Multistation spray nozzle automatic cleaning equipment and cleaning method

A self-cleaning, multi-station technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as blockage of piezoelectric nozzles, inconvenient cleaning, and printers that cannot be used normally. The effect of stable and controllable pressure, high cleaning efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

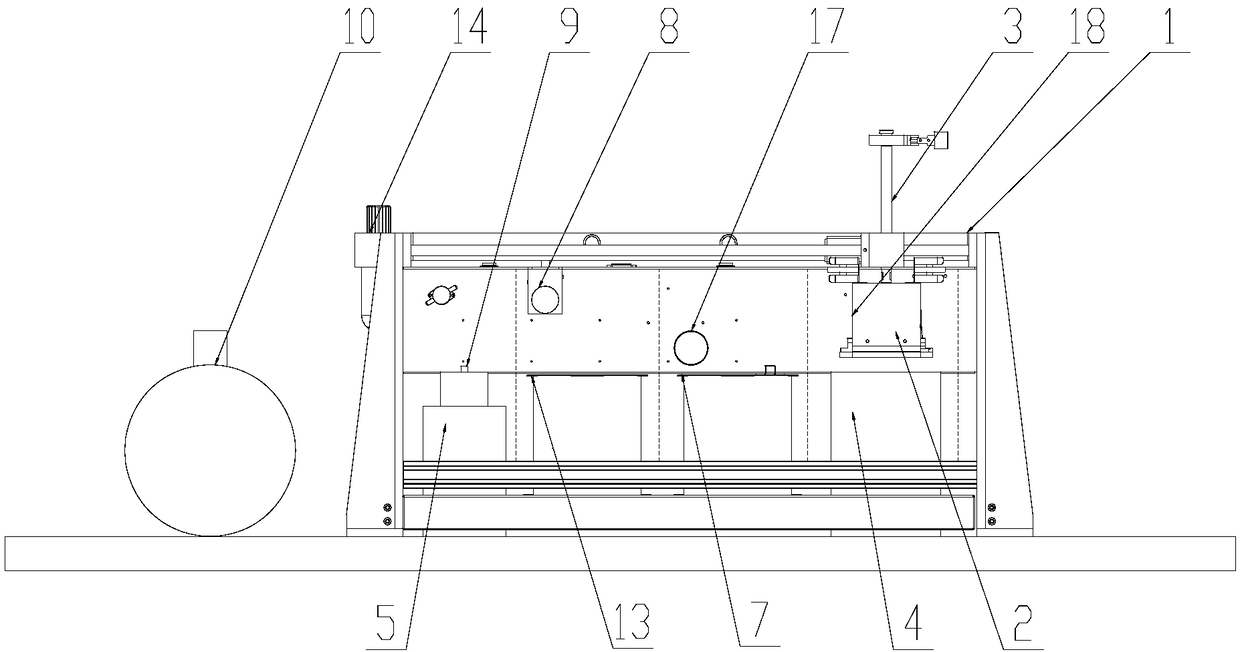

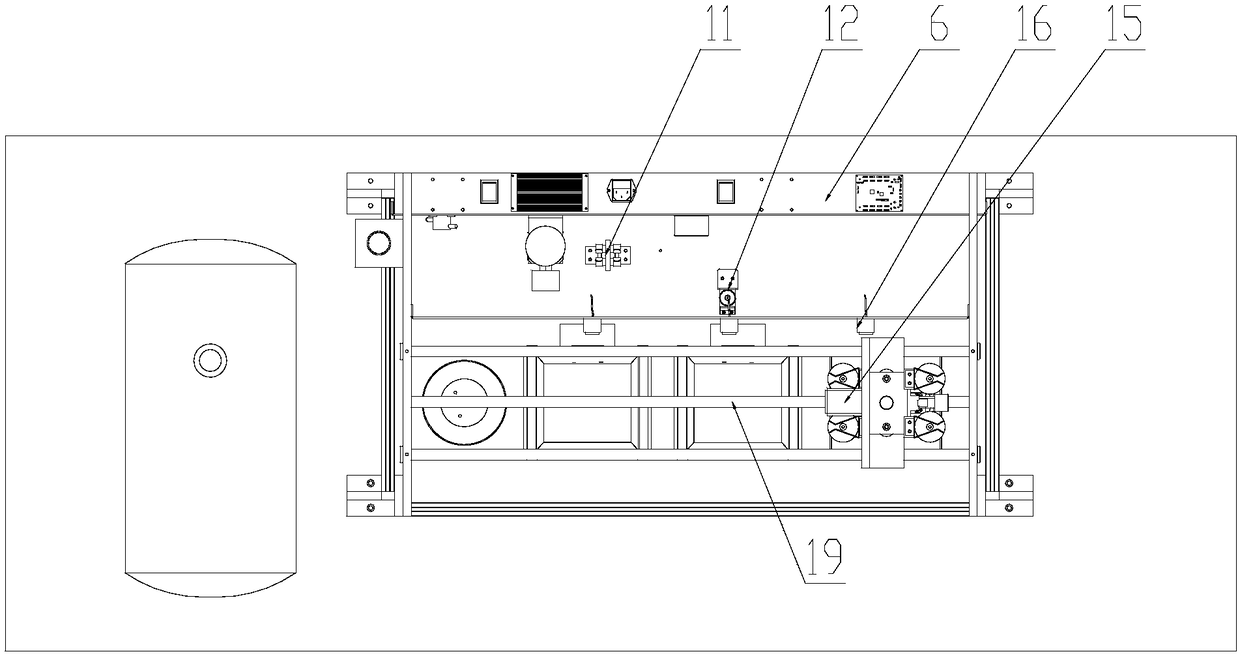

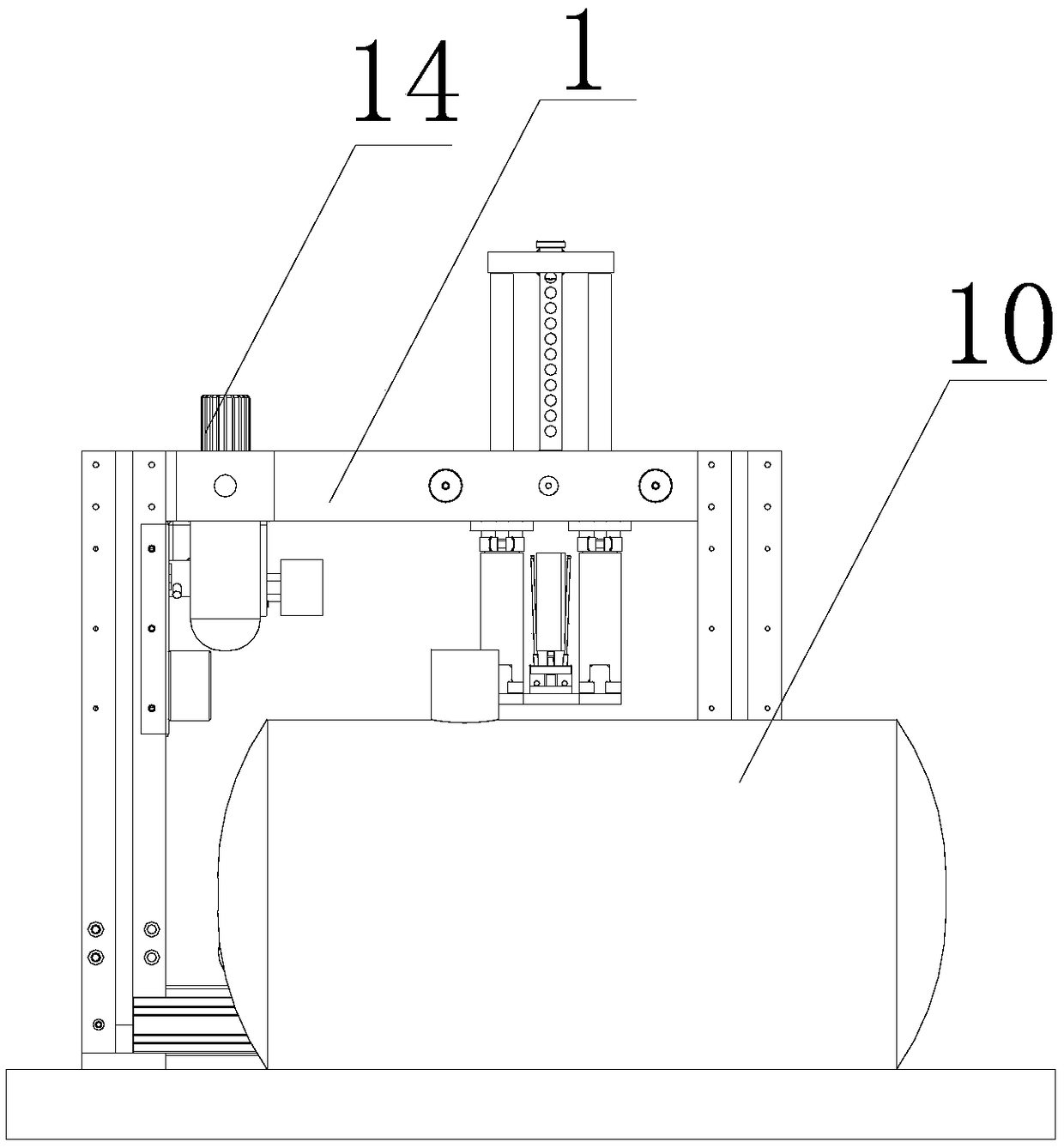

[0031] The present invention provides an automatic cleaning equipment for multi-station nozzles, which includes an air compressor 10 arranged at the end of the equipment frame 1, and a pressure reservoir is arranged on the equipment frame 1 on the right side of the air compressor 10 from left to right. Liquid tank 5, a row of waste ink stations, a cleaning liquid circulation cleaning station and an ultrasonic automatic cleaning station.

[0032] The waste ink discharge station is provided with a waste liquid tank 13, and the cleaning liquid circulation cleaning station is provided with a circulation cleaning recovery tank 7, and the ink tube connects the pressure liquid storage tank 5 to the ink inlet of the nozzle 2, The ink outlet of the nozzle 2 is aligned with the opening on the upper end of the recycling cleaning tank 7, and a precision pressure regulating valve 8 is arranged on the connecting ink pipe, and a liquid level sensor 9 is arranged inside the pressure storage ta...

Embodiment 2

[0039] The present invention also provides a cleaning method for multi-station nozzle automatic cleaning equipment, which is divided into the following steps:

[0040] 1) The waste ink discharge station is used to drain away the waste ink and waste residue inside the nozzle 2, clean the nozzle 2, and connect the cleaning liquid from the ink inlet of the nozzle 2 during use , discharged from the ink outlet and the nozzle 2, thereby taking away the waste ink in the nozzle 2, completing the first step of preliminary cleaning, and the cleaned waste ink will be directly discharged through the waste liquid tank 13 below ;

[0041] 2) The cleaning liquid circulation cleaning station is used to carry out long-term automatic cleaning of the clean cleaning liquid inside the nozzle 2 through a certain pressure (generally 10kPa-100kPa, adjusted according to the maximum pressure range of the different nozzles). Circular flushing is used to remove the internal impurities of the nozzle 2. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com