Repulsive clamping static contact structure of low-voltage circuit breaker

A low-voltage circuit breaker and static contact technology, which is applied to circuit breaker contacts, circuit breaker components, etc., can solve problems such as wear of the dynamic and static contacts of the circuit breaker, accelerated material migration of the dynamic and static contacts, and impact on the life of the dynamic and static contacts. , to achieve the effect of improving contact life, low production cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

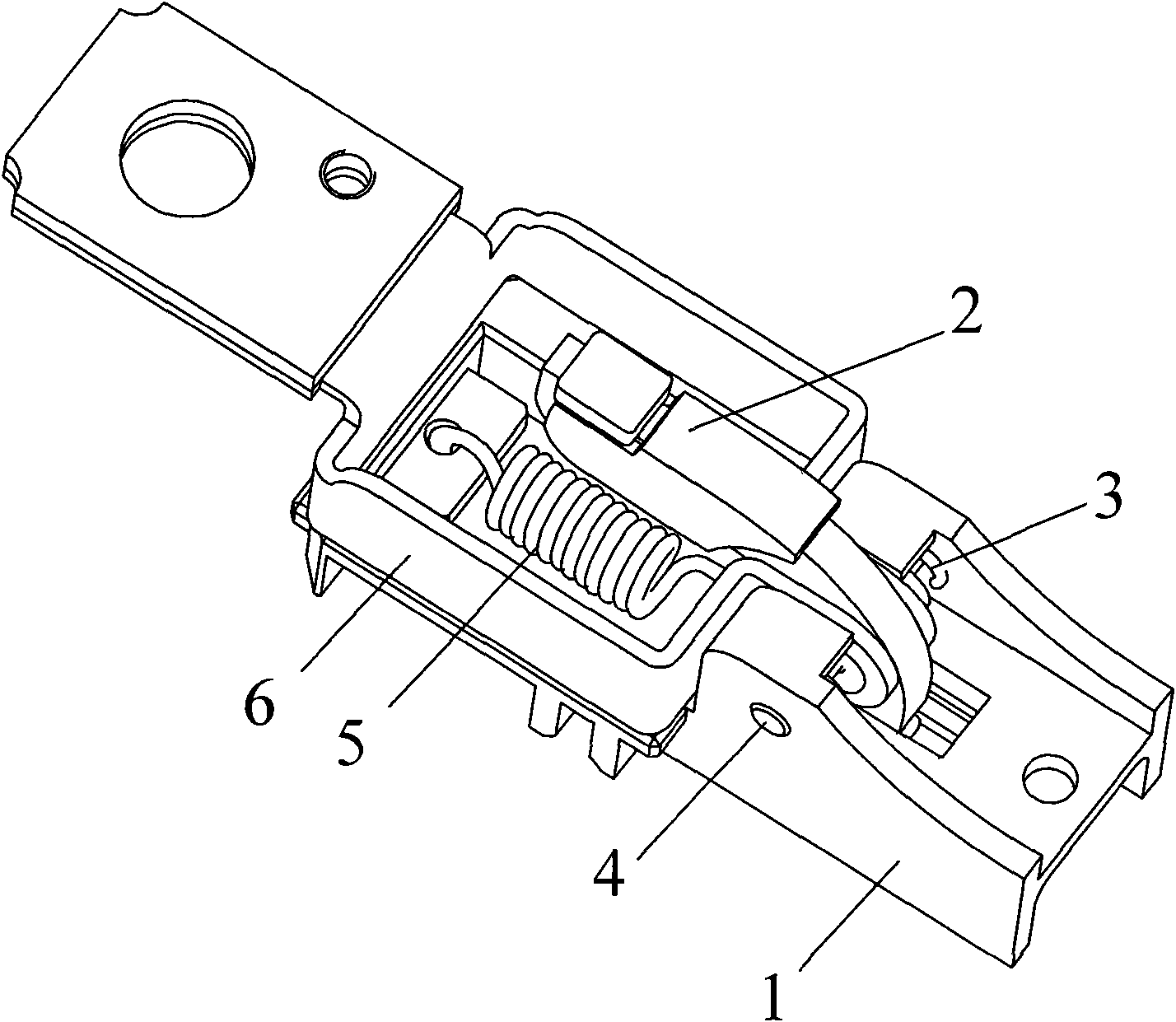

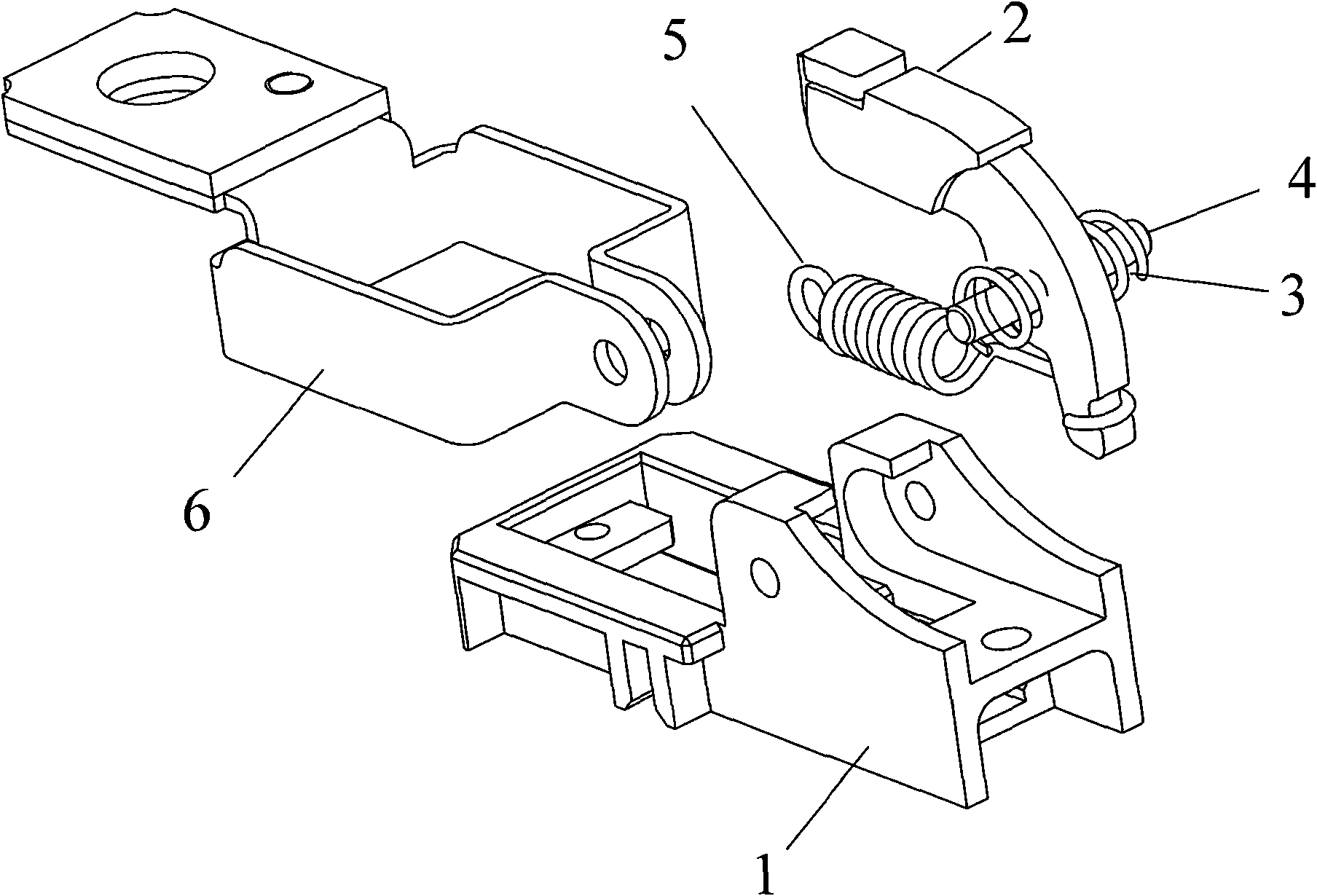

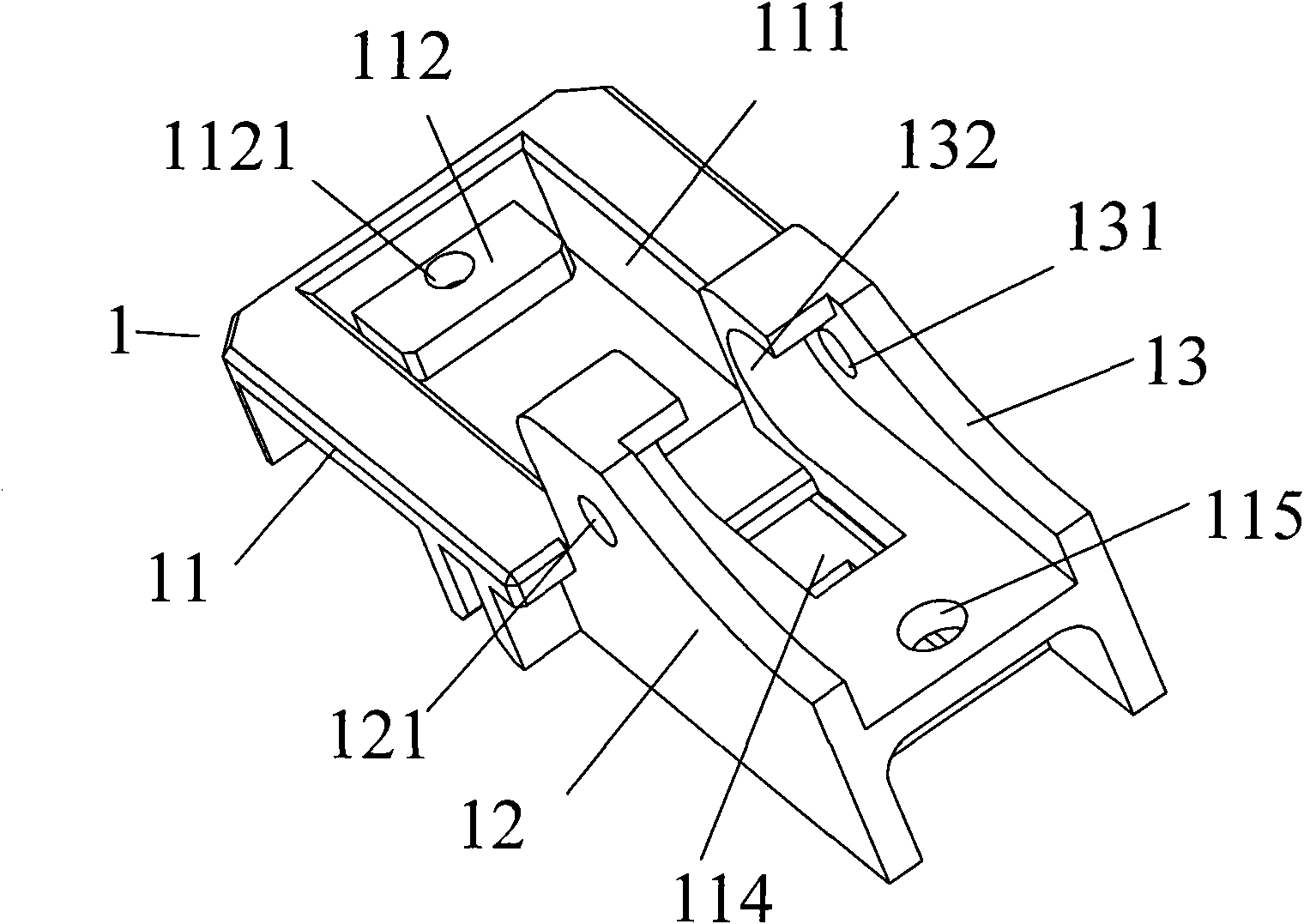

[0021] Such as Figure 1-2 As shown, the present invention is composed of a bracket 1, a static contact 2, a compression spring 3, a tension spring 5, a positioning shaft 4 and a connecting row 6. The two ends of the positioning shaft 4 are fixed on the bracket 1, and the middle of the positioning shaft 4 passes through the The static contact 2 and the compression spring 3 respectively arranged on both sides of the static contact 2, the compression spring 3 is enveloped in the bracket 1 and makes the connecting row 6 press the static contact 2 tightly, and the free end 22 of the static contact 2 is arranged on the bracket In the through groove of the bottom wall 11 of 1, the extension spring 5 is located in the first through groove 111 of the bracket 1 and its hanging angle 51 is fixed on the first boss 112 in the first through groove 111, the other of the extension spring 5 The hanging angle 52 passes through another through groove of the bottom wall 11 of the bracket 1 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com