Insertion strip for cars and mounting structure thereof

An installation structure and molding technology, applied in the directions of transportation, packaging, vehicle parts, etc., can solve problems such as damage to appearance, end caps and molding slack, etc., and achieve the effects of reliable installation, simple manufacturing steps, and cost realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

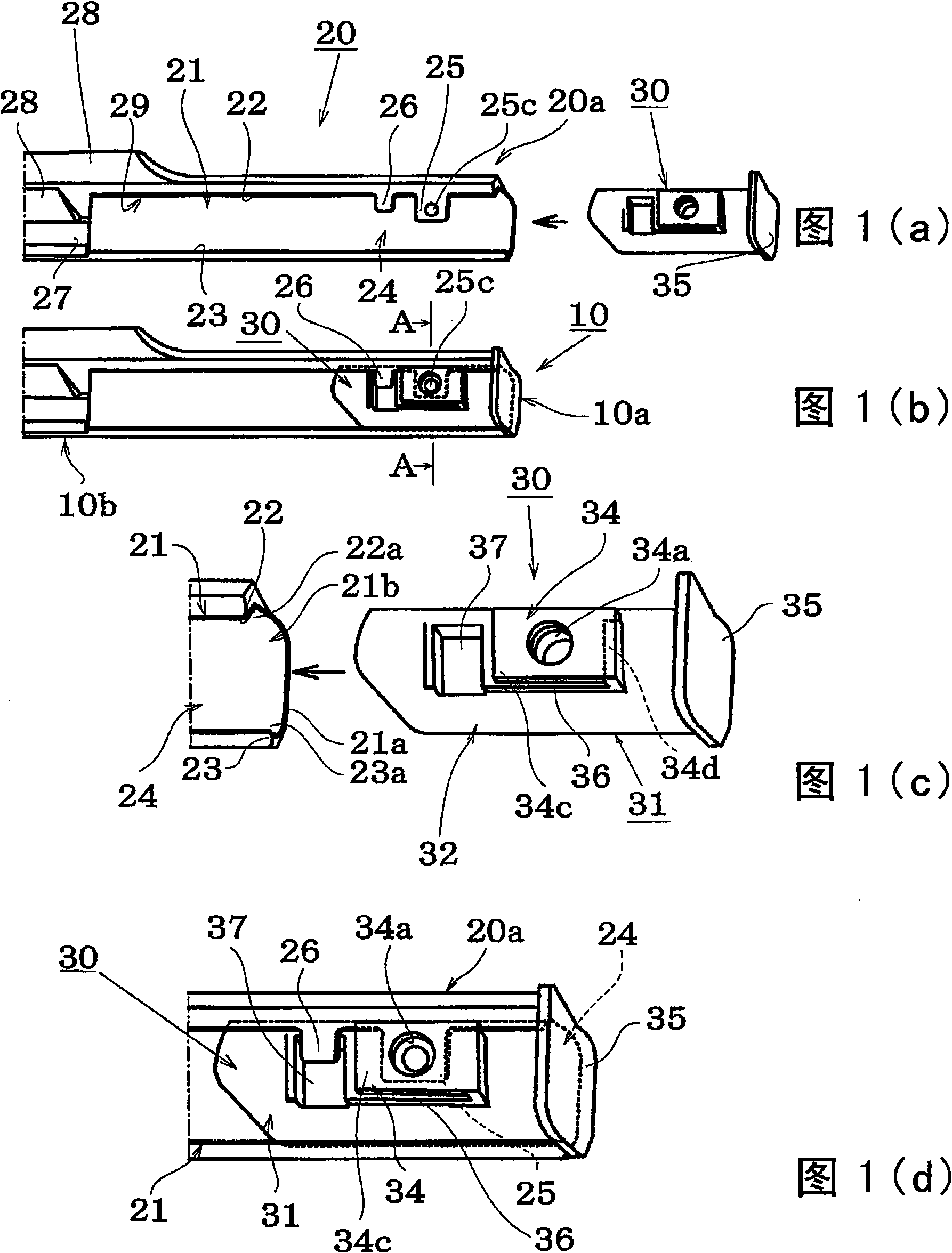

[0042] An embodiment in which the automotive molding of the present invention is used for a water-cut door molding 10 will be described with reference to the drawings.

[0043] Fig. 1 (a) shows that water-cut door molding 10 is decomposed into molding body 20 and end cap 30, from Figure 5 The exterior explanatory diagram viewed from the door panel 2 side (indoor side) shown, FIG. 1(b) shows the exterior explanatory diagram of installing the end cover 30 on the molding main body 20;

[0044] In FIG. 1( a ) and FIG. 1( b ), for the sake of explanation, only a part of the molding edge portion 10 a and the molding middle portion 10 b is drawn, and illustration of other parts is omitted.

[0045] Fig. 1 (c) shows the explanatory drawing near the end cap 30 of Fig. 1 (a) being enlarged, and Fig. 1 (d) shows the explanatory drawing near the end cap 30 of Fig. 1 (b) being enlarged;

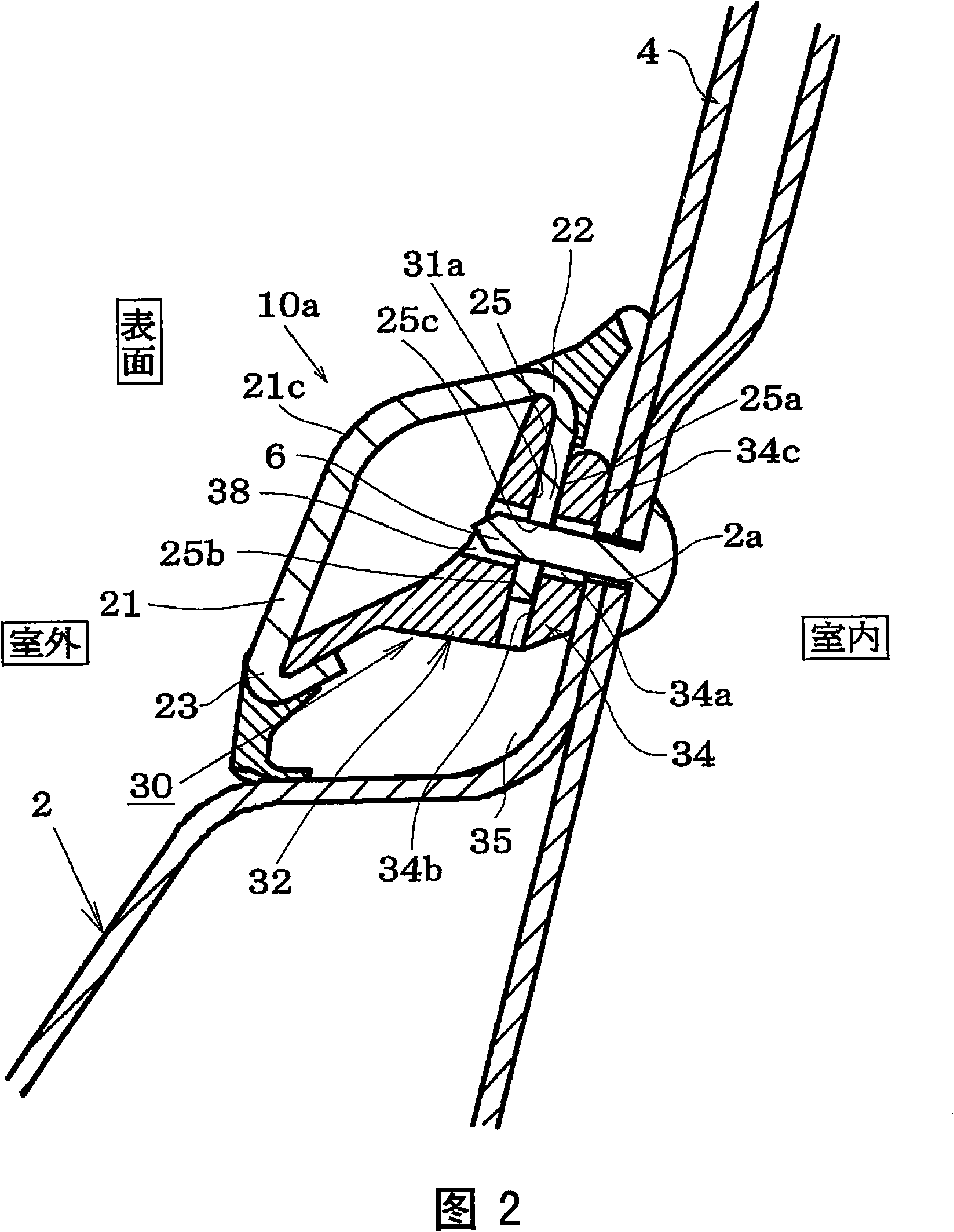

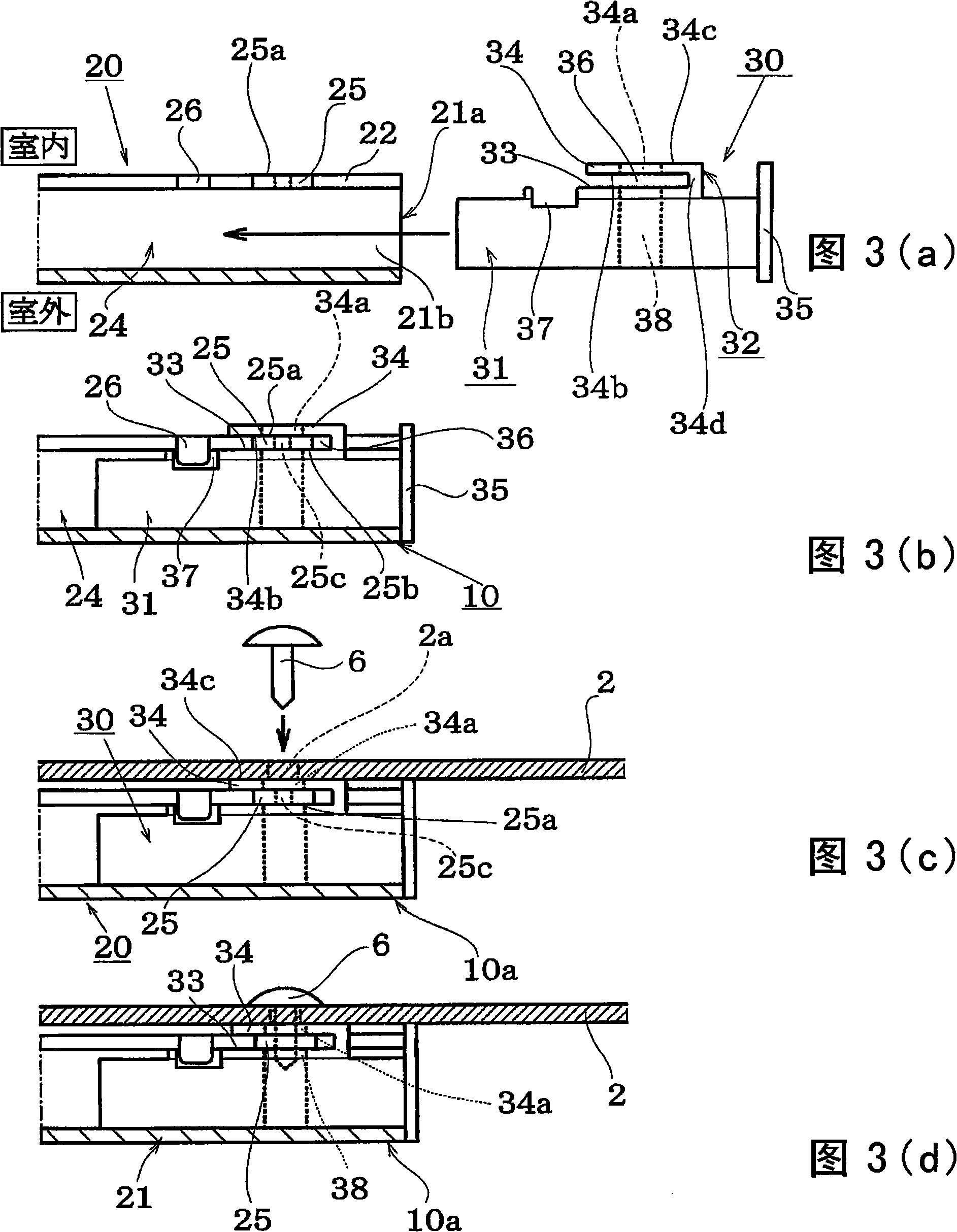

[0046] In addition, FIG. 2 shows a longitudinal sectional view corresponding to line A-A in the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com