Water proof device of open driving part in water jet loom

A water-jet loom and waterproof device technology, applied to looms, other opening mechanisms, textiles, etc., can solve problems such as adhesion, high humidity, corrosion, etc., and achieve reliable and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

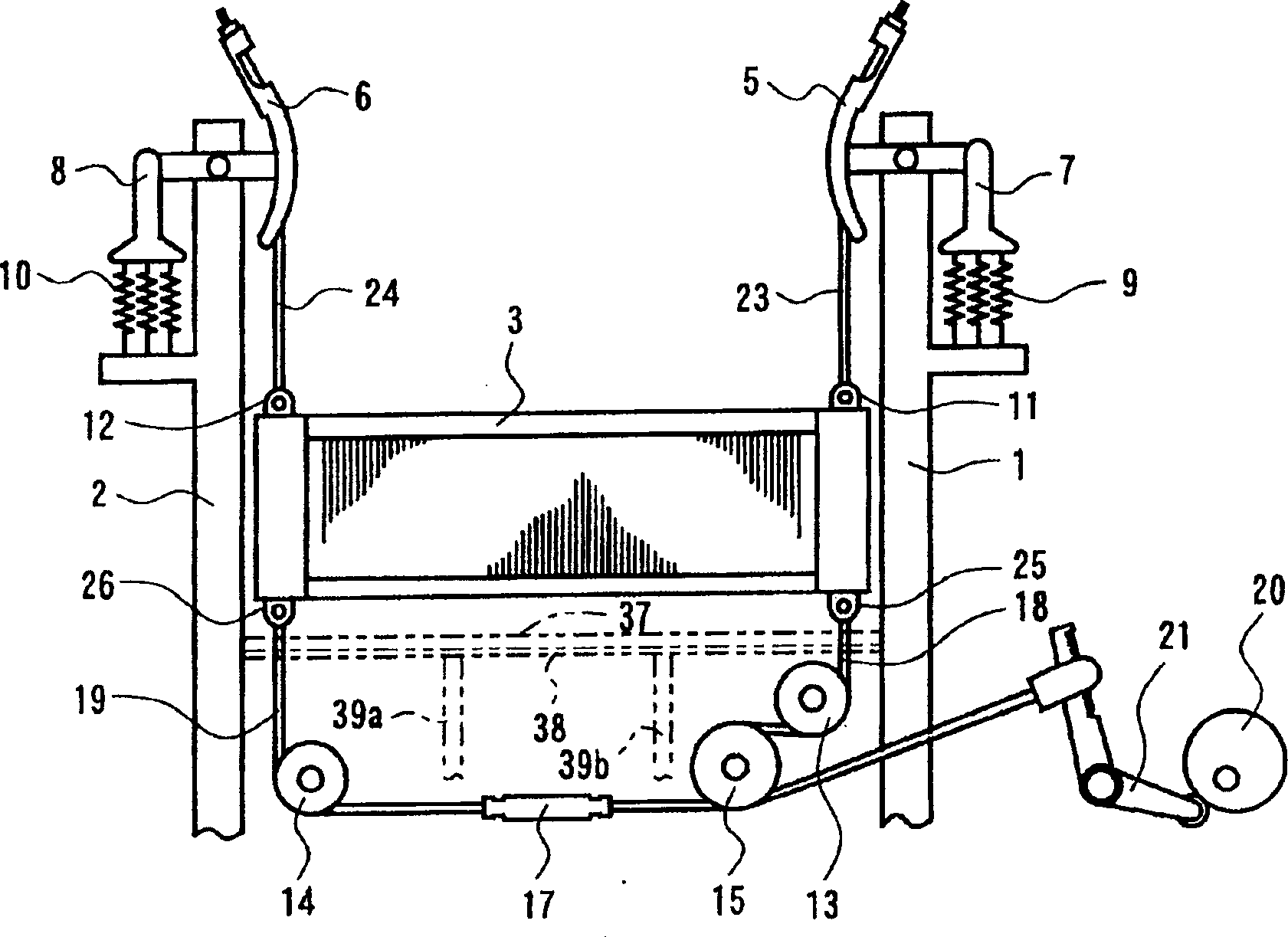

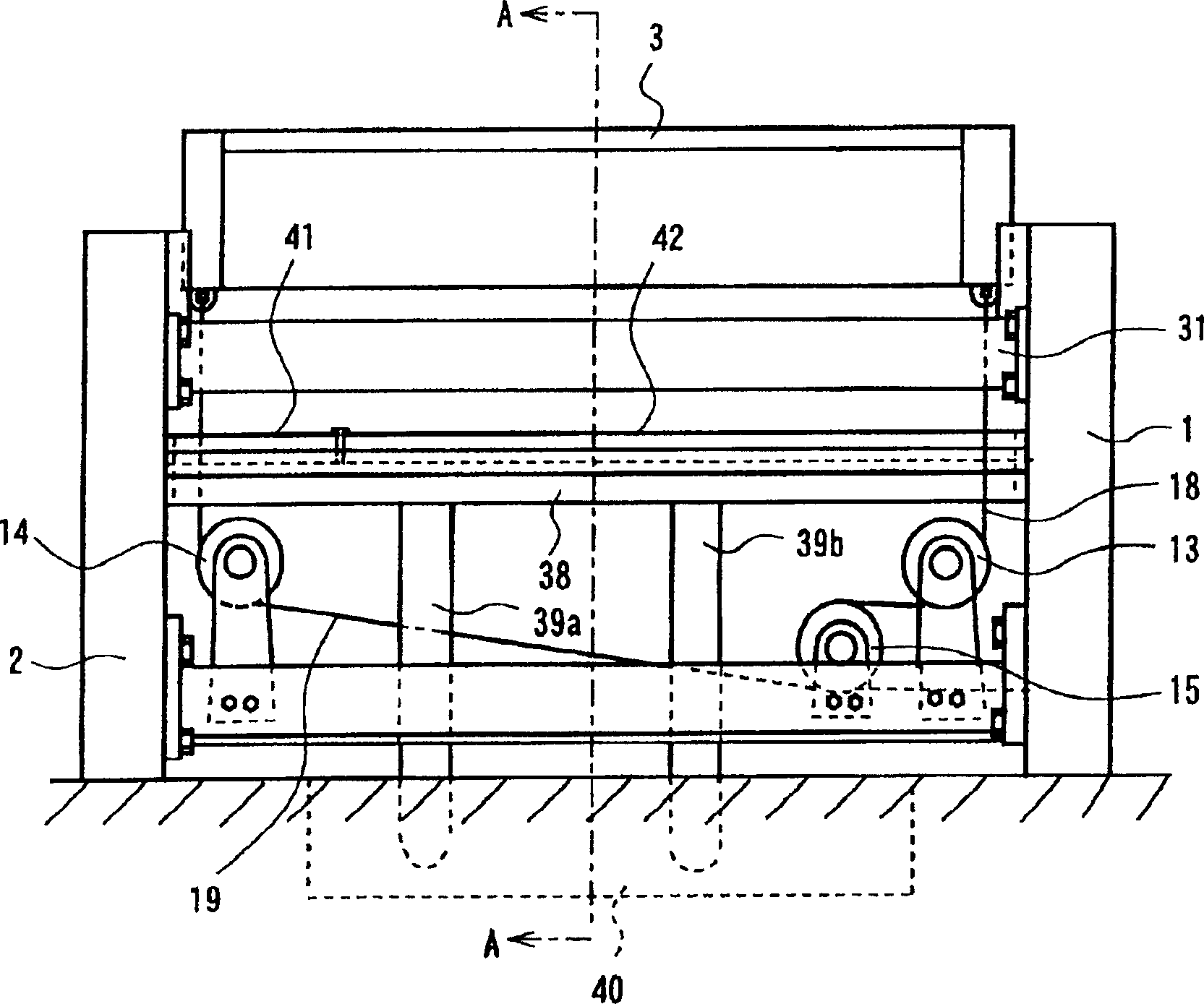

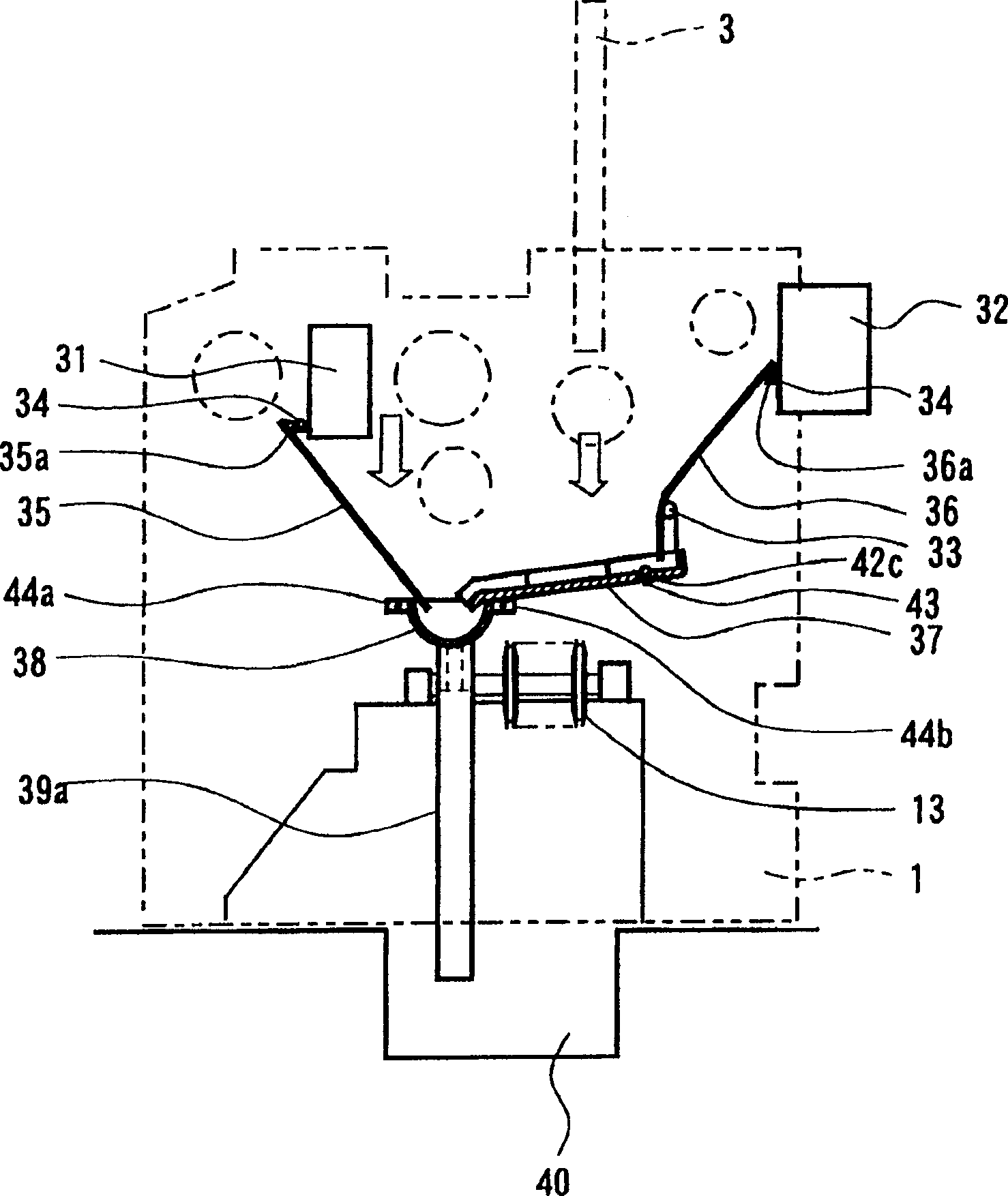

[0035] Below, according to Figure 1 to Figure 5 The first embodiment will be described.

[0036] figure 1 It is a schematic configuration diagram illustrating the passive shedding device of the water jet loom embodying the present invention. A heald frame 3 is provided between frames 1 and 2, and ropes are attached to accessories 11 and 12 on the left and right upper parts of the heald frame 3 23,24, these ropes 23,24 are connected on the hanging heald rods 5,6. Spring hangers 7, 8 are locked on the aforementioned hanging heald rods 5, 6, and due to the action of the springs 9, 10, the aforementioned ropes 23, 24 are always in a state of upward tension.

[0037] Also, ropes 18, 19 are installed on the fittings 25, 26 of the left and right lower parts of the aforementioned heald frame 3. on the frame drive mechanism. A wire tensioner 17 and the like for adjusting the length of the ropes 18 and 19 are provided in the middle of the aforementioned ropes 18 and 19 . The above...

no. 2 Embodiment approach

[0062] Below, according to Figure 5 and Figure 6 A modified example of the waterproof device for the opening drive unit in the water jet loom according to the first embodiment will be described.

[0063] A waterproof device for an opening drive unit according to a second embodiment is formed by integrally forming the upper groove and the middle groove in the first embodiment.

[0064] Therefore, here, for convenience of description, part of symbols described above are commonly used, description of common structures is omitted, and only changes are described.

[0065] Such as Figure 5 As shown, the waterproof groove 51 is composed of the following parts: a flat plate portion 52 formed by transparent resin material or glass material and guiding water from the rear to the front; a barrel portion located at the front end of the flat plate portion 52 for collecting water and draining 53; partition walls 54, 55, 56 erected on the periphery of the flat plate portion 52 to preve...

no. 3 Embodiment approach

[0083] based on the following Figure 7 and Figure 8 Other modified examples will be described.

[0084] The waterproof device of the opening driving part according to the third embodiment is formed by integrally forming the above-mentioned intermediate groove and the hose in the above-mentioned first embodiment.

[0085] Therefore, here, for convenience of description, some of the symbols described above are commonly used, the description of the common structure is omitted, and only the changed parts will be described.

[0086] Such as Figure 7 As shown, the discharge tank 71 is formed of a transparent resin material or glass material, and consists of a barrel portion 72 that collects water falling from above, a storage portion 75 formed below the central portion of the barrel portion 72, and a drain connected thereto. Part 73 constitutes.

[0087] The barrel portion 72 is formed by side walls 72a, 72b, bottom plates 72e, 72f, and side plates 72c, 72d formed along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com