Oil-water separation device and method for polymerized resin liquid in C5 petroleum resin production

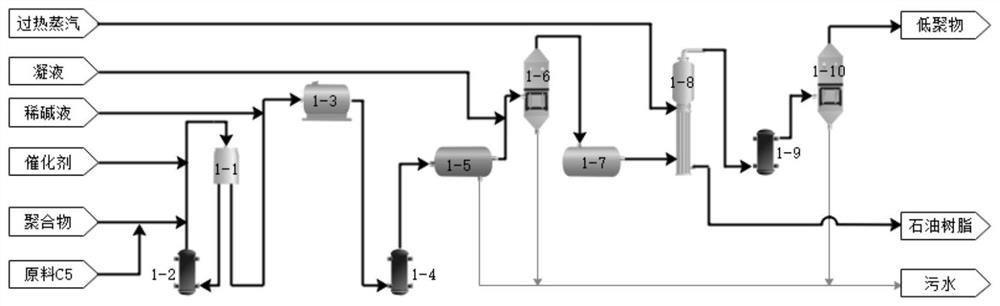

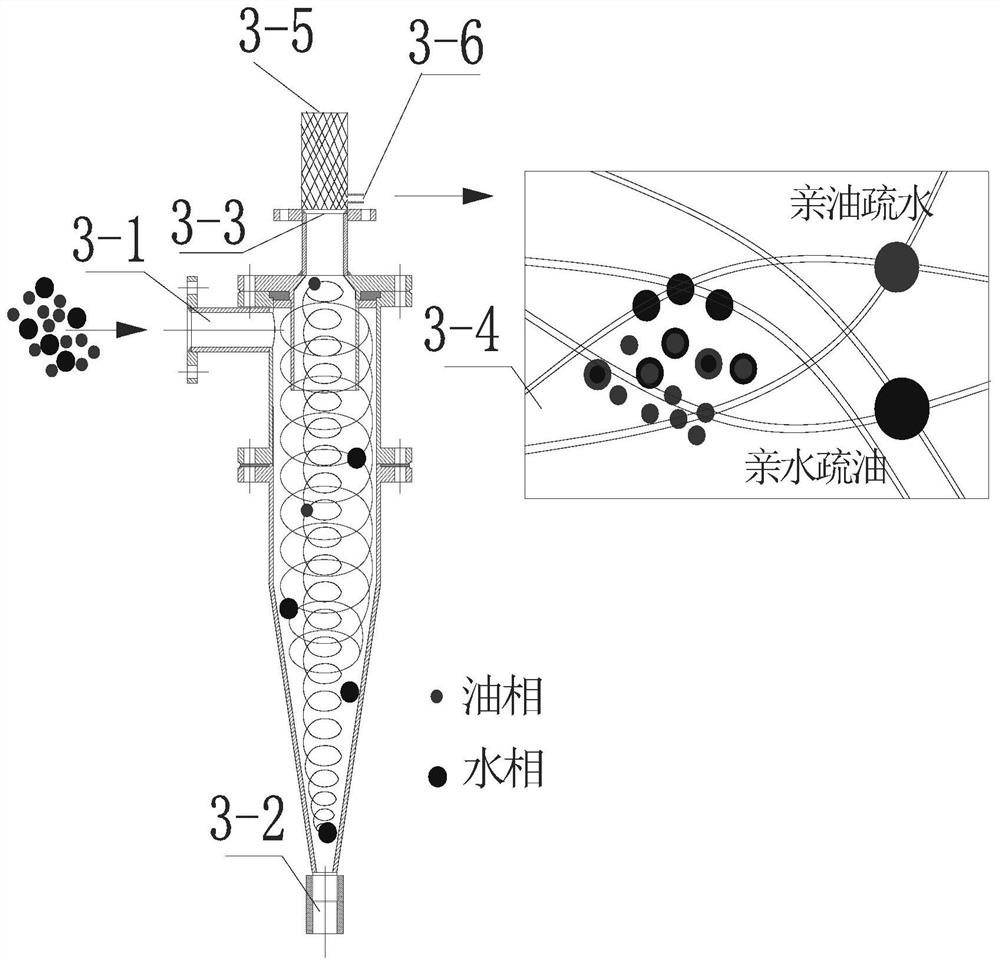

A technology of oil-water separation device and polymer resin, which is applied in the direction of grease/oily substance/suspton removal device, chemical instrument and method, neutralization water/sewage treatment, etc., which can solve the problem of large discharge of high-concentration wastewater and poor dehydration and decolorization effect high efficiency, high catalyst consumption, etc., to achieve high-efficiency separation, reduced catalyst consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In a 110,000-ton / year C5 petroleum resin production process, according to the method of the present invention, a cyclone fiber heterojunction device is used to carry out deep oil-water separation treatment on the polymerized petroleum resin liquid, and its specific operation process and effects are described as follows:

[0060] 1. Material properties and related parameters

[0061] The polymerization liquid to be treated in the production of petroleum resin is a liquid-liquid two-phase mixture, in which the impurities are dispersed water, suspended water and emulsified water in a free state. 3 , the weight of the water phase is 10%, the viscosity is 1cp, and the processing capacity is 8-25t / h.

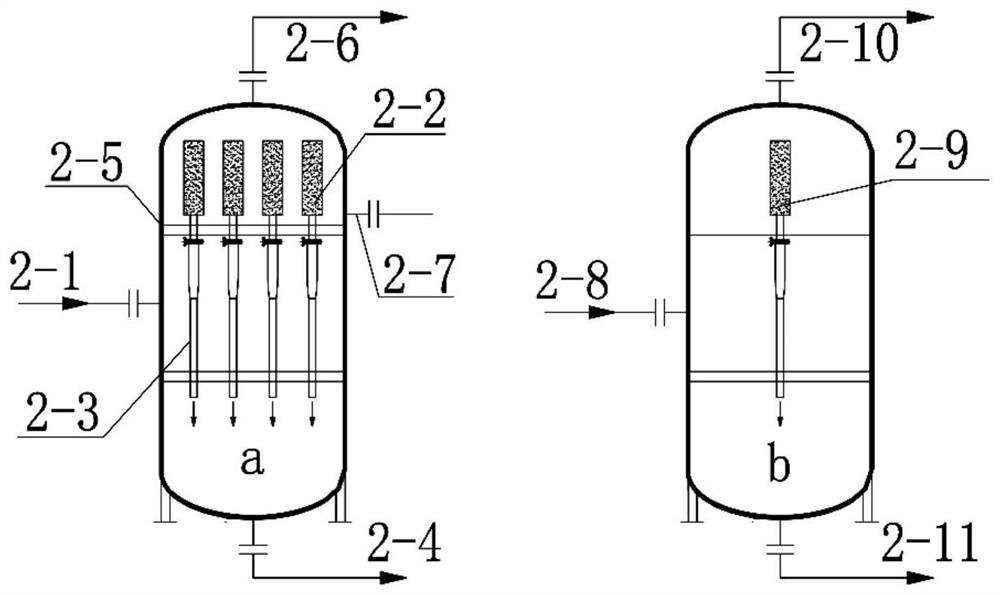

[0062] 2. Polymer resin liquid cyclone fiber heterojunction device

[0063] The device adopts the method of swirl tube combined with fiber heterojunction filter element, selects 10 swirl tubes to be processed in parallel, and is in a vertical state. The size of the swirl tube ...

Embodiment 2

[0070] In a 110,000-ton / year C5 petroleum resin production process, according to the method of the present invention, the oligomer mixture is subjected to deep oil-water separation treatment using a swirling fiber heterojunction device. The specific operation process and effects are described as follows:

[0071] 1. Material properties and related parameters

[0072] The polymerization liquid to be treated in the production of petroleum resin is a liquid-liquid two-phase mixture, in which the impurities are dispersed water, suspended water and emulsified water in a free state. 3 , the weight of the water phase is 70%, the viscosity is 1cp, and the processing capacity is 2t / h.

[0073] 2. Oligomer Cyclone Fiber Heterojunction Device

[0074] The device adopts the method of swirl tube combined with fiber heterojunction filter element, and selects one swirl tube for treatment, in which the size of the swirl tube is DN35, and the processing capacity of a single swirl tube is 0.8-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com