Rubber tube-free precise plate-type filtering machine

A plate filter, precise technology, applied in the filter field, can solve the problems of hose joint loosening, hose twisting and cracking, hose twisting, etc., and achieve the effects of good sealing, prolonging service life, and fast pressure replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

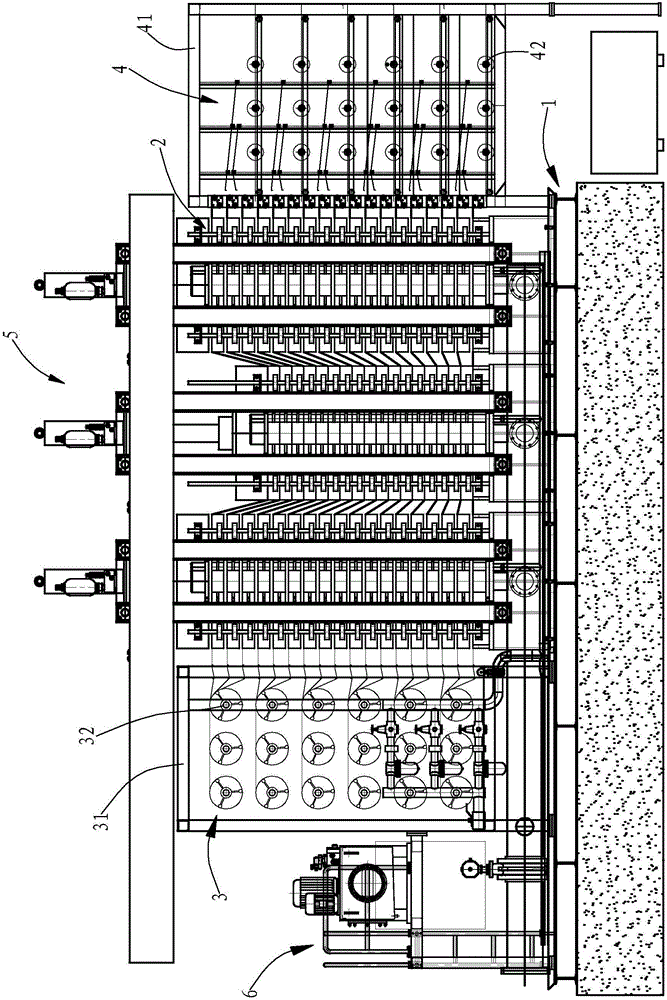

[0068] Such as figure 1 As shown, the hoseless precision plate filter in this embodiment includes a frame 1 and a filter box 2 installed on the frame 1, a paper feeding mechanism 3, a paper discharging mechanism 4, hydraulic equipment 5, and an electric control equipment 6 , the paper feed mechanism 3 and the paper discharge mechanism 4 are respectively located on both sides of the filter box 2 to drive the filter paper to complete the filtering work in the filter box 2, the hydraulic equipment 5 cooperates with the filter box 2 to perform the filtering work, the paper feed mechanism 3, and the paper discharge mechanism 4 The hydraulic equipment 5 is respectively connected with the electronic control equipment 6 and is controlled by the electronic control equipment 6 , so that the entire filtering work is completed under the control of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com