Bus duct connector with high protection grade

A busway connector and high-protection technology, which is applied in the direction of docking busbars, busbar installation, and fully enclosed busbar devices, etc., can solve the problems that the waterproof effect cannot be guaranteed, the sealant is easy to age and fall off, and affects the safe operation of equipment, etc. Achieve the effect of stable size, high torque value and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

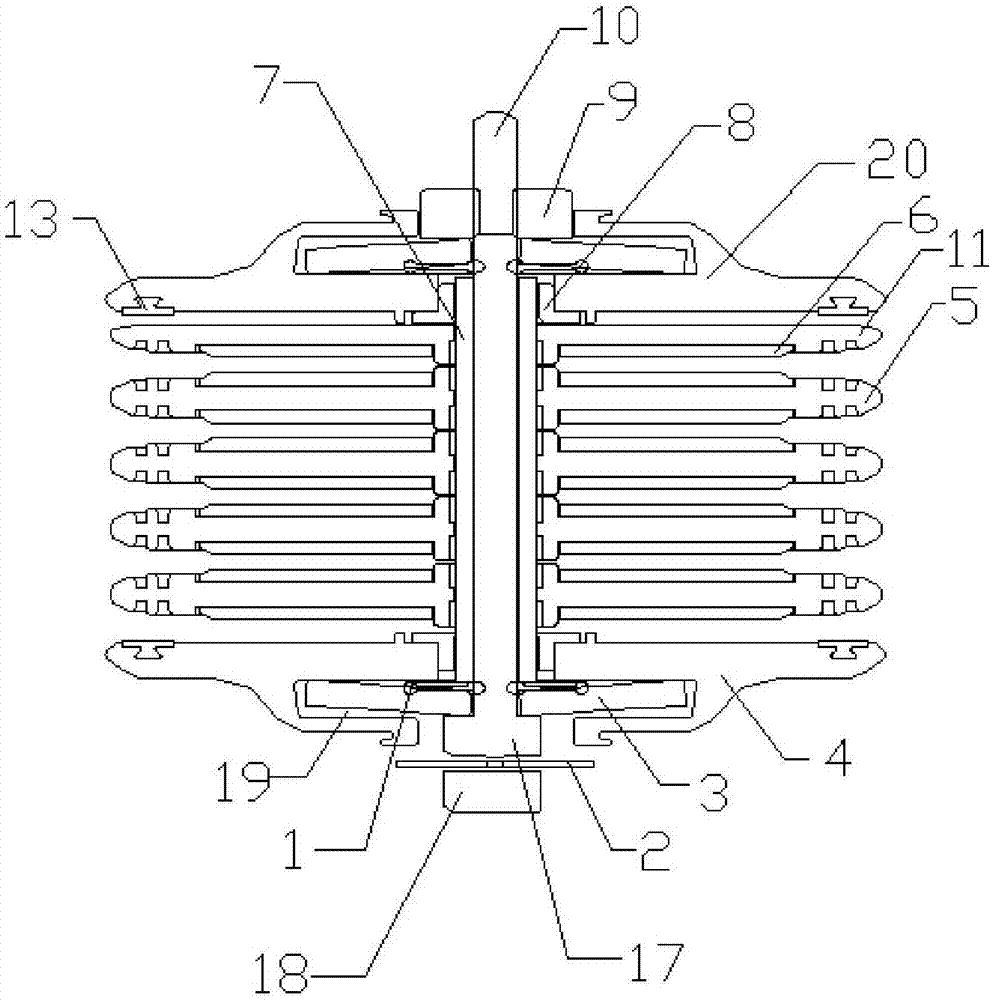

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

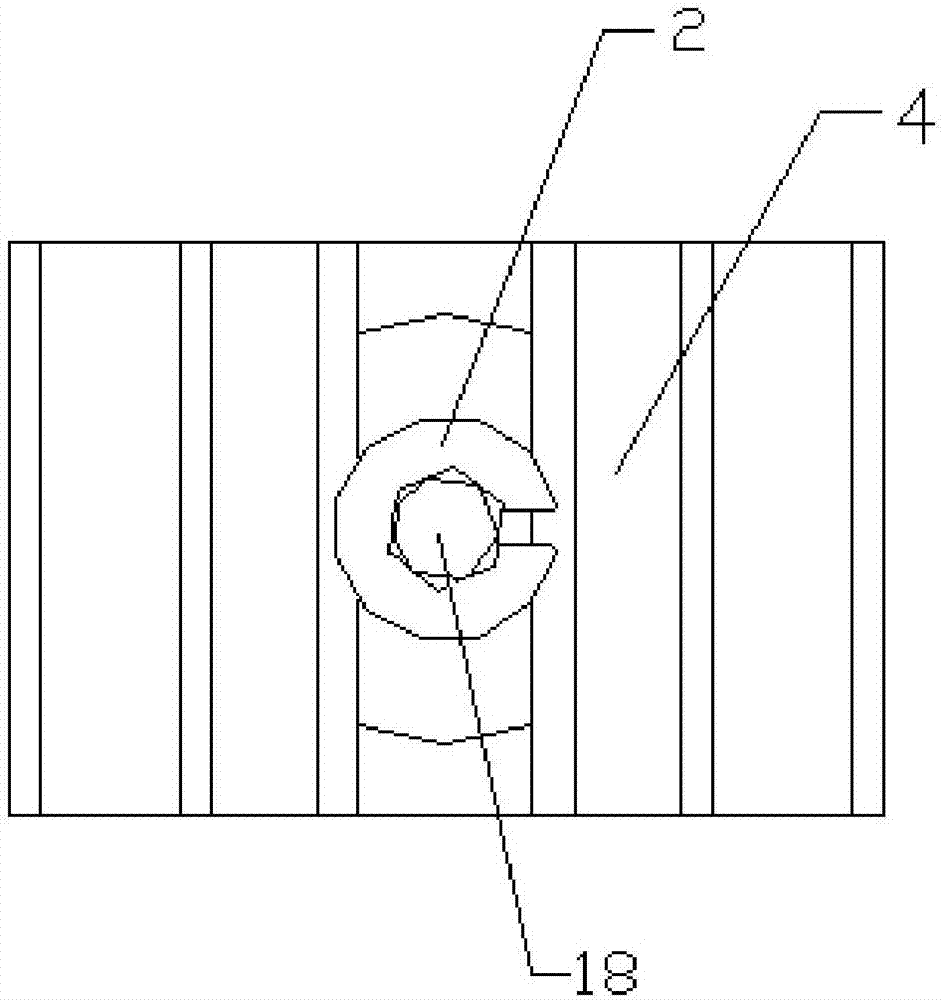

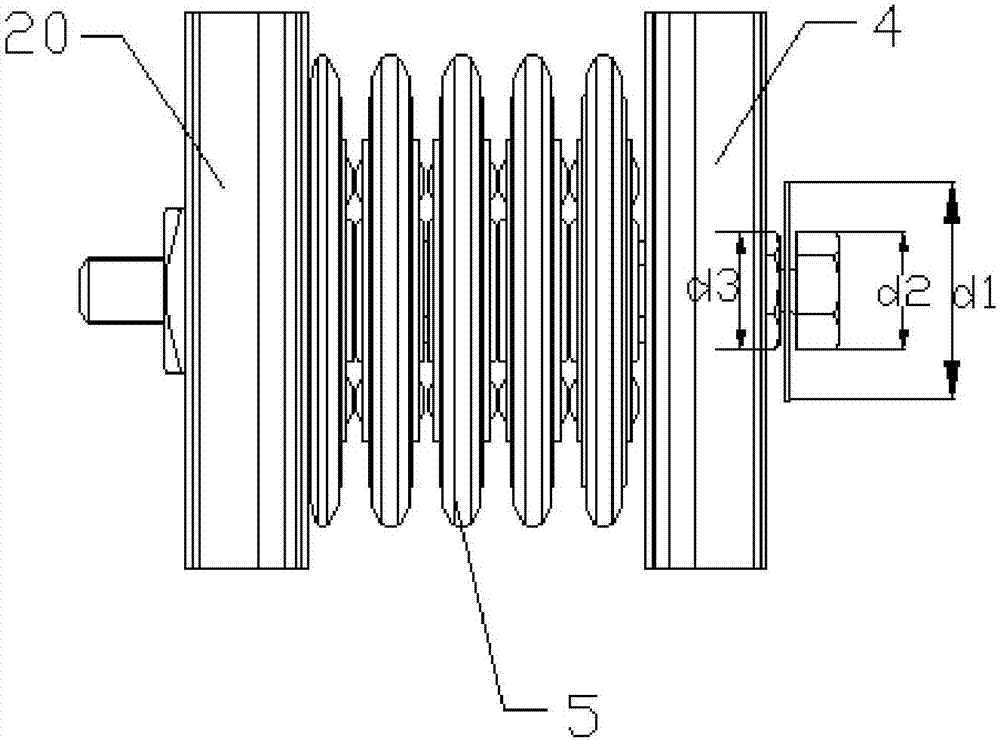

[0022] As shown in the figure, a busway connector with a high protection level includes a torque bolt. The torque bolt includes an inner head, an outer head, and a gasket. The gasket is located between the inner head and the outer head. Both the head and the outer head have a regular hexagonal structure, and the gasket is a notched circular ring structure. The diameter of the gasket is d1, the diameter of the outer head is d2, and the diameter of the inner head is d3, 2*d2>d1 >d2=d3; a butterfly spring is arranged above the inner head, the butterfly spring is located in the limiting groove of the first side plate, the butterfly spring is sleeved on the torque bolt, and the butterfly spring and the limiting groove There is a waterproof sealing ring, the waterproof sealing ring is a circular hollow structure, the waterproof sealing ring is sleeved on the torque bolt, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com