Reaction kettle for polyaluminum chloride production

A technology of polyaluminum chloride and reactor, which is applied in the direction of aluminum chloride, aluminum halide, chemical/physical/physicochemical fixed reactors, etc., which can solve the problems of inconvenient operation, poor sealing effect of polyaluminum chloride, and safety The performance is not high, and the installation is stable and reliable, the cooling efficiency is high, and the reaction efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

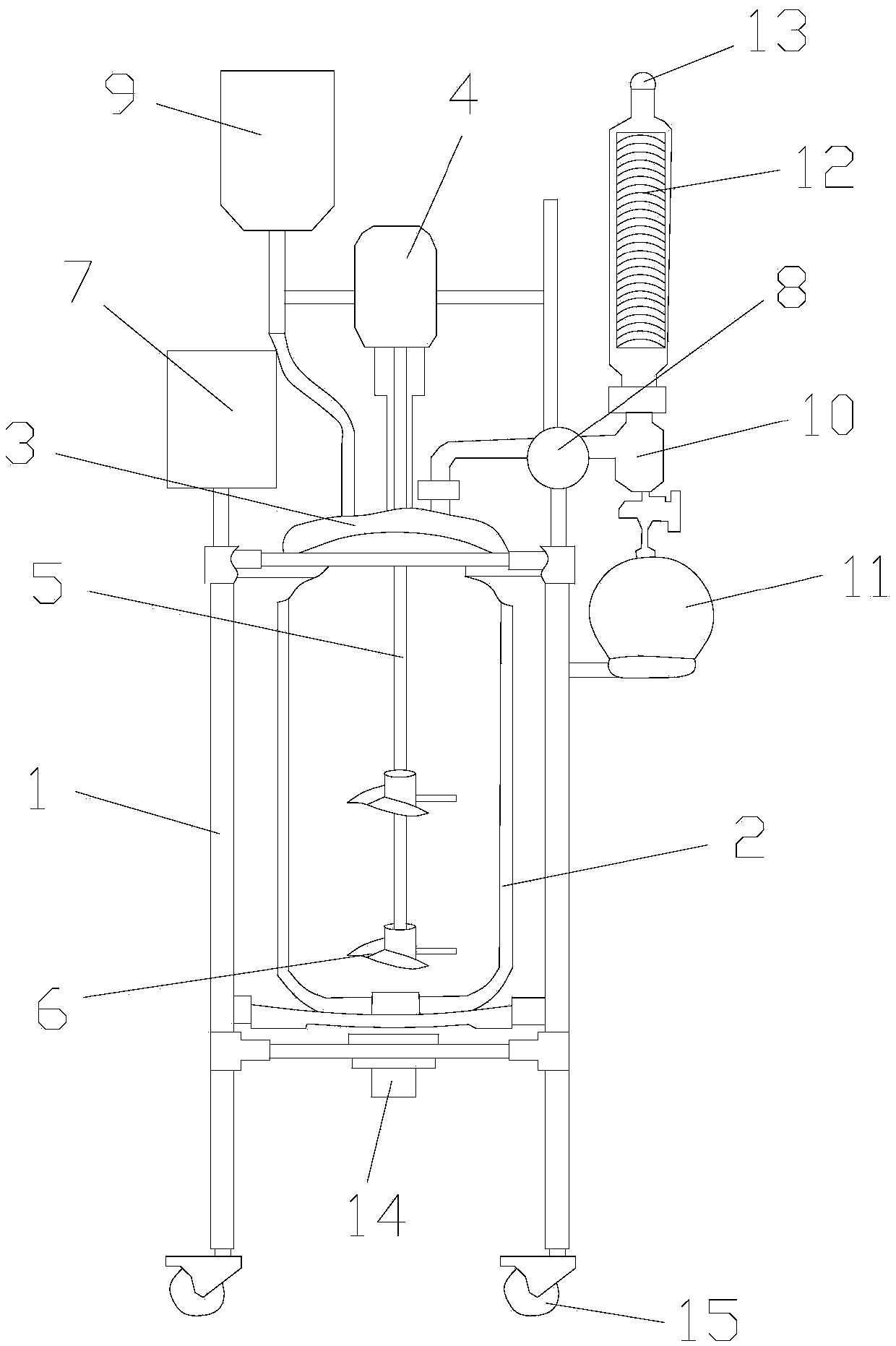

[0017] Such as figure 1 As shown, a reaction kettle for polyaluminum chloride production comprises a bracket 1, a kettle body 2, a kettle cover 3 and a motor 4, the kettle body 2 is arranged in the bracket 1, and the kettle cover 3 is arranged on the kettle body 2 Above, the kettle cover 3 is sealed and connected with the kettle body 2, the motor 4 is arranged on the kettle cover 3, a stirring rod 5 is installed under the motor 4, and the stirring rod 5 is connected with the motor 4 in transmission, and the stirring A stirring impeller 6 is arranged on the rod 5, a control box 7 and a vacuum gauge 8 are respectively arranged on both sides of the support 1, a constant pressure funnel 9 and a reflux head 10 are also installed on the kettle cover 3, and the constant pressure funnel 9 and the reflux head 10 are communicated with the kettle body 2 respectively, a collecting bottle 11 is installed under the reflux head 10 , a condenser 12 is arranged on the reflux head 10 , and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com