Novel oil separator

An oil separator, a new type of technology, used in refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of reduced life, reduced heat transfer effect of condensers and evaporators, compressor failures, etc., to ensure cleanliness. , Prevent foreign matter from entering the oil separator, and the effect of stable and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

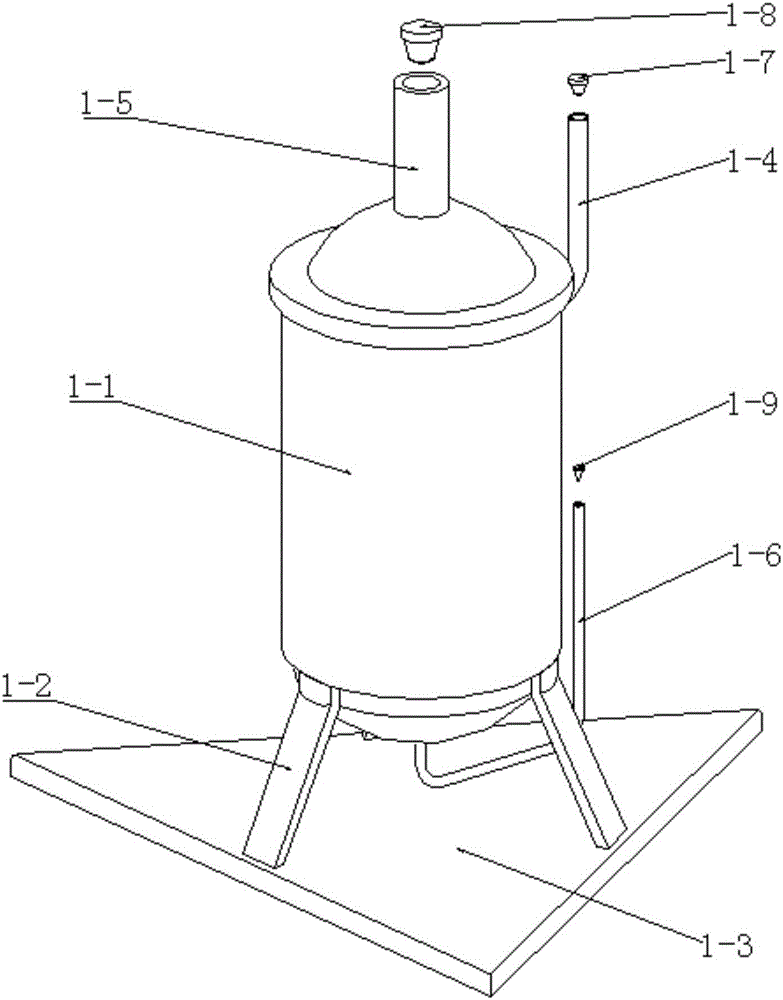

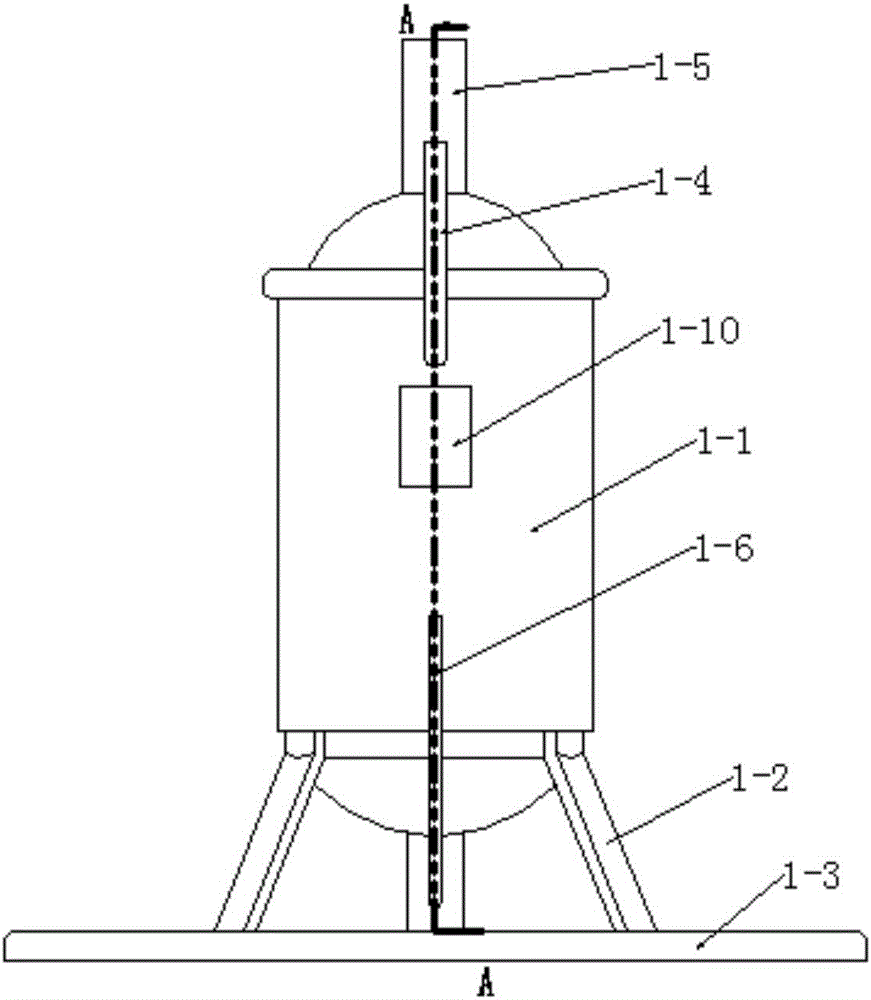

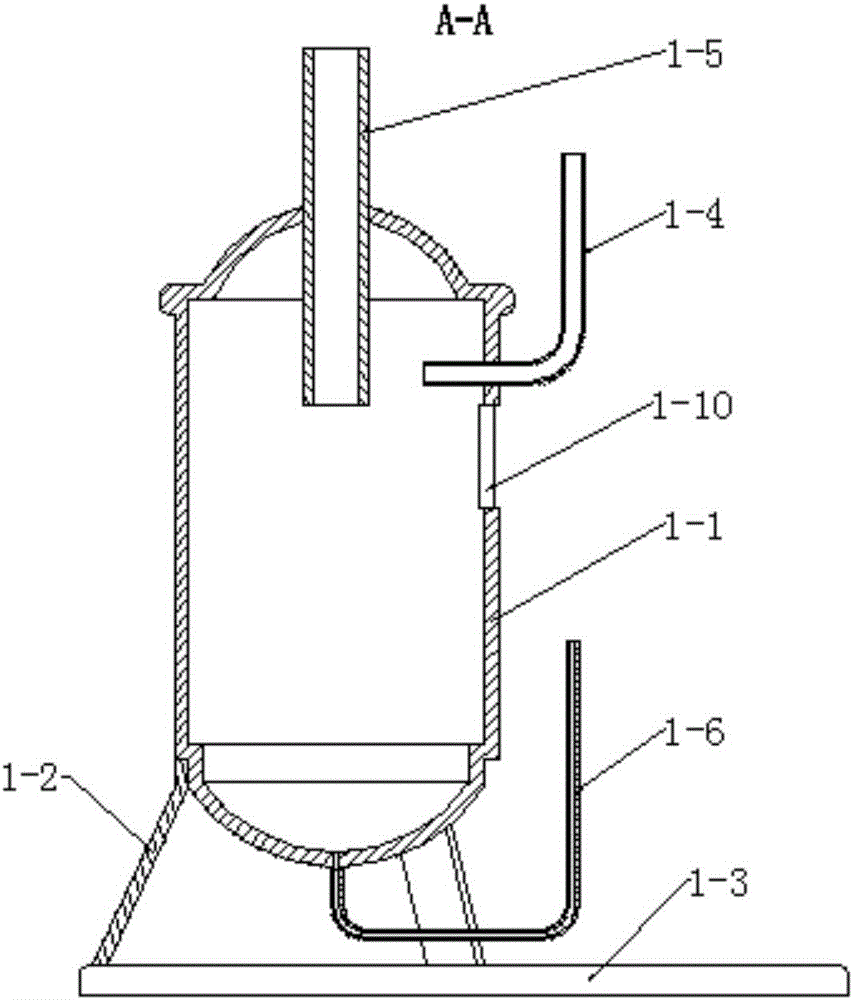

[0026] First, for the inertial oil separator, before we install it, first remove the air inlet sealing plug 1-7 at the air inlet of the air inlet pipe 1-4 and the air outlet at the outlet pipe 1-5. The air outlet sealing plug 1-8 is provided, and the oil return sealing plug 1-9 is provided at the oil outlet of the oil return pipe 1 1-6 to prevent moisture from entering the inertial oil separator and causing parts production. Rust can also prevent foreign matter from entering the inside of the inertial oil separator. Appropriate measures should be taken during the removal operation to prevent damage to the intake pipe 1-1-4, the outlet pipe 1-1-5 and the oil return pipe 1-1-6. The assembly and use of the three procedures, after the inertial oil separator is installed between the compressor discharge port and the condenser, the high-pressure refrigerant vapor with lubricating oil vapor and lubricating oil droplet particles is discharged from the intake pipe 1-1-4 Into the cylinde...

Embodiment 2

[0028] The first choice for the filter oil separator, before we install it, remove the air inlet sealing plug 2 2-10 at the air inlet of the air inlet pipe 2 2-3 and the air outlet of the air outlet pipe 2 2-4. Equipped with air outlet sealing plug two 2-11, the first oil return pipe two 2-5 and the second oil return pipe two 2-6 are equipped with oil return sealing plug two 2-12 at the oil outlet to prevent moisture from entering The inside of the filter oil separator causes the parts to rust, and at the same time, it can prevent foreign matter from entering the inside of the filter oil separator. Appropriate measures should be taken in the removal operation to prevent damage to the intake pipe 2 2-3, the outlet pipe 2 2-4, and the second The first oil return pipe two 2-5 and the second oil return pipe two 2-6 cause damage, which affects the assembly and use of the next process. After installing the filter oil separator between the compressor exhaust port and the condenser, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com