Micro-cultivator

A micro-tiller and throttle technology, which is applied in the field of micro-tillers, can solve the problems that the adjustment handle is not well positioned, the limit is not obtained, and the controllability of the micro-tiller is poor, and the connection is simple and reliable. , Low manufacturing cost, and improved maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

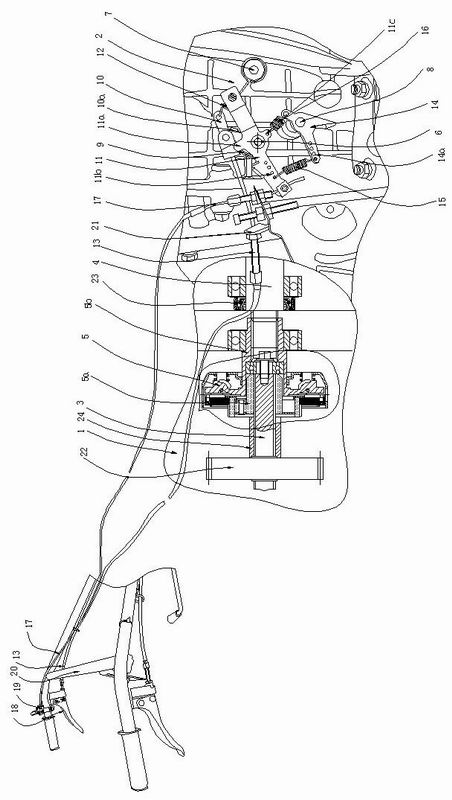

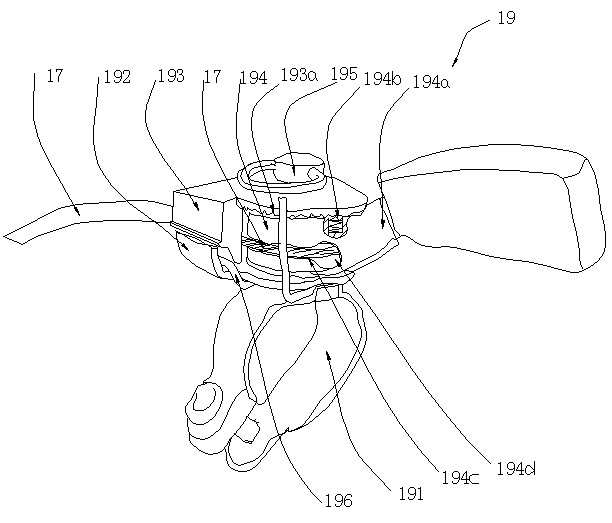

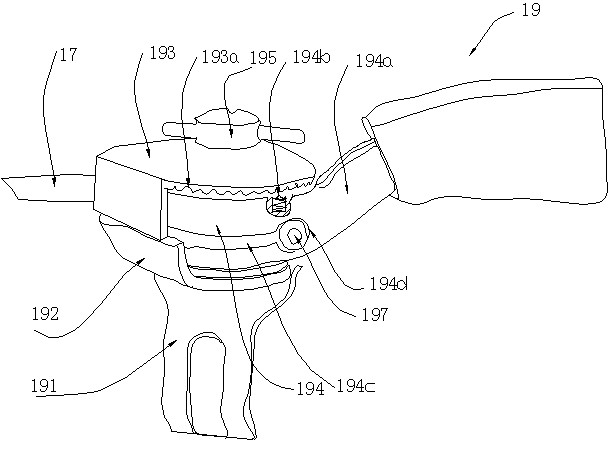

[0025] Such as Figure 1 ~ Figure 4 Shown a kind of tillage machine, is made of components such as deceleration case body 1, crank case body 2, armrest frame 20, and parts such as deceleration case body 1, crank case body 2, armrest frame 20 are prior art, here Not to go into details, the reduction box 1 is fixed on the left side of the crankcase 2, an output shaft 3 is installed in the reduction box 1, a crankshaft 4 is installed in the crankcase 2, and the crankshaft 4. The left end extends into the reduction box body 1, and an oil seal 23 is set on the crankshaft 4. The output shaft 3 and the crankshaft 4 are arranged facing each other, and a driving gear 22 is fixedly sleeved on the left end of the output shaft 3. A clutch 5 is installed between the output shaft 3 and the crankshaft 4, the driven shaft sleeve 5a on the clutch 5 is fixedly sleeved on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com