Pressure sensor

A pressure sensor and pressure technology, applied in the field of sensors, can solve the problem of low pressure detection range, etc., and achieve the effect of convenient and fast installation, convenient and fast connection, and reliable implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

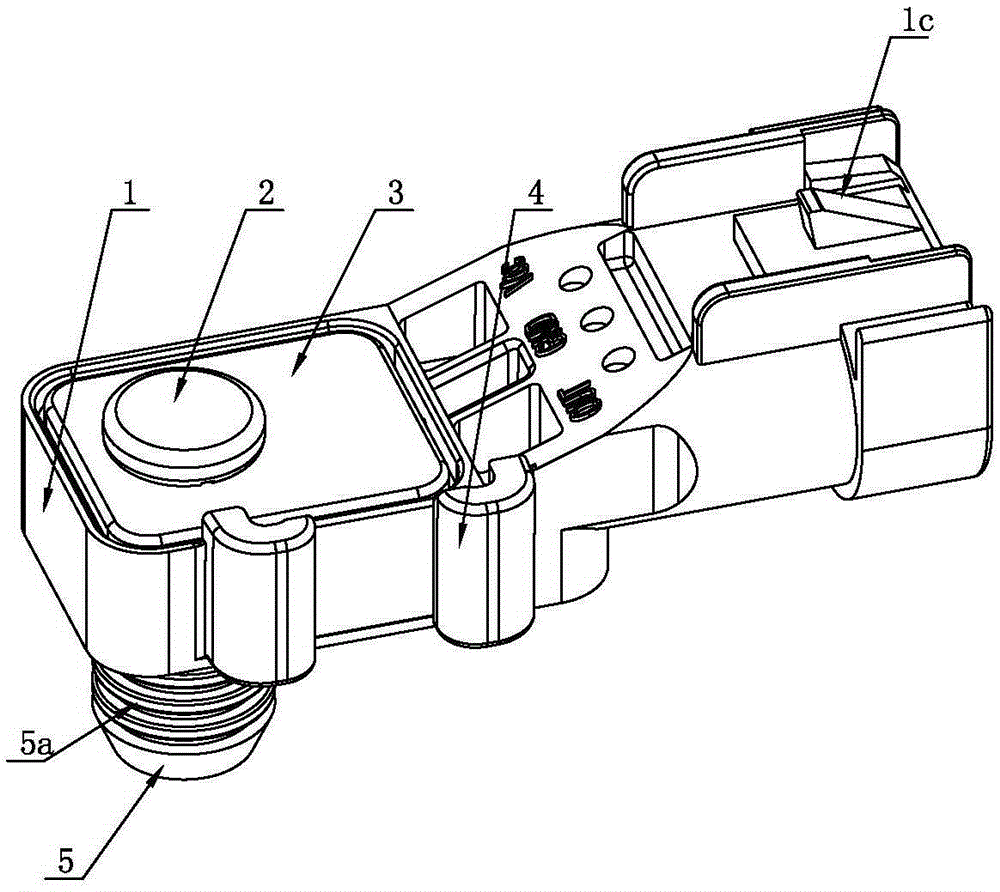

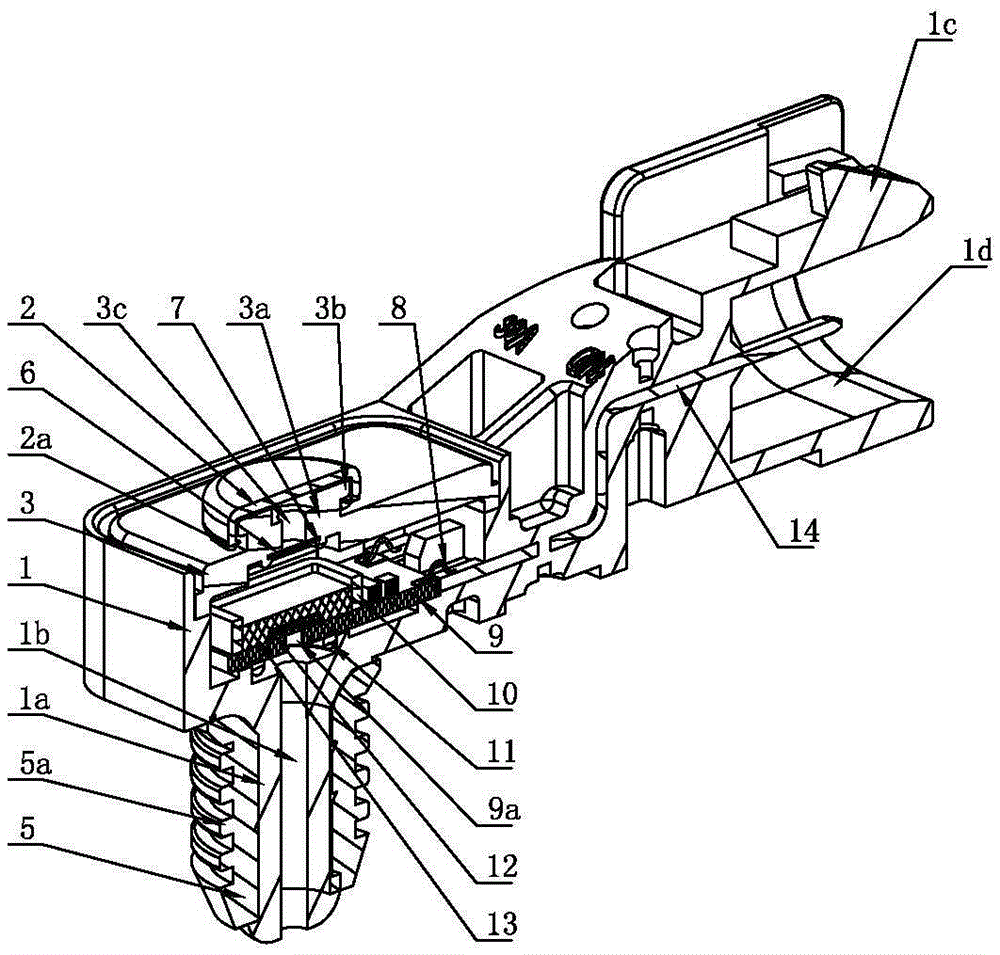

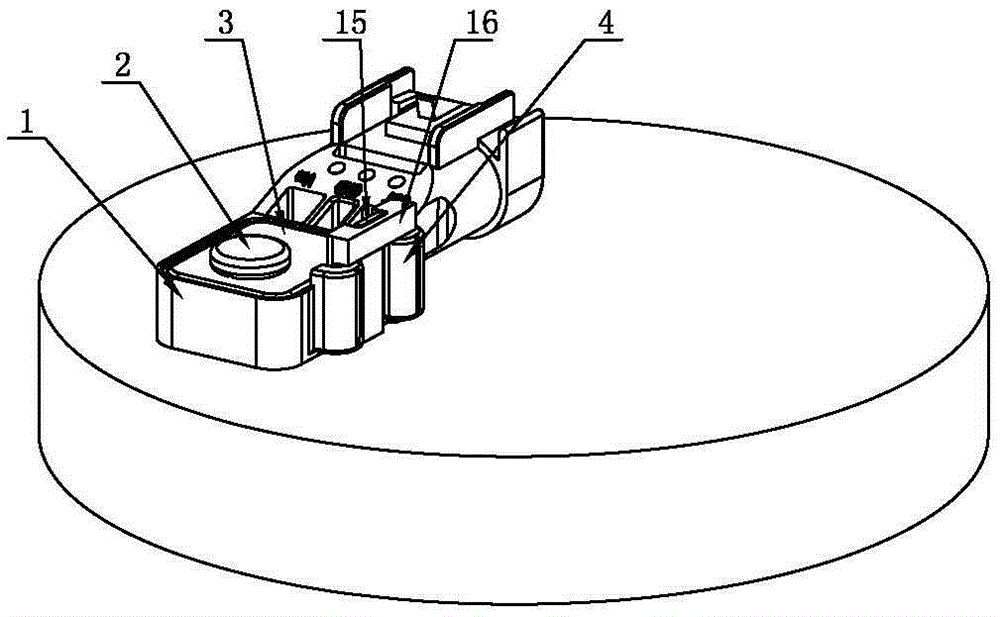

[0021] Such as Figure 1-5 The shown pressure sensor includes a plug-in housing 1, the front end of the housing 1 is processed with a cavity for measuring relative pressure, and the rear end of the housing 1 is processed with a plug-in piece 1c and a socket hole 1d. The bottom of the cavity is processed with a protruding steam pipeline 1a, and a pressure through hole 1b that communicates with the cavity is opened in the steam pipeline 1a. A sealing tube 5 is set on the outside of the steam pipeline 1a, and the outer circumference of the sealing tube 5 is processed with multiple channels. The sealing ring 5a, the sealing ring 5a is made of fluorine rubber material, the top of the steam pipeline 1a is riveted with a substrate 9, and the top of the steam pipeline 1a is processed with a concave platform, and the sealing substrate 9 and the steam pipeline 1a are arranged in the concave platform Functional O-ring 11, O-ring 11 is made of fluorine rubber material, the substrate 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com