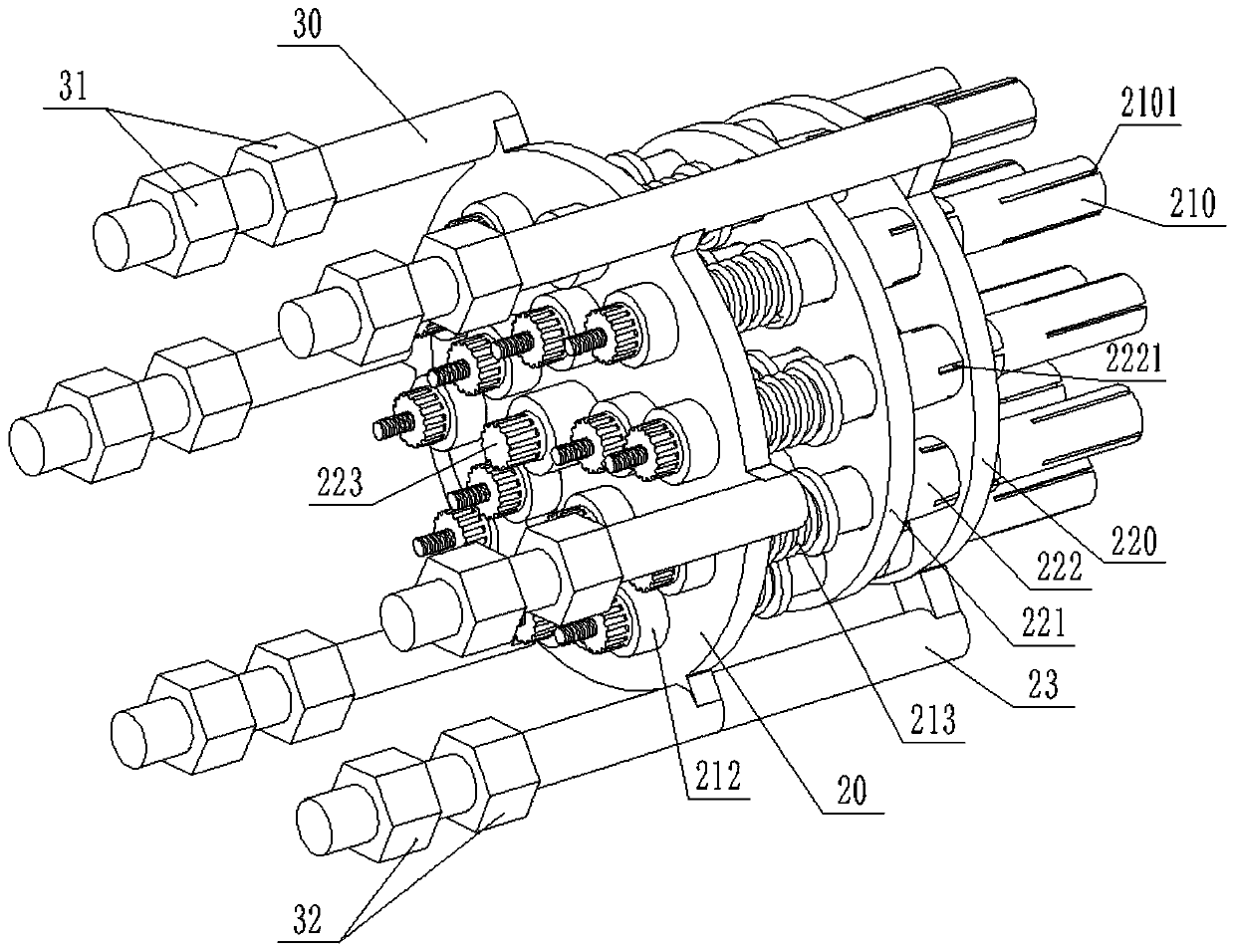

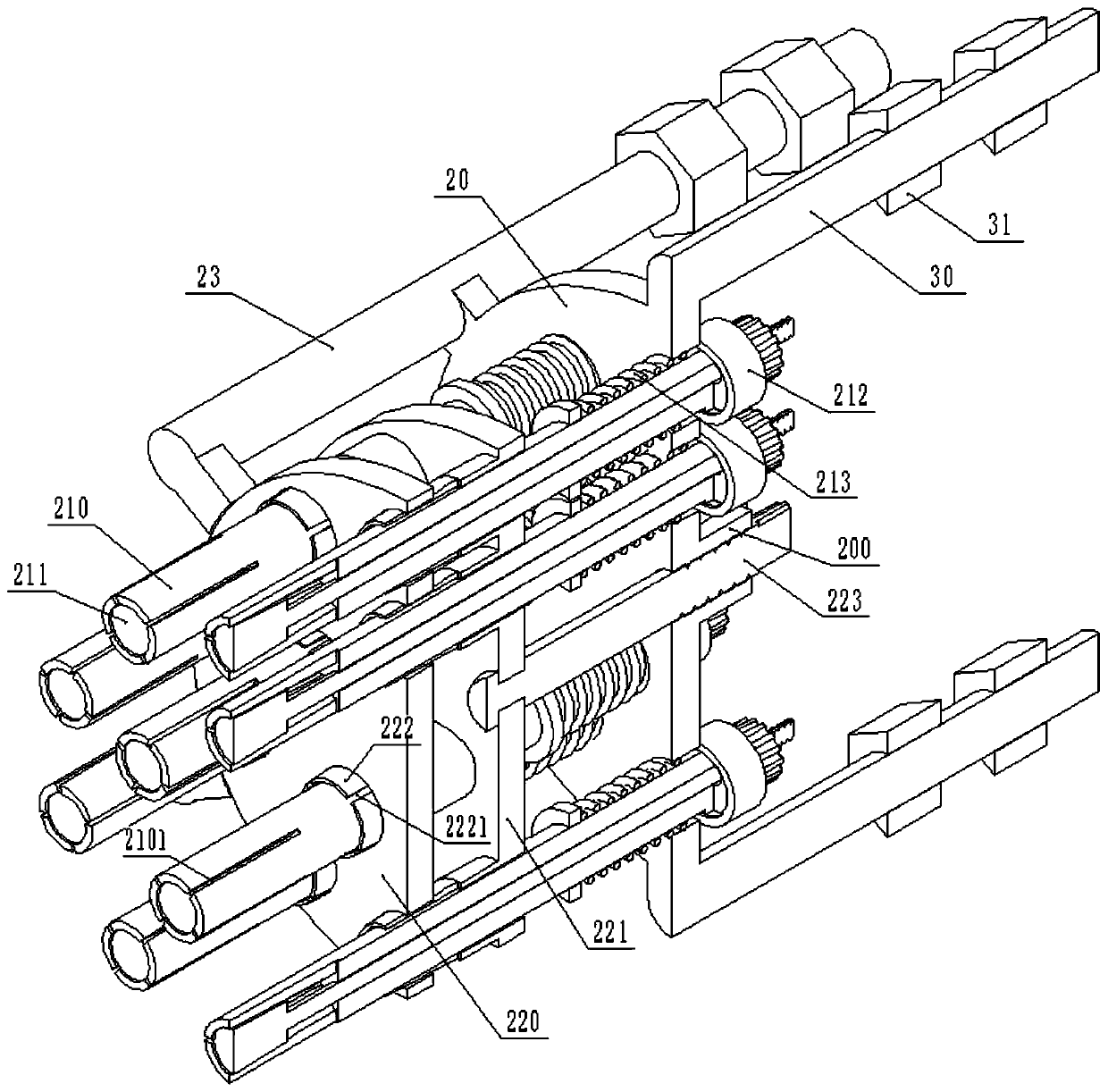

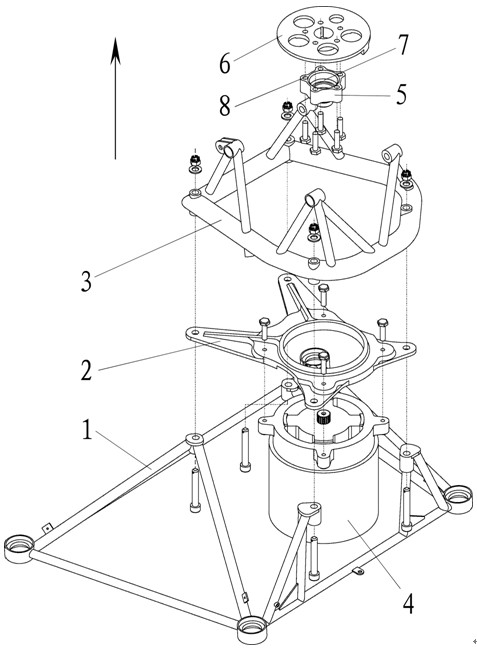

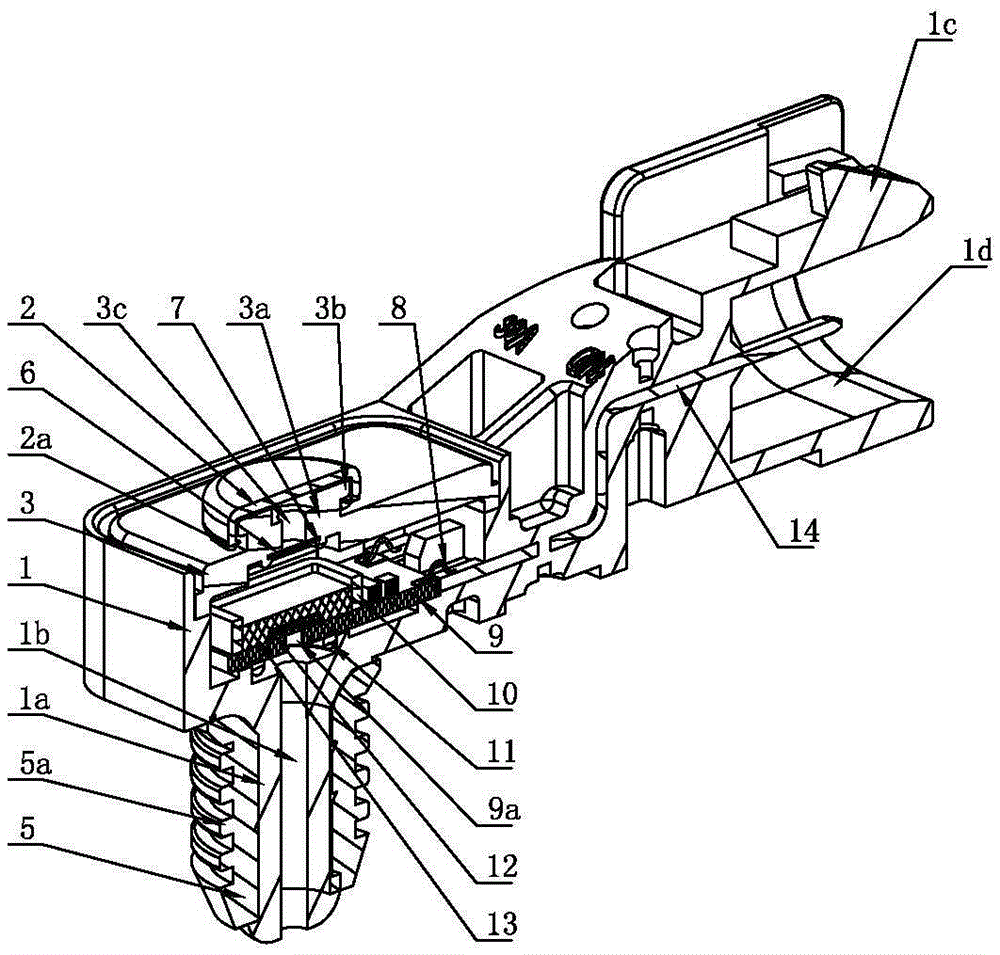

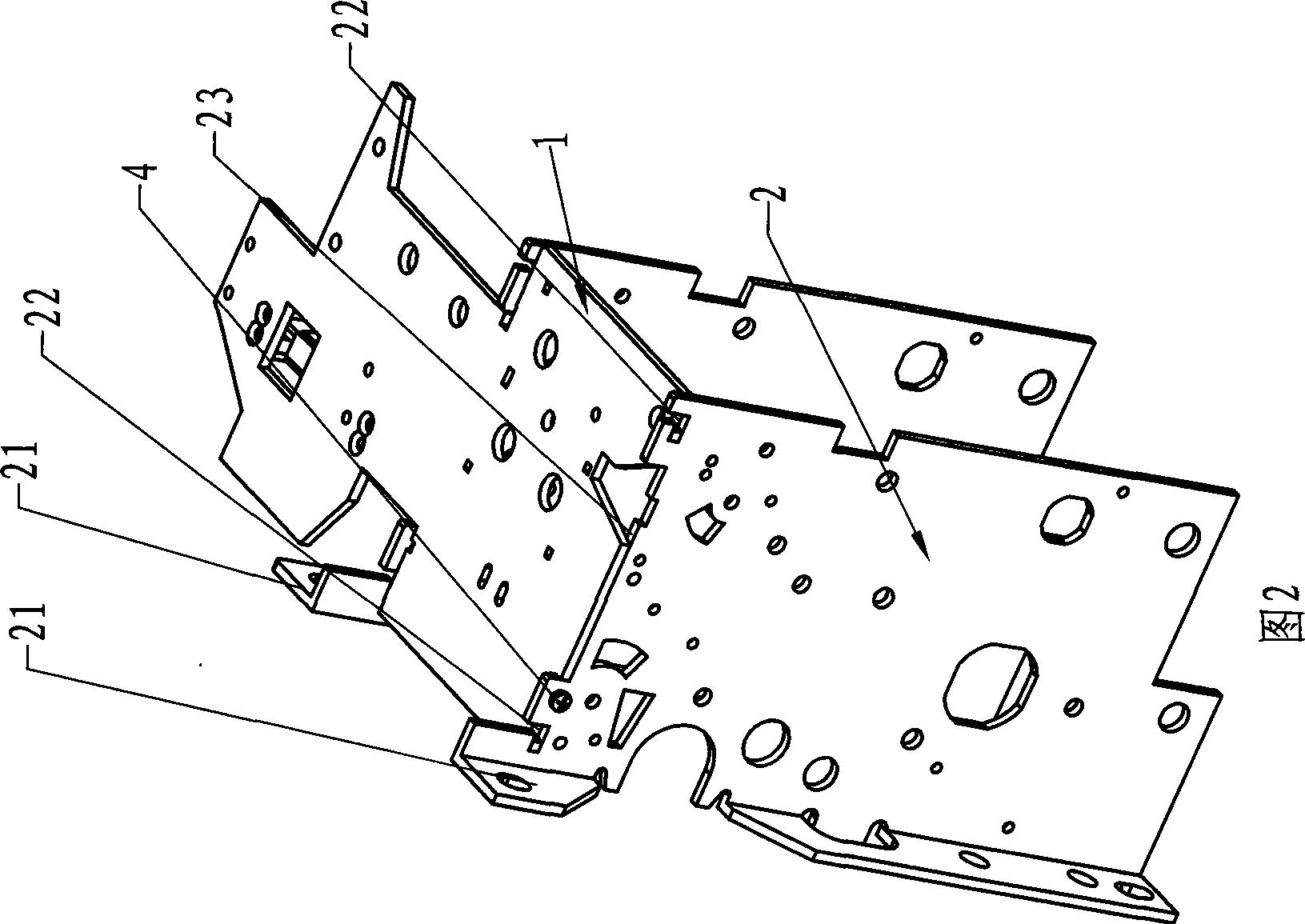

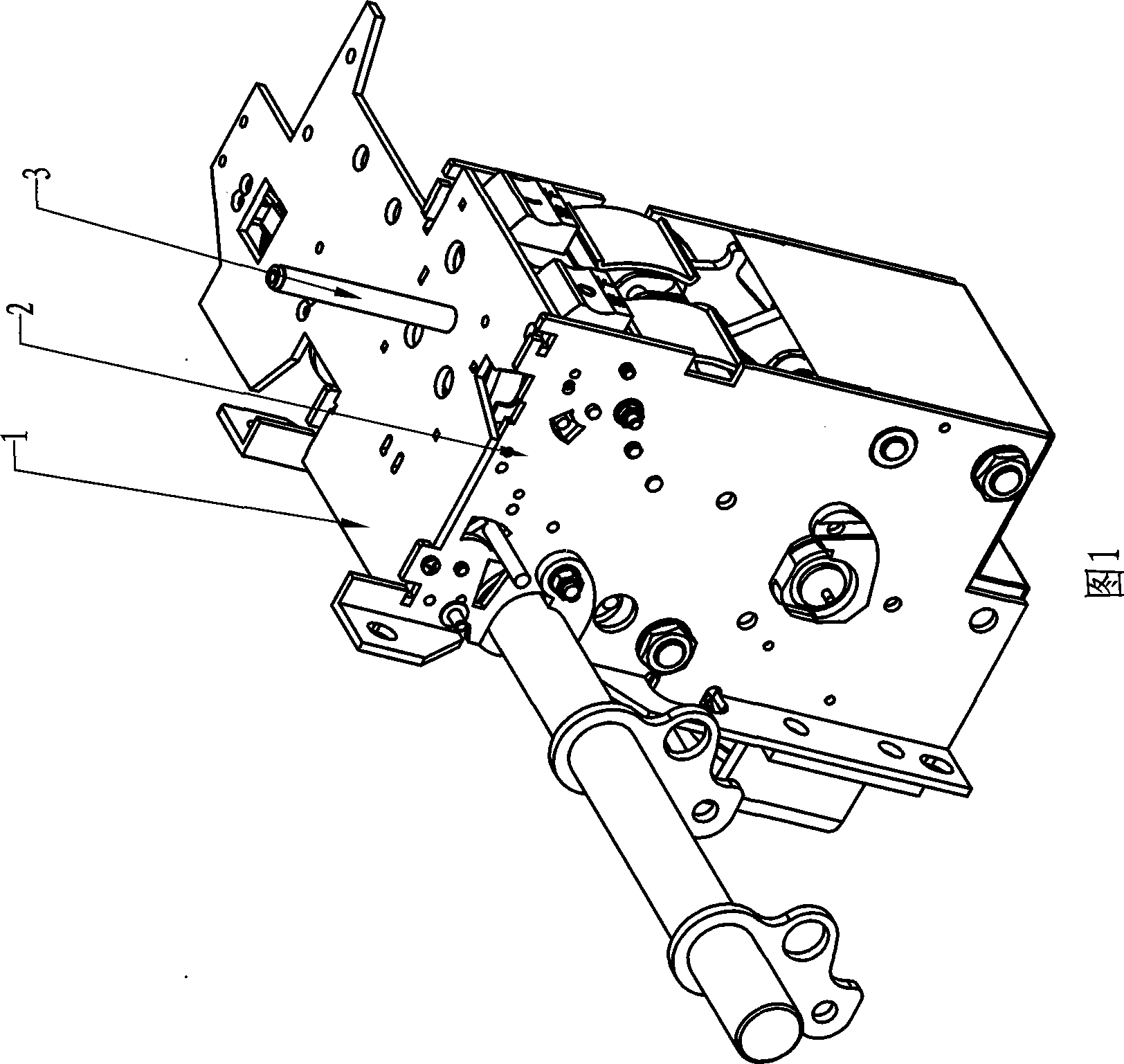

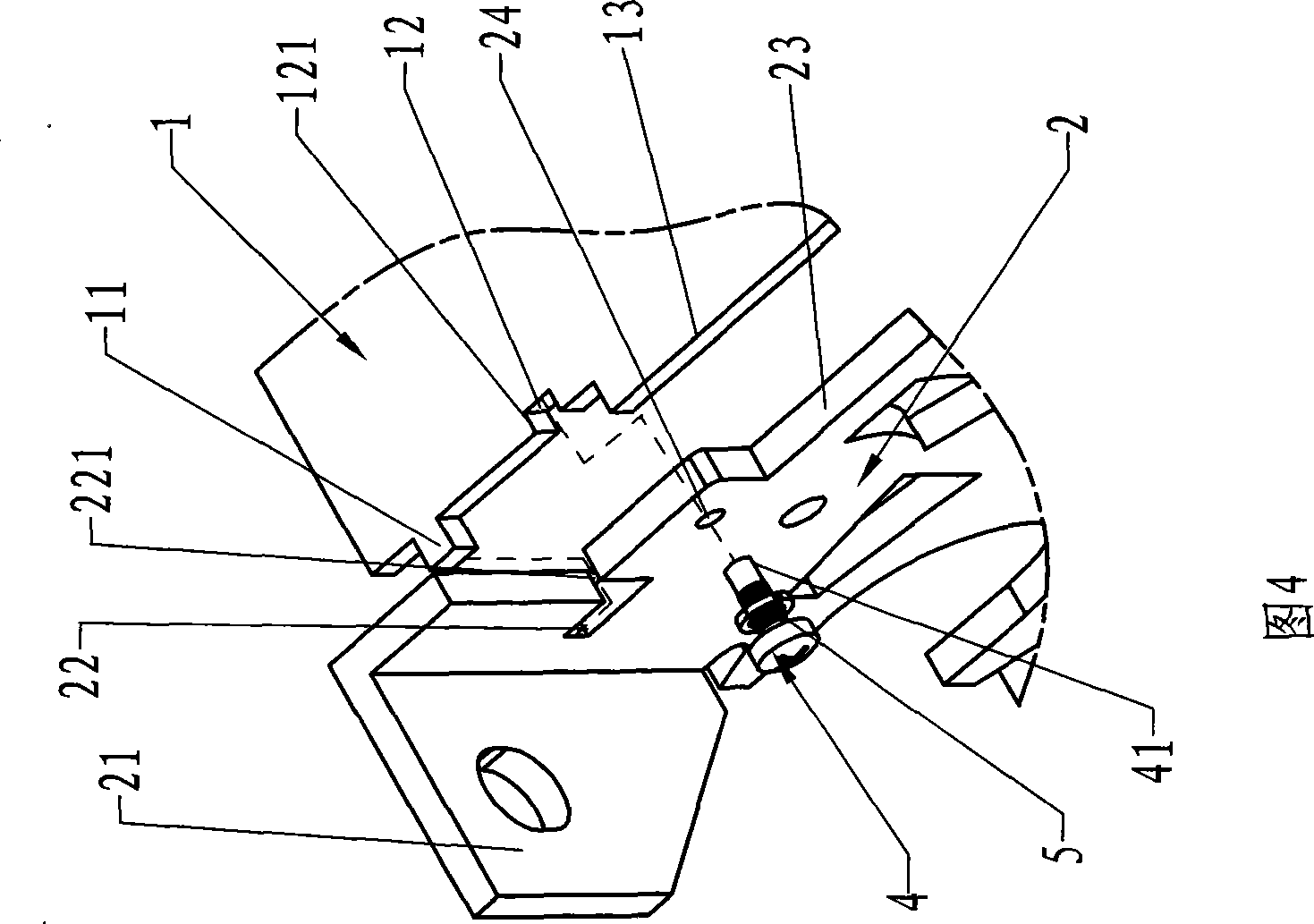

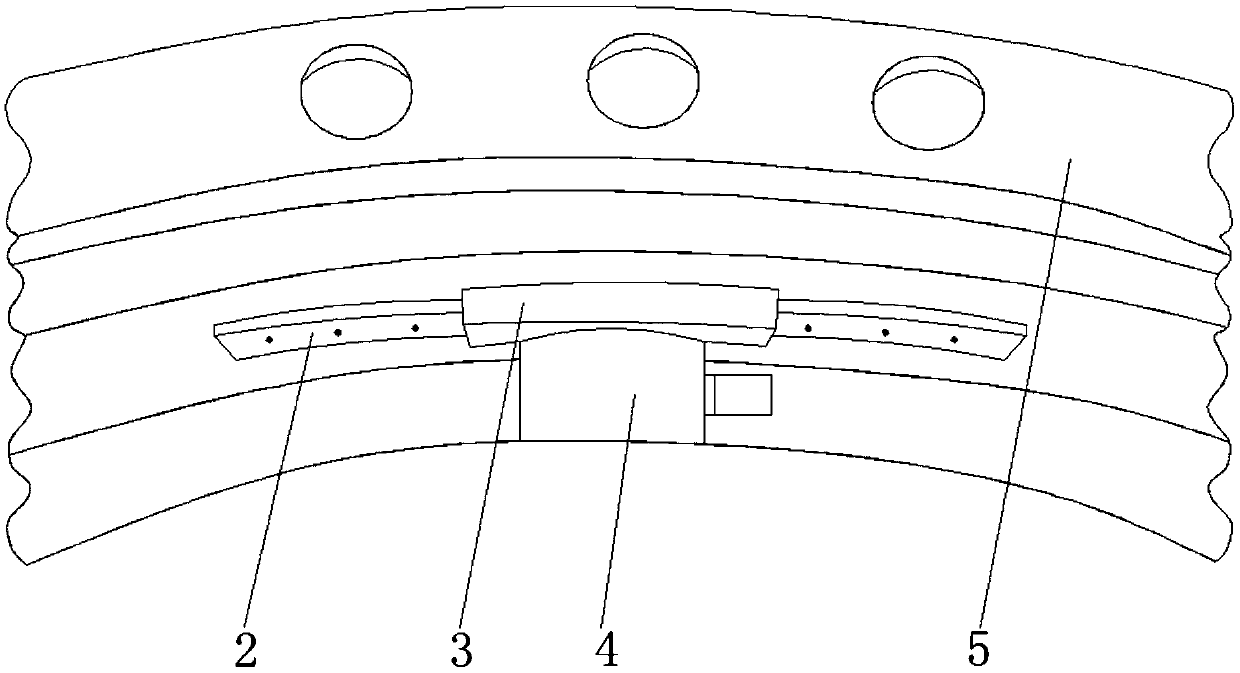

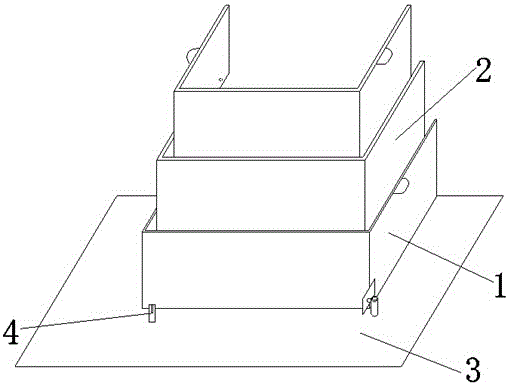

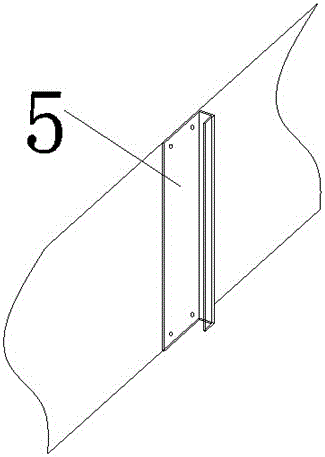

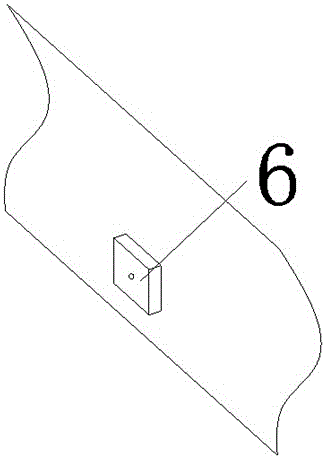

Engine suspension rigidity testing tool

ActiveCN104142235AReliable installationAvoid resonanceMachine part testingAutomotive engineeringEngineering

The invention provides an engine suspension rigidity testing tool. The engine suspension rigidity testing tool comprises an installing panel, an angle adjusting supporting device and an installing base. The angle adjusting supporting device is fixedly installed on the installing base, the installing panel is fixedly installed at the upper end of the angle adjusting supporting device, and the angle between the installing panel and the horizontal plane can be adjusted through the angle adjusting supporting device. Installing holes suitable for installing a suspension with different fixing modes are distributed in the installing panel. The angle adjusting supporting device is adopted, an angle adjusting mechanism and a locking structure are used in cooperation, the inclined angle of the main installing plane can be adjusted at will, any inclined angle can be accurately controlled, and the engine suspension rigidity testing tool is universal for carrying out the rigidity test on the suspension at any inclined angle. The main installing plane is provided with the installing holes suitable for installing the suspension with the different modes, and the engine suspension rigidity testing tool is universal for carrying out the rigidity test on the suspension at any inclined angle. According to the engine suspension rigidity testing tool, tool manufacturing cost can be effectively reduced, and working efficiency and testing accuracy are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

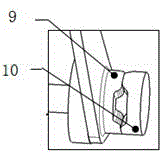

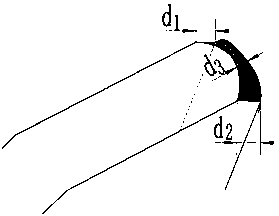

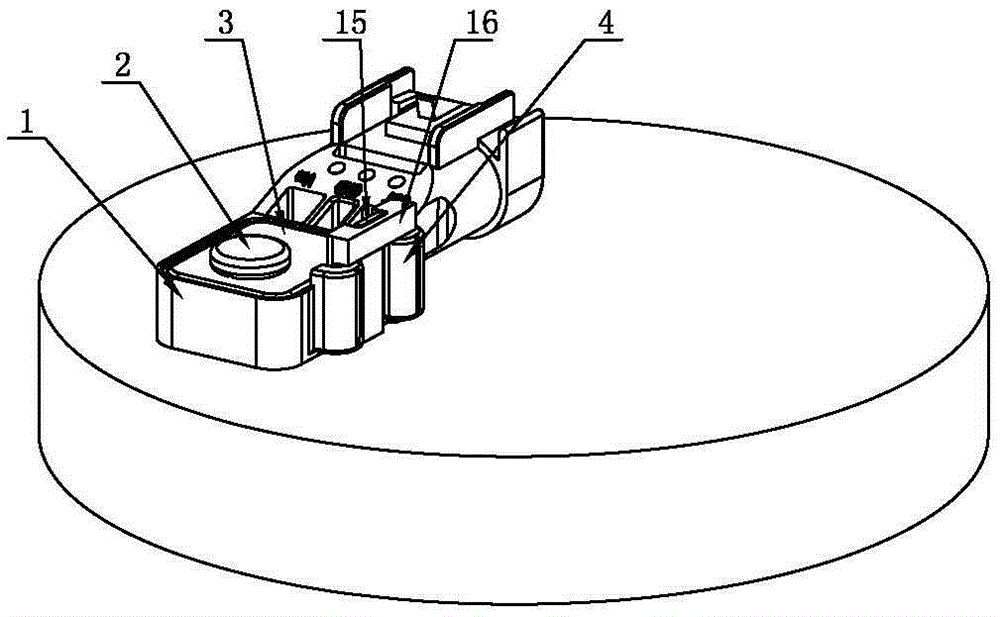

System and method for detection of band saw blade sawtooth wear loss

ActiveCN109269425AImprove Wear Test EfficiencyHigh degree of automationUsing optical meansElectricityVisual inspection

The invention relates to a system and method for detection of band saw blade sawtooth wear loss. The system comprises: a visual inspection module for detecting the band saw blade sawtooth tip wear width, an X-direction tooth feeding device for driving a to-be-detected band saw blade to move along the X-axis direction, a Y-direction limit device for limiting the position of the to-be-detected bandsaw blade in the Y-axis direction, a Z-direction limit device for limiting the position of the to-be-detected band saw blade in the Z-axis direction, and an upper computer in electric connection or communication connection with the visual inspection module. The system and method provided by the invention have a high degree of automation, and realize high efficiency and on-line detection of the band saw blade sawtooth tip wear loss. The whole process adopts machine detection, personal error is avoided, and the reliability is high. In addition, the system and method can guarantee consistent measurement conditions of all sawteeth, have statistical significance, and are convenient for assessment of the band saw blade wear condition from the perspective of big data.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

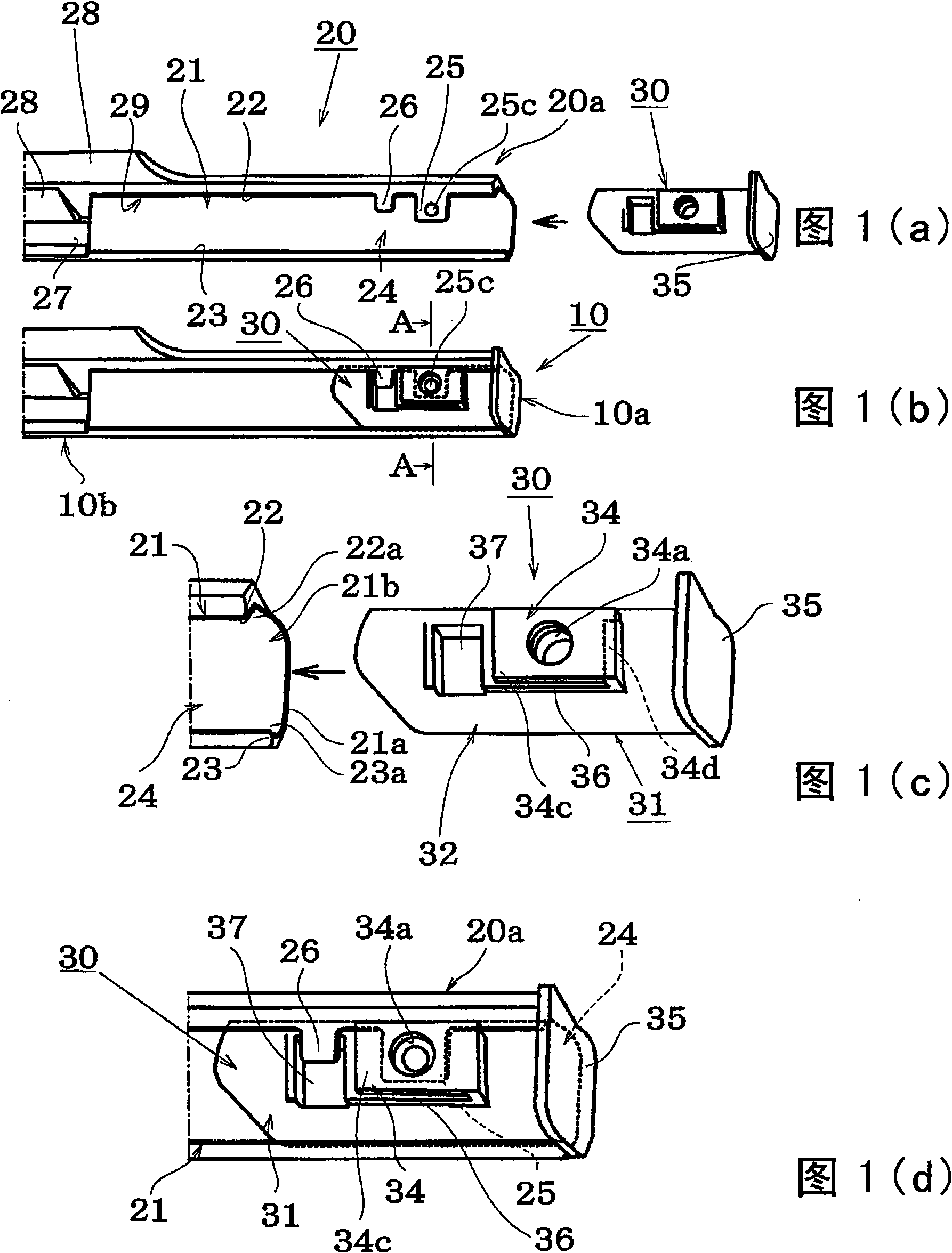

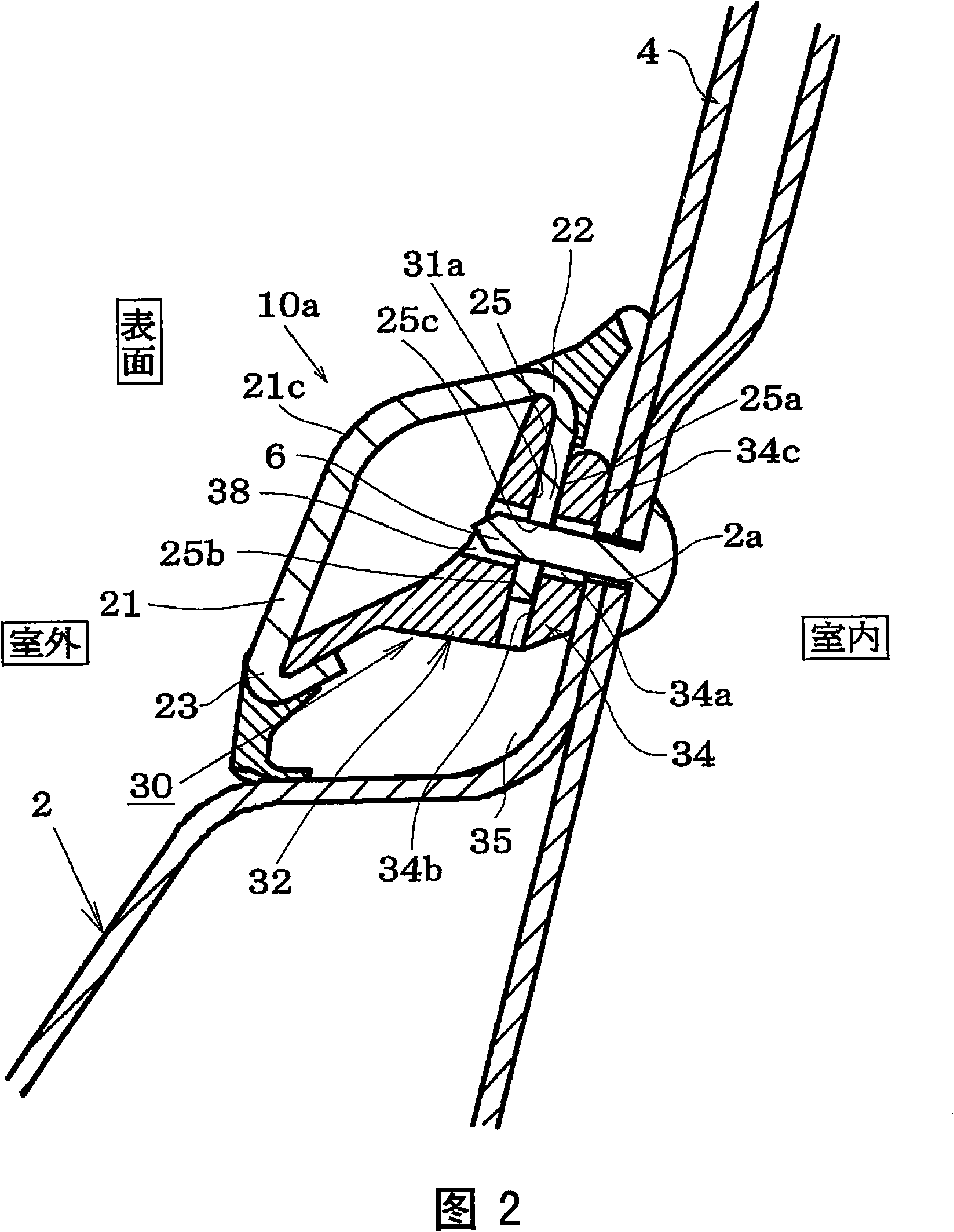

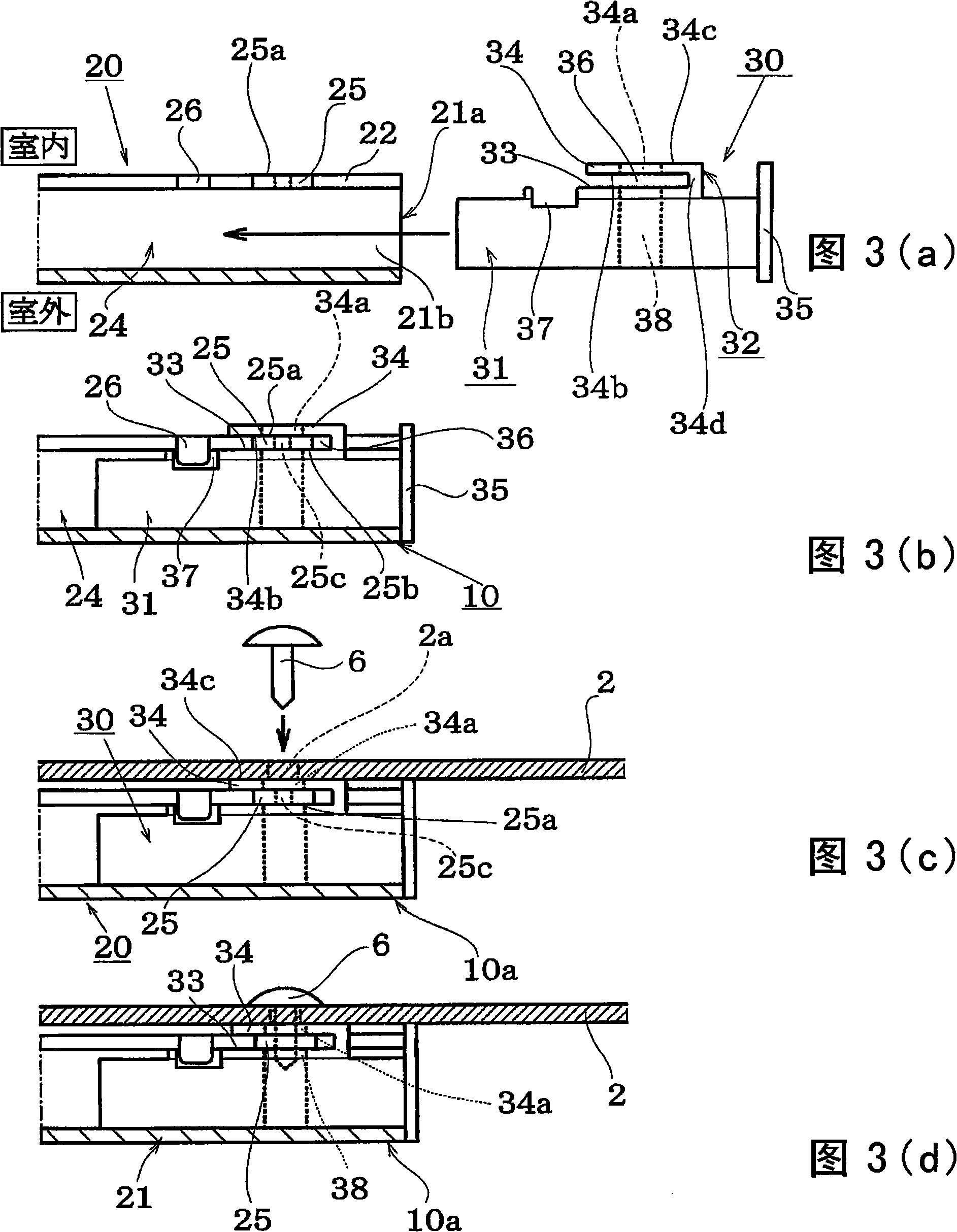

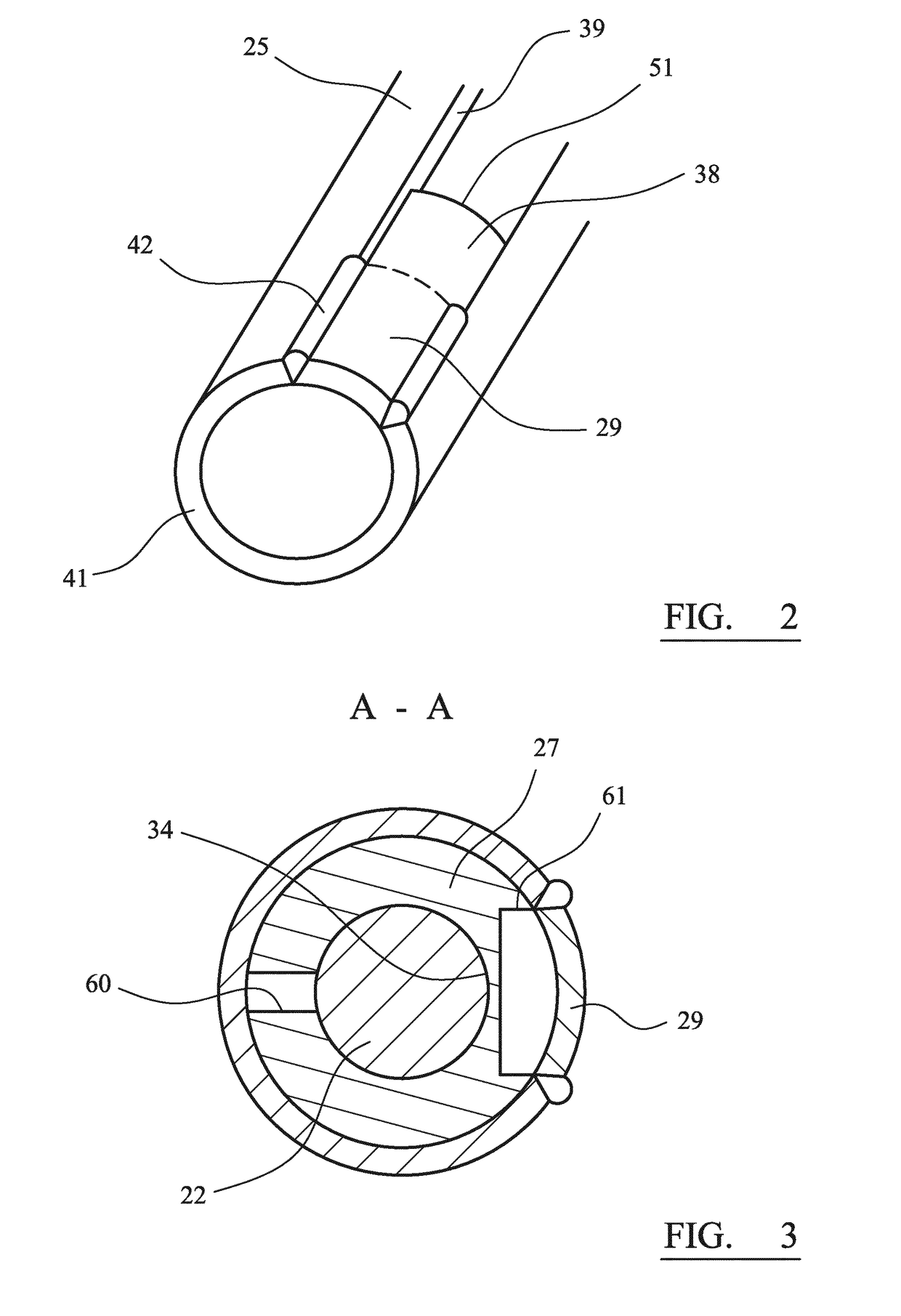

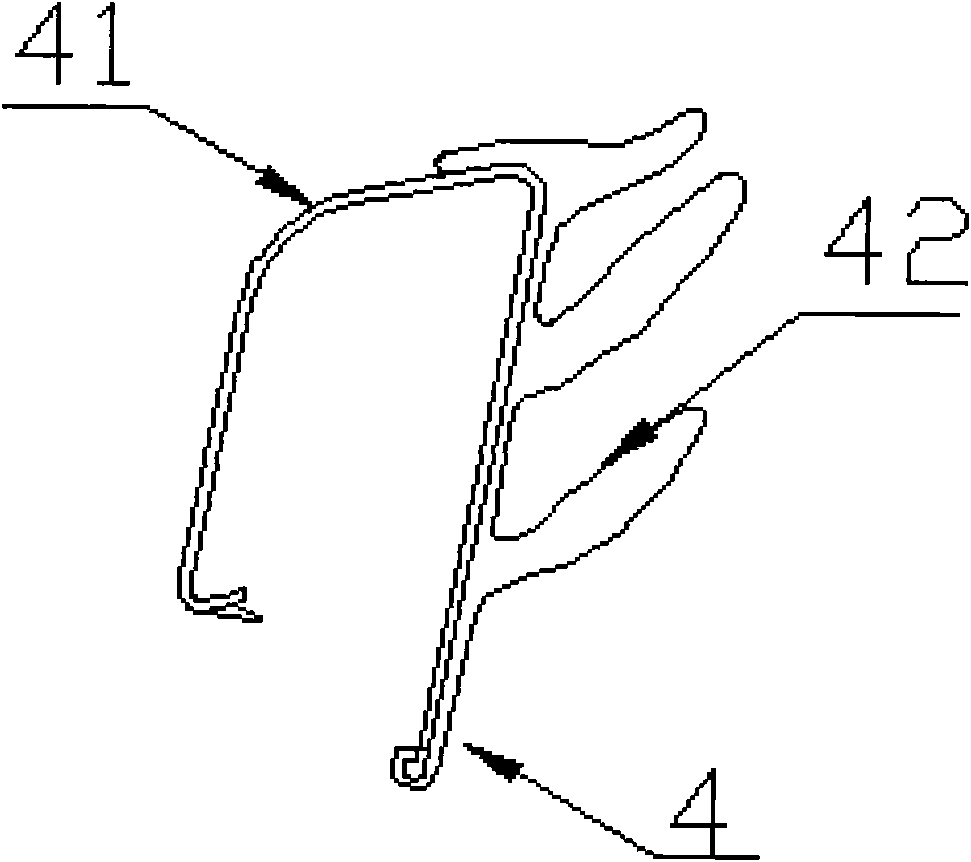

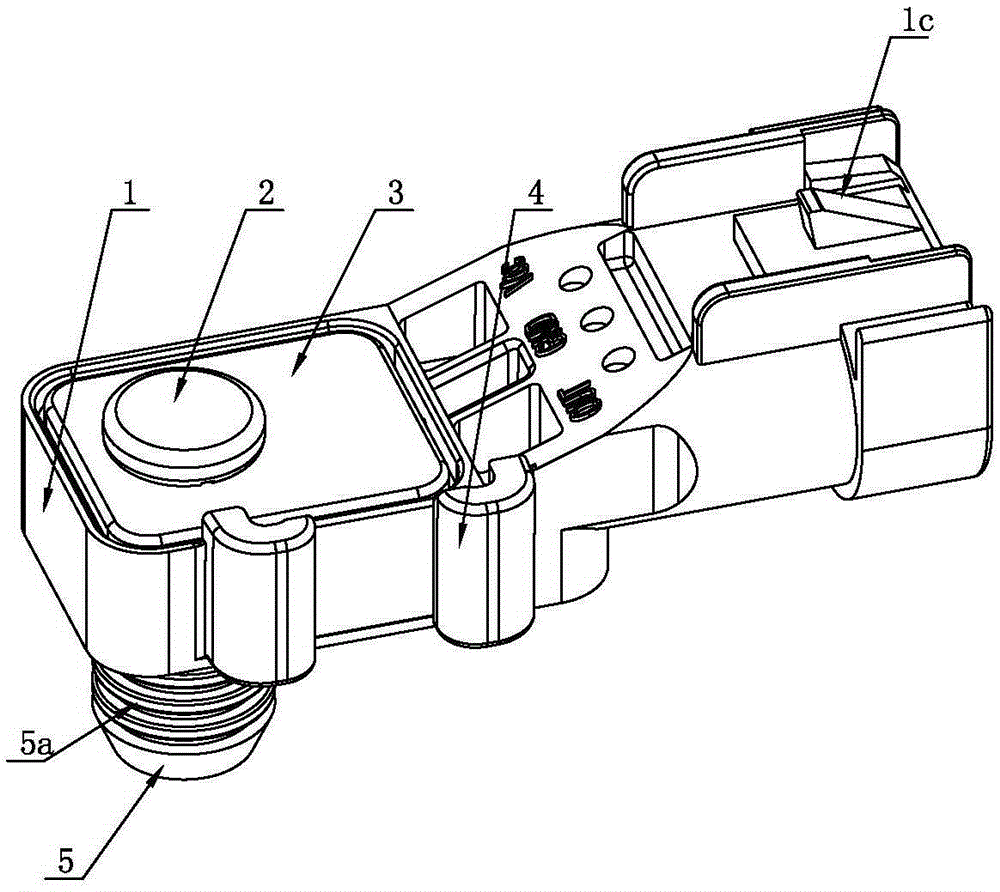

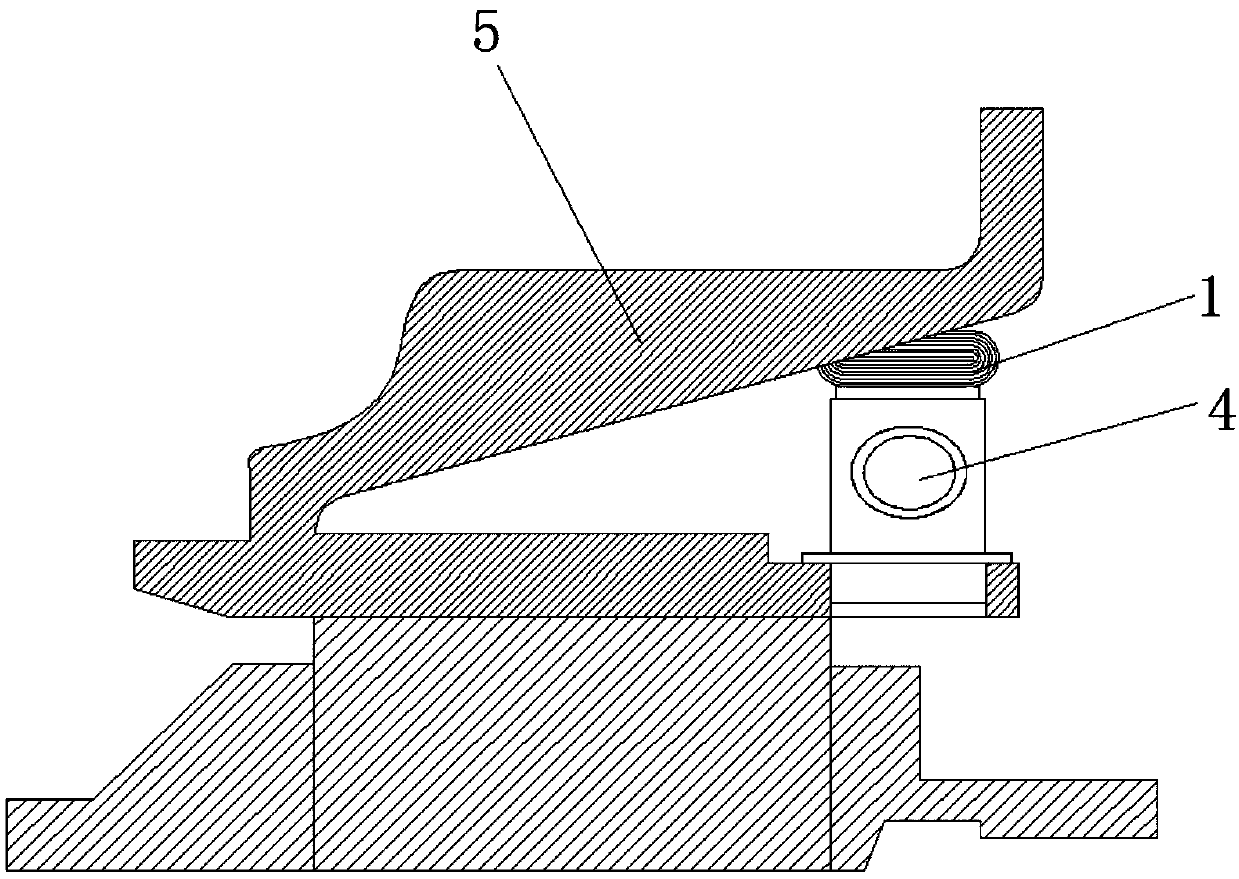

Insertion strip for cars and mounting structure thereof

InactiveCN101314346AReliable installationSimplify manufacturing stepsVehicle componentsEngineeringHelix

The objective of the invention lies in providing a vehicle fillet and a mounting structure thereof, which can lead to excellent mountability and low-cost production of a fillet end. A mounting structure of the vehicle fillet mounts the end of the fillet body to a door plate, and is characterized in that the fillet body comprises a core component made of metal and a wind stop which is in composite molding from the core component towards door glass side, a buckling sheet is provided at inner side of the core component, an end cover comprising an insertion inserting into the end of the fillet body is adopted; In the case of a cover section sealing the end of the fillet body, the insertion comprises a base between a core material and the buckling sheet while the end cover is inserted into the end of the fillet body; a touch section, which is revolved to enter into a gap between the buckling sheet and the door plate, inserts the end cover into the end of the fillet body, screws the buckling component helically from the inner side of door plate room, and fastens the buckling sheet and the door plate for connection.

Owner:KATAYAMA KOGYO CO LTD

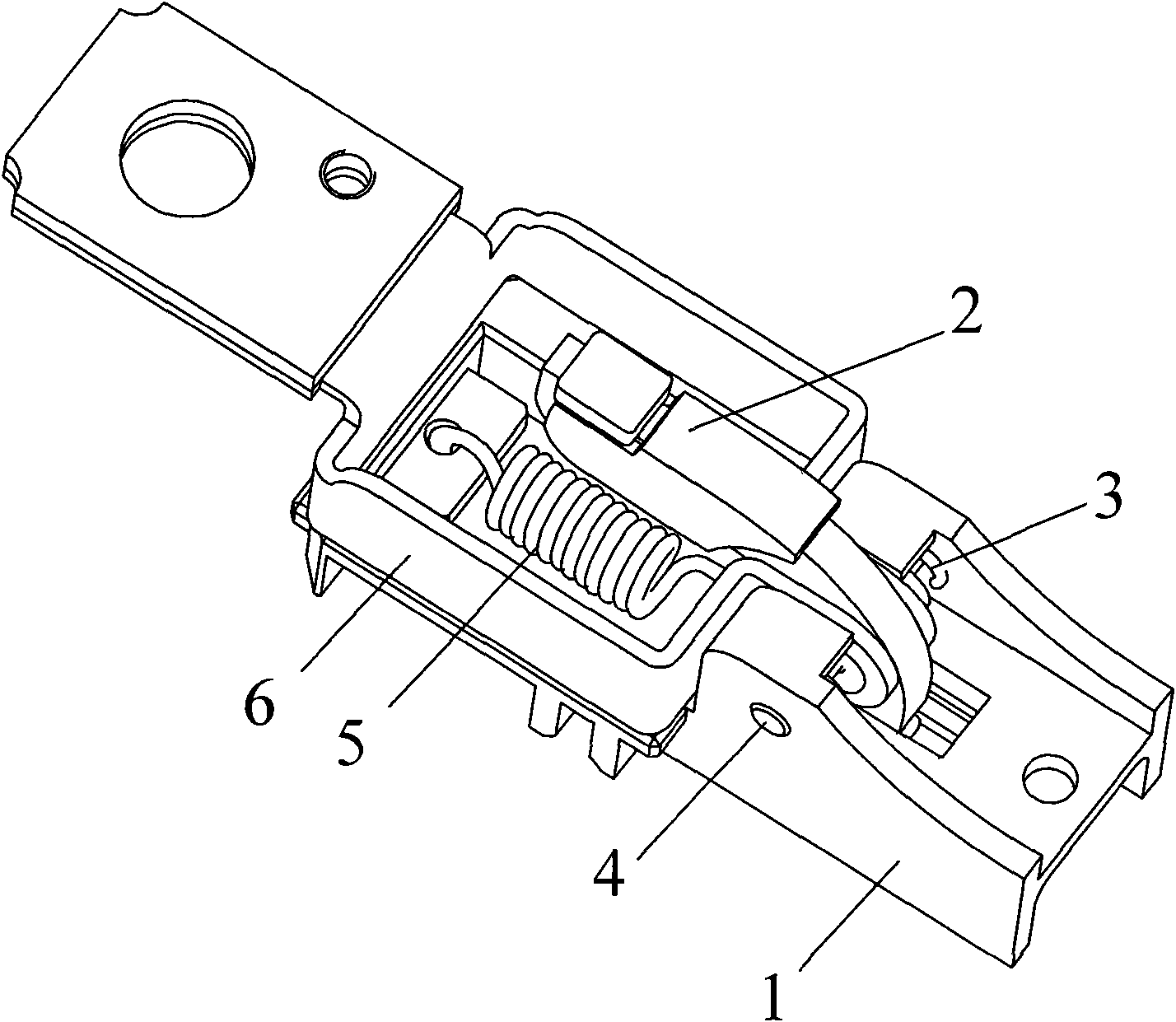

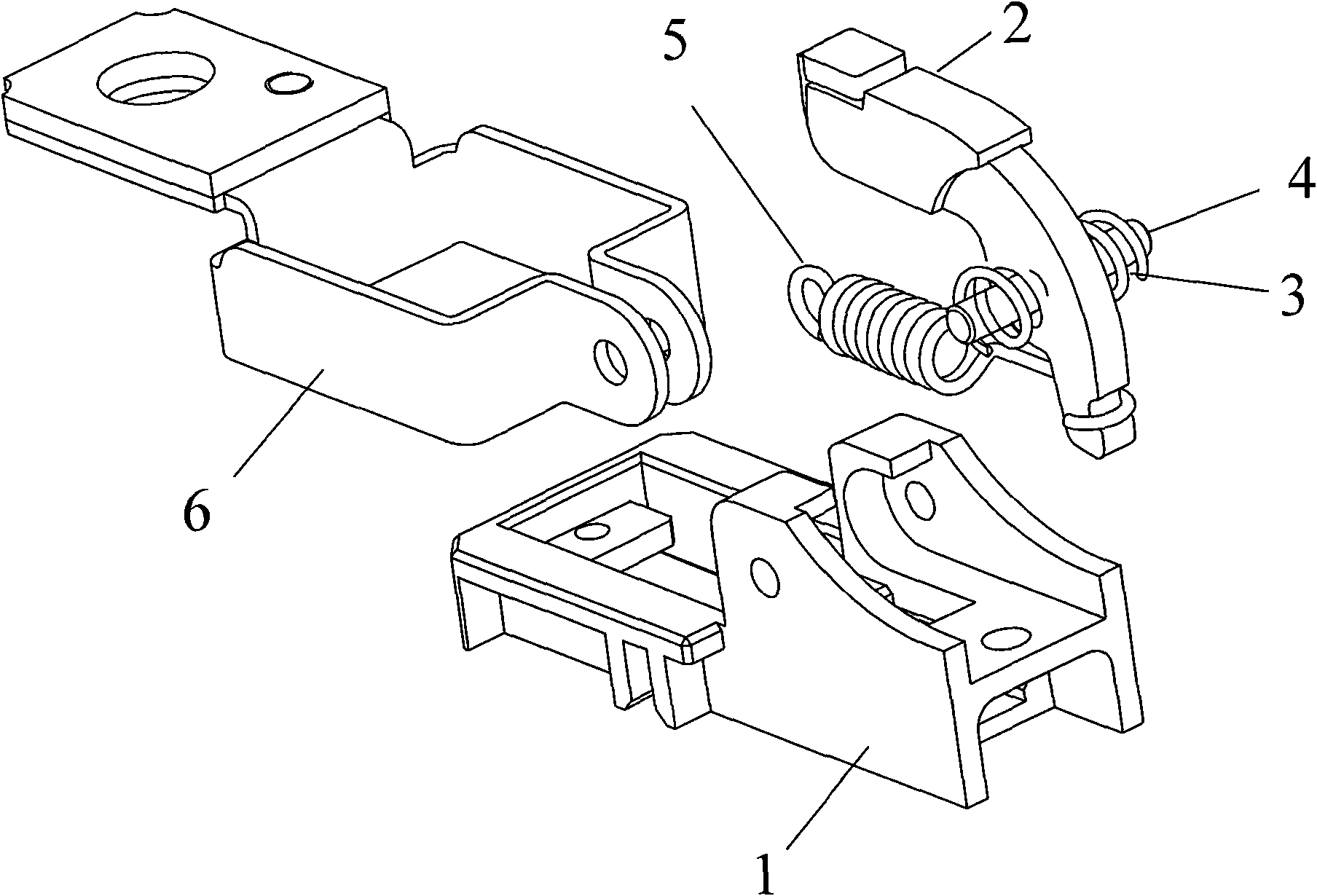

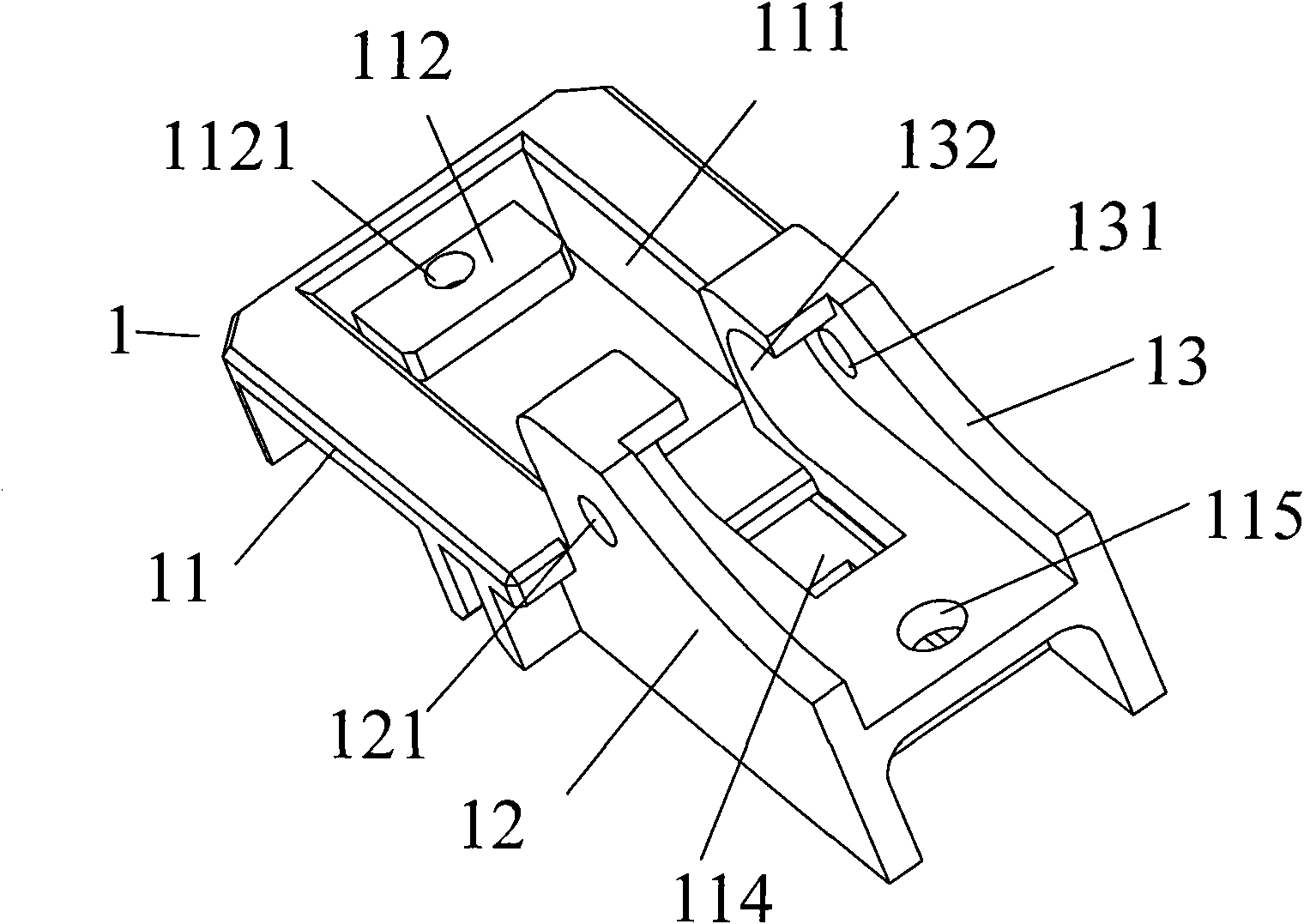

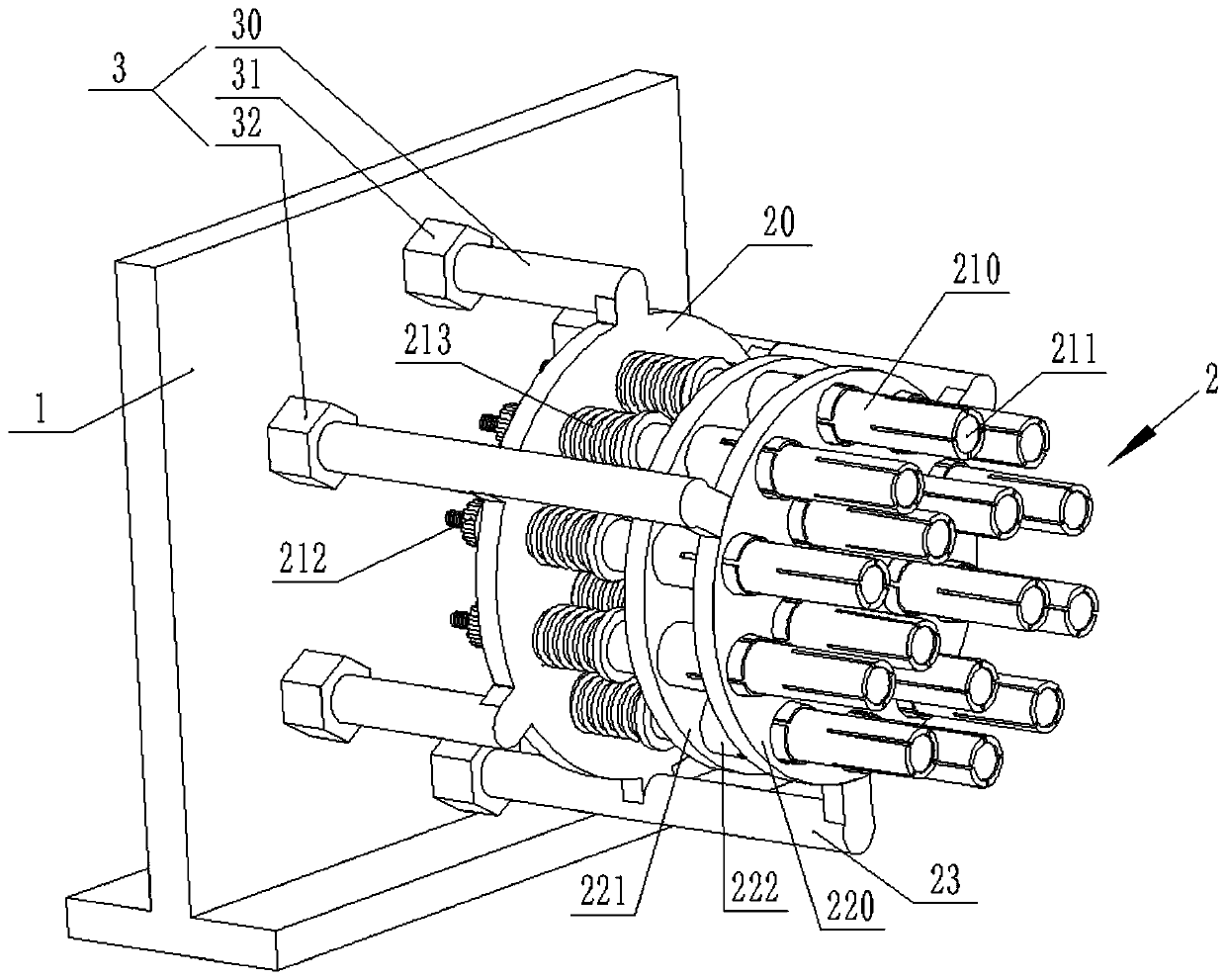

Repulsive clamping static contact structure of low-voltage circuit breaker

ActiveCN101783269AModular structureEasy to assembleCircuit-breaking switch contactsLow voltage circuitsElectrical connection

The invention discloses a repulsive clamping static contact structure of low-voltage circuit breaker. The two ends of a locating shaft are fixed on a support, the middle of the locating shaft penetrates a static contact and pressure springs which are respectively arranged at the two sides of the static contact, the pressure spring is enveloped in the support and causes a connector row to compact the static contact, the free end of the static contact is arranged in a through slot on the bottom wall of the support, a tension spring is arranged in a first through slot of the support and corner approach thereof is fixed on a first boss in the first through slot, and the other corner approach of the tension spring penetrates the other through slot on the bottom wall of the support and is fixedly connected with the free end of the static contact. The static contact structure of the invention is modularized, clamping structure is adopted to realize electrical connection between static contact and inlet wire row, contact resistance is less, service life of static contact of circuit breaker can be prolonged, assembly is simple, and production cost is low.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

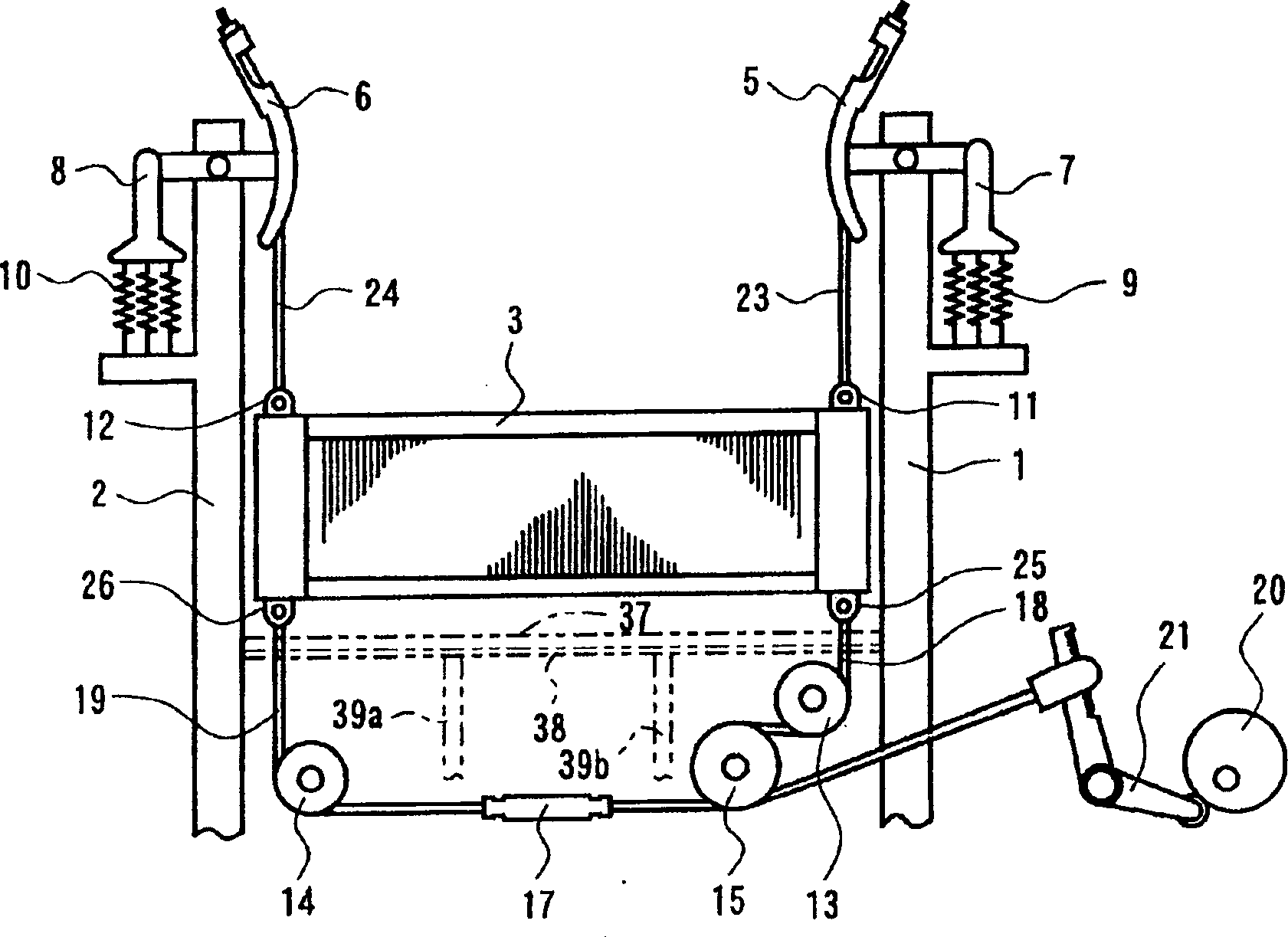

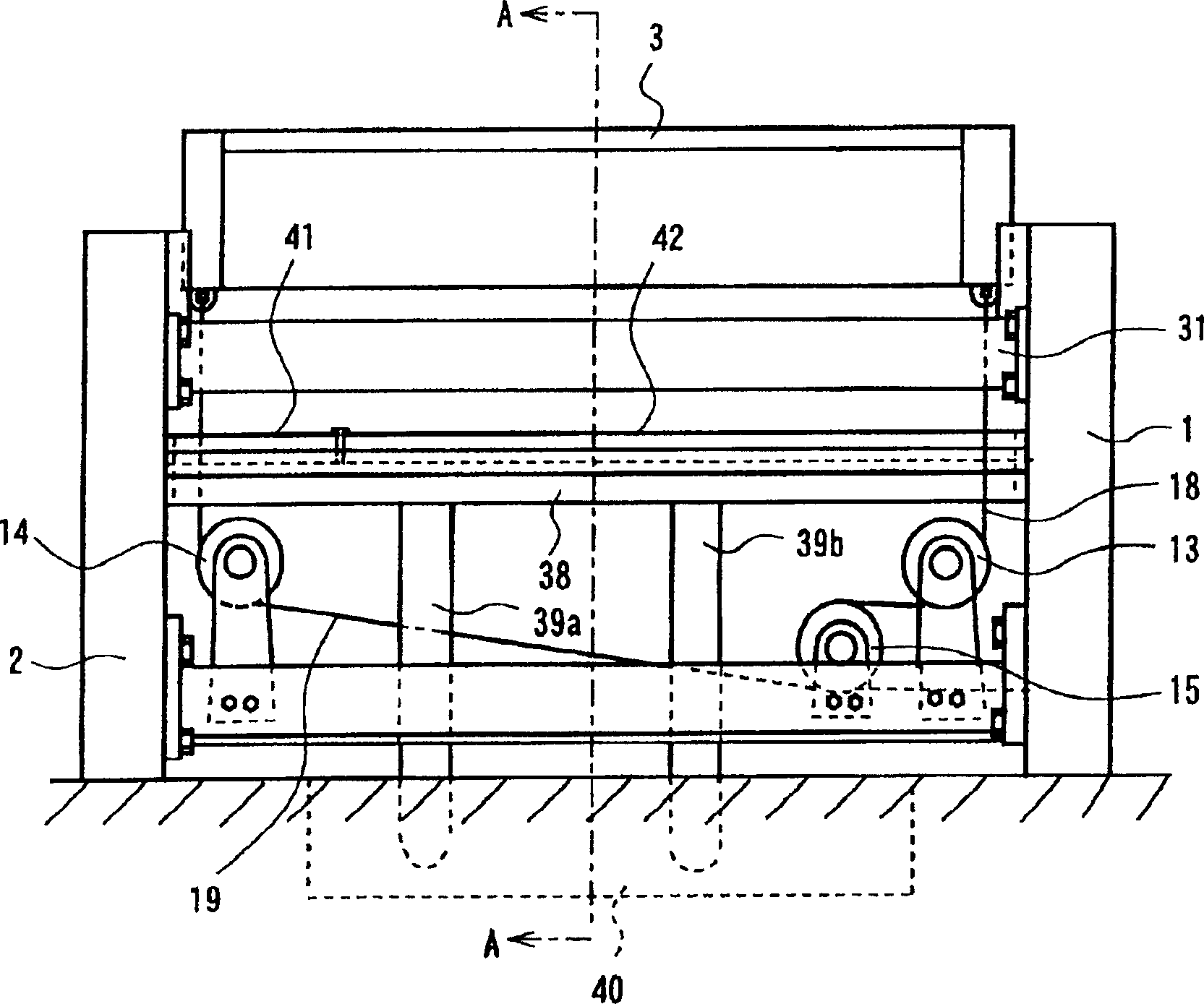

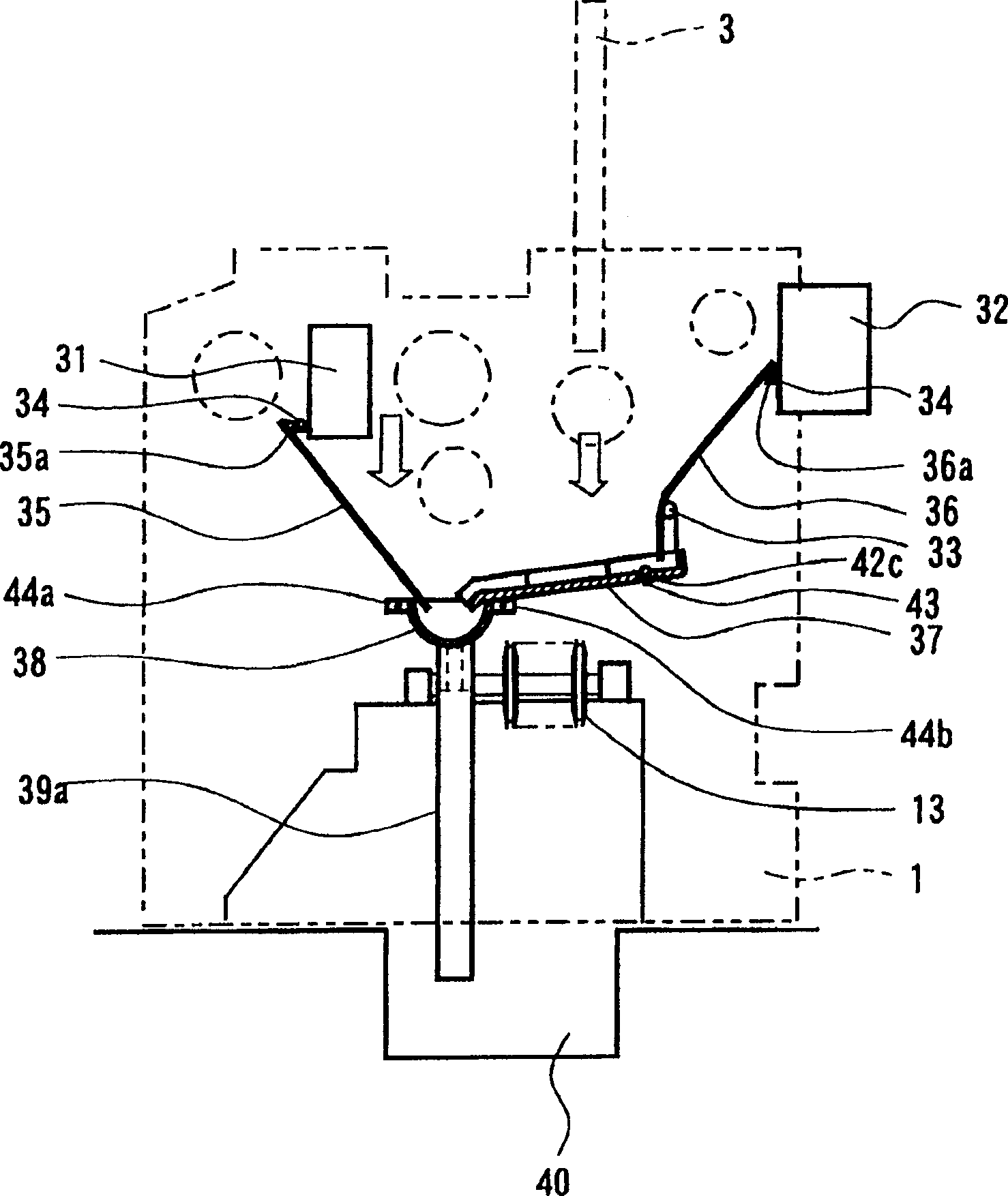

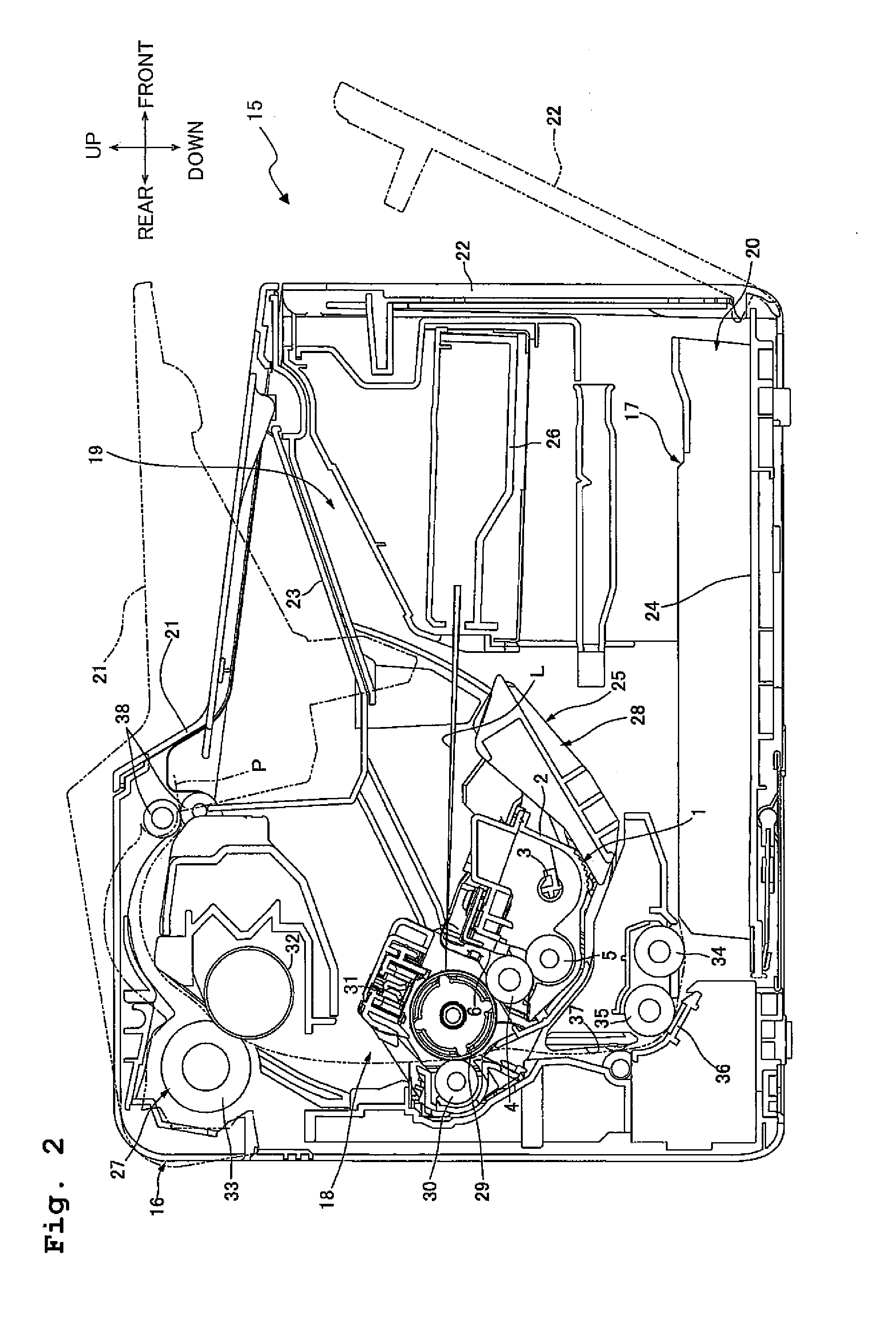

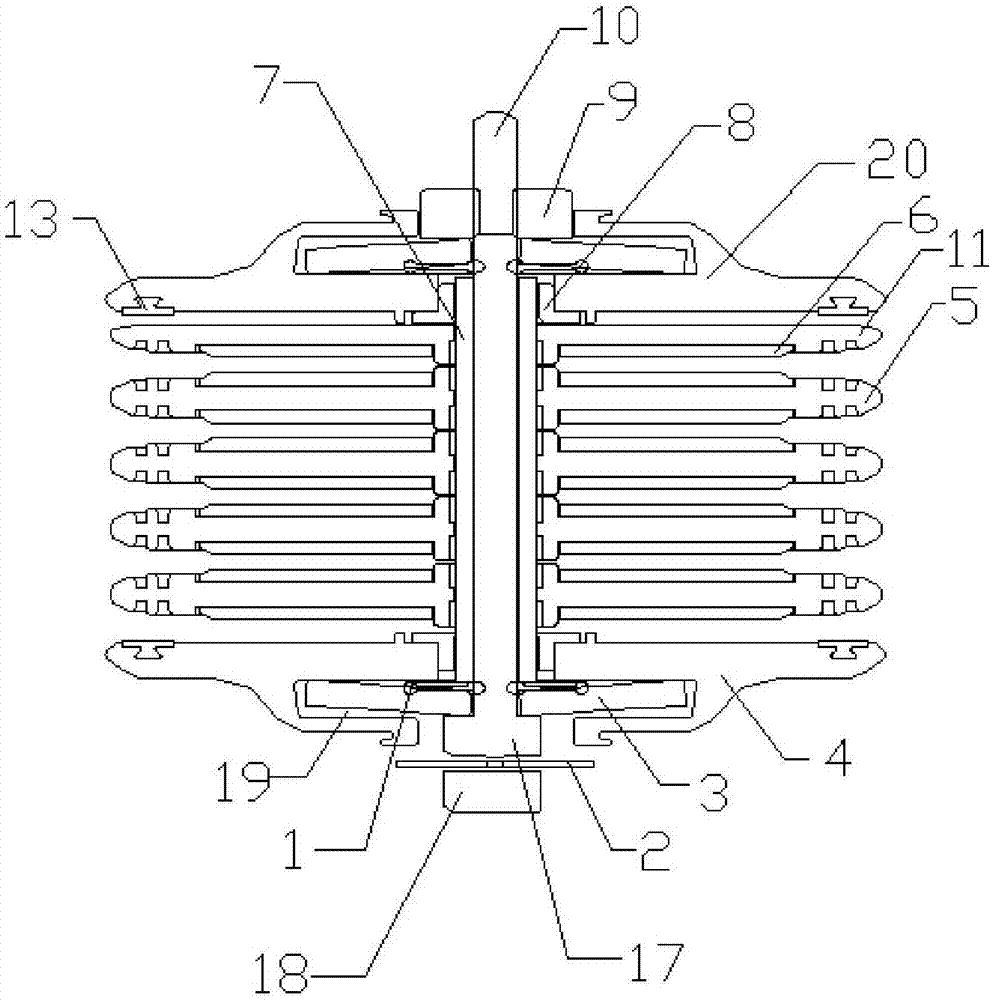

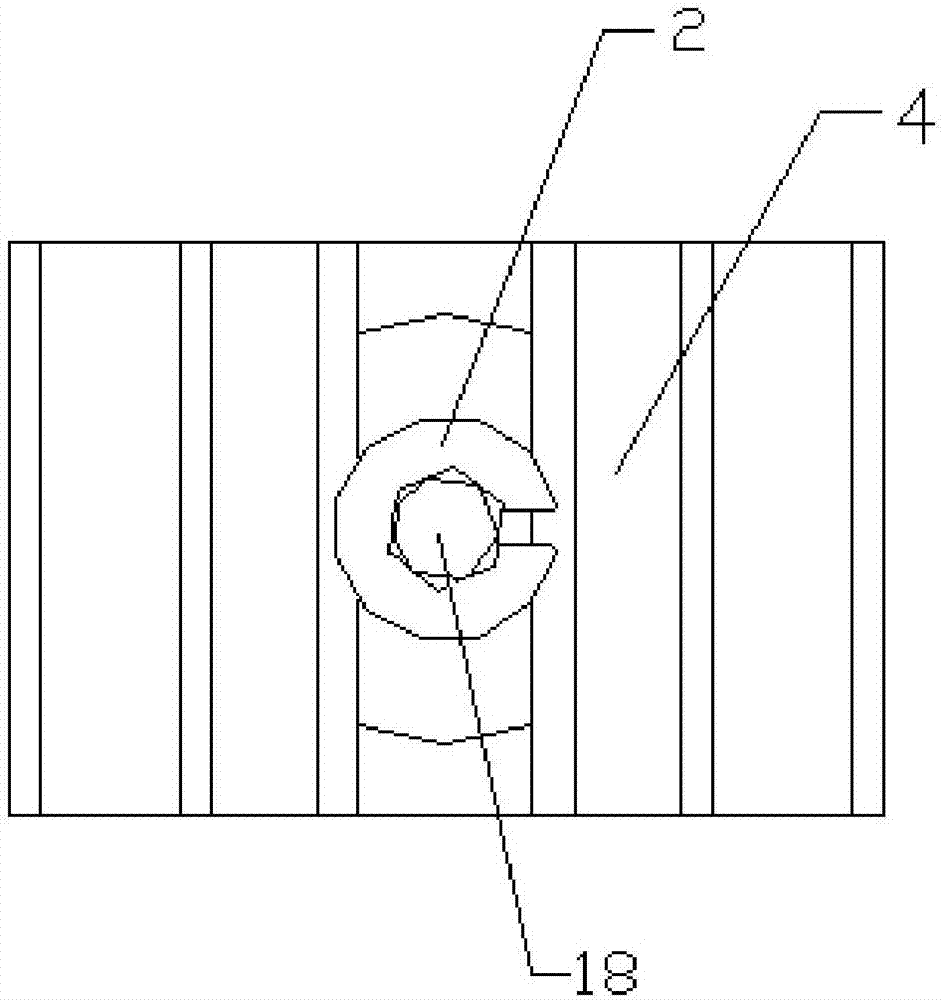

Water proof device of open driving part in water jet loom

ActiveCN1715472AEasy to installReliable installationLoomsOther shedding mechanismWater jetEngineering

The subject of the invention is designed to provide a waterproof device for the opening driving part of a water jet loom. The invention can prevent the opening driving part from getting wet or being attached by drop by a cover and by discharging water out of the water jet loom from an outlet. The cover, which is used for sheltering and guiding falling water, is arranged at the upper part of the opening driving part. The waterproof device has a driving device for a heald frame (3) that is positioned on the ground and the opening device of the water het loom that is connected with a steel cable on the heald frame (3) and a guide roll is positioned below the heald frame (3). The invention is characterized in that a lagging (35) is installed in front of the heald frame (3), a driving shaft baffle (36) is installed behind the heald frame and a groove is installed below the heald frame (3) and the lower ends of the lagging (35) and the driving shaft baffle (36) are designed to come down to the groove. And a flexible pipe (39) is arranged to discharge the water in the groove out of the groove from the outlet of the groove.

Owner:TOYOTA IND CORP

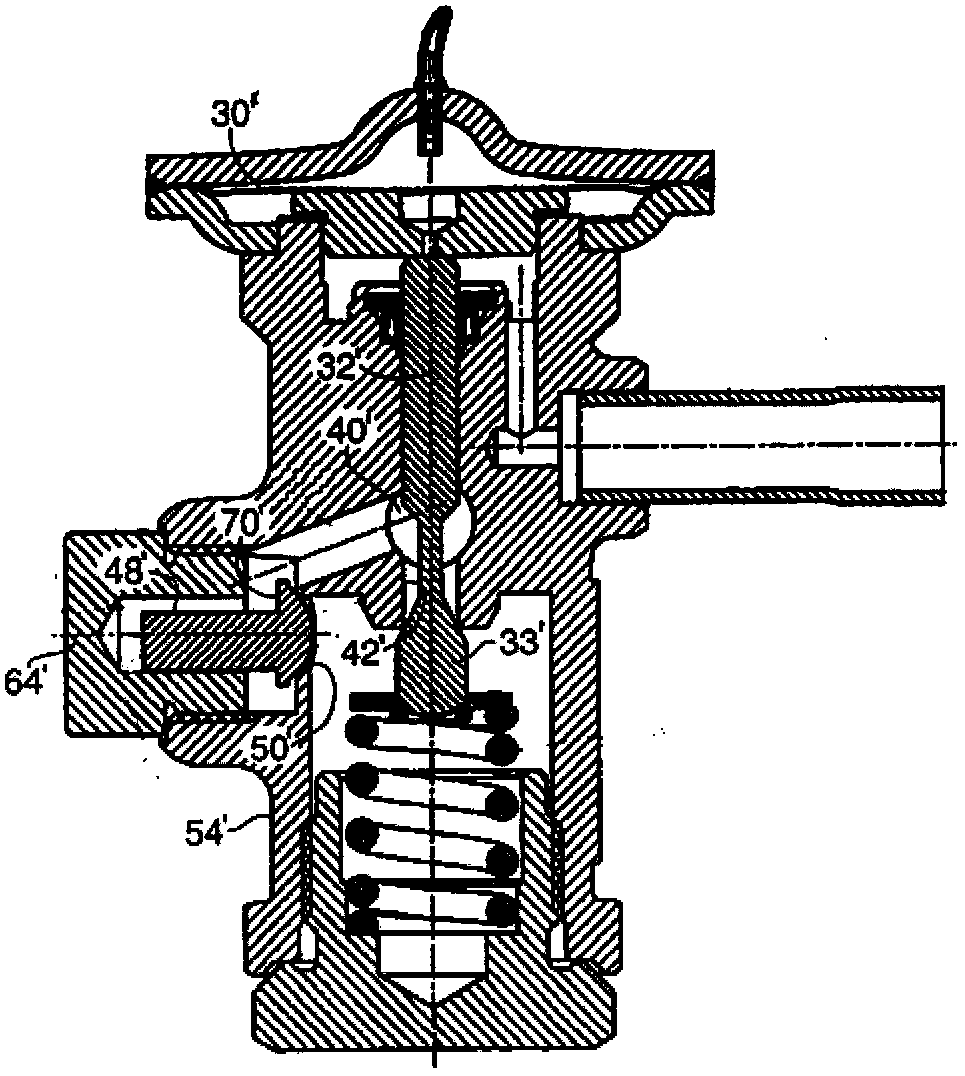

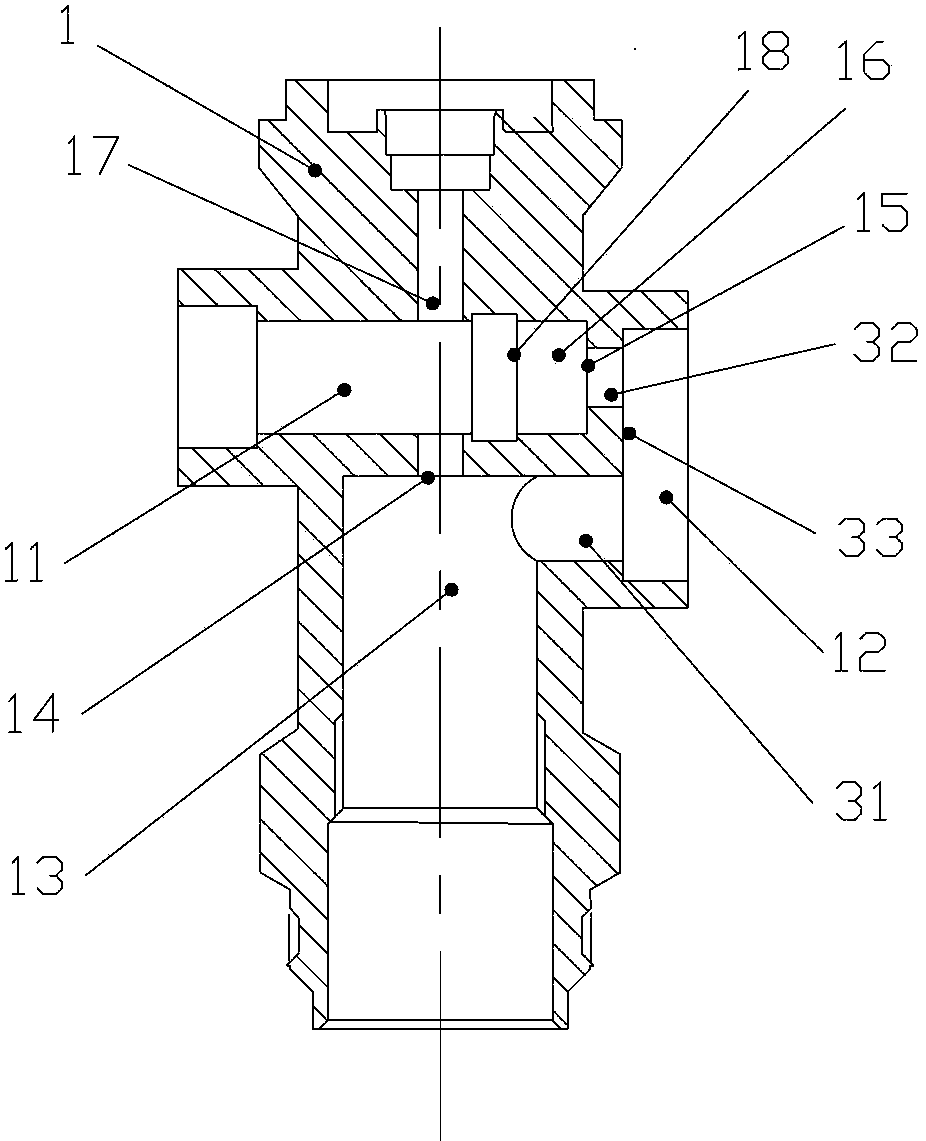

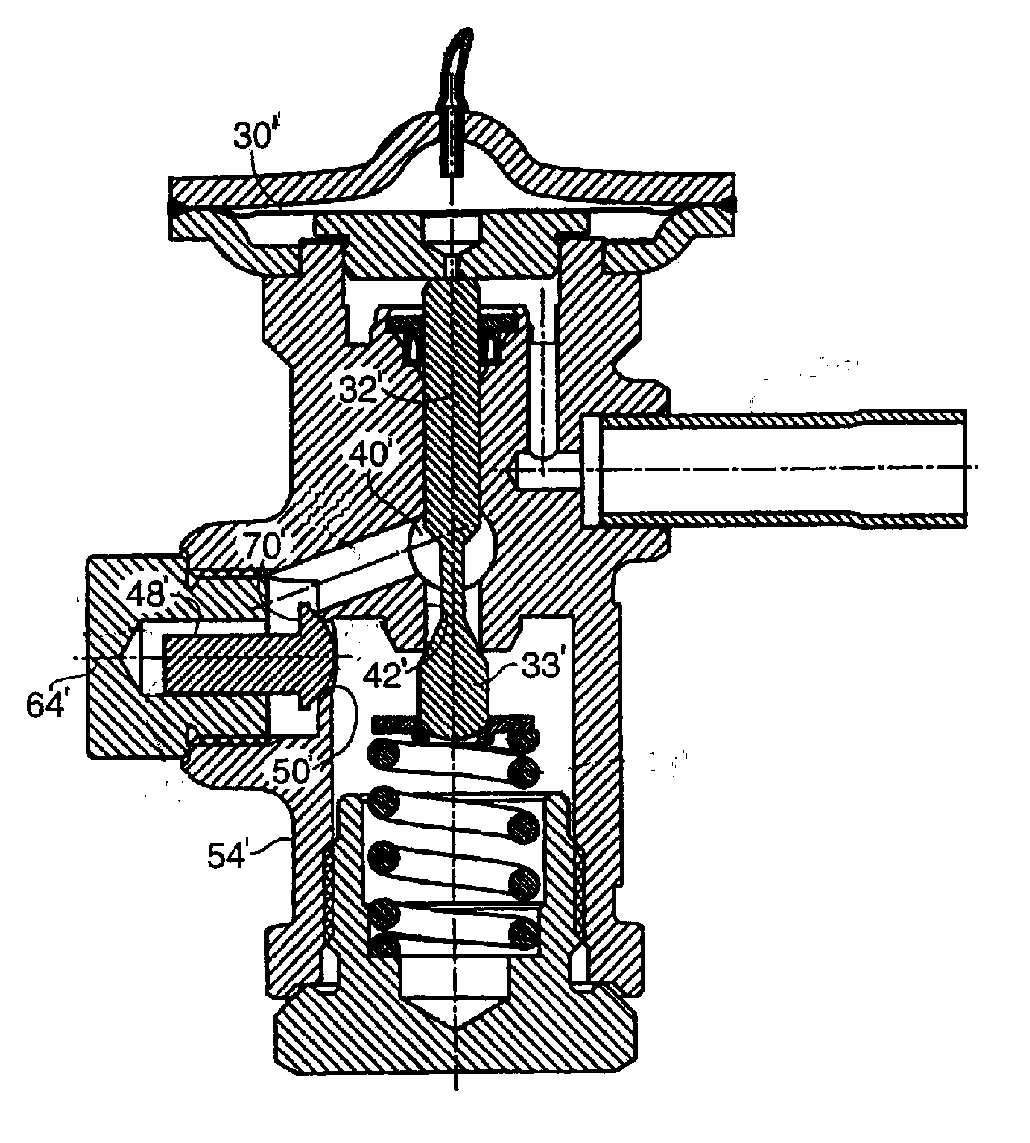

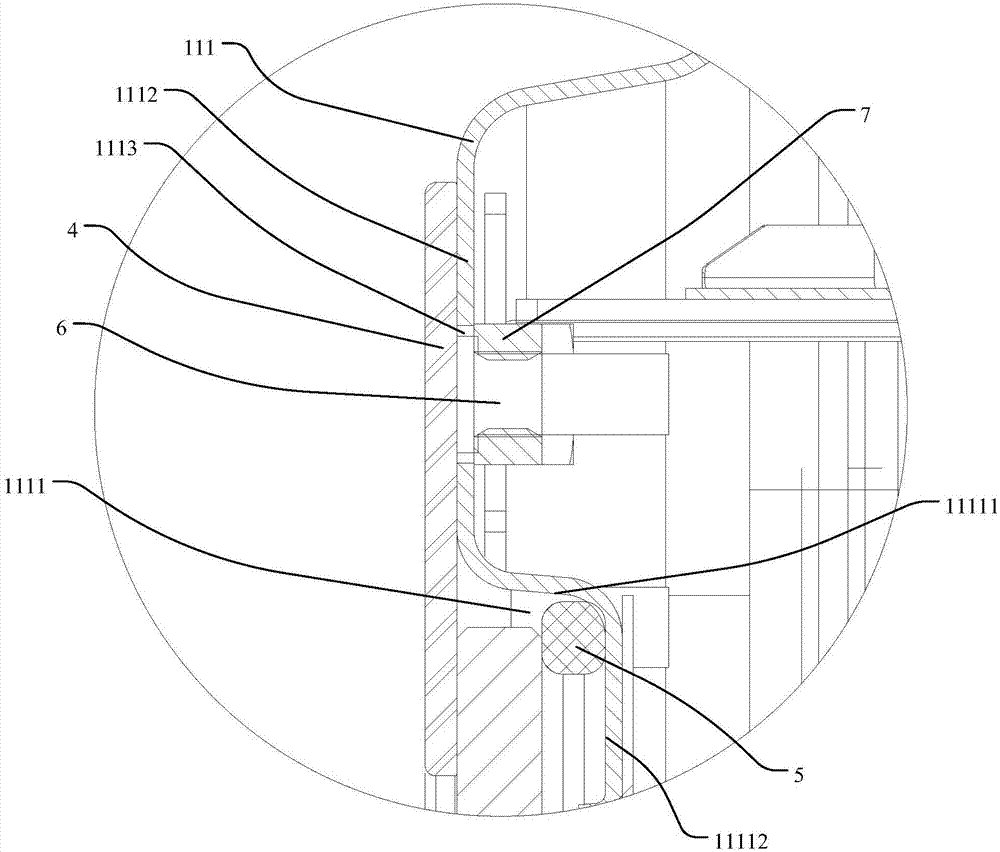

Thermostatic expansion valve with one-way control function

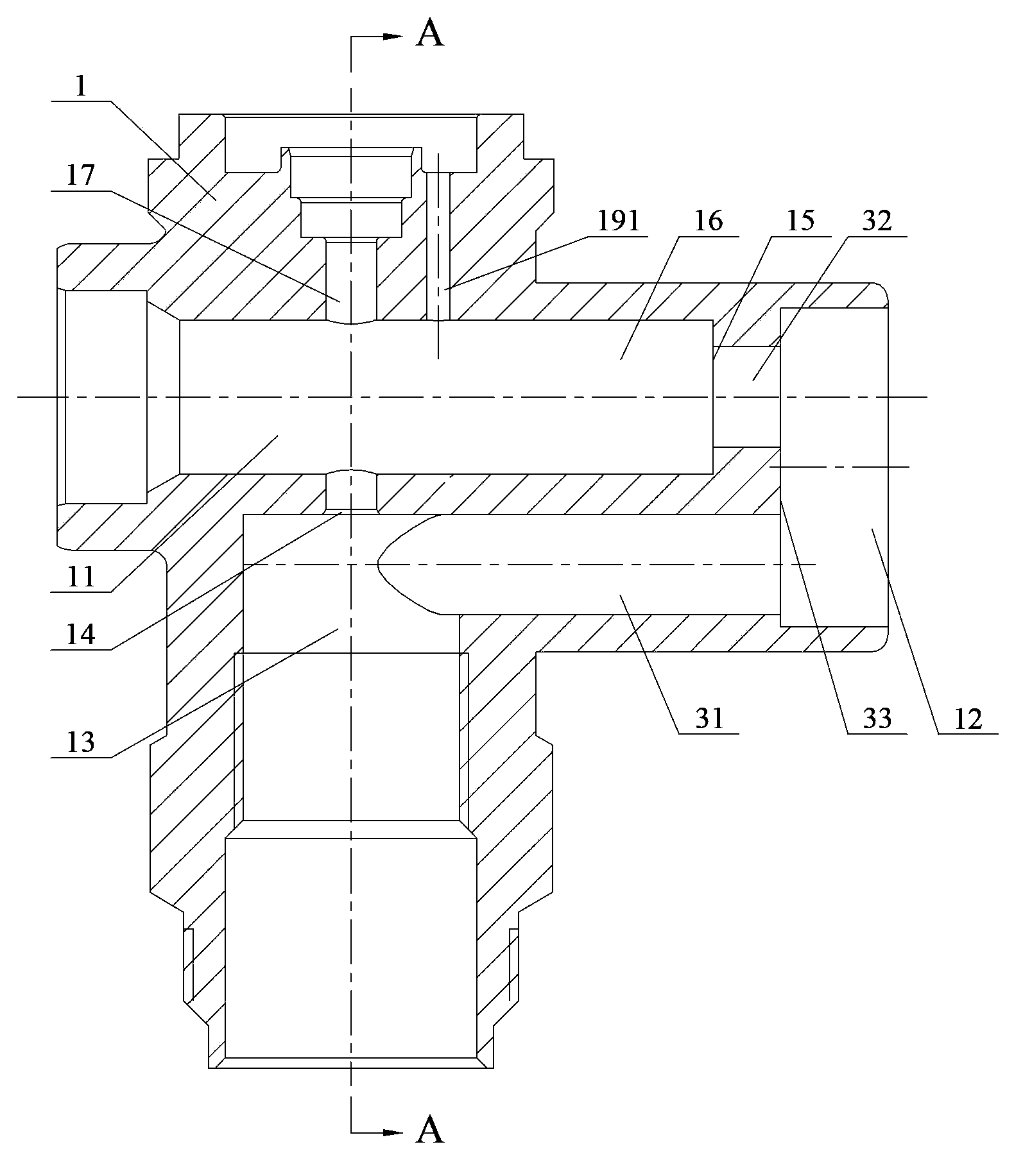

InactiveCN103542645AEasy to processReliable installationFluid circulation arrangementMechanical apparatusControl functionMechanical engineering

The invention discloses a thermostatic expansion valve with the one-way control function. The thermostatic expansion valve with the one-way control function is characterized in that a valve body (1) further comprises a containing portion (16) extending to the inner portion of the valve body (1) from an inlet channel (11), a second valve port (15) is formed in the containing portion (16), a second valve element component (5) is arranged in the containing portion (16), an inner cavity (13) is communicated with an outlet channel (12) through a first communicating channel (31), the containing portion (16) is communicated with the outlet channel (12) through a second communicating channel (32), the outlet channel (12) and the first communicating channel (31) are arranged in a parallel communicated mode, and the outlet channel (12) and the second communicating channel (32) are arranged in a parallel communicating mode. Compared with the prior art, the thermostatic expansion valve with the one-way control function has the advantages that the containing portion of the second valve element component is an extending portion of an inlet channel on the valve body, a hole does not need to be formed additionally, the structure is convenient to machine, the second valve element component is simple and reliable in installation, and the hidden danger of outward leakage is reduced; meanwhile, the first communicating channel and the second communicating channel are arranged parallel to the outlet channel in a communicated mode, so that the resistance of fluid is reduced and the environment of a flow path system is improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

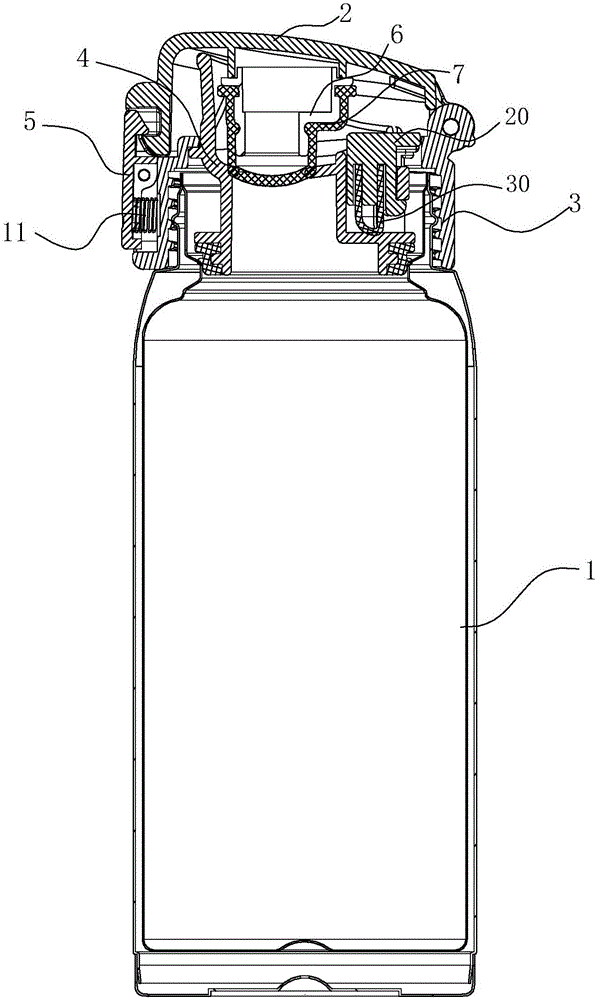

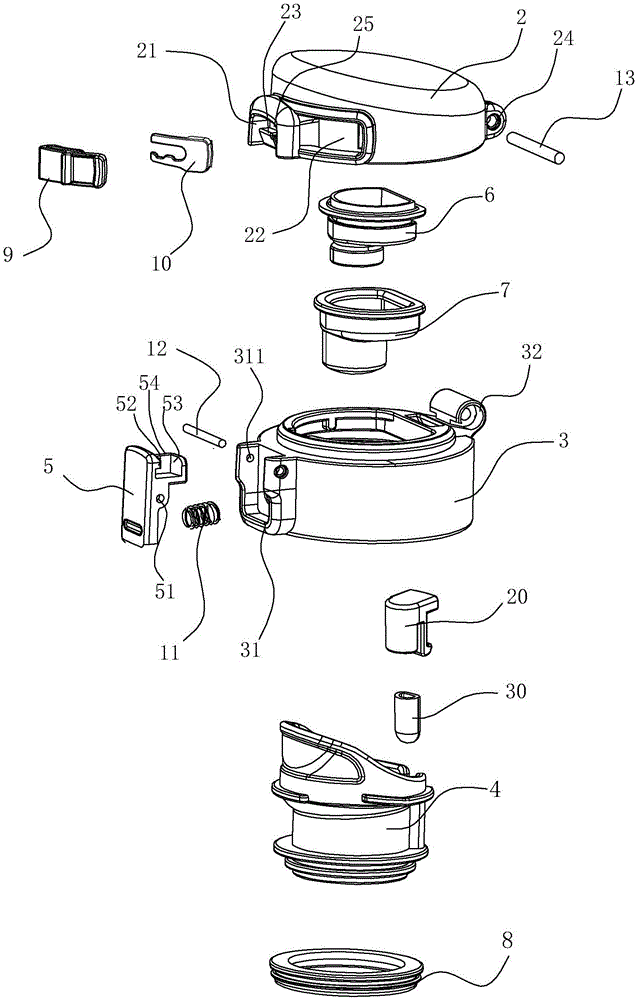

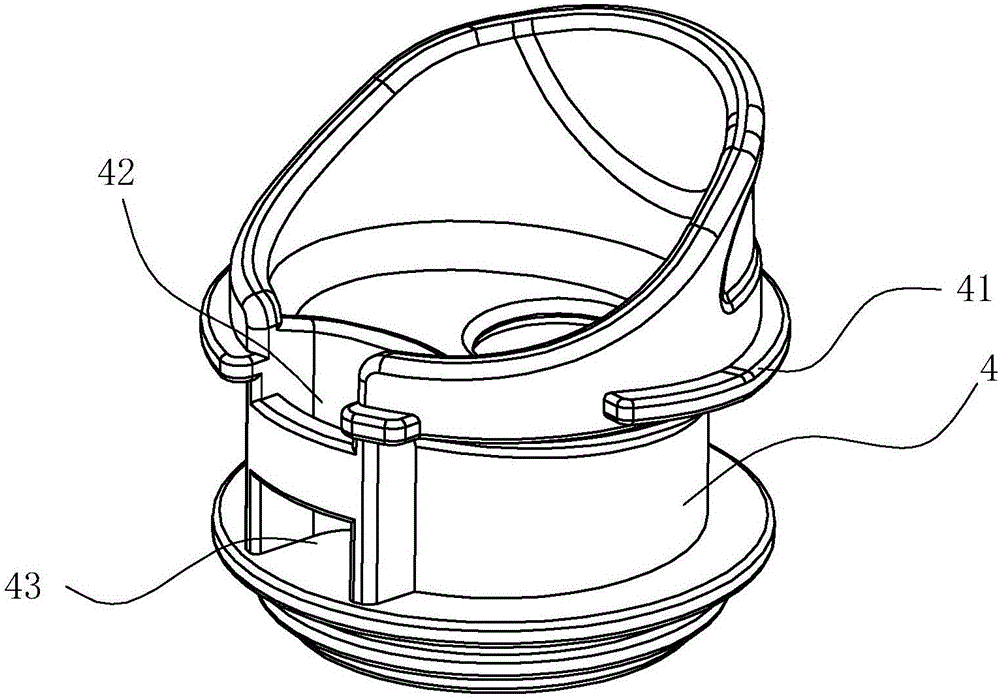

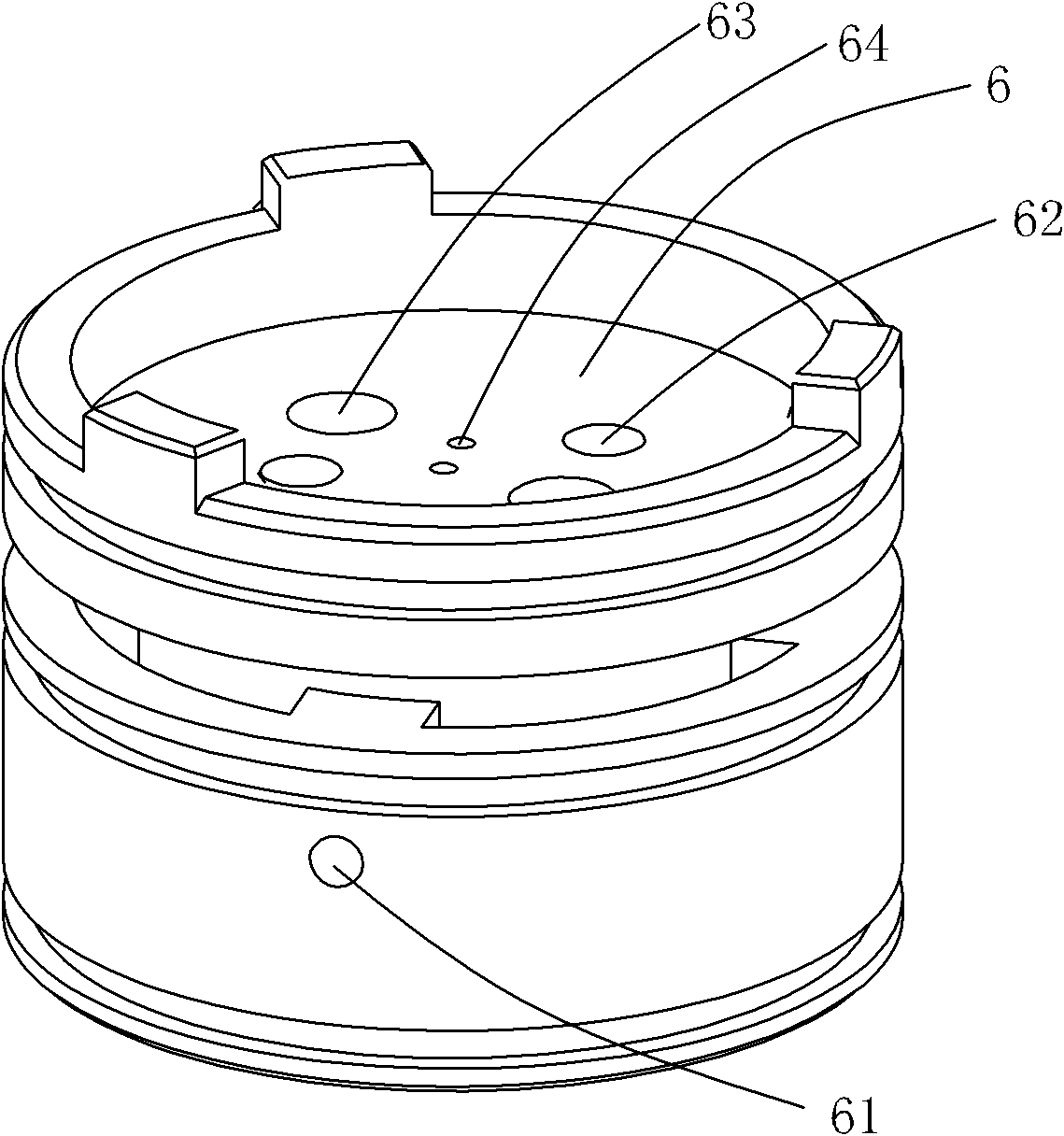

Thermos cup

ActiveCN105996666AEasy to clean and maintainReliable installationDrinking vesselsEngineeringMechanical engineering

Owner:宁波立羊真空器皿有限公司

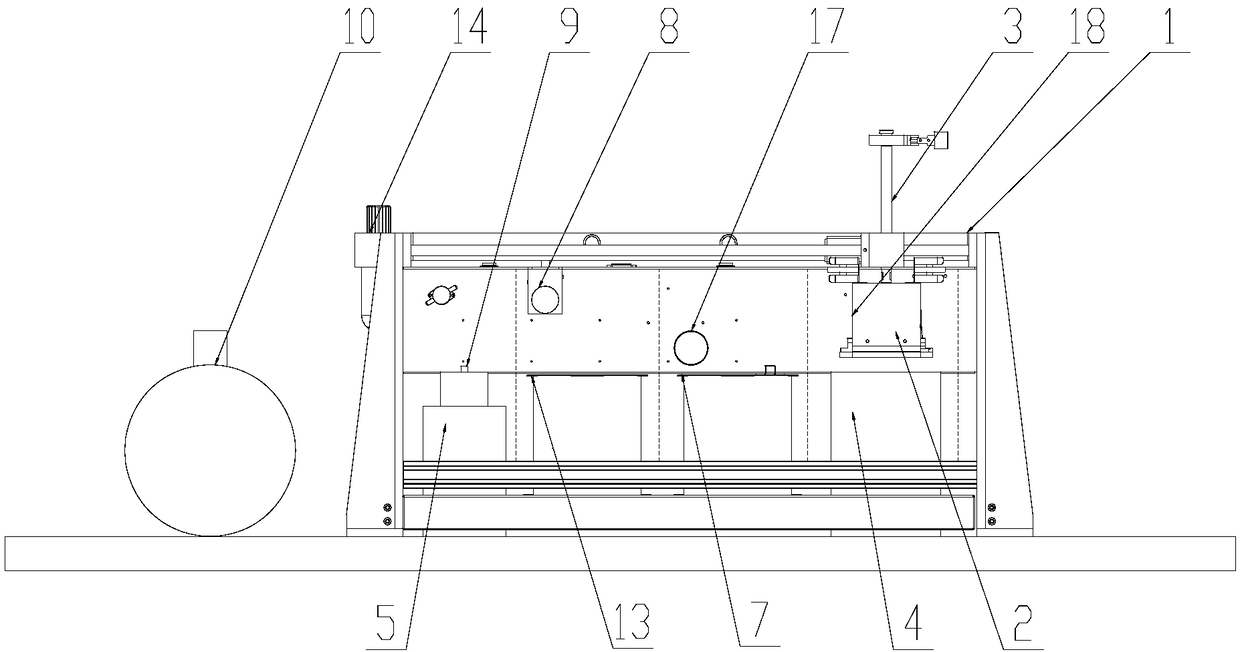

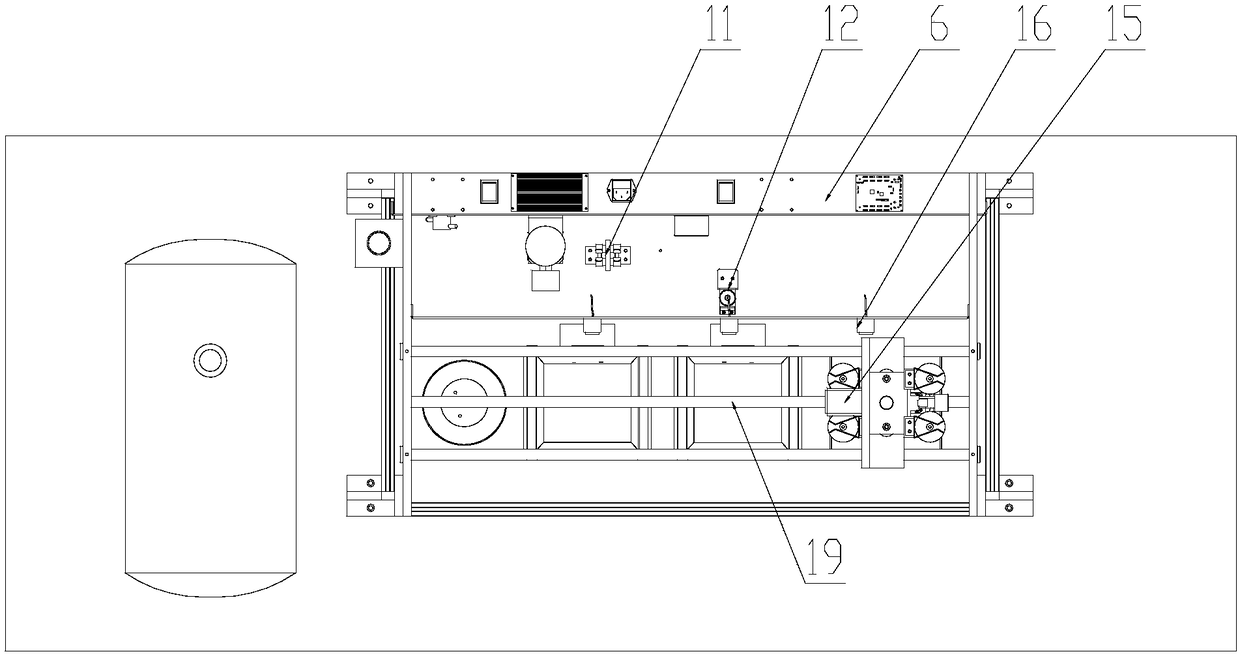

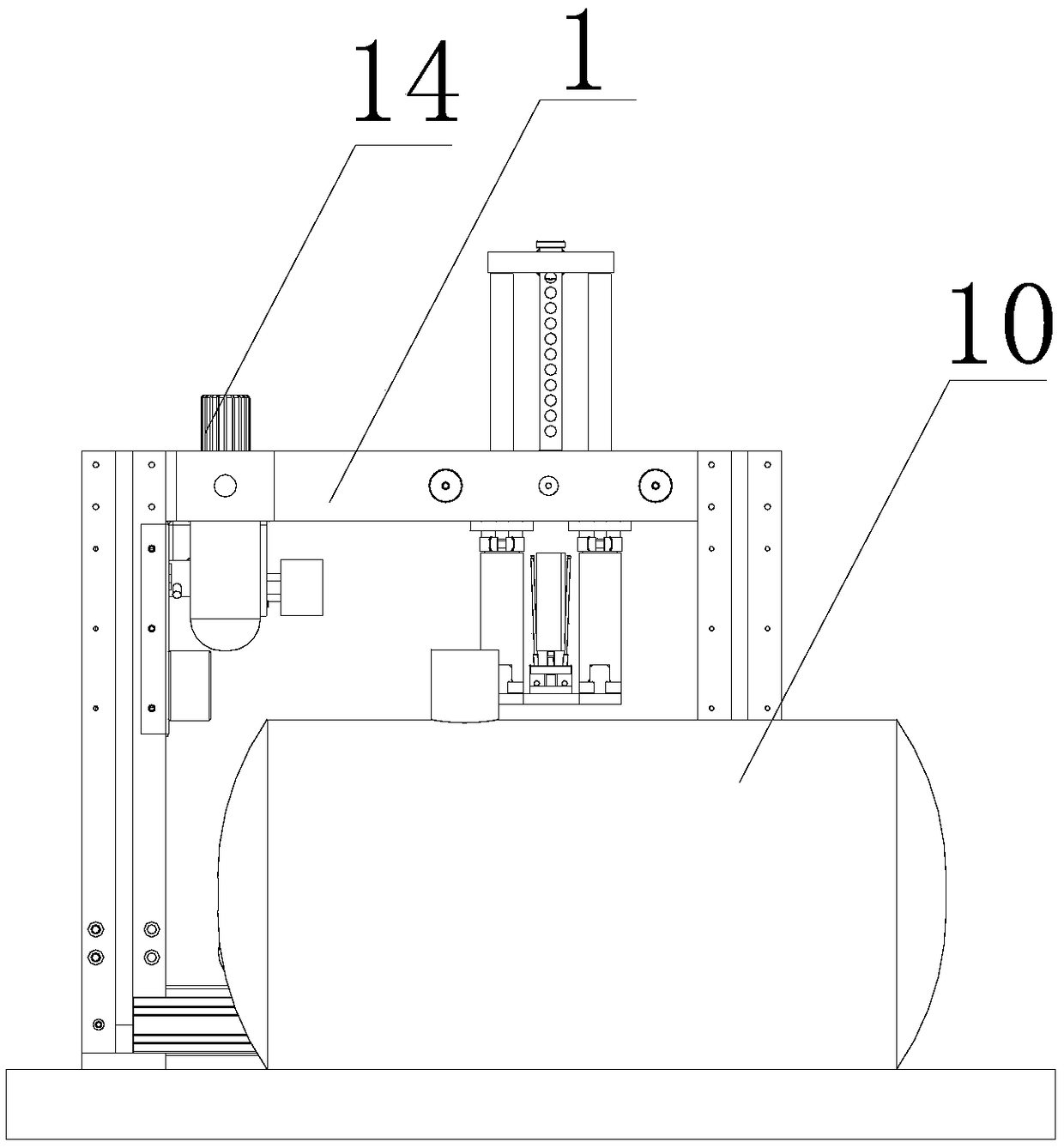

Multistation spray nozzle automatic cleaning equipment and cleaning method

PendingCN109127538AImprove cleaning efficiencyEasy to cleanCleaning using liquidsAutomatic test equipmentSpray nozzle

The invention provides multistation spray nozzle automatic cleaning equipment and a cleaning method. According to the equipment, an air compressor is mounted at one end of an equipment framework. A pressure reservoir, a waste ink discharging station, a cleaning fluid circulating cleaning station and an ultrasonic automatic cleaning station are formed in and arranged on the equipment framework. A waste liquid groove is formed in the waste ink discharging station. A circulating cleaning recovery groove is formed in the cleaning fluid circulating cleaning station. An ink pipe is connected with anink inlet enabling ink to enter a spray nozzle from the pressure reservoir. An ink outlet of the spray nozzle is aligned with an opening in the upper end of the circulating cleaning recovery groove.A precise regulating valve is arranged on the connecting ink pipe. A liquid level sensor is arranged inside the pressure reservoir. According to the cleaning equipment and the cleaning method providedby the invention, the three stations for waste ink clearing, circulating cleaning and ultrasonic cleaning are arranged, assembly line type operation is adopted, moving among the stations is achievedthrough transverse moving slide rails and limit switches, the spray nozzle does not need to be dismounted or mounted again, operation is quite convenient and fast, and the cleaning efficiency is quitehigh.

Owner:SHANGHAI SONICJET TECH

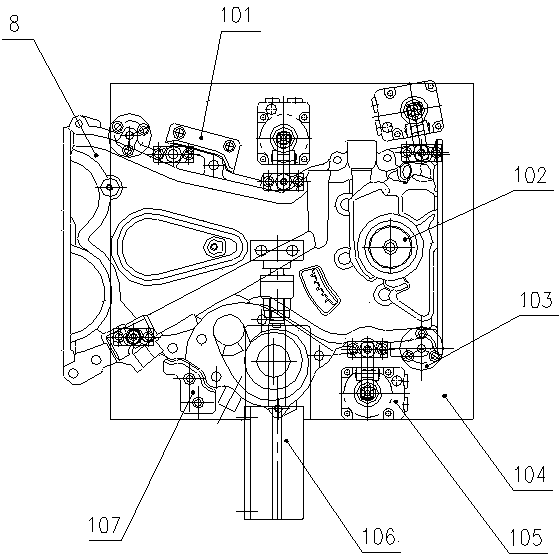

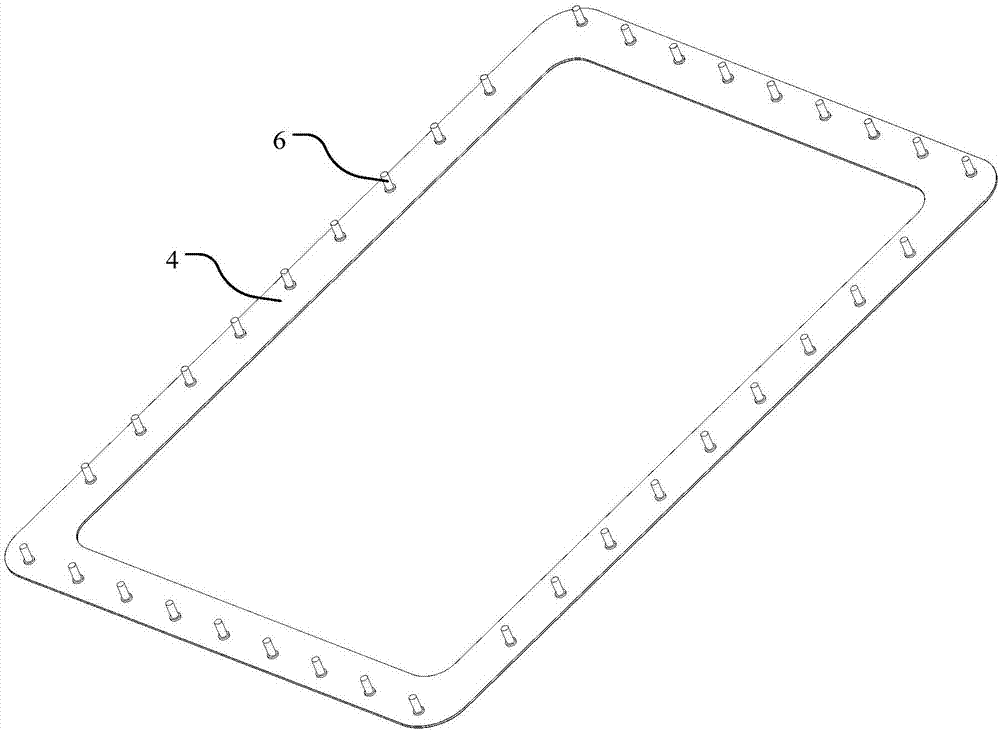

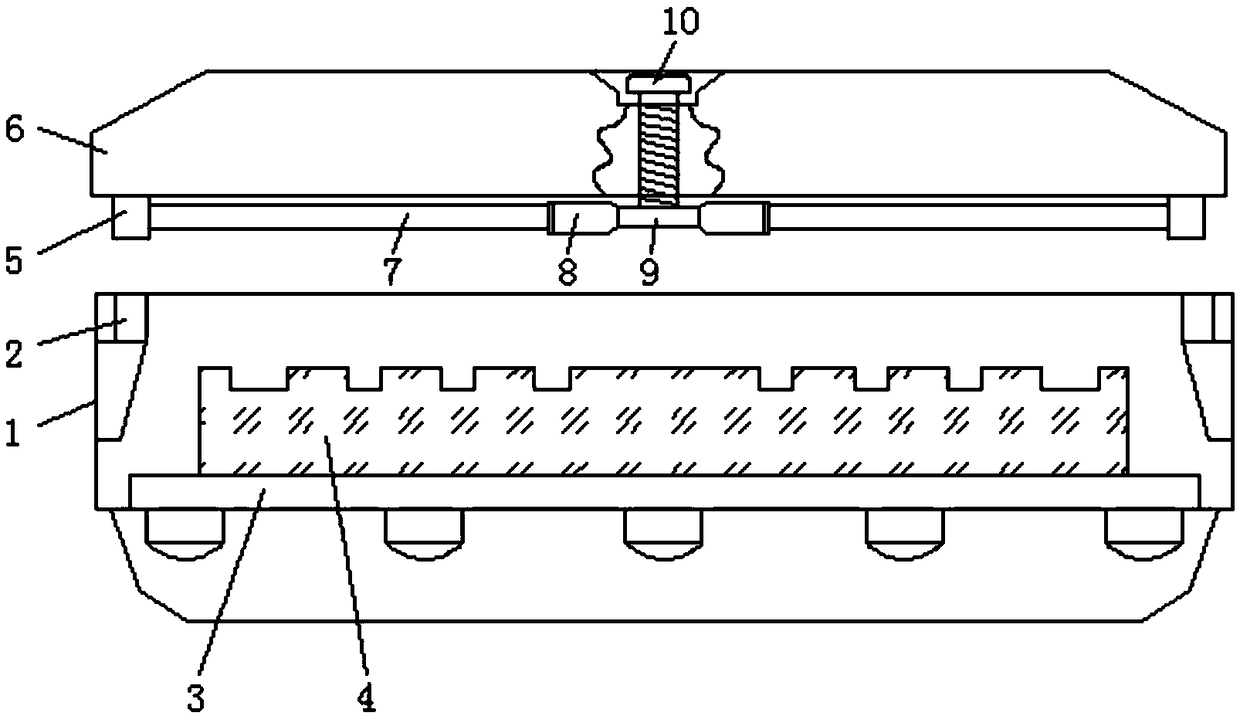

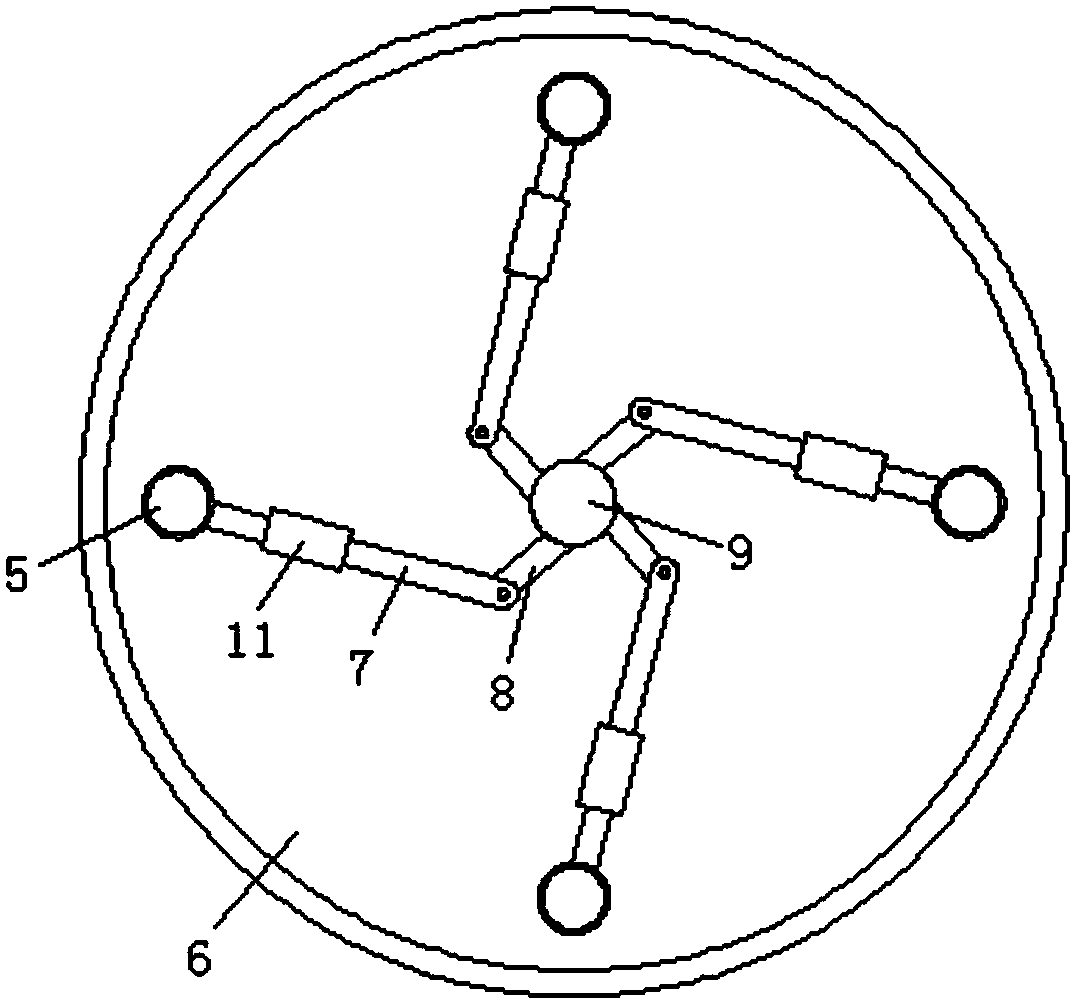

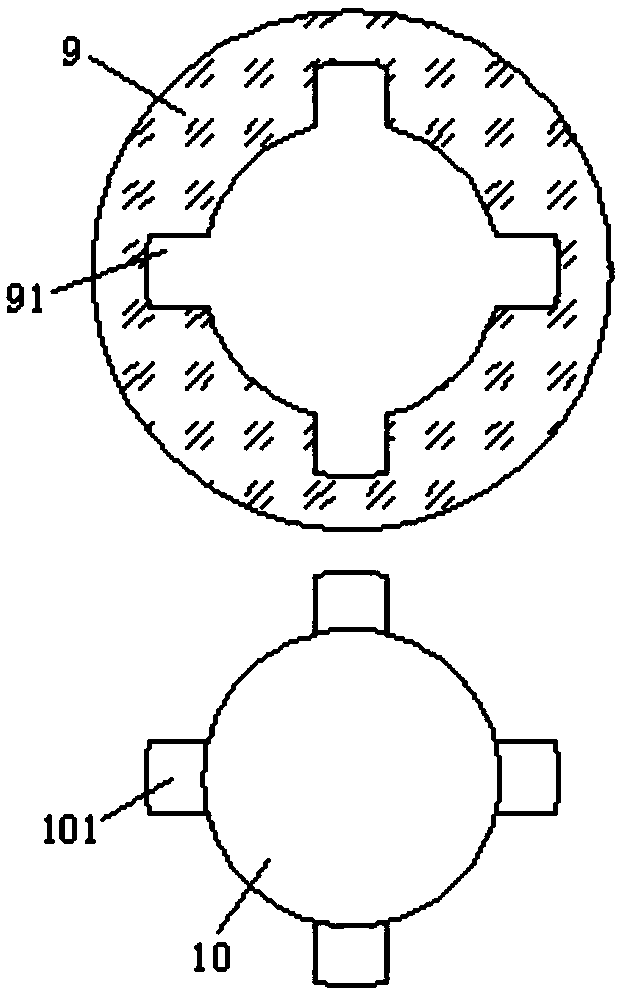

Clamp for numerical control machining

ActiveCN111251028AReliable installationIngenious structural designExpansion mandrelsPositioning apparatusLocking plateLocknut

The invention discloses a clamp for numerical control machining. The clamp comprises a support and an inner hole positioning and expansion mechanism. The inner hole positioning and expansion mechanismcomprises an installing plate, an expansion assembly and a locking assembly. The expansion assembly comprises an expansion sleeve, a spindle and a locking nut. The locking assembly comprises a locking plate, locking sleeves screws and a positioning plate. The installing plate is connected with the support. A plurality of first positioning holes are circumferentially and evenly distributed in theinstalling plate. A plurality of through holes are circumferentially and evenly distributed in the positioning plate. Each through hole is aligned and connected with the corresponding locking sleeve.A plurality of second positioning holes are circumferentially and evenly distributed in the locking plate. The first positioning holes, the through holes and the second positioning holes are the samein number and corresponding in position. The clamp is ingenious in structural design, convenient to use and reliable in clamping.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

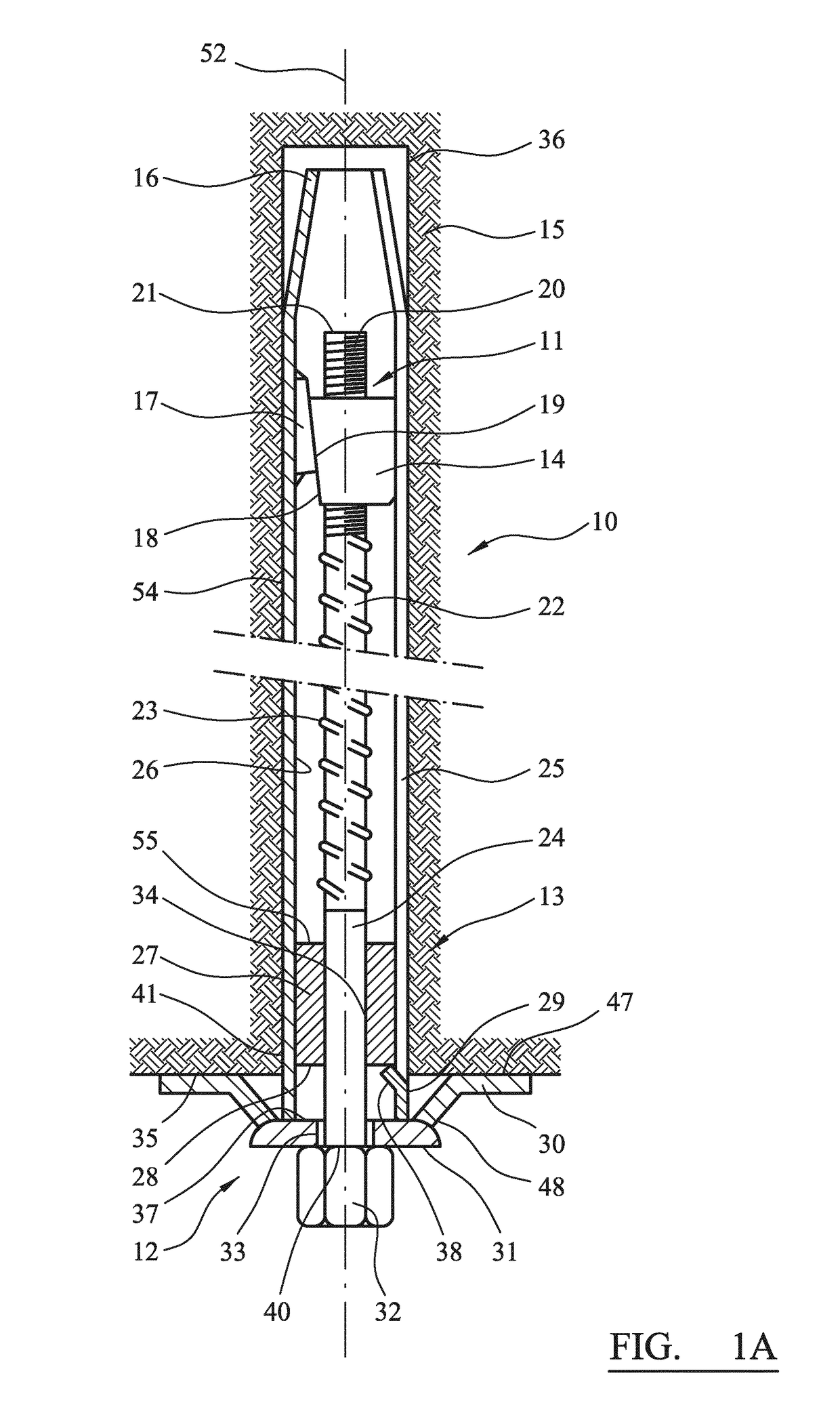

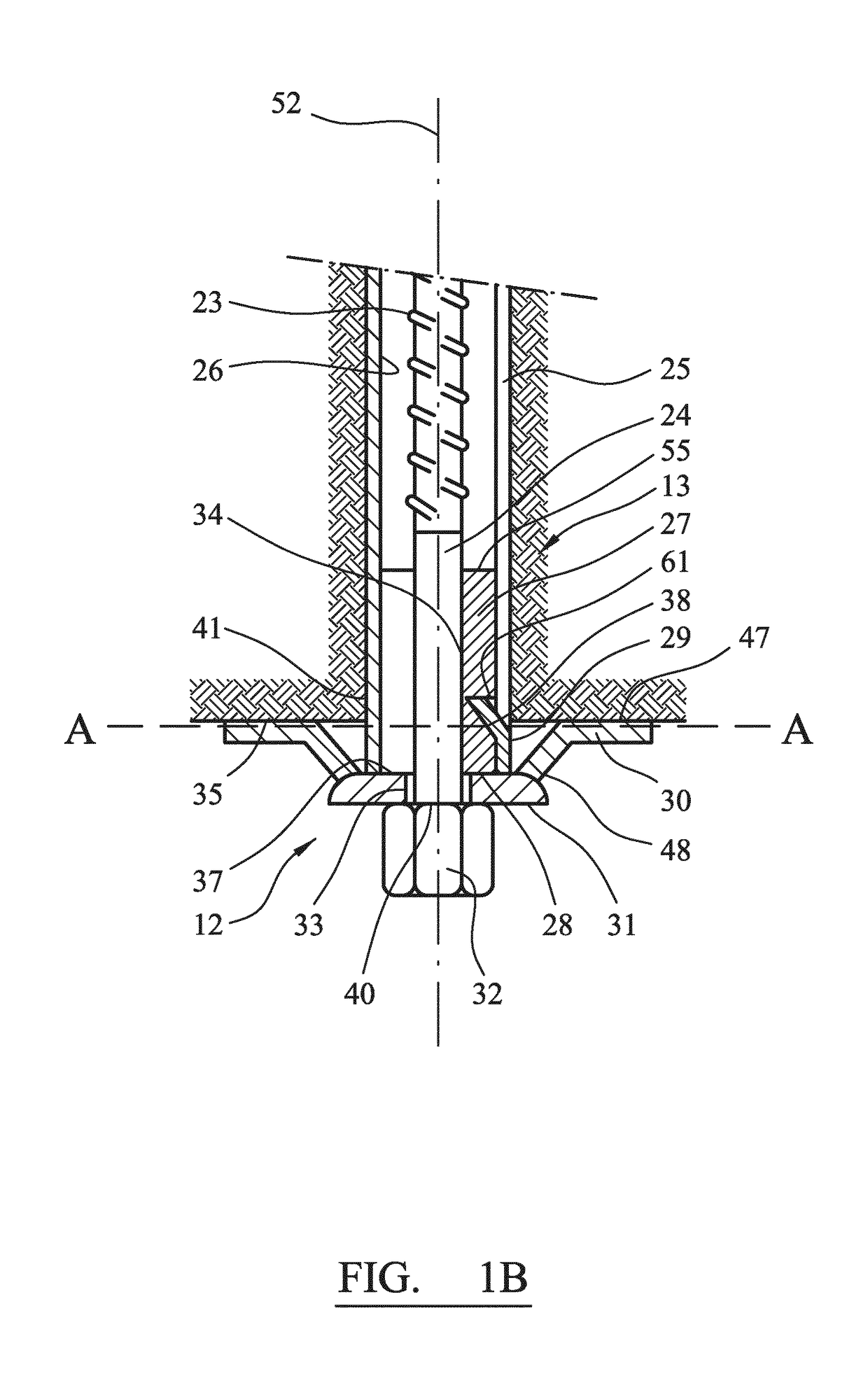

Friction bolt

ActiveUS20180347358A1Reliable installationAvoid unintentional misalignment damageAnchoring boltsMechanical engineering

A friction bolt assembly to frictionally engage a bore formed in rock strata includes an elongate tube and an expander mechanism acted on by an anchor mechanism via an elongate bar or cable. A retainer mechanism is mounted to act between the bar or cable and the tube to prevent ejection of the bar or cable from the assembly should the bar or cable break.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

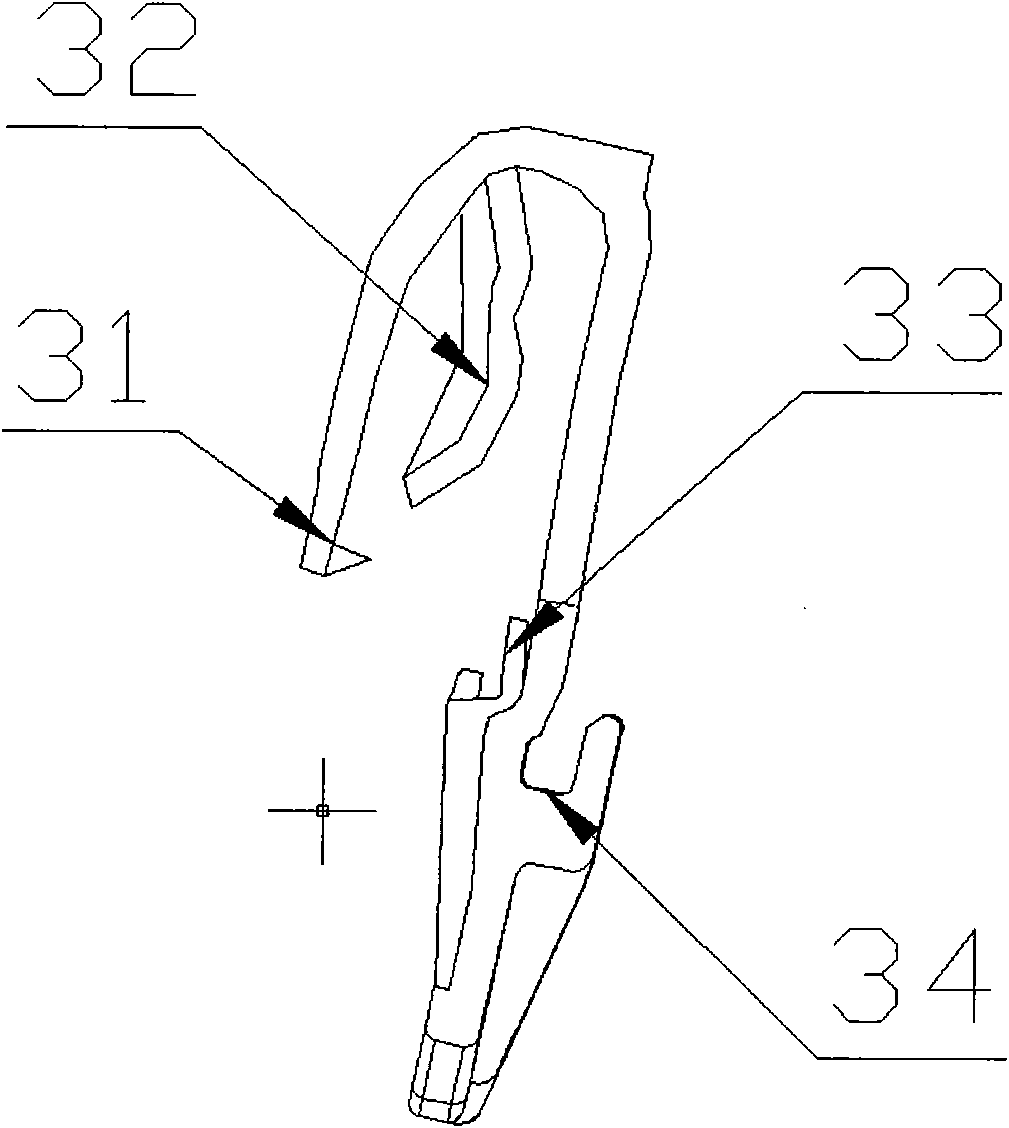

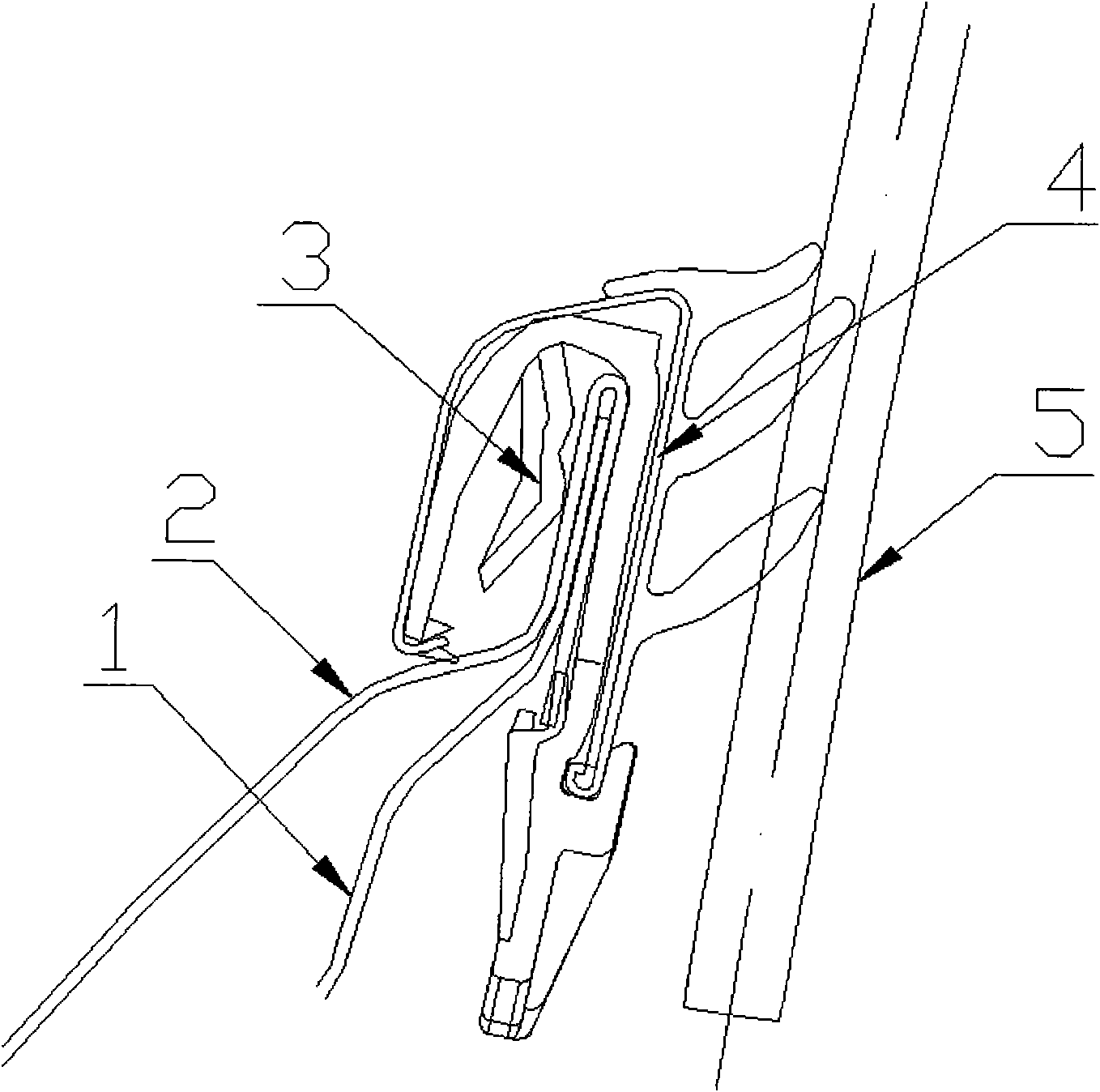

Outer holding strip assembly of automobile door

ActiveCN101863218AReliable installationStable performanceEngine sealsVehicle sealing arrangementsCar doorAnti theft

The invention discloses an outer holding strip assembly of an automobile door, which comprises an outer holding strip body, wherein the outer holding strip body consists of a framework of which the cross section is inverted U-shaped and a lip edge, the lip edge is integrated with the framework and is positioned on one side of the framework; the upper part of a clamp is also inverted U-shaped; the clamp is provided with an overhead hook, elastic clamping teeth, an inner neck and an outer neck; the clamp is arranged in an inverted U-shaped clamping groove of the outer holding strip body; and the overhead hook at the left lower end of the clamp is in interference fit with the left lower end of the framework, and the outer neck on the right outer side is in interference fit with the right lower end of the framework to ensure that the clamp and the outer holding strip body are combined into a whole body. The outer holding strip assembly of the automobile door has the following obvious advantages that: because of the special structure of the clamp, the outer holding strip body is reliably arranged on the automobile door and has stable performance; the outer holding strip body cannot be dismounted under the condition that the automobile door is locked and the automobile window glass is raised to ensure that the outer holding strip body has a strong anti-theft function; and the outer holding strip body is well matched with an automobile body metal plate, and not only improves the sealability but also makes the automobile body beautiful and smooth.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method and structure for installing electricity generator on unmanned plane

InactiveCN102417038AReliable installationSmooth runningAircraft componentsAirplaneElectric generator

The invention discloses a method and a structure for installing an electricity generator on an unmanned plane. The electricity generator is a JF 3.5kw / 28V direct-current electricity generator, wherein the input shaft of the electricity generator is a spline shaft; the radial runout of the spline shaft is not more than 0.2mm; and the input shaft of the electricity generator is rigidly connected with a flying wheel plate of an output shaft of an engine directly through a coupler, so that the output torque of the engine is ensured to be quickly and accurately transmitted and the power loss is minimal in a transmission process. By the method and the structure, the installation is reliable, the running is stable, overmuch engine output power is not used, the power demand of pickaback and task equipment of the unmanned plane can be ensured when the unmanned plane flies, the engine output power consumed by the electricity generator is ensured to be minimal when power equipment normally runs, and the working efficiency of the 3.5kw / 28V direct-current electricity generator is improved.

Owner:贵州贵航无人机有限责任公司

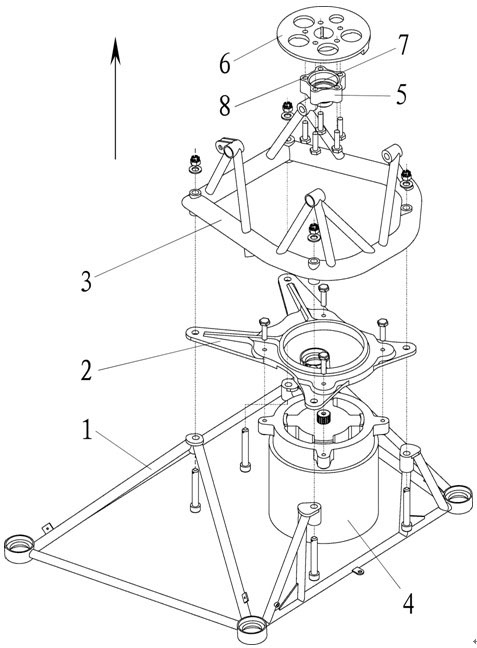

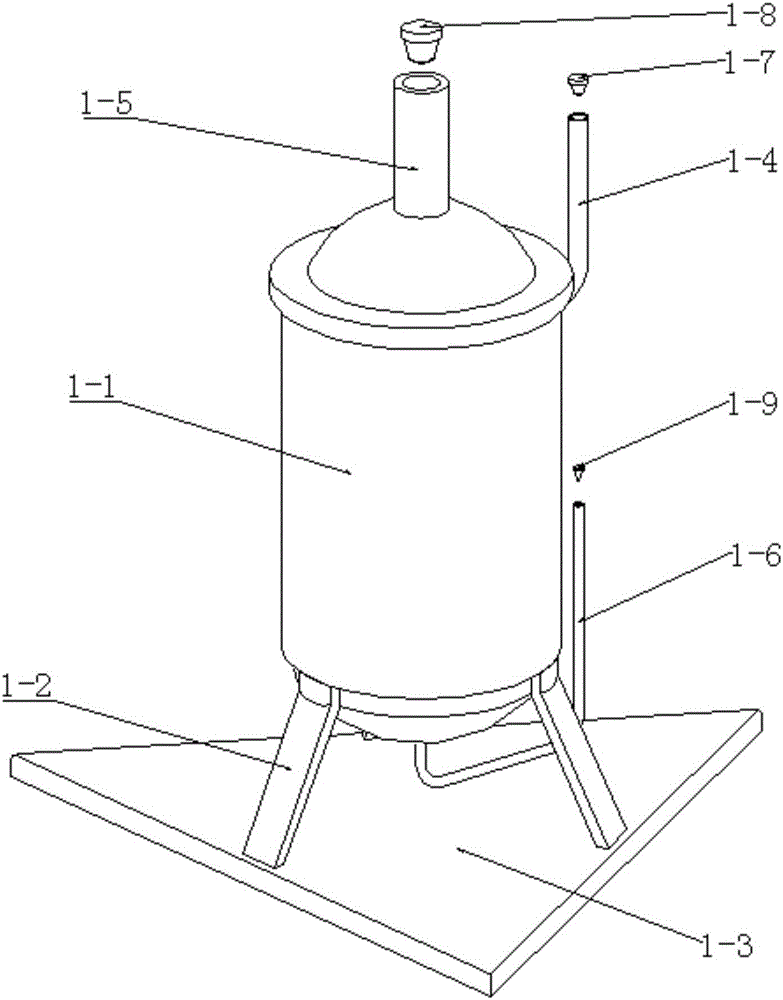

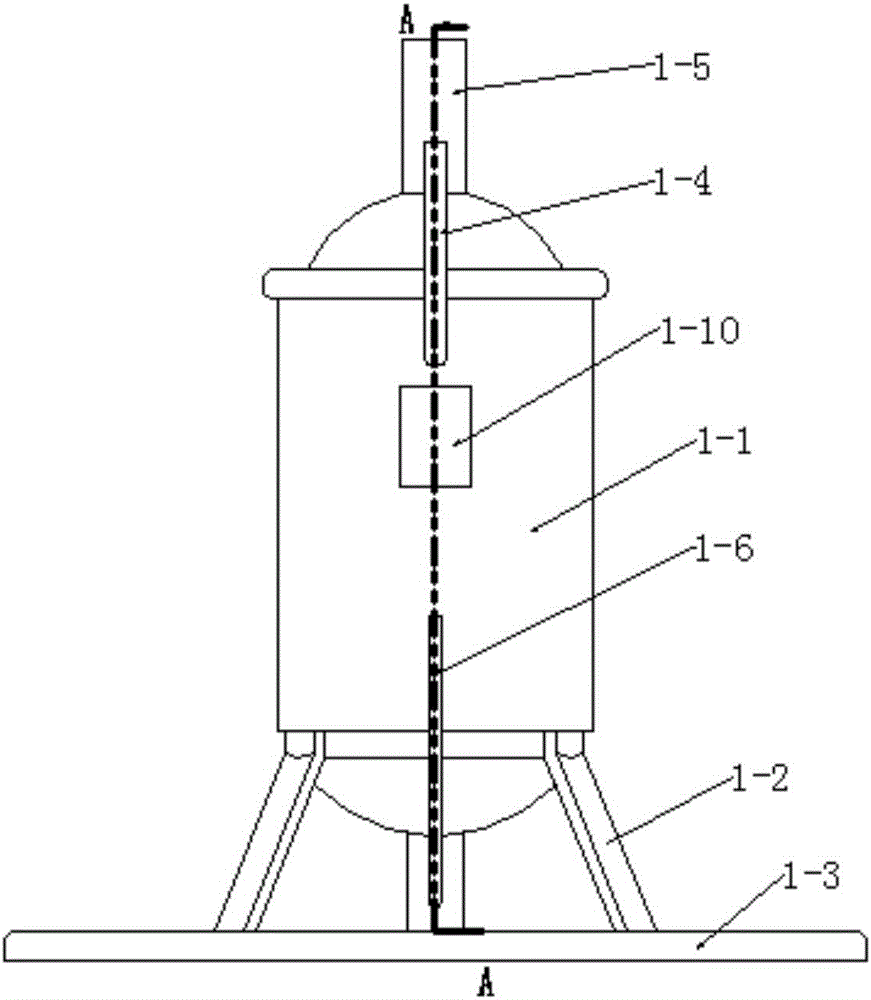

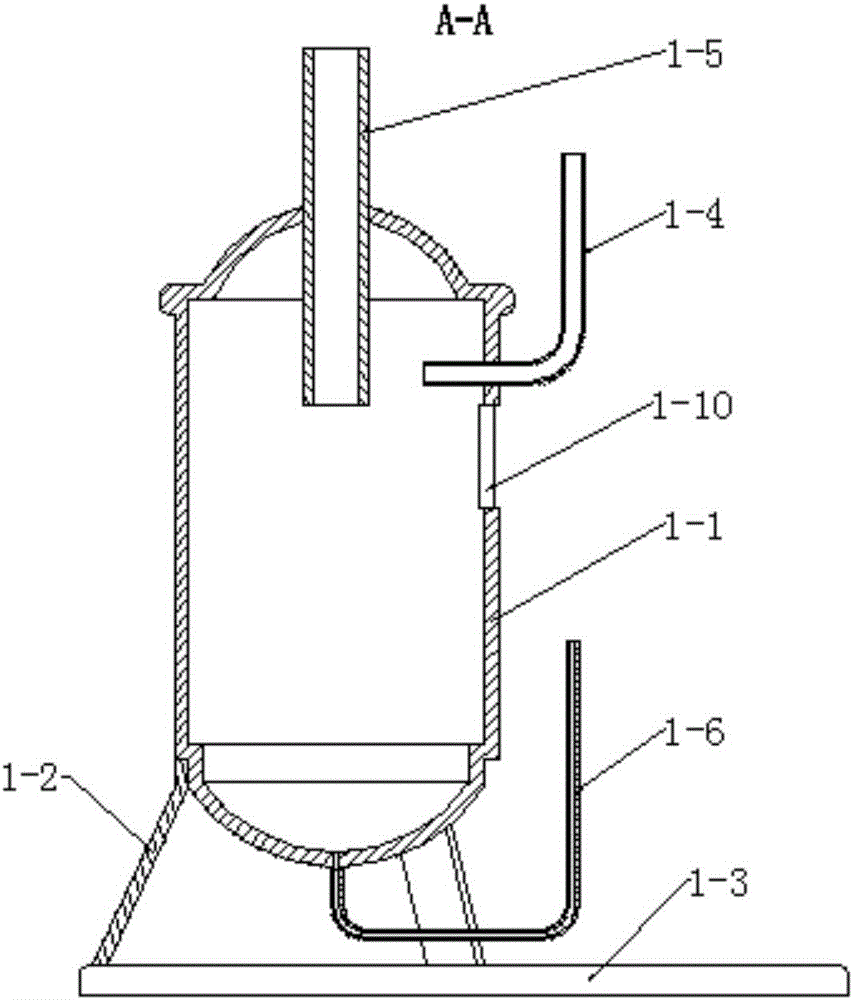

Reaction kettle for polyaluminum chloride production

InactiveCN105363401AReliable installationImprove reaction efficiencyAluminium chloridesChemical/physical/physico-chemical stationary reactorsImpellerReflux

The invention discloses a reaction kettle for polyaluminum chloride production. The reaction kettle comprises a bracket, a kettle body, a kettle cover and a motor; the kettle body is arranged in the bracket, the kettle cover is arranged on the kettle body, and the kettle cover is sealedly connected with the kettle body; the motor is arranged on the kettle cover; a stirring rod is arranged below the motor and is in drive connection with the motor, and the stirring rod is provided with a stirring impeller; two sides of the bracket are respectively provided with a control box and a vacuum gauge; the kettle cover is also provided with a constant pressure funnel and a reflux head, the constant pressure funnel and the reflux head both communicate with the kettle body, a collection bottle is arranged below the reflux head, the reflux head is provided with a condenser, and the top of the condenser is provided with an air exhaust port. The reaction kettle for polyaluminum chloride production has the advantages of convenient use, safety and reliability, high stability, and good reaction effect.

Owner:JIASHAN LVYE ENVIRONMENTAL PROTECTION MATERIAL FACTORY

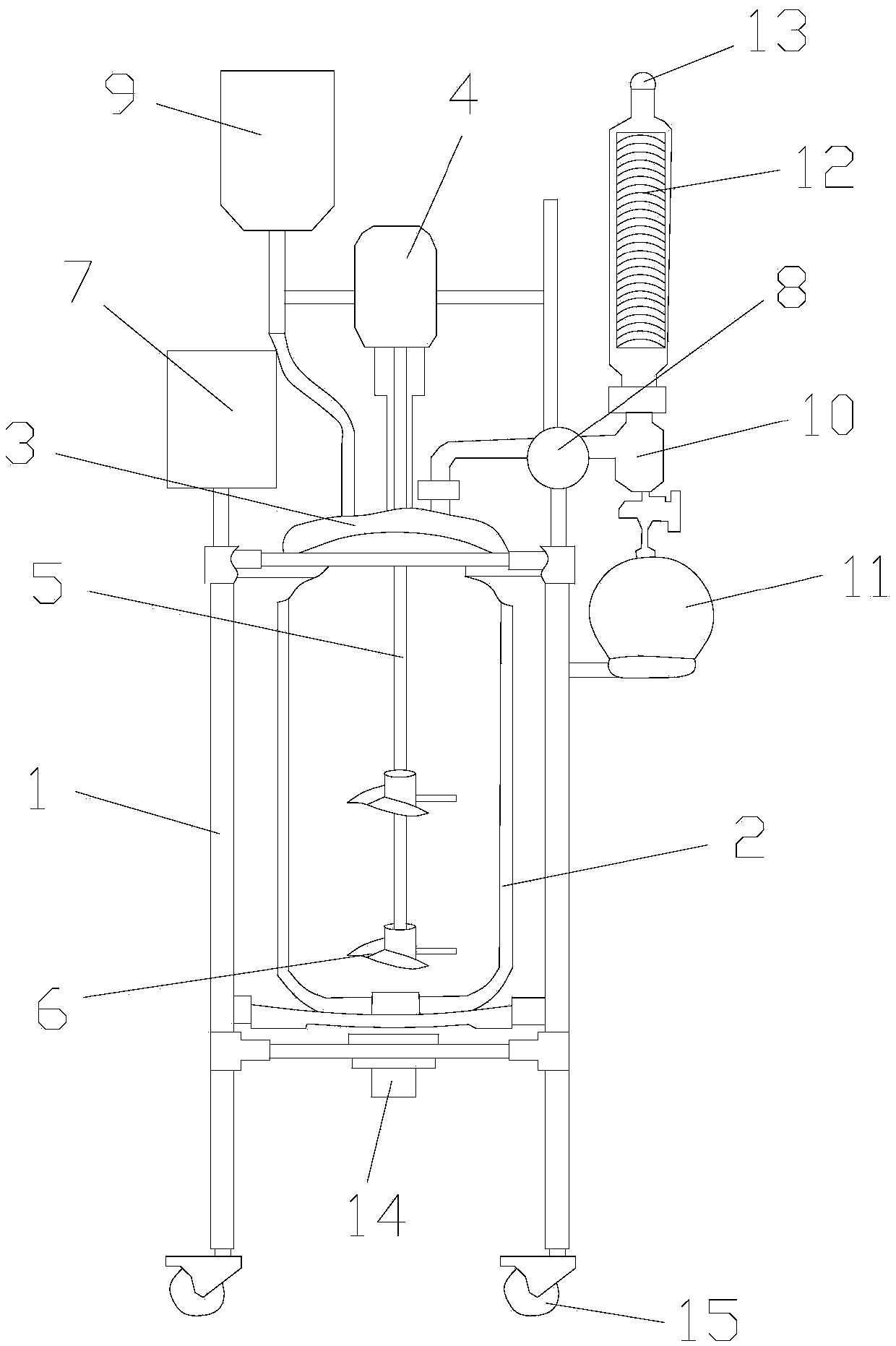

Pressure sensor

ActiveCN106740064AStable deliveryEasy to assembleUnderstructuresFuel supplyFuel tankMembrane configuration

The invention discloses a pressure sensor and belongs to the field of pressure inspection equipment. The pressure sensor comprises a plug-in type housing. Steam pipes are arranged at the front end of the housing. Pressure through holes are formed in the inside of the steam pipes; the outer parts of steam pipes are sleeved with sealed pipes; the top of each steam pipe is connected with a base board in a riveting mode; vent holes are formed in the base board; a pressure sensor chip is arranged on the base board; the pressure sensor chip is fixed with glue. A cover board is arranged on the cavity in an enclosing mode, the cover board is provided with a boss; the edge of the boss is provided with a flange ; the boss is sleeved with a dust cap; a pressure hole is formed in the middle part of the boss; the bottom of the pressure hole is closed through a filter membrane; the filter membrane is fixed through a convex ring; the pressure sensor chip and the base board are connected through bonding wires, the base board and a plug-in terminal are connected through bonding wires; the plug-in terminal passes through the housing and reaches out via a plug-in hole; the side face of the housing is provided with a lock catch component. The pressure sensor has the advantages of being reliable in structure, simple in manufacture, easy to assemble, low in cost and used for the pressure inspection of the traditional low pressure oil tank.

Owner:JIANGSU AOLIWEI SENSING TECH

Kitchen shower head with various water outlet modes

The invention provides a kitchen shower head with various water outlet modes. The kitchen shower head comprises a shower head body with an air suction hole, a fixed sheet and a rotating member, wherein the top surface of the rotating member is sealed with the end face of the fixed sheet; the fixed sheet is provided with a water flowing hole; the rotating member is provided with a first water flowing hole, a second water flowing hole and a third water flowing hole with small aperture which correspond to the water flowing hole of the fixed sheet; both the first water flowing hole and the third water flowing hole are communicated with a cylindrical water supply cavity; the second water flowing hole is communicated with a water supply cavity of the shower head; the shower head body is also provided with the air suction hole; and the angle for turning the air suction hole of the rotating member to the air suction hole of the shower head body is the same as that for turning the third water flowing hole to the water flowing hole of the fixed sheet. The kitchen shower head simultaneously has a shower head water outlet mode and a cylindrical water outlet mode; high-flow cylinder water is cylindrical water and low-flow cylindrical water forms bubbled water; and further, the washing effect is not changed and the water saving efficiency is higher.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

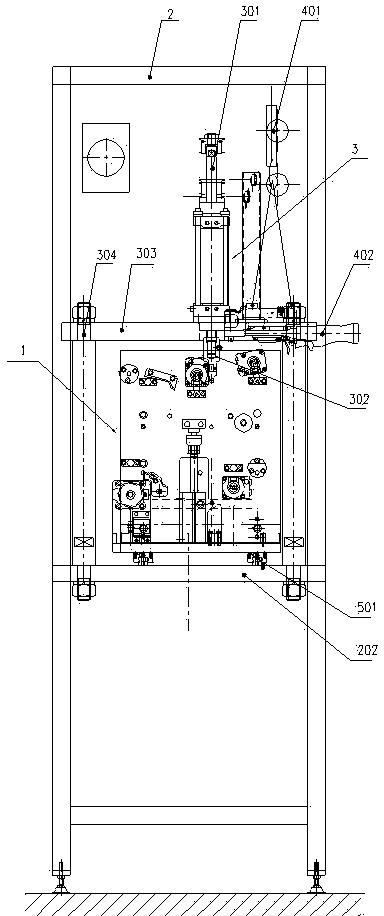

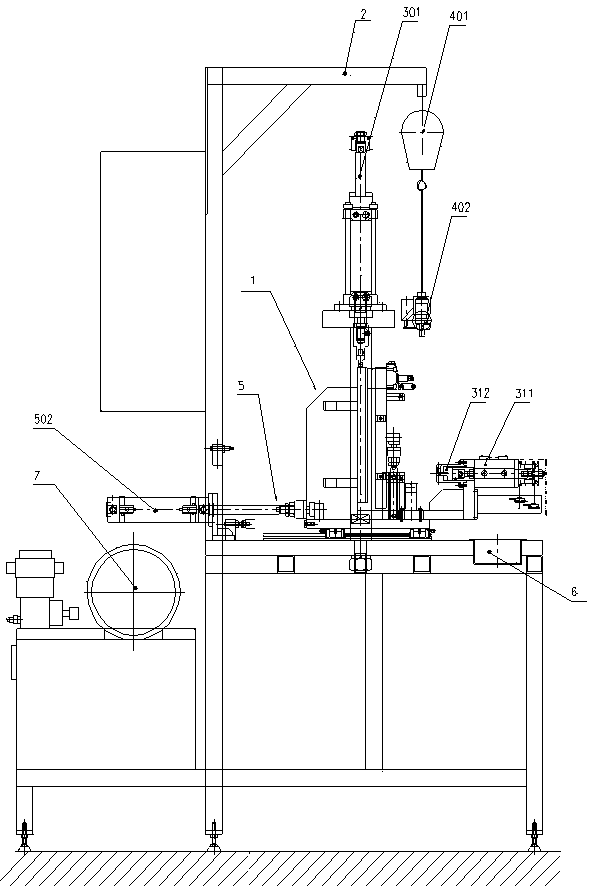

Engine oil pump shell steel ball and plug pressing method and controller

ActiveCN103978368AImprove work efficiencyReliable installationAssembly machinesElectricityElectromagnetic valve

The invention relates to the field of the automobile industry, in particular to an engine oil pump shell steel ball and plug pressing method and a controller. The method includes the steps of equipment preparation, element loading, feeding, ball pressing, plug beating, resetting and the like. The controller comprises a programmable controller which controls a clamping cylinder, a drive oil cylinder, an air suction type ejector rod and a translation oil cylinder through electromagnetic valves, the programmable controller is electrically connected with a main motor used for beating a plug through a frequency converter, the limiting position of the drive oil cylinder and the translation oil cylinder is provided with a proximity switch, and the proximity switch is electrically connected with an input port of the programmable controller. By means of the method and the controller, a steel ball and the plug can be pressed into an oil cylinder shell in a one-shot mode, and accordingly work efficiency is improved. High pressure keeps for three seconds after the steel ball is pressed into the oil pump shell, and installation is more reliable. Motions of the assemblies are controlled through the programmable controller with preset programs, positions of execution mechanisms are fed back through the proximity switch, and a whole device is automatically and safely obtained.

Owner:TAIZHOU JIUYI ELECTROMECHANICAL

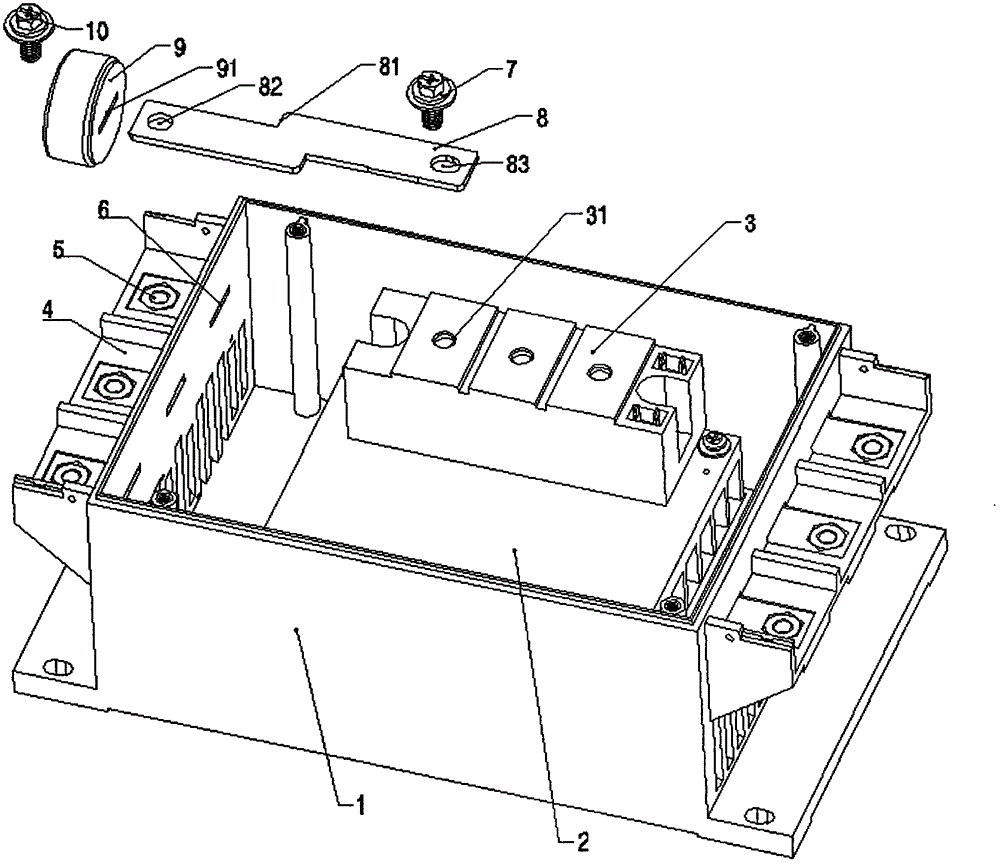

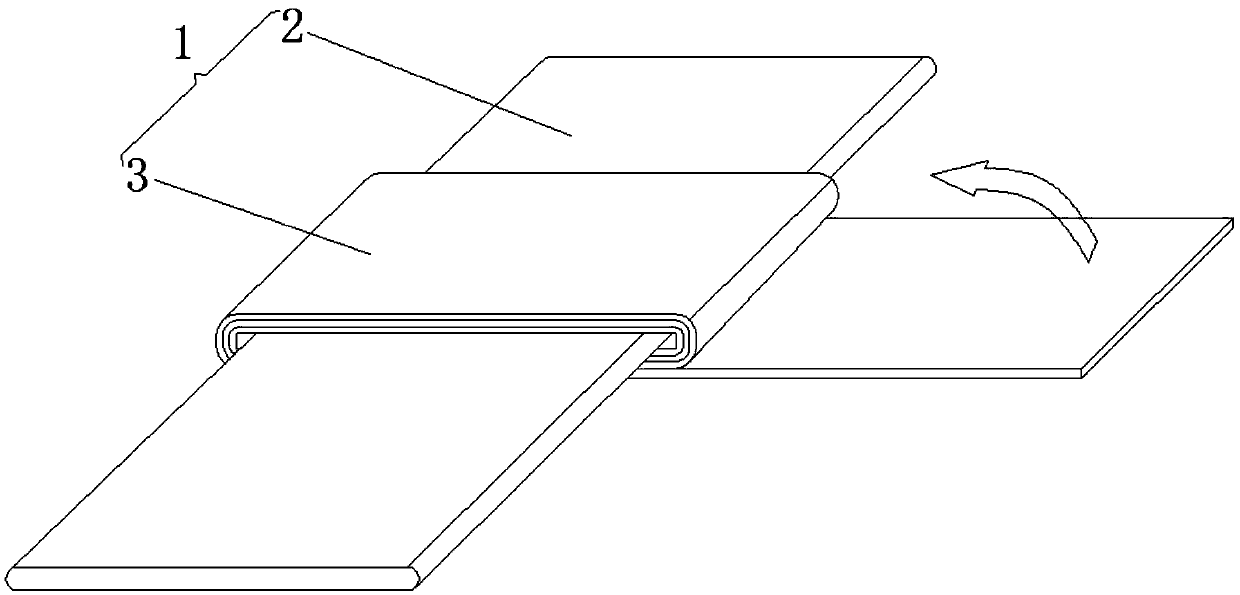

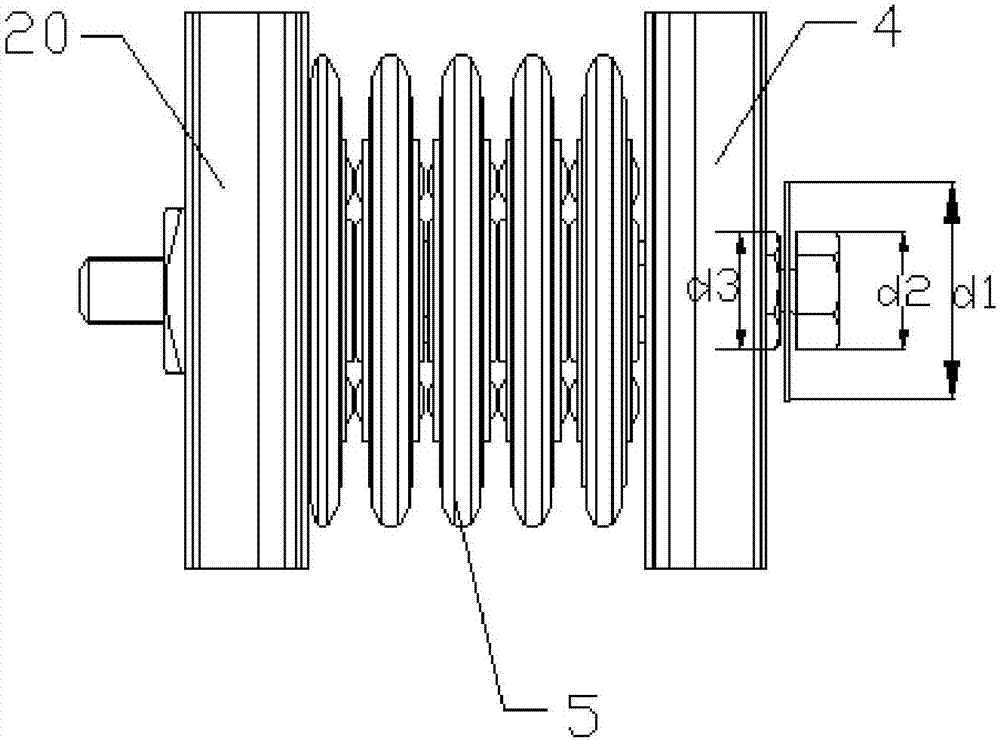

Soft starter with current detection apparatus without screw and buckle for fixation

InactiveCN104821748AEasy to installReliable installationStarter detailsEngineeringSilicon-controlled rectifier

The invention relates to a soft starter with a current detection apparatus without screw and buckle for fixation. The soft starter comprises a soft starter housing, a copper bar for current conduction, and a current detection apparatus passing through the copper bar. Positioning holes are formed in one side of the soft starter housing. A folding angle is arranged at the middle of the copper bar and holes are formed in the two ends of the copper bar. A square hole is formed in the middle of the current detection apparatus. According to the invention, a cooling plate is installed at the bottom of the soft starter housing body and a silicon controlled rectifier is installed into the cooling plate; the copper bar is inserted into the current detection apparatus and passes through an outlet slot; and the two ends of the copper bar are respectively fixed in positioning holes of a housing boss and the silicon controlled rectifier, thereby completing installation. The current detection apparatus does not need any buckle or screw for fixation, so that the cost is saved; and the installation becomes simple and convenient and the firmness is reliable.

Owner:SUZHOU ANCHORWILL TECH

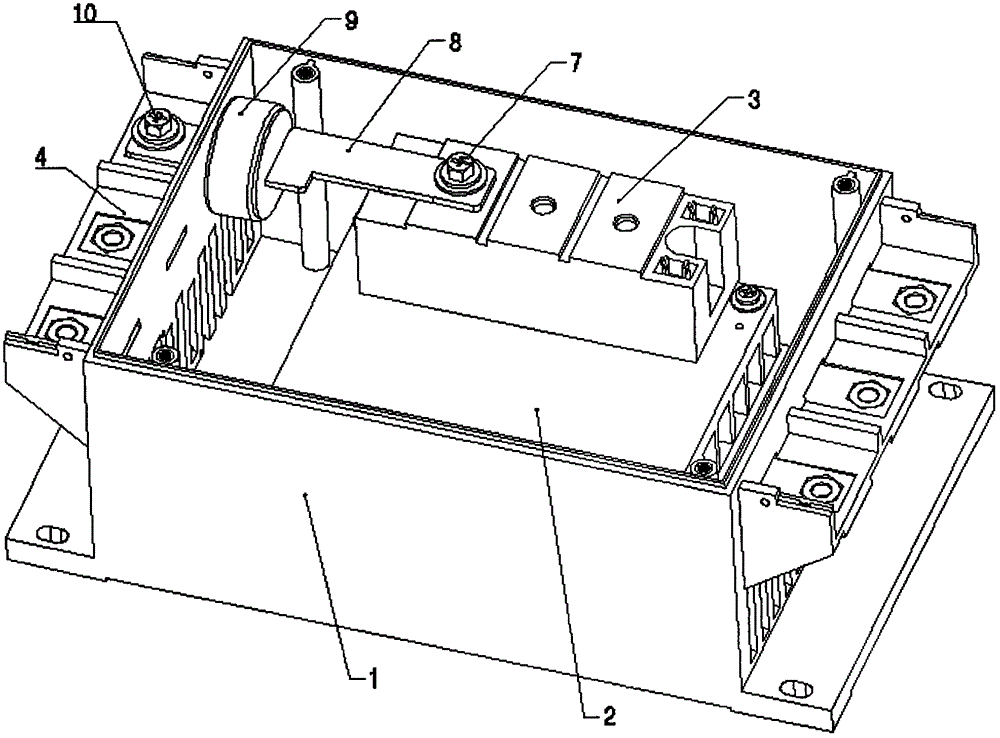

Operating mechanism for circuit breaker

InactiveCN101364504AEasy to operateReliable installationProtective switch detailsEngineeringCircuit breaker

The invention relates to an operating mechanism of a circuit breaker, particularly to an operating mechanism of a circuit breaker, a cover plate of which can be conveniently disassembled and assembled. The operating mechanism comprises a cover plate, a right side plate and a left side plate; projecting lugs are arranged on the back sides of the left and the right side plates and used for being connected with a base of a circuit breaker body; clamping grooves are formed on the upper end surfaces of the left and the right side plates close to the front and the rear sides; the openings of the clamping grooves are positioned on the front sides; and tenons matched with the clamping grooves are correspondingly arranged on the cover plate. The operating mechanism is characterized in that a lock groove is formed on the side wall of the cover plate, which is opposite to the side plate; a screw hole is formed on one side plate correspondingly and vertically penetrates the side plate; a lock screw passes through the screw holes and is matched with the rear side wall of the lock groove.

Owner:ZHEJIANG TENGEN ELECTRIC

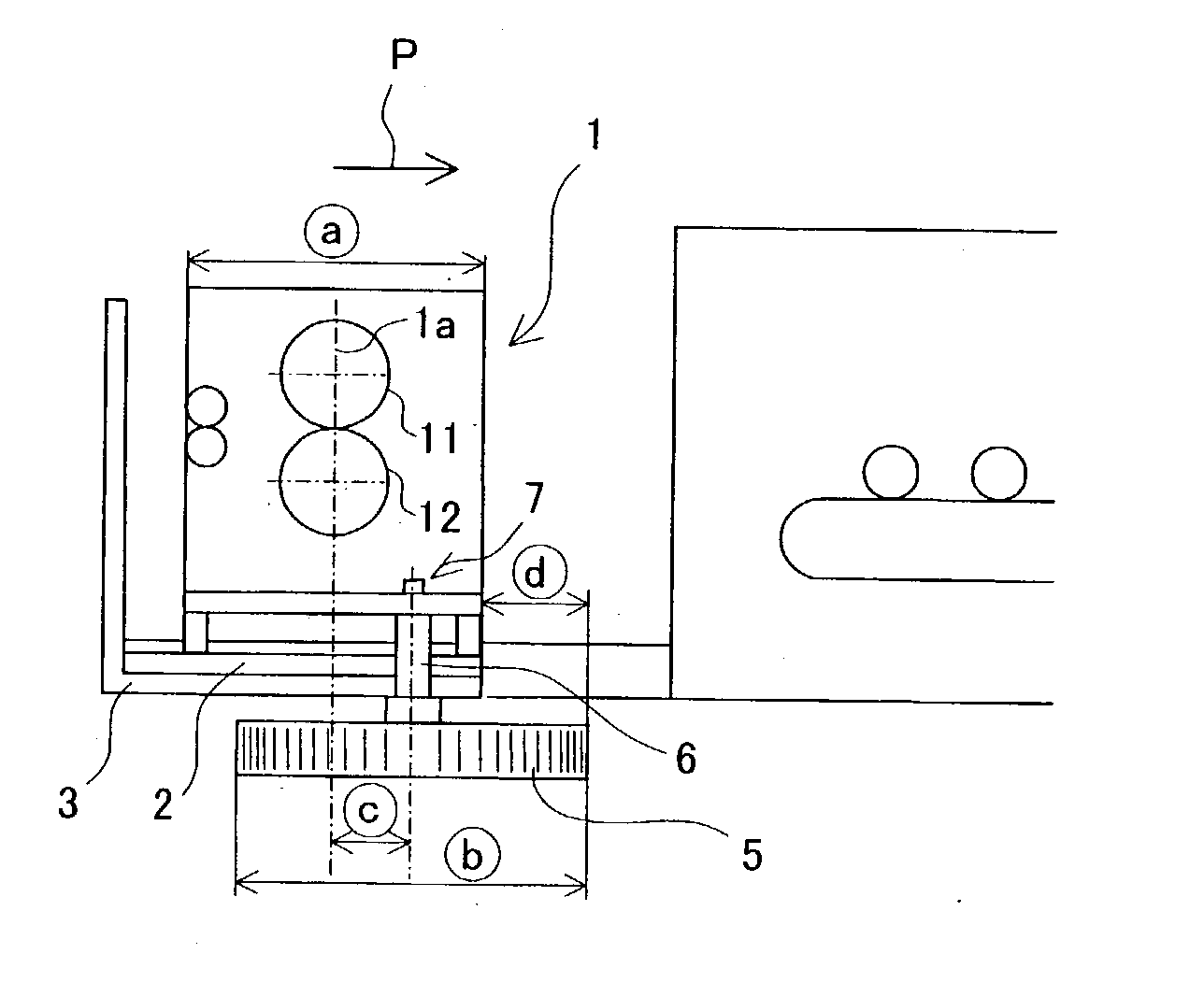

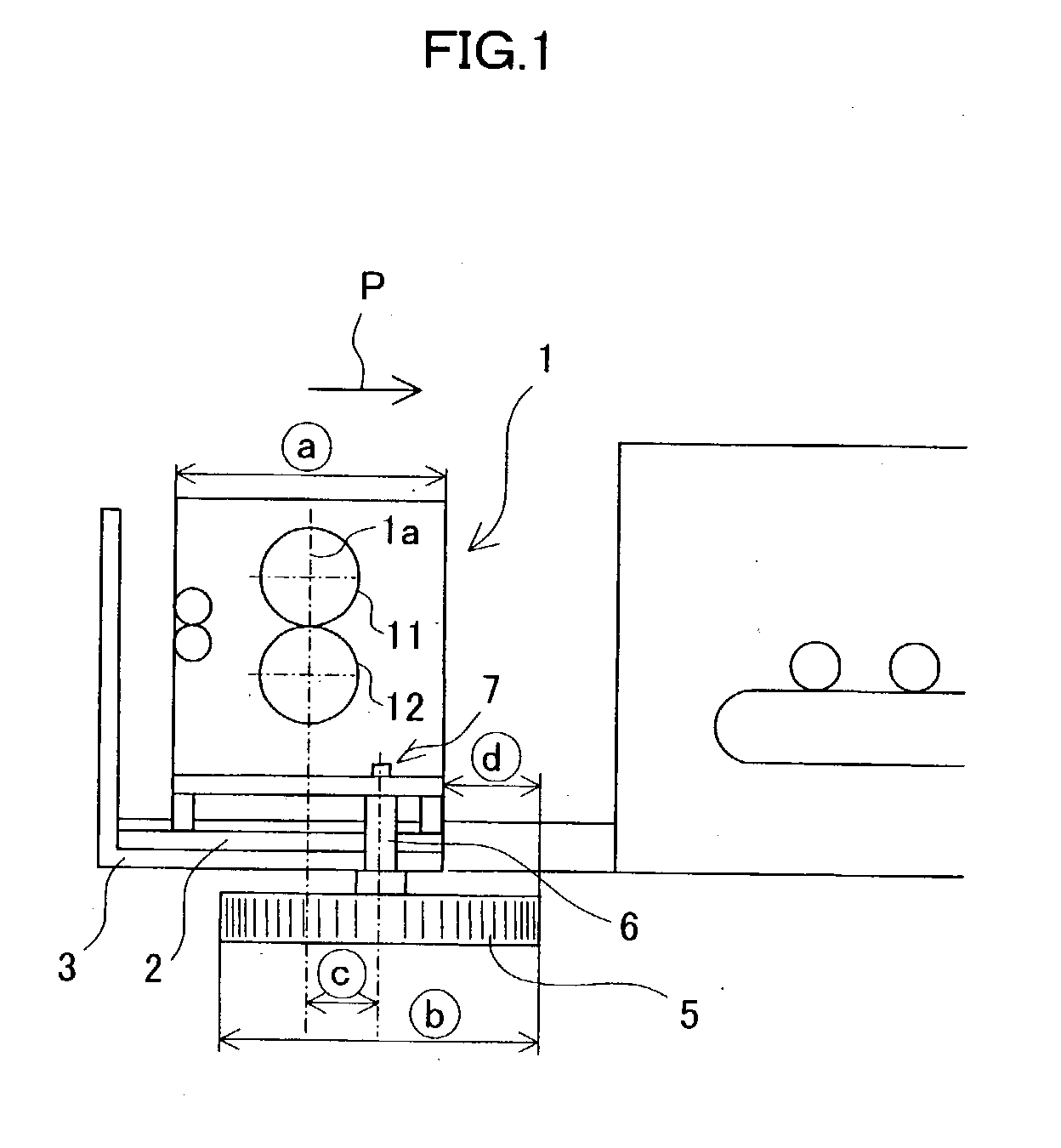

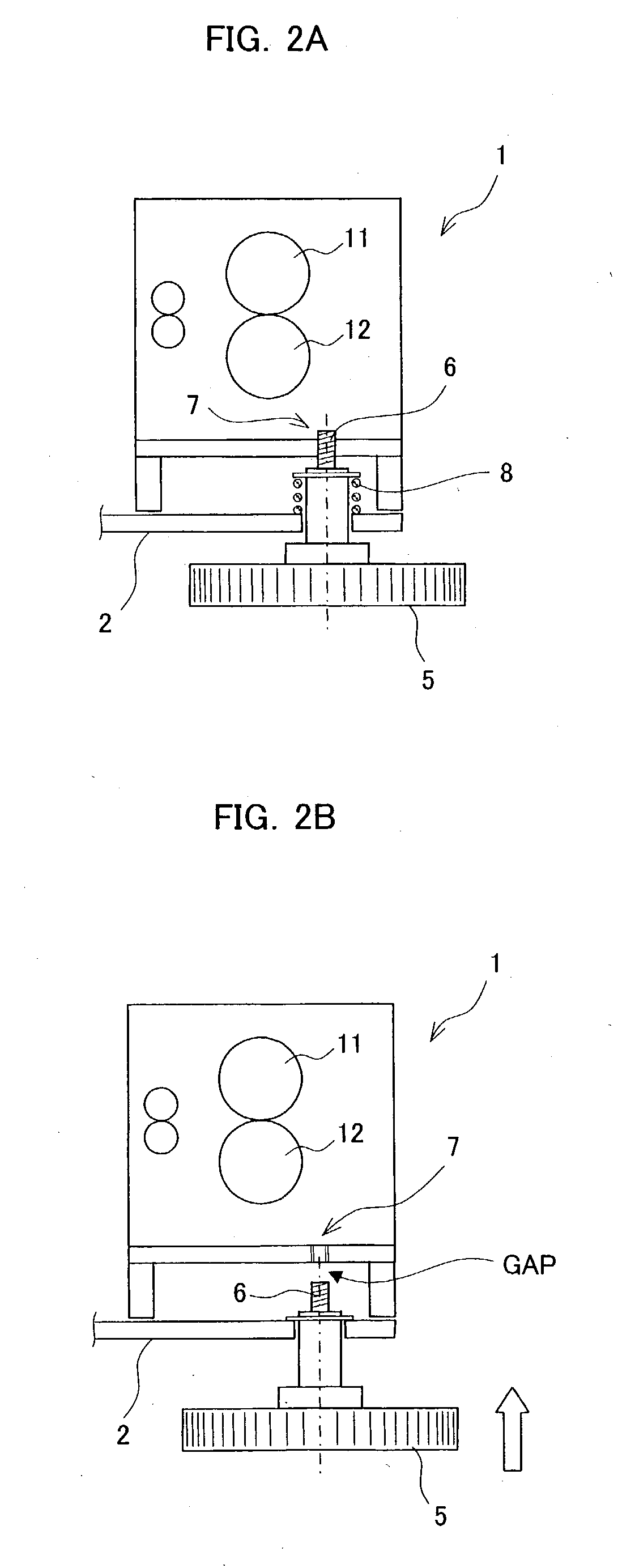

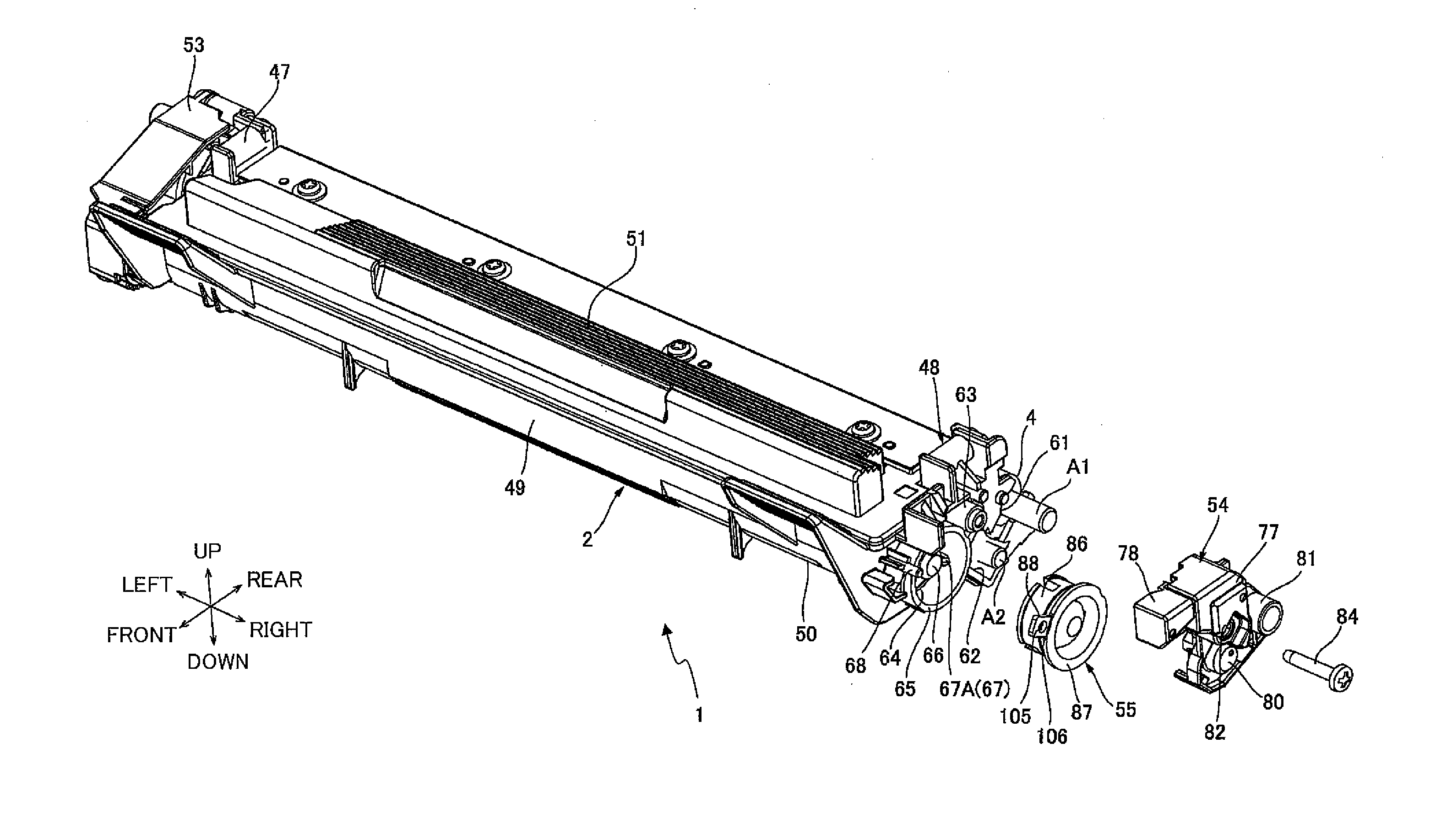

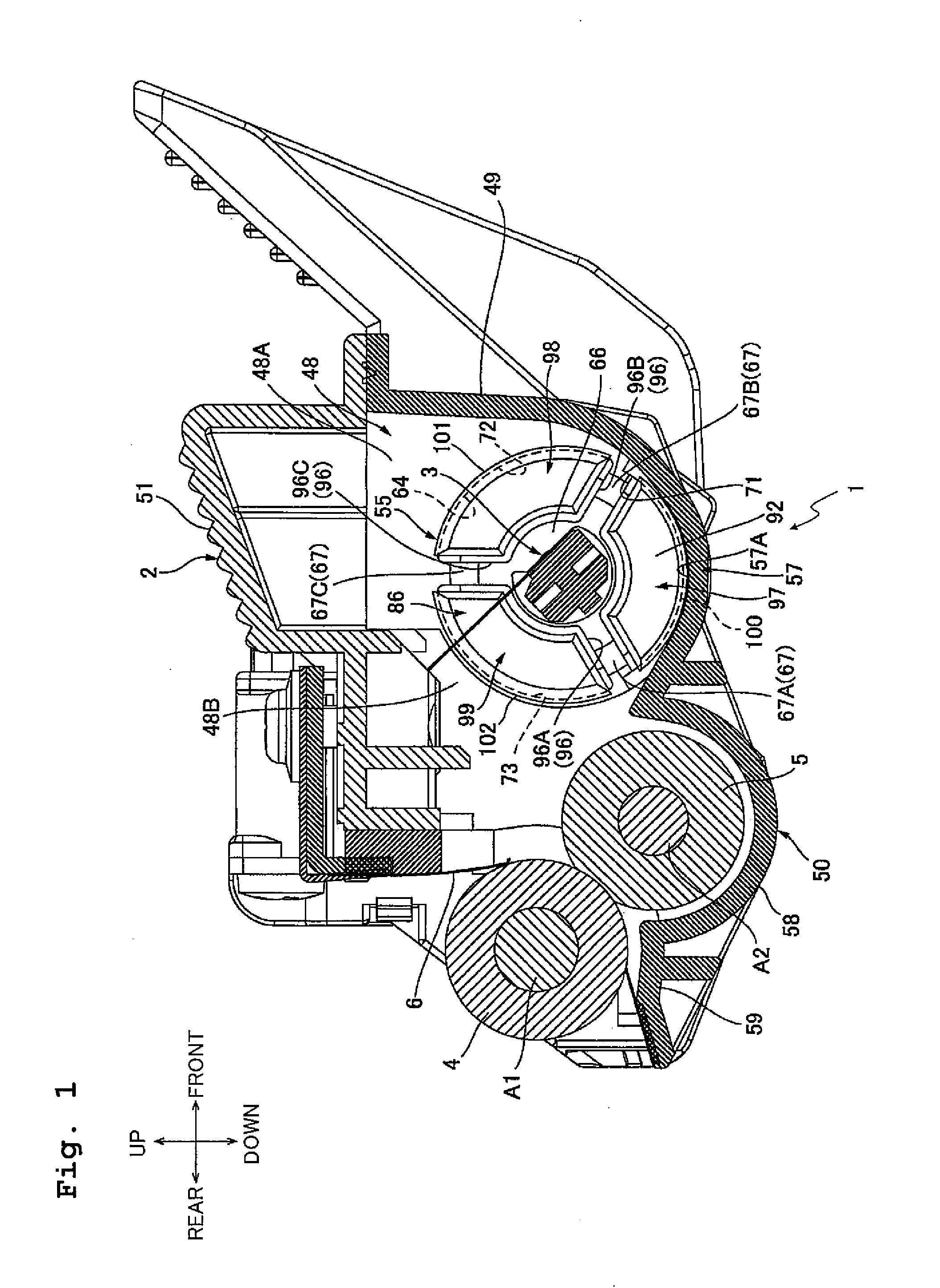

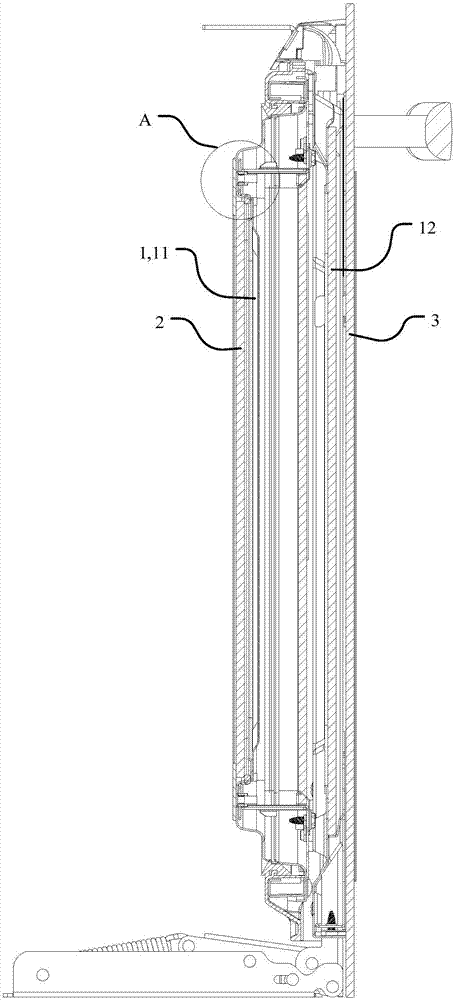

Functional unit support mechanism and image forming apparatus provided with the support mechanism

ActiveUS20030219277A1Work safely and efficientlyReliable installationElectrographic process apparatusOther printing apparatusScrew threadEngineering

Owner:SHARP KK

Mounting and fixing device and mounting method for capacitive gap sensor

InactiveCN109539966AReliable installationGuaranteed stable workUsing electrical meansEngineeringElectrical and Electronics engineering

The present invention provides a mounting and fixing device and a mounting method for a capacitive gap sensor. The device comprises a fixing member, the fixing member comprises a fixing piece, the outer surface of the fixing piece is wound with a metal piece, the fixing piece is located in a gap formed between the capacitive gap sensor and an engine part, the surface of one side of the metal pieceis closely adhered to the end face of the capacitive gap sensor, the surface of the other side of the metal piece is closely adhered to the surface of the engine part, and the capacitive gap sensor is arranged on the engine part. The mounting and fixing device and the mounting method for a capacitive gap sensor employ a mode of winding and filling by employing the metal piece and cooperating withspot welding and fixing to allow the capacitive gap sensor to be closely mounted at the engine measurement portion to ensure that the capacitive gap sensor can be reliably mounted in a narrow and irregular space and ensure the stable work of the sensor in the engine test process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cartridge and lid member for cartridge

ActiveUS20150117907A1Downsizing of cartridgeReliable installationElectrographic process apparatusEngineeringMechanical engineering

There is provided a cartridge, including: a casing including an inlet portion configured to be filled with a developer; and a lid member configured to close the inlet portion by being installed to the inlet portion from an installation direction, wherein the casing includes a first protruding portion which projects inward beyond an inner surface of the inlet portion in a direction perpendicular to the installation direction; and the lid member includes a recessed portion which is recessed from an outer surface of the lid member in the direction perpendicular to the installation direction and is configured to be engaged with the first protruding portion in a case that the lid member is installed to the inlet portion.

Owner:BROTHER KOGYO KK

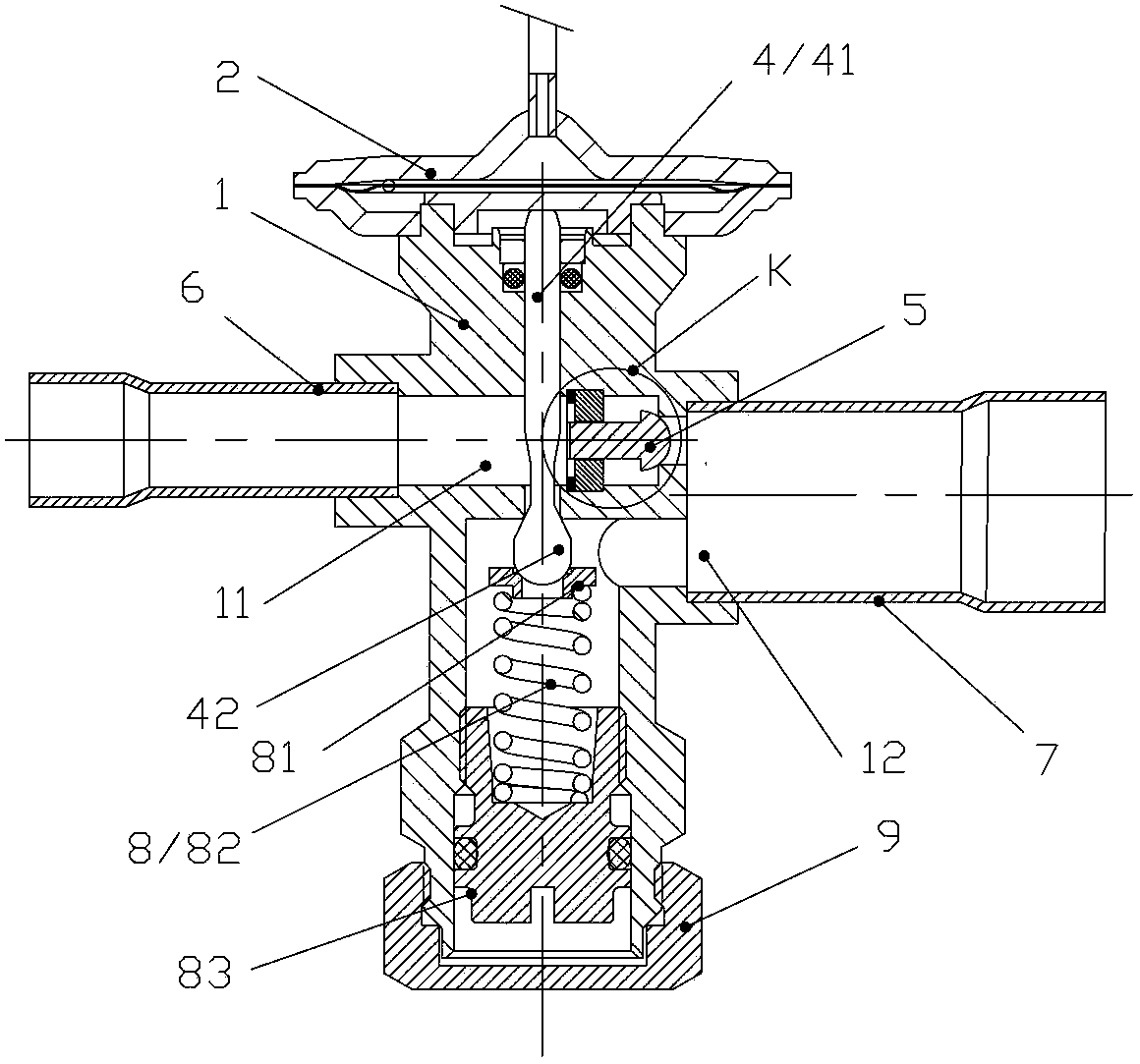

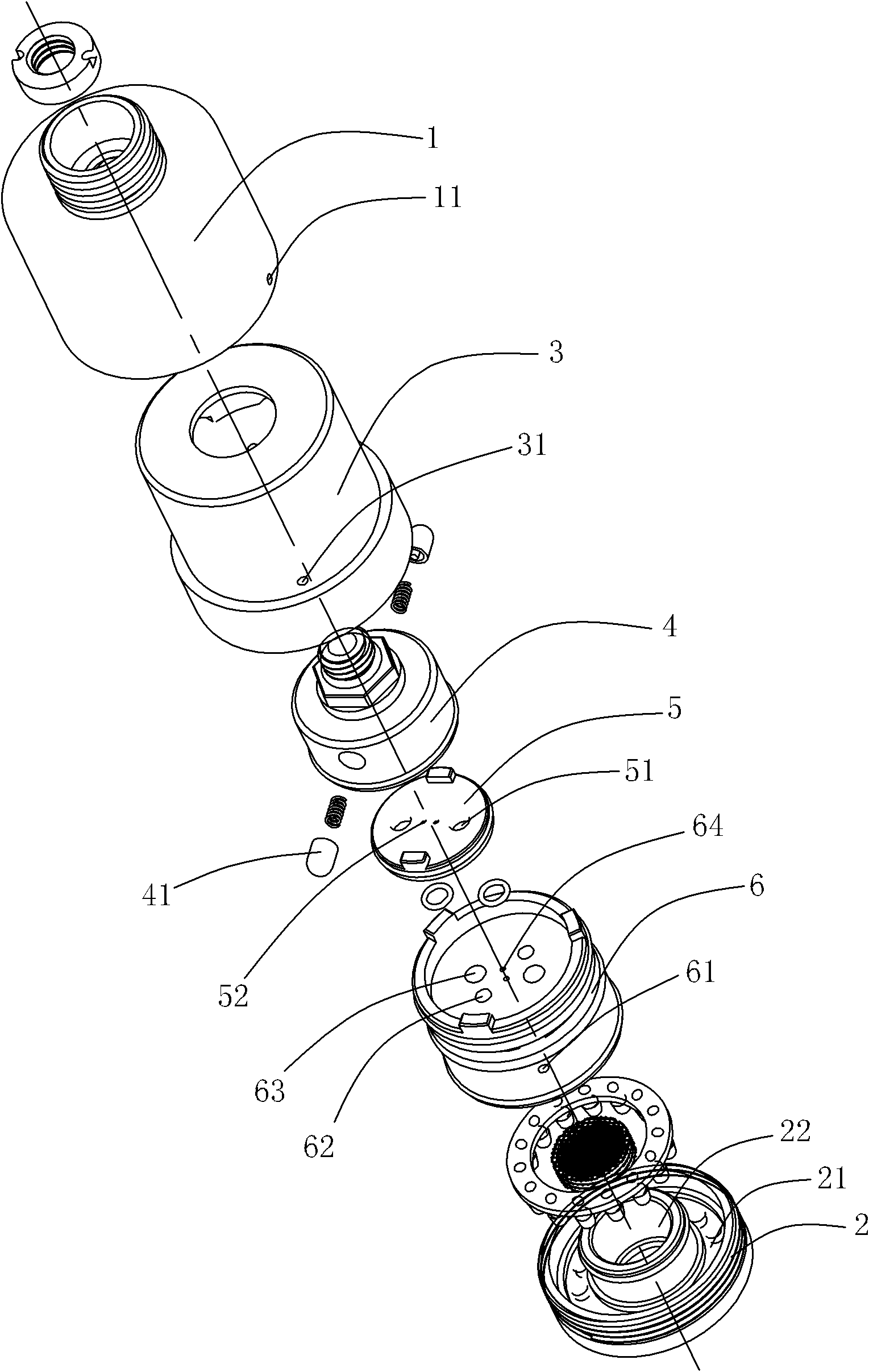

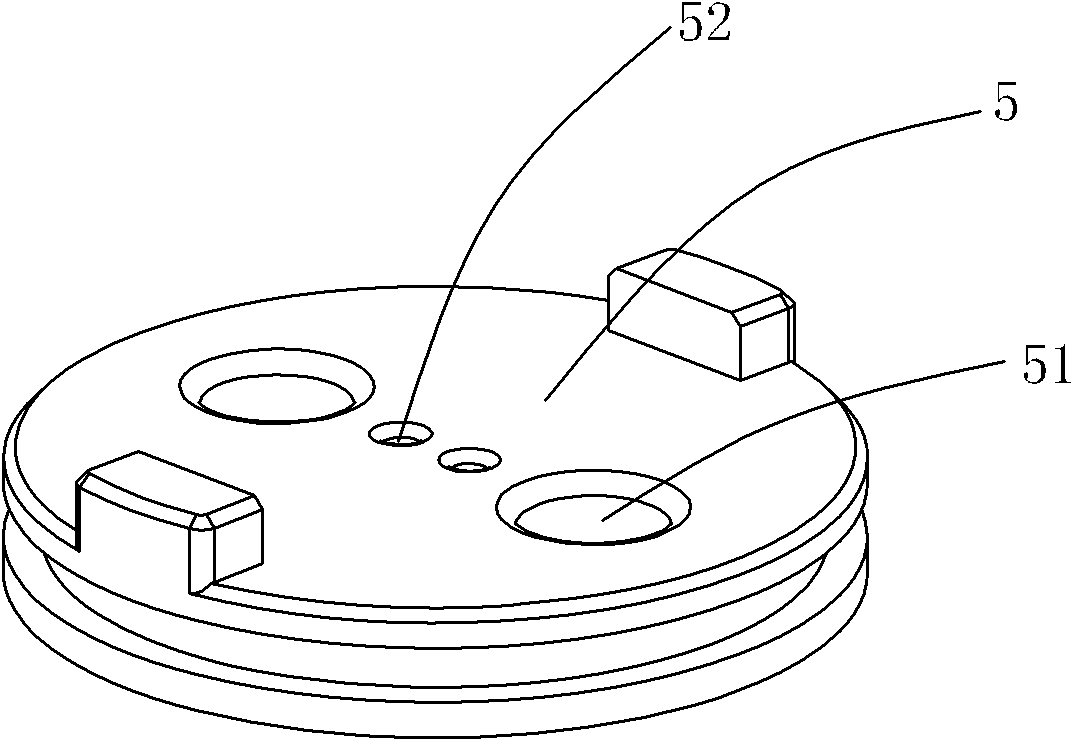

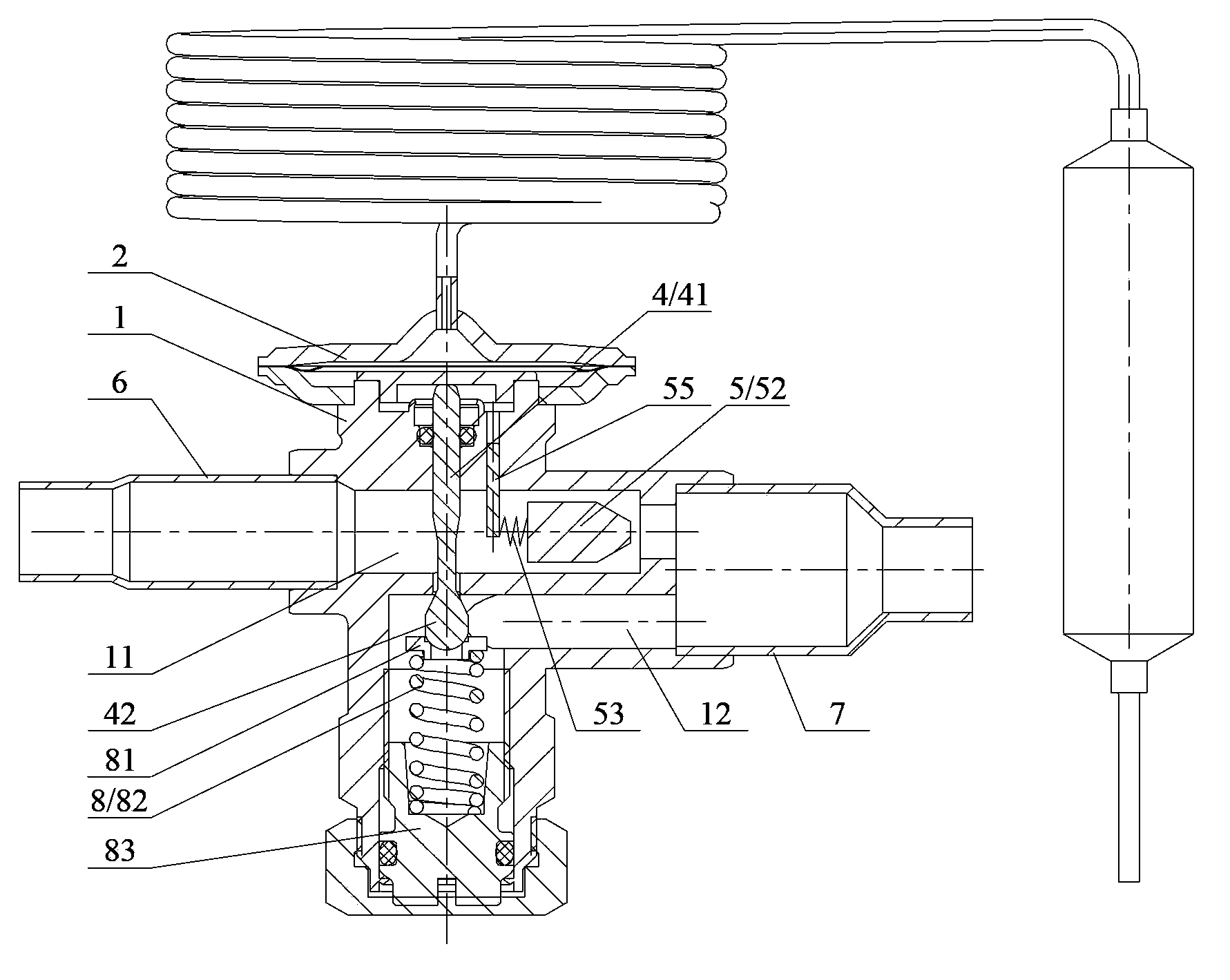

Thermal expansion valve with unidirectional control function

ActiveCN103791663ASimple structure processingReliable installationFluid circulation arrangementMechanical apparatusControl functionValve stem

The invention discloses a thermal expansion valve with a unidirectional control function. The thermal expansion valve comprises a valve body having an inlet passage and an outlet passage, a temperature sensing part disposed at one end of the valve body, and a first spool part disposed in an inner cavity of the valve body. The first spool part comprises a valve stem and a first spool; the valve stem is abutted to the temperature sensing part; the first spool coordinates with a first valve port in the inner cavity to control the quantity of medium fluid flowing from the inlet passage to the outlet passage. The valve body further comprises an accommodating portion extending from the inlet passage to the inside of the valve body. The accommodating portion is provided with a second valve port. A second spool part is disposed in the accommodating portion. A limit pin used for limiting an opening position of the second spool part is further disposed in the accommodating portion. When the medium flows from the inlet passage to the outlet passage, the second valve port is closed; when the medium flows from the outlet passage to the inlet passage, the second valve port opens. Compared with the prior art, the thermal expansion valve has the advantages that the influence upon flow capacity of the unidirectional valve is effectively decreased on the premise of improving manufacturability.

Owner:浙江三花商用制冷有限公司

Lifted and pulled water-retaining cover

InactiveCN105750672ASimple structureReliable installationElectrical-based auxillary apparatusMagnetArchitectural engineering

Owner:上海略云精密数控机床有限公司

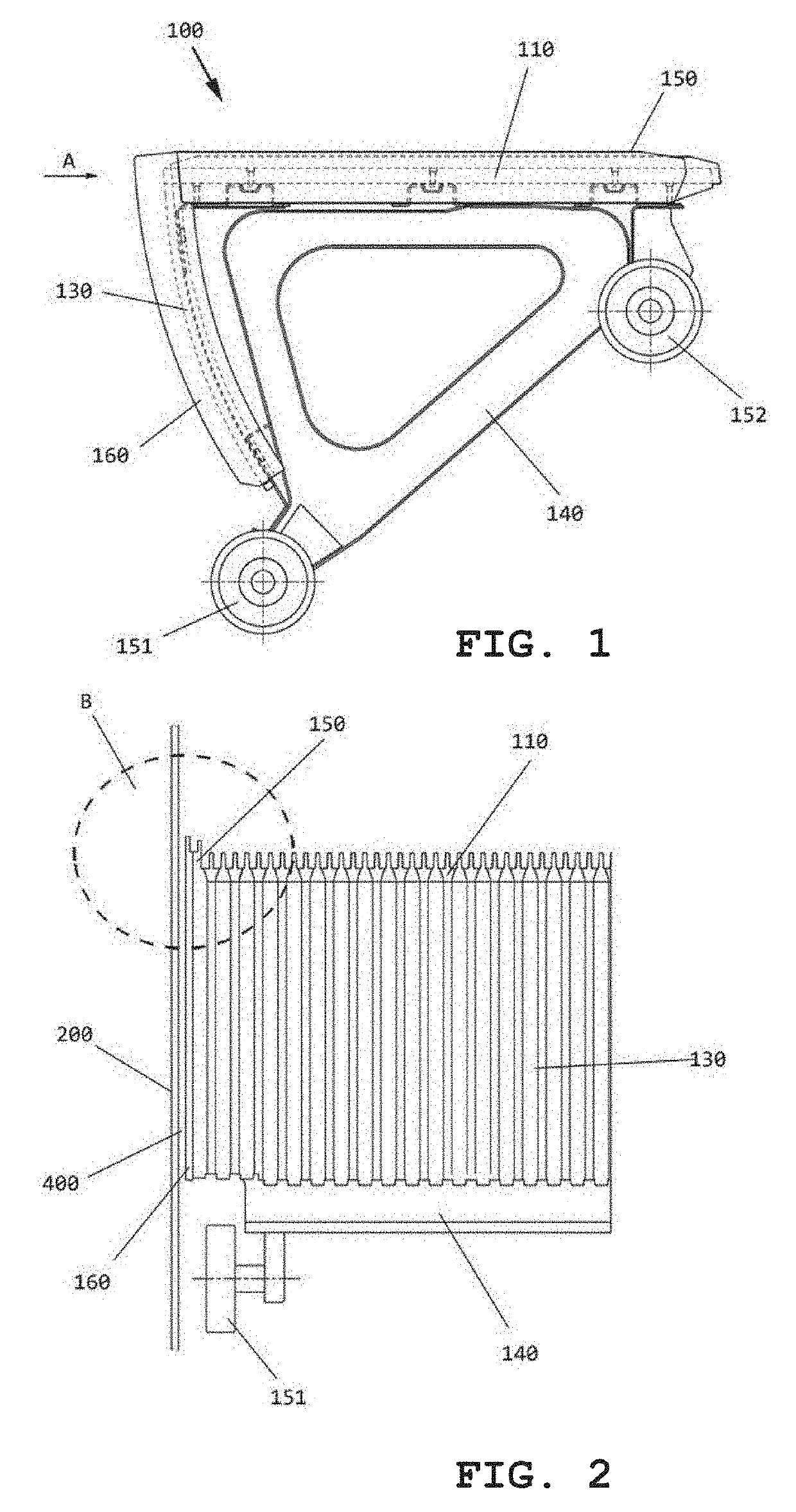

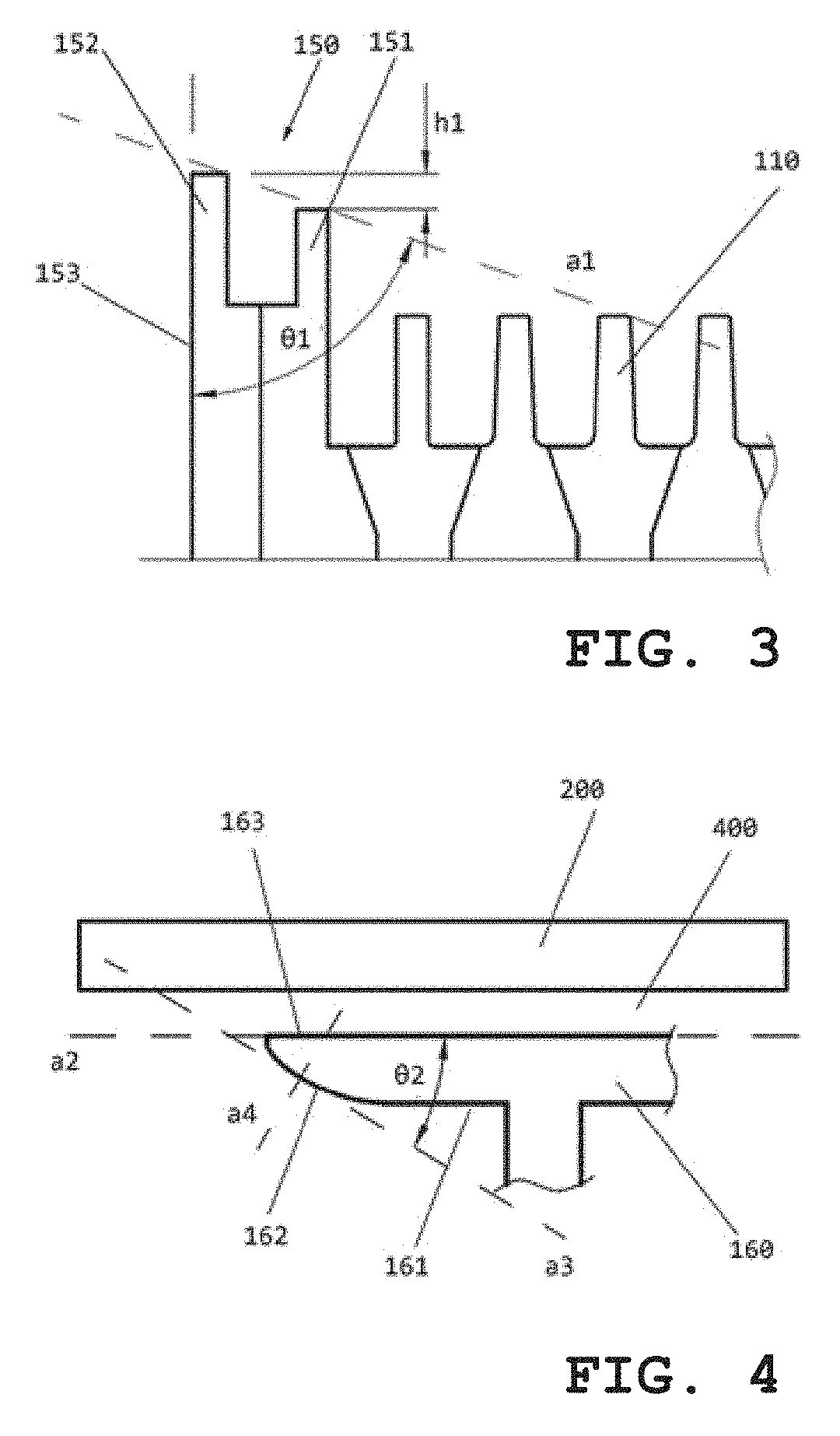

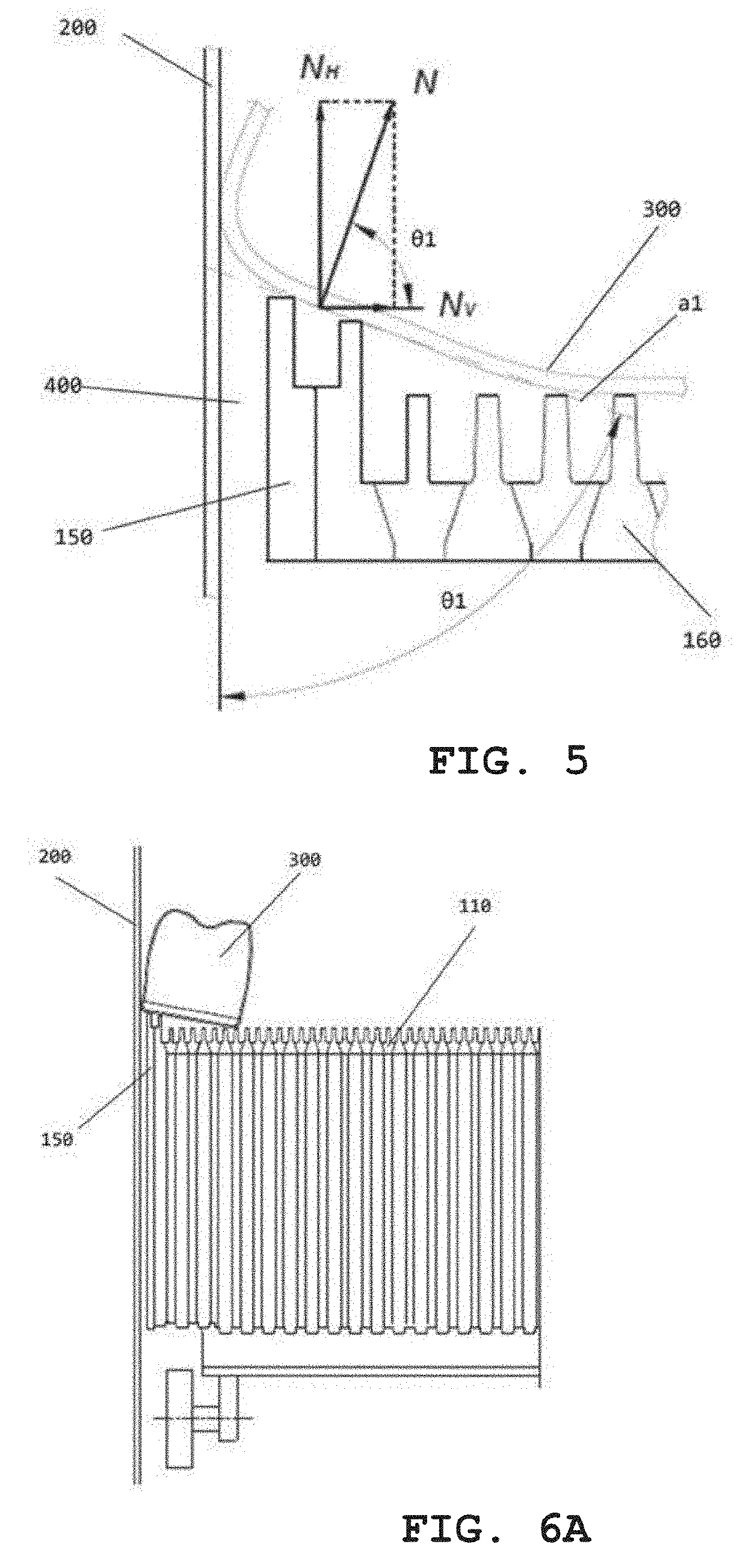

Passenger transferring device

ActiveUS20190263632A1Simple structureReliable installationEscalatorsEngineeringMechanical engineering

A passenger conveying device, including: an entrance, an exit, and a plurality of steps disposed between the entrance and the exit. A skirt guard panel is respectively disposed on two sides of the step, and the step is constructed to reciprocally move between the entrance and the exit along a path defined by the skirt guard panel. The step includes a tread, a tread guard panel is attached to each of two sides of tread, and the tread guard panel is located between the tread and the skirt guard panel. The tread guard panel includes two or more protrusions, each protrusion is constructed to protrude with respect to an upper surface of the tread, and a protrusion farther away from the tread has a larger protrusion height. The passenger conveying device of the present invention has the advantages of simple structure, reliable installation, and convenient maintenance.

Owner:OTIS ELEVATOR CO

Door of household appliance and oven with door

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Novel oil separator

InactiveCN106369897AReliable installationGuaranteed cleanlinessRefrigeration componentsEvaporatorHigh pressure

The invention discloses a novel oil separator which comprises an inertial oil separator body and a filtering oil separator body, wherein the inertial oil separator body comprises a cylinder I, supporting legs I, a baseplate, a gas inlet pipe I, a gas outlet pipe I and an oil return pipe I; the filtering oil separator body comprises a cylinder II, supporting legs II, a gas inlet pipe II, a gas outlet pipe II, a first oil return pipe II and a second oil return pipe II; the baseplate is of a triangular structure; an observation window I is arranged on the side wall of the cylinder I; an observation window II is arranged on the side wall of the cylinder II; a metal wire filtering screen is arranged at the inner top end of the cylinder II, takes the shape of a hemispherical curved surface, and is fixedly connected with the inner wall of the cylinder II; a gap is reserved between the metal wire filtering screen and the inner wall of the cylinder II; a gas outlet pipe shield is arranged at the lower end of the metal wire filtering screen; an end part of the gas outlet pipe II is positioned at the middle of the gas outlet pipe shield; and an oil collecting tank is arranged on the inner wall of the lower part inside the cylinder II. The novel oil separator disclosed by the invention is used for separating out lubricating oil in high-pressure gas and solving the problems that the heat transfer effect is impacted and the refrigerating efficiency is reduced because excessive lubricating oil enters a condenser and an evaporator.

Owner:WUHU SANHUA REFRIGERATION FITTINGS

LED lamp convenient to maintain

InactiveCN108709166ASimple and ingenious structureReliable installationLight fasteningsSemiconductor devices for light sourcesEngineeringLED lamp

The invention discloses an LED lamp convenient to maintain. The LED lamp comprises a bottom shell, an LED substrate, a driving module and a top cover; the LED substrate is mounted at the inner side bottom of the bottom shell; the driving module is mounted at the top of the LED substrate; and four loop bars are distributed at the top edge of the bottom shell around the circle center in an equal angle mode. A bolt is rotated to drive a second sleeve to rotate, under rotating of the second sleeve, the angle of four transverse rods is deflected, and therefore limiting rod can be pushed to move; under the push force, the limiting rods penetrate through one sides of sleeves and extend into inner cavities of the loop bars to clamp the loop bars and the sleeves and complete fixing installation ofthe top cover and the bottom shell. During disassembly, the bolt is rotated to the opposite direction to disassemble the LED lamp easily. The structure is simple and ingenious; and only one bolt is needed to complete disassembly and installation of the LED lamp, the installation effect is stable and reliable, and maintenance is convenient.

Owner:CHENGDU YIRUIXIN TECH CO LTD

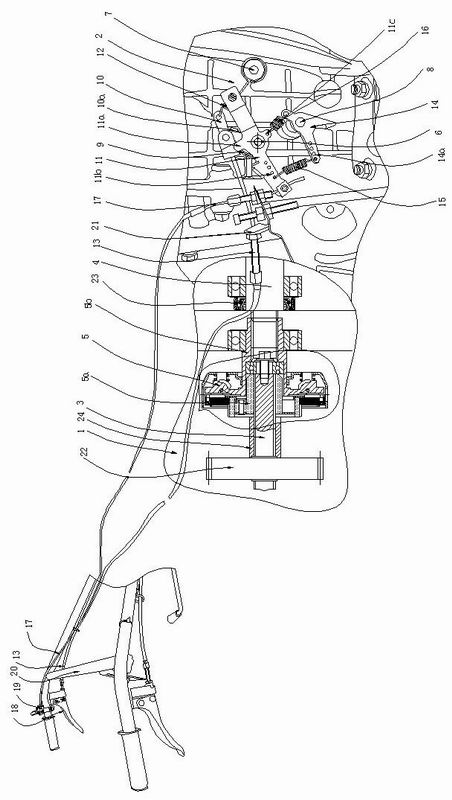

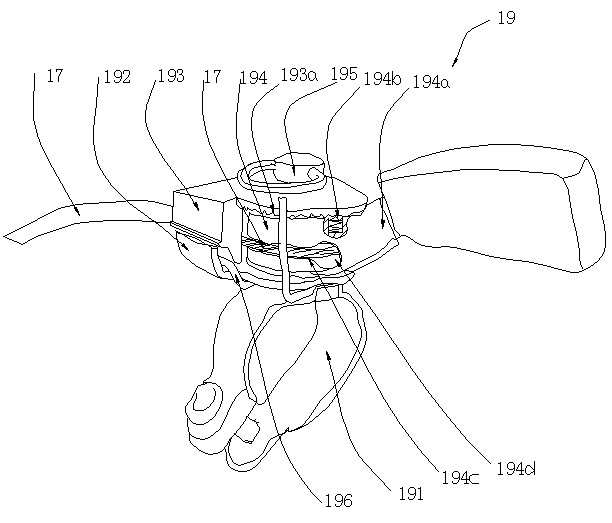

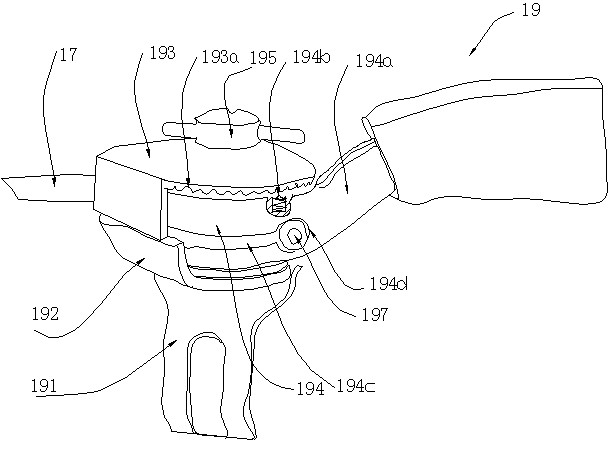

Micro-cultivator

InactiveCN102072027ASimple and reliable connectionReliable installationCasingsEngine controllersClutchEngineering

The invention discloses a micro-cultivator. A clutch capable of automatically clutching is installed between an output shaft and a crank shaft; a crank shaft box body is provided with an operating arm mounting post and a spring mounting post provided with a return support, wherein the operating arm mounting post is successively sheathed with an accelerator return torsional spring, the return support and an accelerator operating arm from inside to outside; the accelerator is provided with an accelerator arm; a return stay wire spring is connected between the right end of the return support andthe spring mounting post; the left end of the return support is connected with an accelerator return stay wire connected with a shutdown handle; the middle of the accelerator operating arm is installed on the accelerator arm mounting post; the middle of the accelerator arm is installed on the accelerator; a refuelling spring and an fuel return spring which are respectively positioned on the left side and the right side of the accelerator are connected between the accelerator operating arm and the accelerator arm; an accelerator wire is connected between the accelerator operating arm and a control device; and the return support and the accelerator operating arm are respectively and correspondingly provided with a pushing support lug and a stirring support lug. The micro-cultivator can better automatically clutch, accelerate, idle and stop.

Owner:周树明 +1

Bus duct connector with high protection grade

InactiveCN107069618AReliable installationDimensionally stableTotally enclosed bus-bar installationsButt joining bus-barsHead gasketBusbar

The invention provides a busway connector with high protection level, which is provided with a positioning boss to ensure reliable and fast installation of the connector and stable dimensions; a waterproof sealing ring and a waterproof sealing strip are provided, which can play a better waterproof effect. , to ensure that the connector is in a dry state, avoid short circuit between lines, and the protection level can reach IP65; the maximum torque of the torque bolt is 70Nm, the torque value is high, and the performance is stable; the four-corner nut is located at the opening of the limit slot. This structure can ensure that the nut will not rotate with the bolt during the process of screwing the torque bolt, so that the tightening operation is more convenient; the torque bolt is provided with an inner head, an outer head, and a gasket. , the outer head will be disconnected, so the installation is convenient without torque wrench inspection. The setting of the gasket can prevent the staff from carelessly clamping and screwing the outer head and inner head of the torque bolt with a wrench at the same time, resulting in the occurrence of the outer head Unbreakable condition.

Owner:鼎圣集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com