Engine oil pump shell steel ball and plug pressing method and controller

An oil pump housing and engine technology, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency and unreliable installation, and achieve the effects of preventing misoperation, reliable installation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

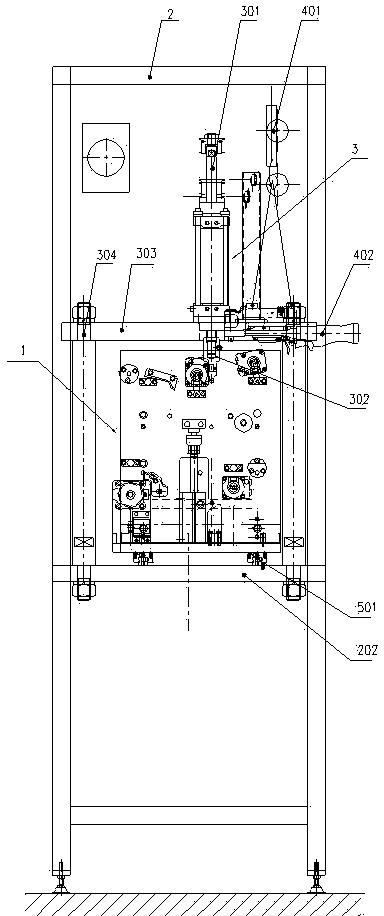

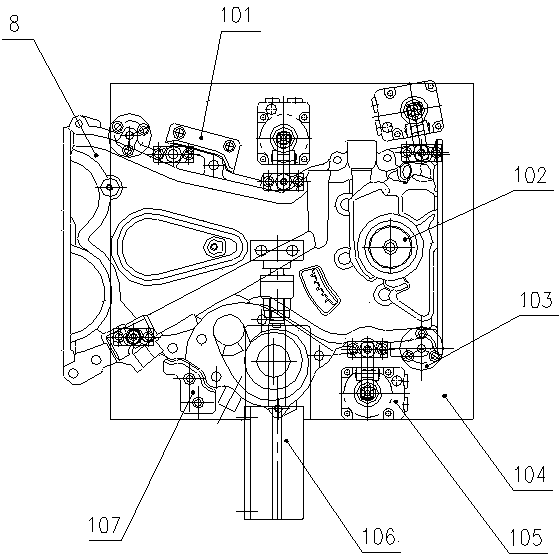

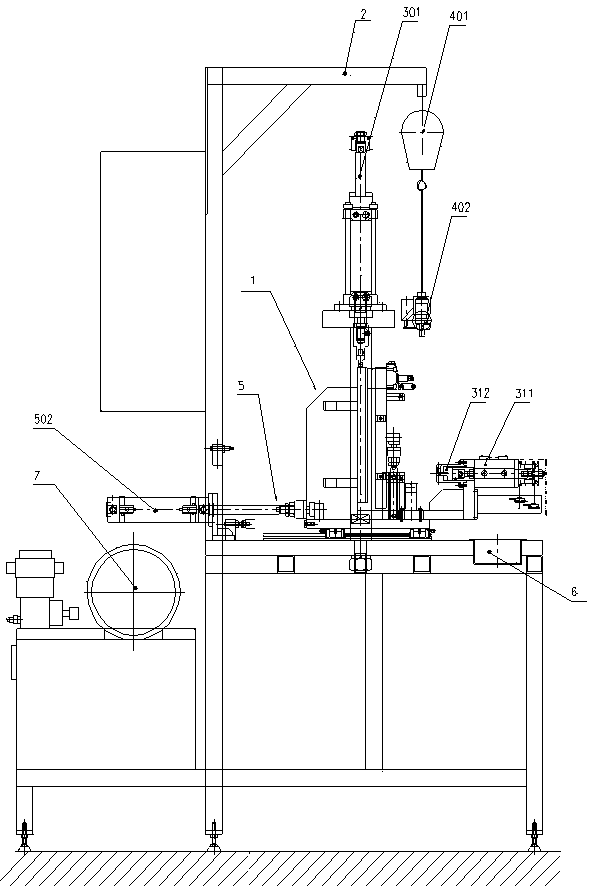

[0029] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, see Figures 1 to 5 :

[0030] A method for pressing the steel ball and the plug of the engine oil pump housing according to the present invention, comprising:

[0031] (1) Equipment preparation: The power source of the whole equipment is provided by the hydraulic system and the pneumatic system 7. The device includes a frame 2 supporting all components, a workpiece clamping assembly 1 for fixing workpieces for easy operation, two sets of steel ball pressing assemblies 3 for pressing steel balls into the oil outlet and oil inlet, and driving the engine oil pump The workpiece translation assembly 5 that the shell moves on the two stations of charging and working, and the plugging head assembly that is loaded into the plug.

[0032] The frame 2 is provided with a workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com