System and method for detection of band saw blade sawtooth wear loss

A technology of wear amount detection and band saw blades, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large man-hours, missing information, unfavorable quality and performance, etc., achieve simple installation methods, avoid human errors, and improve wear The effect of test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

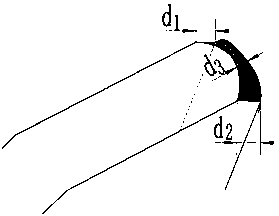

[0053] Such as Figure 4 to Figure 6 As shown, in the system for detecting the sawtooth wear of the band saw blade, a Cartesian coordinate system is established at any position of the system, wherein the Y axis of the Cartesian coordinate system extends along the width direction of the band saw blade to be detected, and the Z axis Extending along the thickness direction of the band saw blade to be detected, the X-axis extends along a direction perpendicular to the plane determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com