Tool positioning-clamping mechanism for milling machine

A tool positioning and clamping mechanism technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of lower repeat positioning accuracy and tool change accuracy, insufficient connection rigidity, and insufficient clamping effect, etc., to achieve clamping Good effect, good connection rigidity, smooth rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

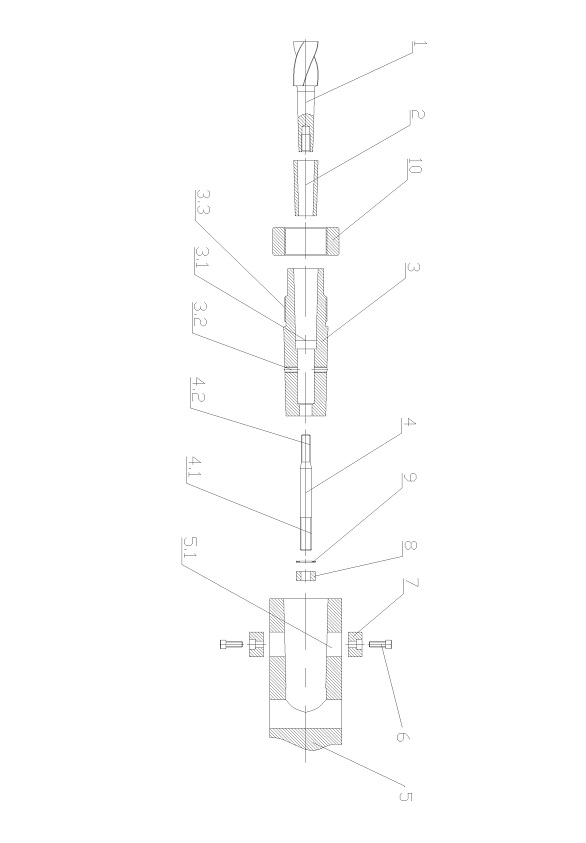

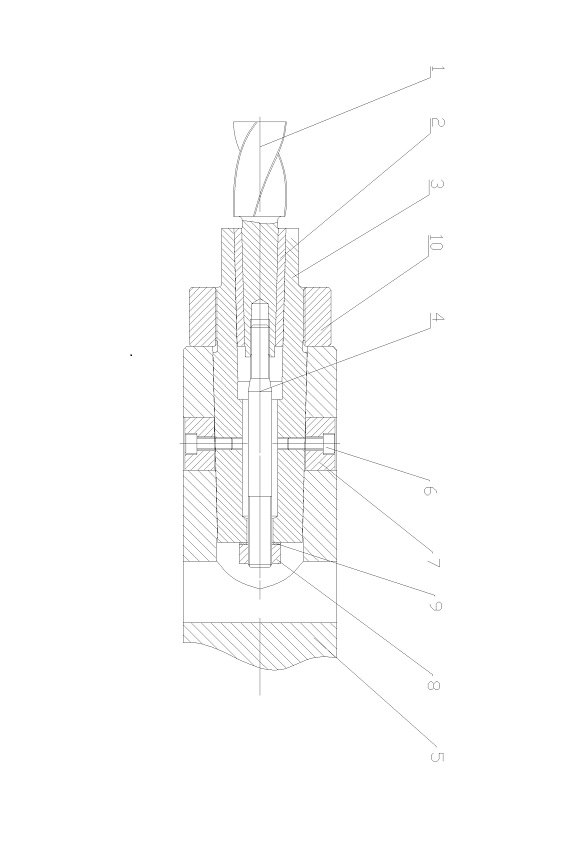

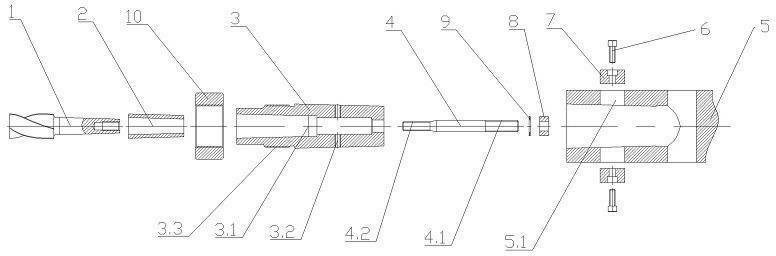

[0016] The following combined with the attachment of the present invention is further explained in detail.

[0017] like figure 1 and 2 Show, a tool positioning and clamping mechanism for milling machines, including knife 1, knife handle body 3, and lever 4.And fixed with the main axis 5 of the machine tool, the handle body 3 is closely fitted with the main axis of the machine tool, the handle body 3 has a central hole 3.1, the tool 1 package is within the center hole 3.1, the lever 4 is set in the center hole 3.1, the lever 4 is 4One end is connected to the handle body 3, and the other end of the lever is connected to the tool 1.

[0018] The knife handle 3 and the main axis of the machine tool 5 are fixed. The main axis of the machine tool 5 is equipped with radial pores 5.1 on the peripheral surface of the outer surface of the machine, and the handle body 3 has the first thread corresponding to the radial pores 5.1 positionPole 3.2, including bolts 6 and waist key 7 for embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com