Lifted and pulled water-retaining cover

A technology for a water blocking cover and a cover plate, which is applied to electric processing equipment, metal processing equipment, accessories, etc., can solve the problems of the weight and volume of the water blocking cover, trouble for operators, deformation of doors, inability to adjust the height, etc., so as to solve the problem of workpiece The installation operation is difficult, the installation difficulty is solved, and the installation is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

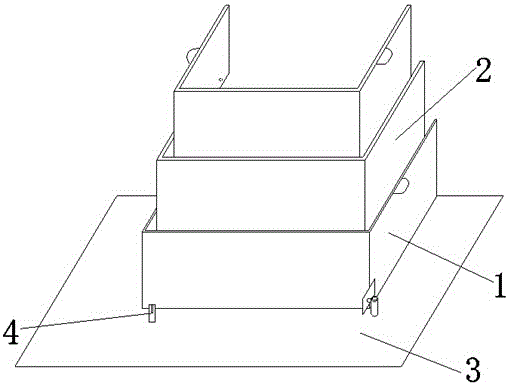

[0017] refer to figure 1 A lifting water retaining cover as shown includes an outer cover plate 1 and a two-layer inner cover plate 2. Both the outer cover plate 1 and the inner cover plate 2 are concave structures composed of three panels; Installed on the worktable 3 of the wire EDM machine.

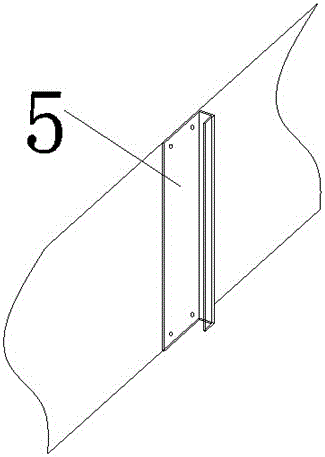

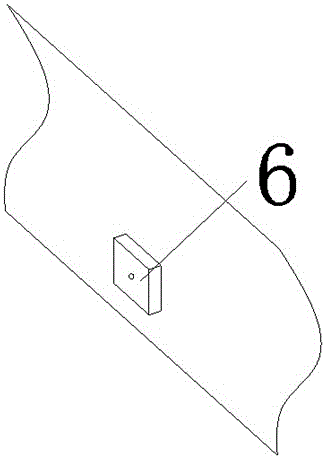

[0018] refer to figure 2 and image 3 As shown, the inner sides of the two opposite panels of the outer cover plate 1 are respectively provided with a unilateral iron groove 5 along the vertical direction, and the outer sides of the two opposite panels of the inner cover plate 2 are correspondingly equipped with a matching unilateral iron groove 5. Magnet 6, the inner side of the two opposite panels of the inner cover plate 2 are also respectively provided with a unilateral iron slot 5 along the vertical direction, and the unilateral iron slot 5 and the magnet 6 on both sides of the same inner cover plate 2 do not overlap each other. , so as not to affect the adsorption between two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com