Patents

Literature

30results about How to "Realize mechanical operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

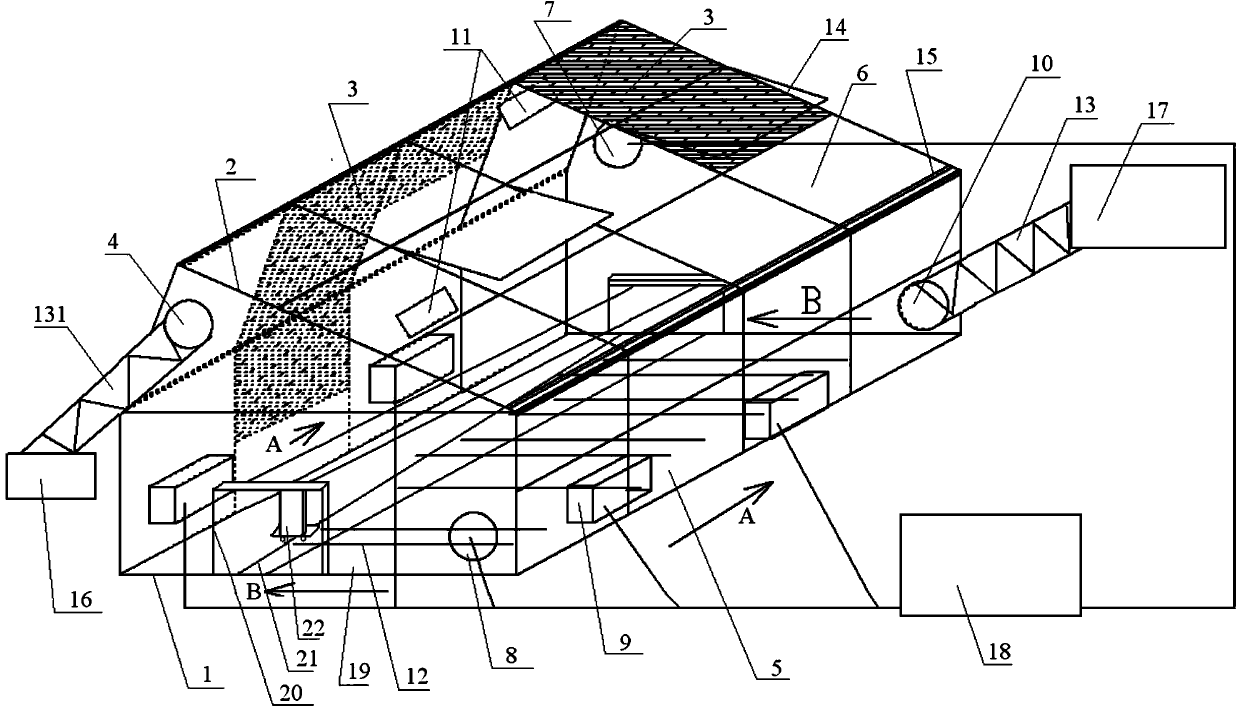

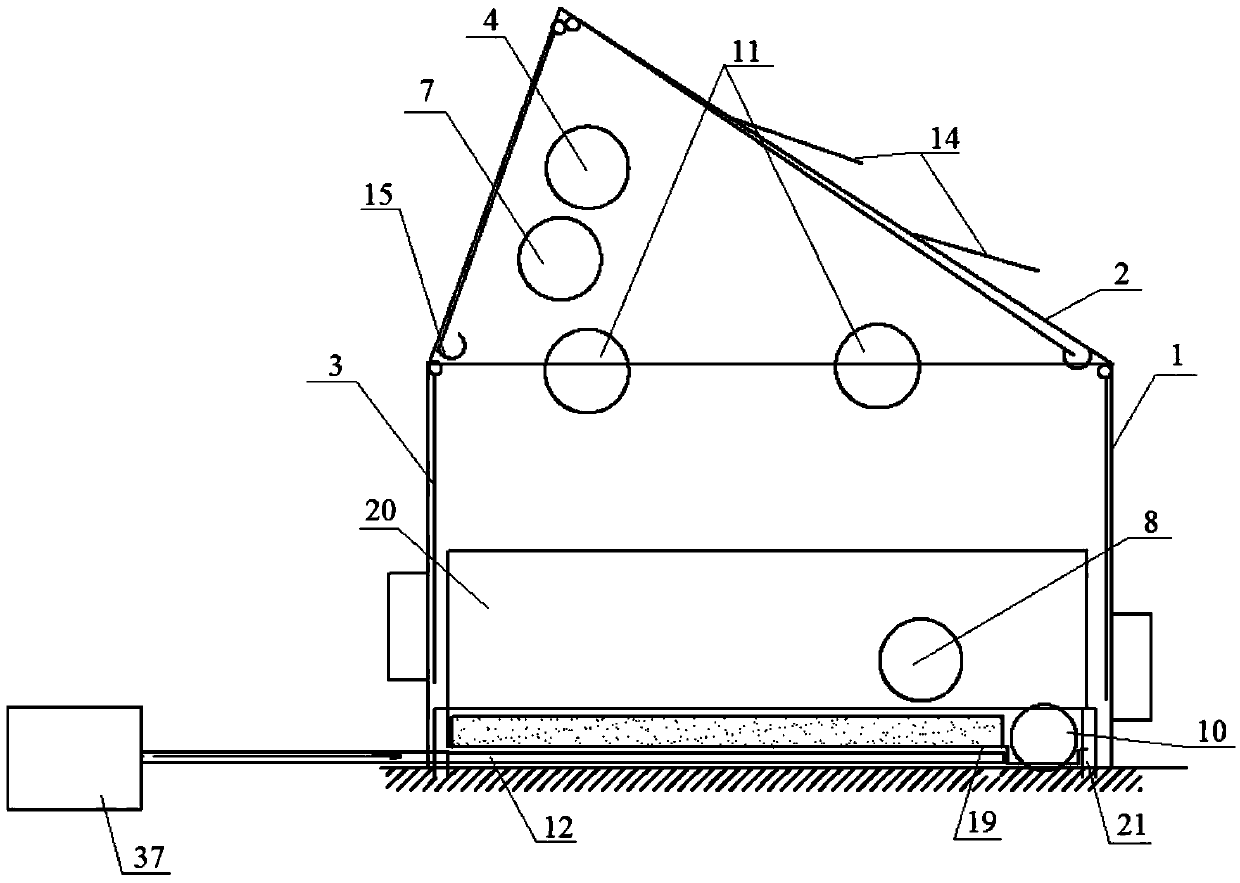

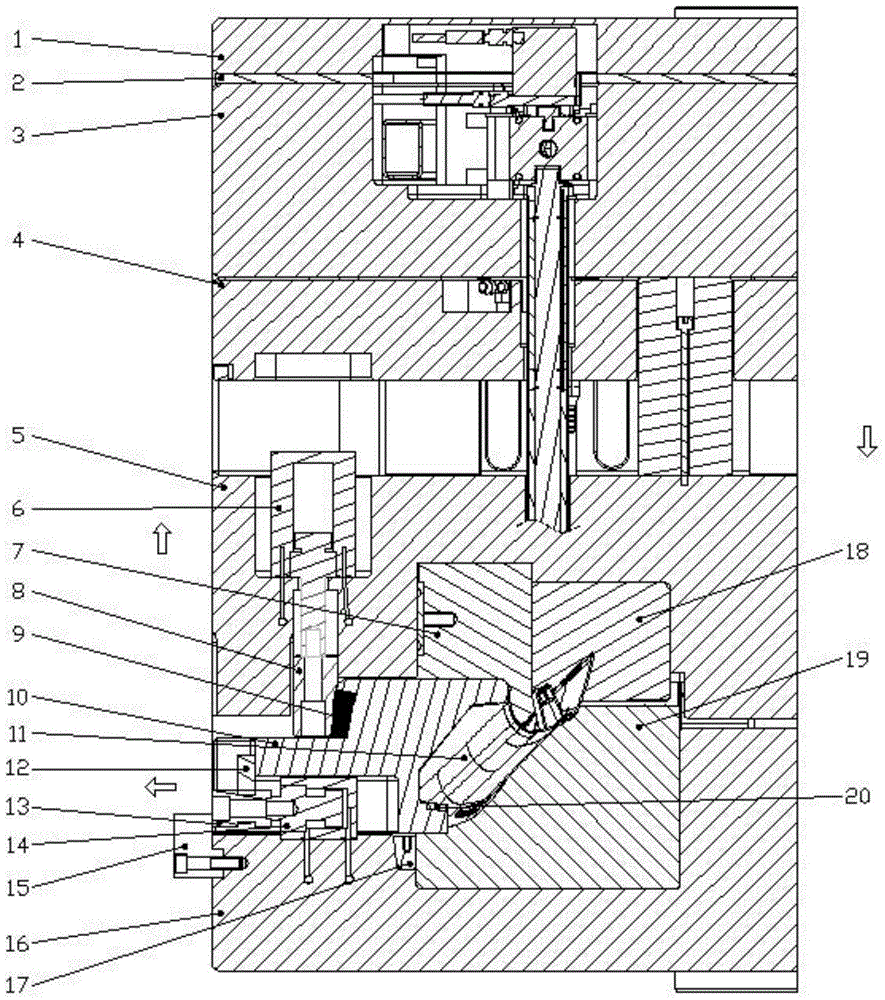

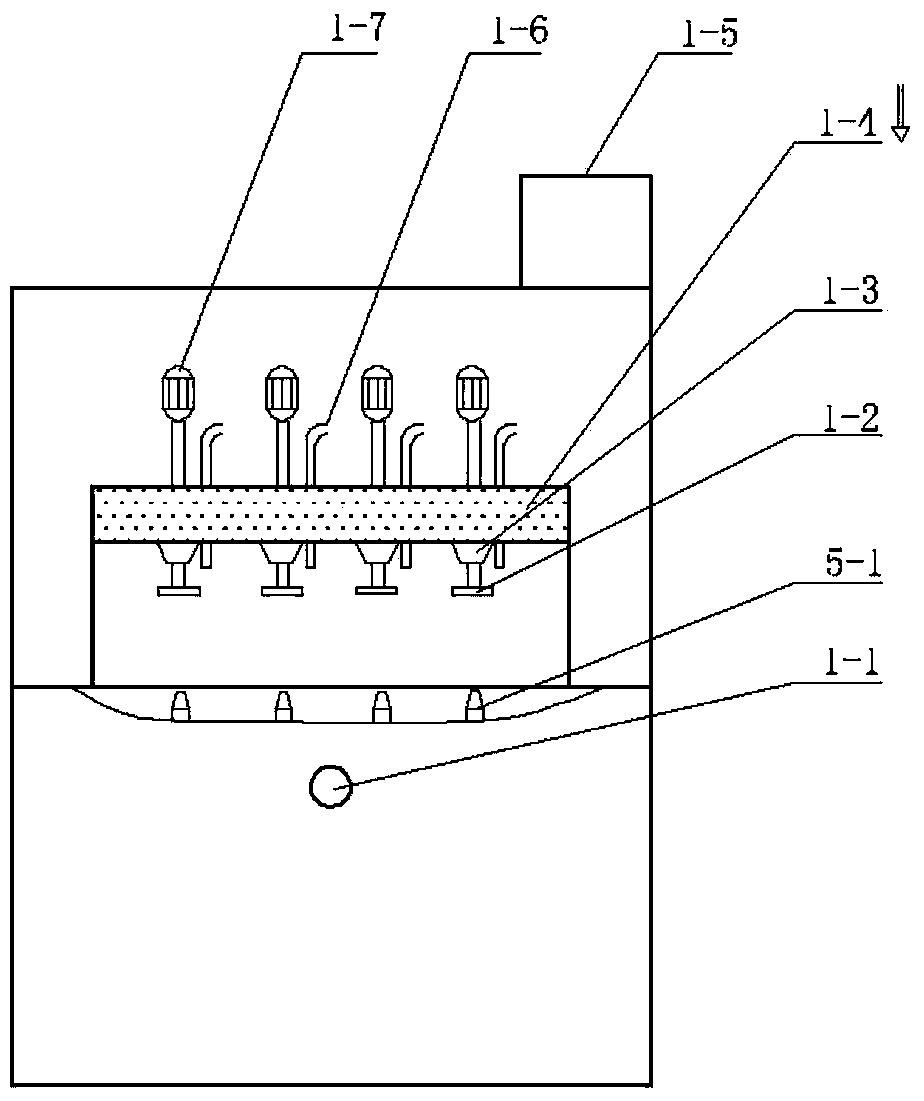

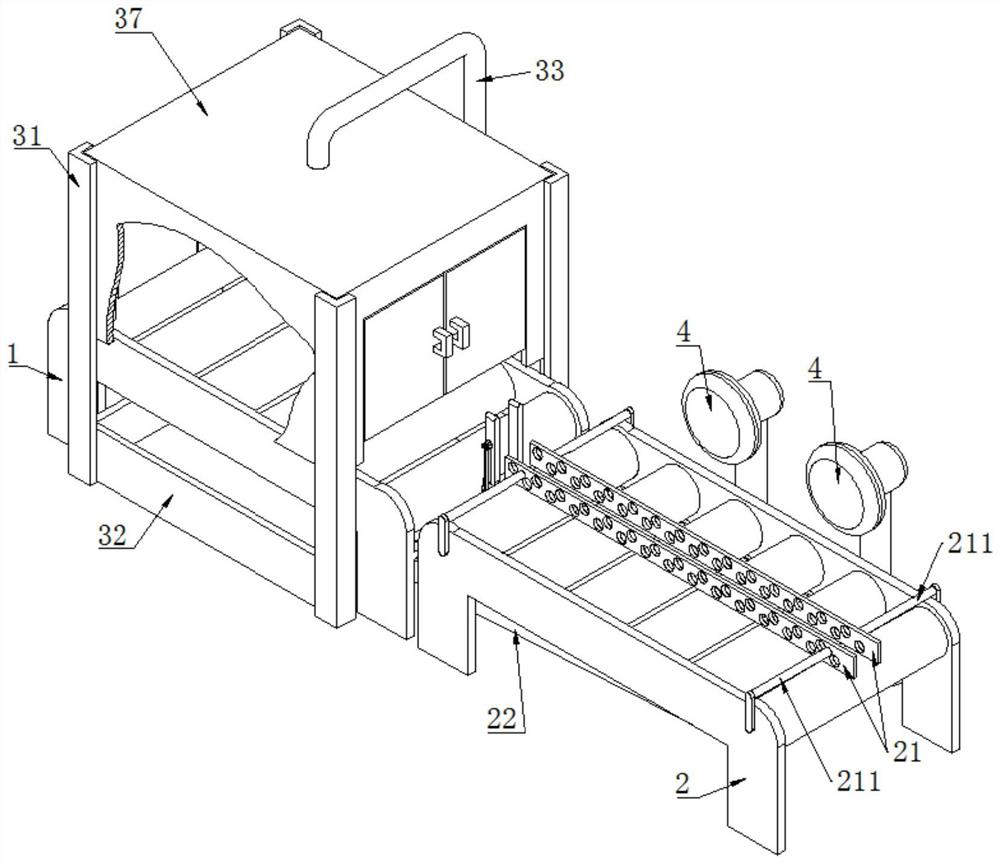

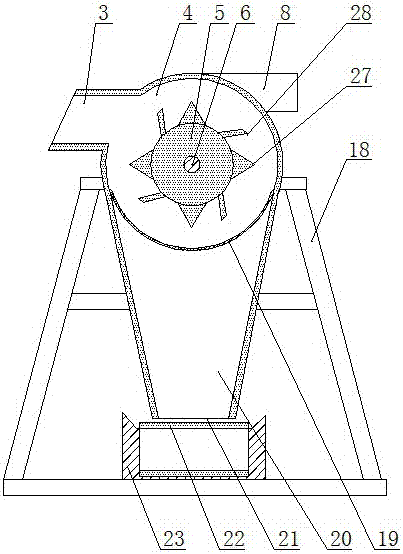

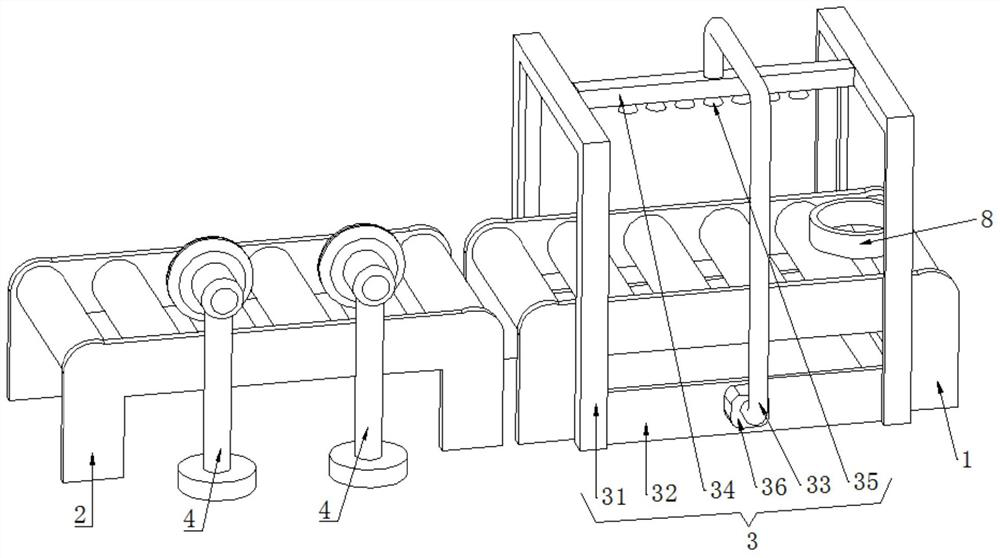

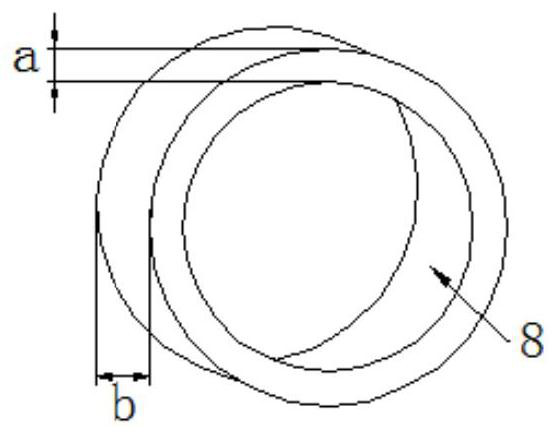

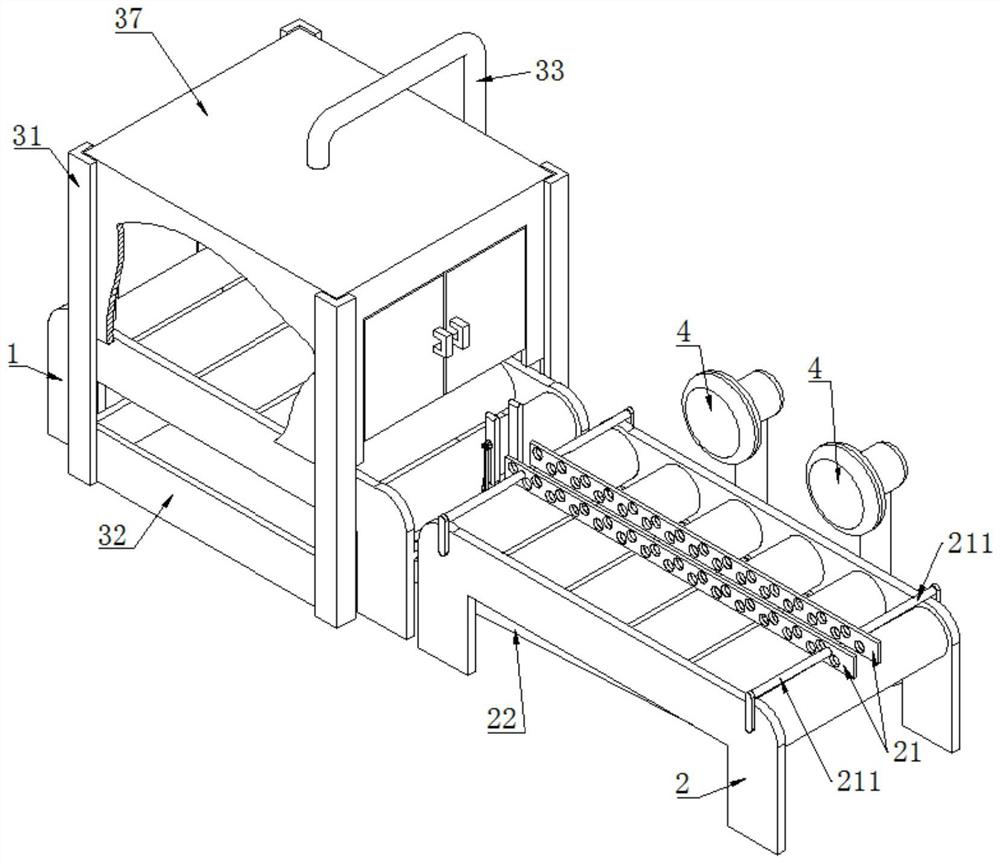

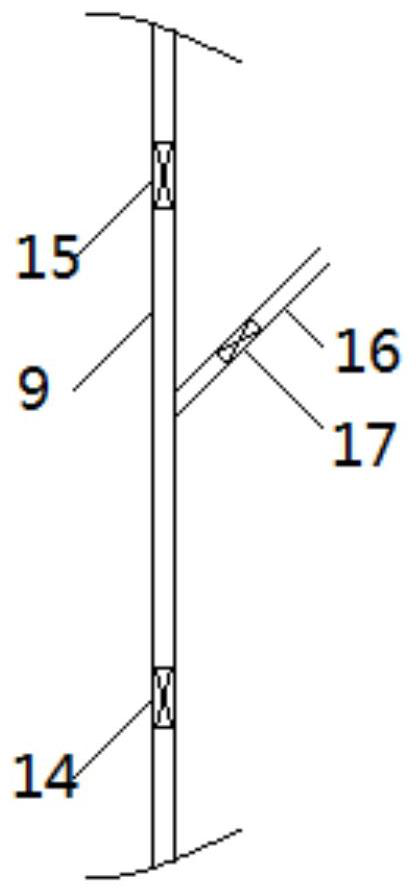

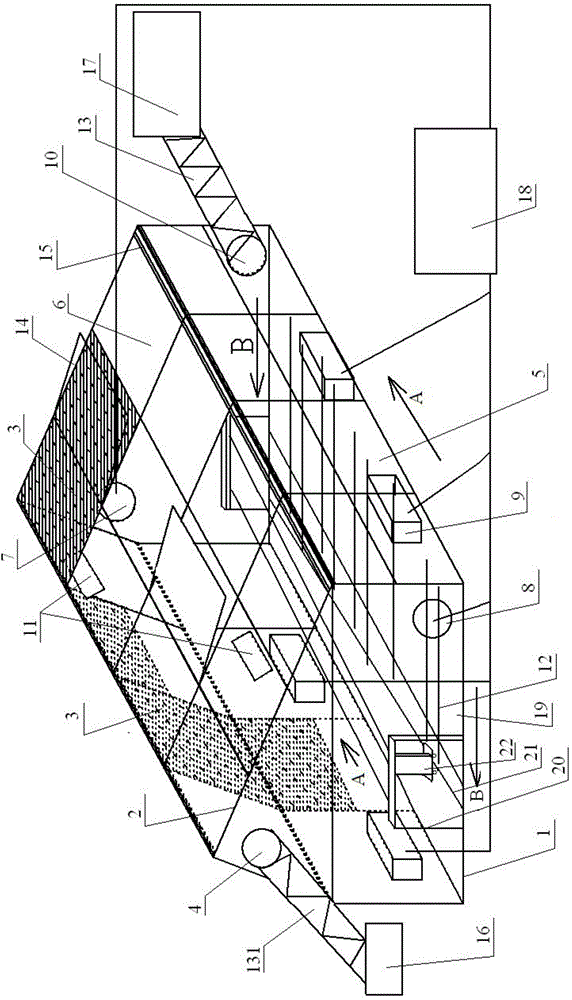

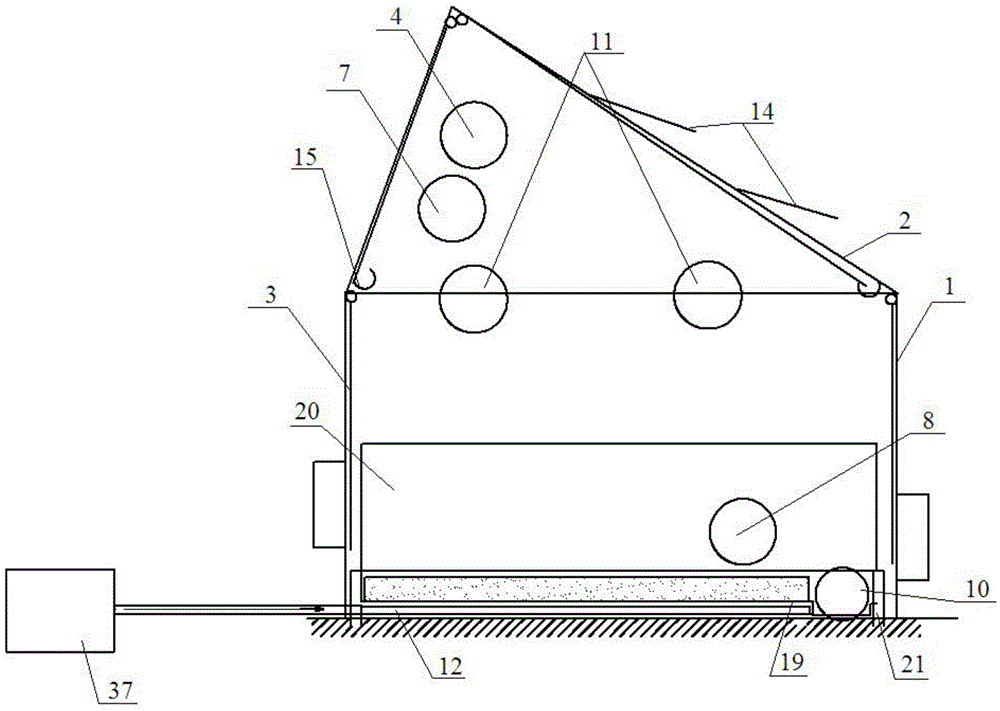

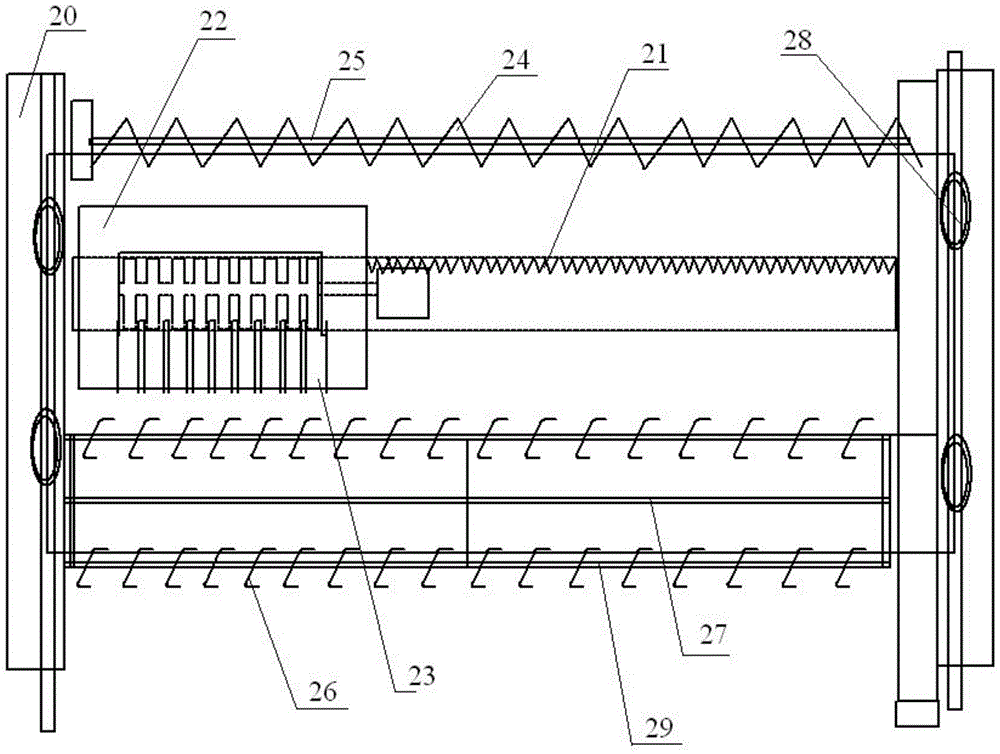

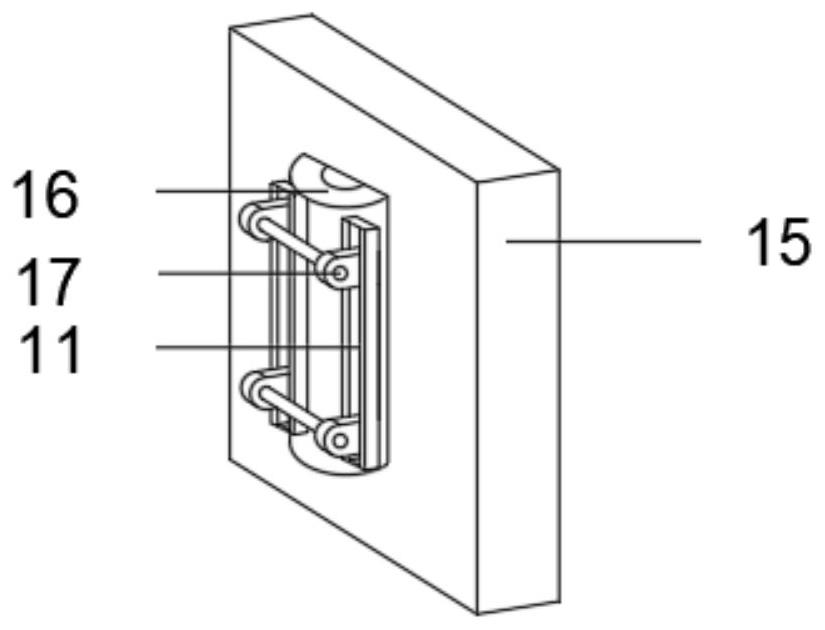

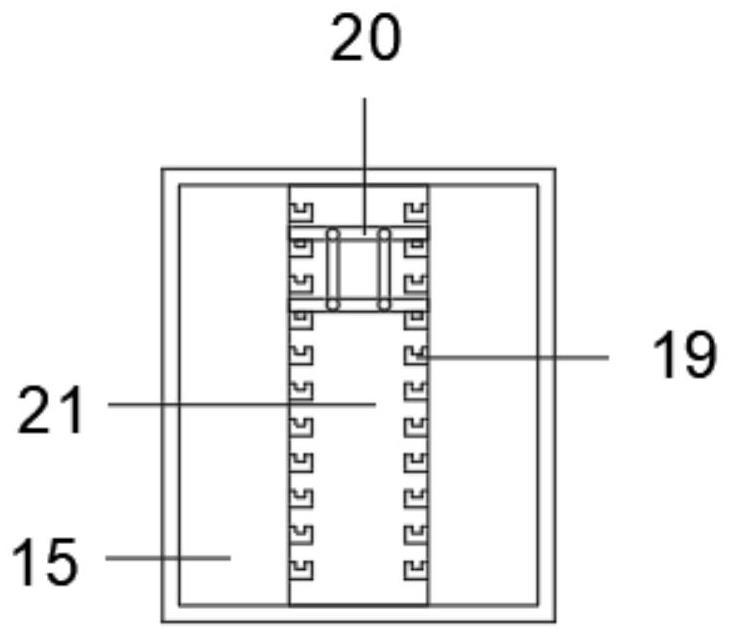

System for drying sludge by virtue of diversified heat energy

InactiveCN103992019AGuaranteed drying efficiencyOvercoming high consumptionSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentToxic gasGeothermal heating

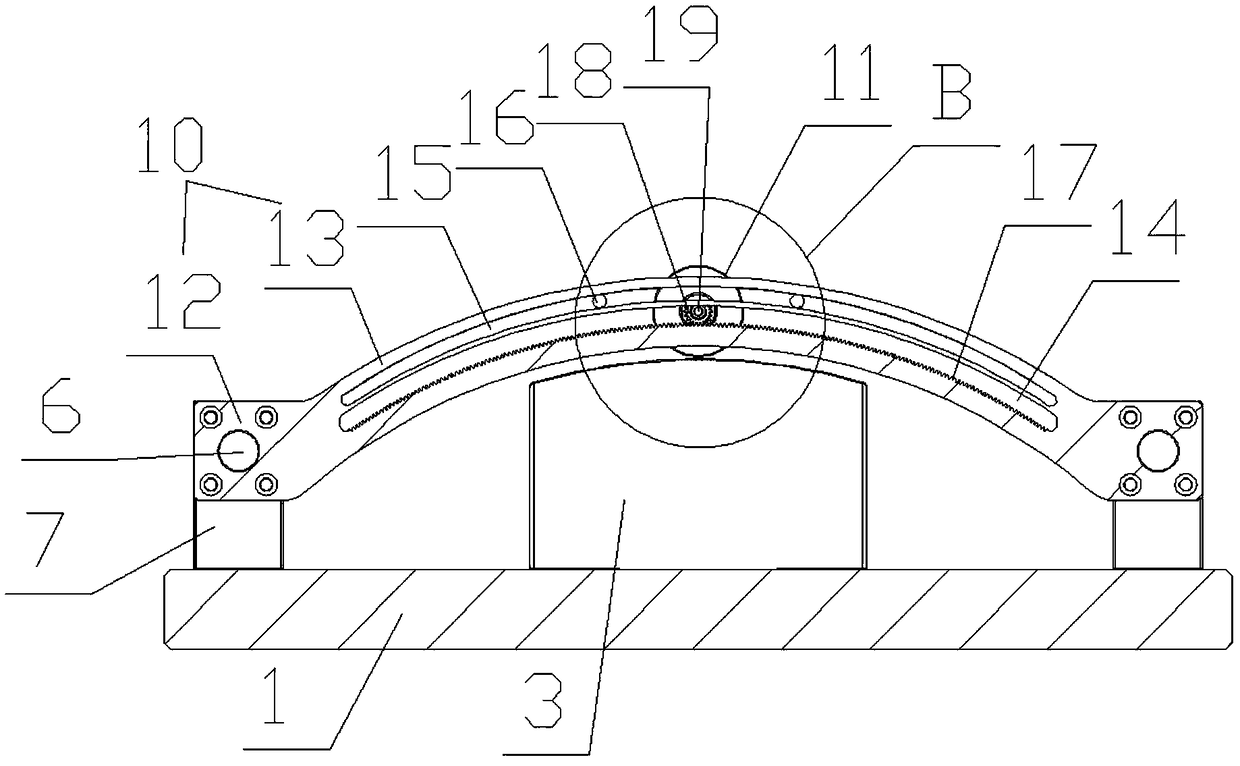

The invention discloses a system for drying sludge by virtue of diversified heat energy. The system comprises a sludge drying platform and a drying chamber body which is arranged on the sludge drying platform in a closed manner and is sealed with the sludge drying platform, wherein the drying chamber body is provided with a heat energy storage device, a gas circulation device and a sludge receiving and conveying device; the sludge drying platform comprises a sludge spreading table and a geothermal heating device arranged at the bottom of the sludge spreading table; the drying chamber body is also provided with a sludge inlet and a dry sludge outlet, the sludge inlet is connected with an external sludge conveying device, and the dry sludge outlet is connected with an external dry sludge conveying device. According to the technical scheme of the invention, the environmental pollution caused by toxic gas, generated in a sludge drying process, discharged to the atmosphere is avoided; sludge is arranged on the sludge spreading table; the sludge drying cycle is shortened and the drying efficiency is improved through the geothermal heating device at the bottom of the sludge spreading table and the gas circulation device of the drying chamber body; due to the sludge receiving and conveying device, the manual intervention in a drying process is avoided, the drying efficiency is improved, and the drying process is safe.

Owner:宋雷震

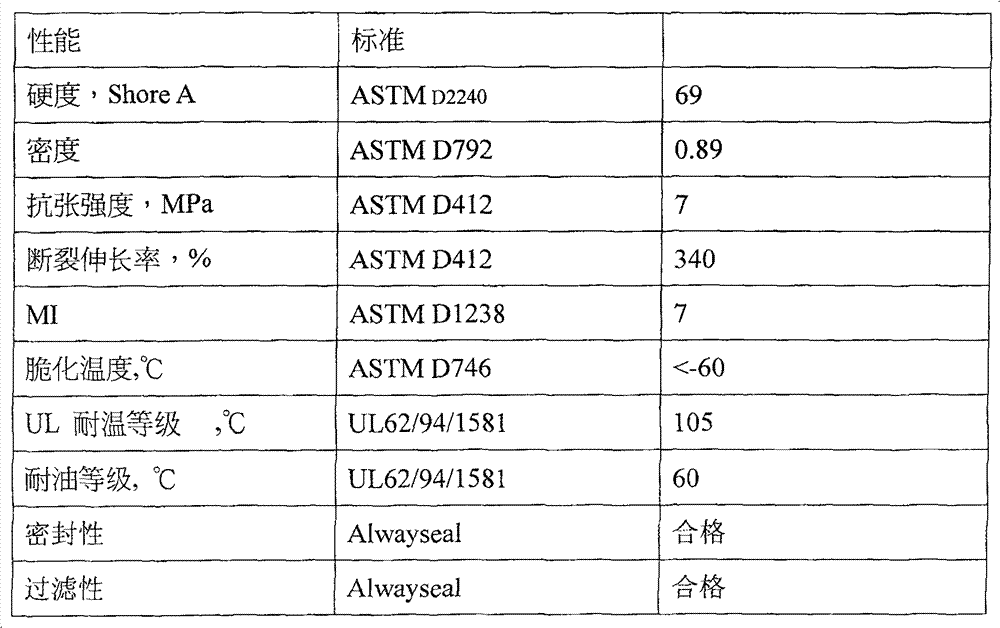

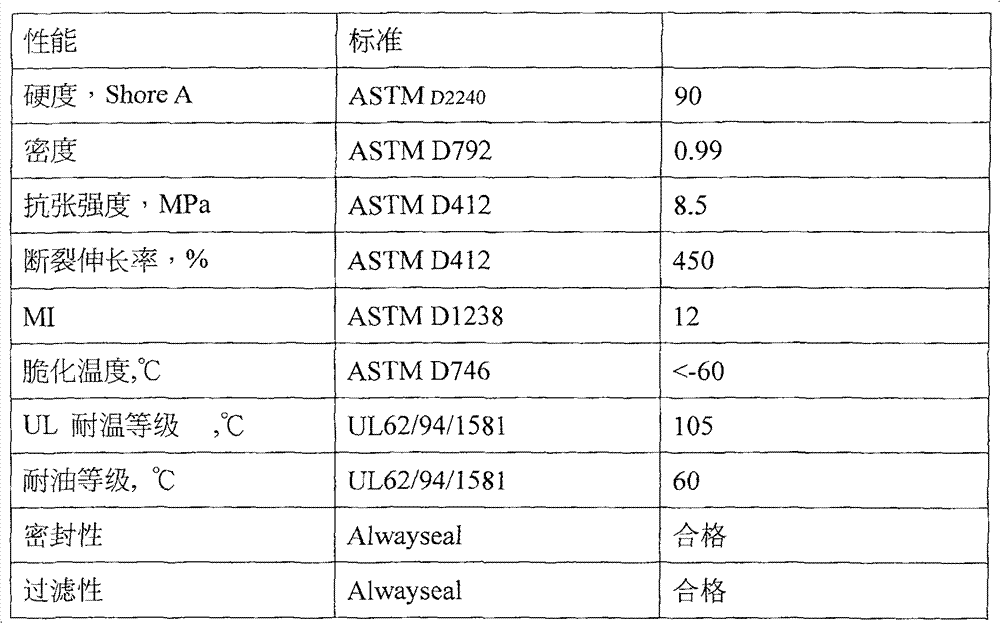

Environment friendly thermoplastic elastomer used as fire-retardant sealing strip and preparation method thereof

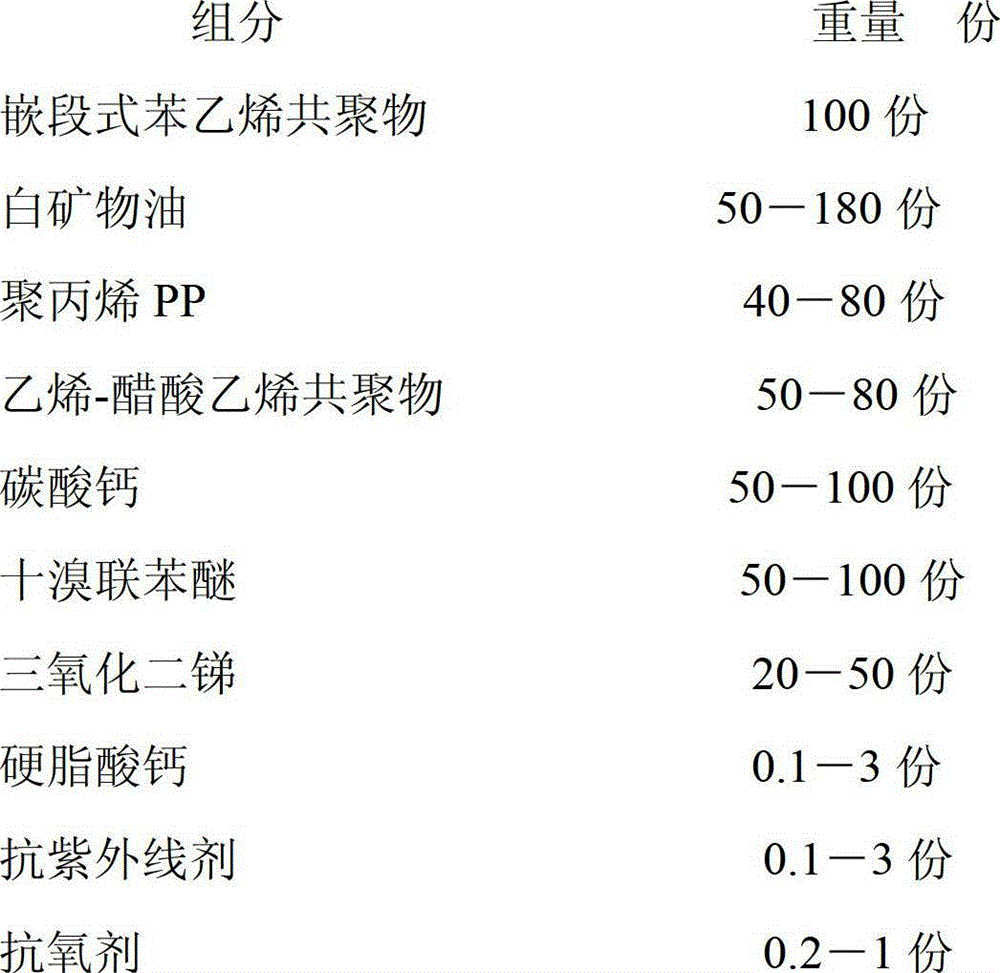

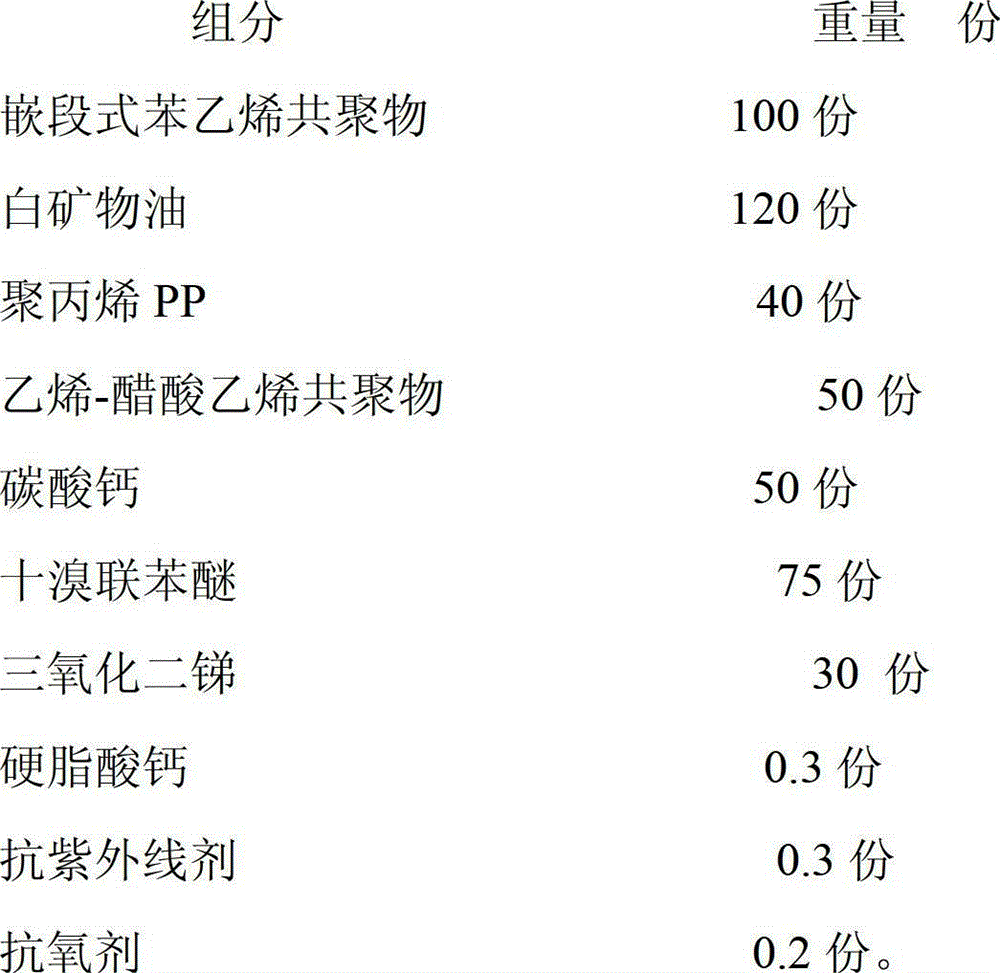

The invention provides a fire-retardant thermoplastic elastomer (TPE) capable of being used as a sealing strip of a bus and a preparation method thereof. The TPE contains the following components in parts by weight: 100 parts of segmented styrene copolymer, 50-180 parts of mineral oil, 40-80 parts of polypropylene PP, 50-80 parts of EVA, 50-100 parts of calcium carbonate, 50-100 parts of decabromodiphenyl oxide, 20-50 parts of antimony trioxide, 0.1-3 parts of calcium stearate and 0.2-1 part of antioxidant. The TPE provided by the invention has good flexibility, fire retardancy and high manufacturing efficiency, is an ideal material for manufacturing the sealing strip of the bus, and can be mechanically operated. The leftover material can be recycled, which is significant to save resources.

Owner:GUANGDONG KINGREAT HITECH

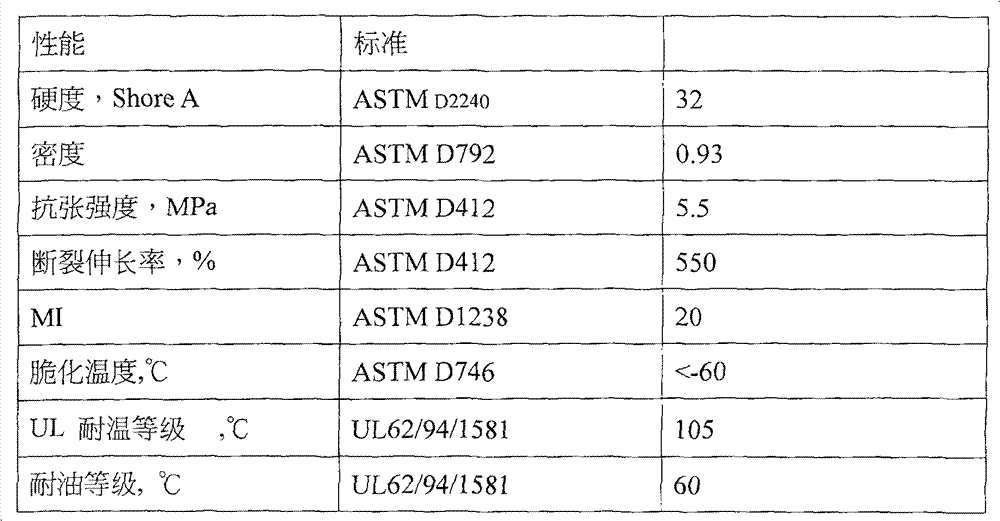

Environment-friendly TPE (thermoplastic elastomer) and method for preparing air strainer by using same

InactiveCN102167880AGood flexibilityImprove plasticityDispersed particle filtrationAntioxidantPolypropylene

The invention provides a biodegradable TPE (thermoplastic elastomer) and a method for preparing airstrainer. The TPE comprises the following components in parts by weight: 100 parts of SEBS (styrene-ethylene-butadiene-styrene), 5-380 parts of white mineral oil, 5-200 parts of PP (polypropylene), 5-100 parts of polyurethane, 0-80 parts of EVA (ethylene-vinyl acetate), 0-100 parts of calcium carbonate, 0-3 parts of calcium stearate, 0.2-1 part of antioxidant, 1-100 parts of maleic anhydride grafted polypropylene, 0-10 parts of titanium dioxide and 1-15 parts of ethylene propylene diene monomer. The TPE provided by the invention has favorable flexibility and high preparation efficiency, is an ideal material for preparing an air strainer, and can be used for mechanical operation, and the scraps can be recycled and reutilized, thereby having an important meaning for saving resources.

Owner:欧瑞喜(福州)塑胶科技有限公司

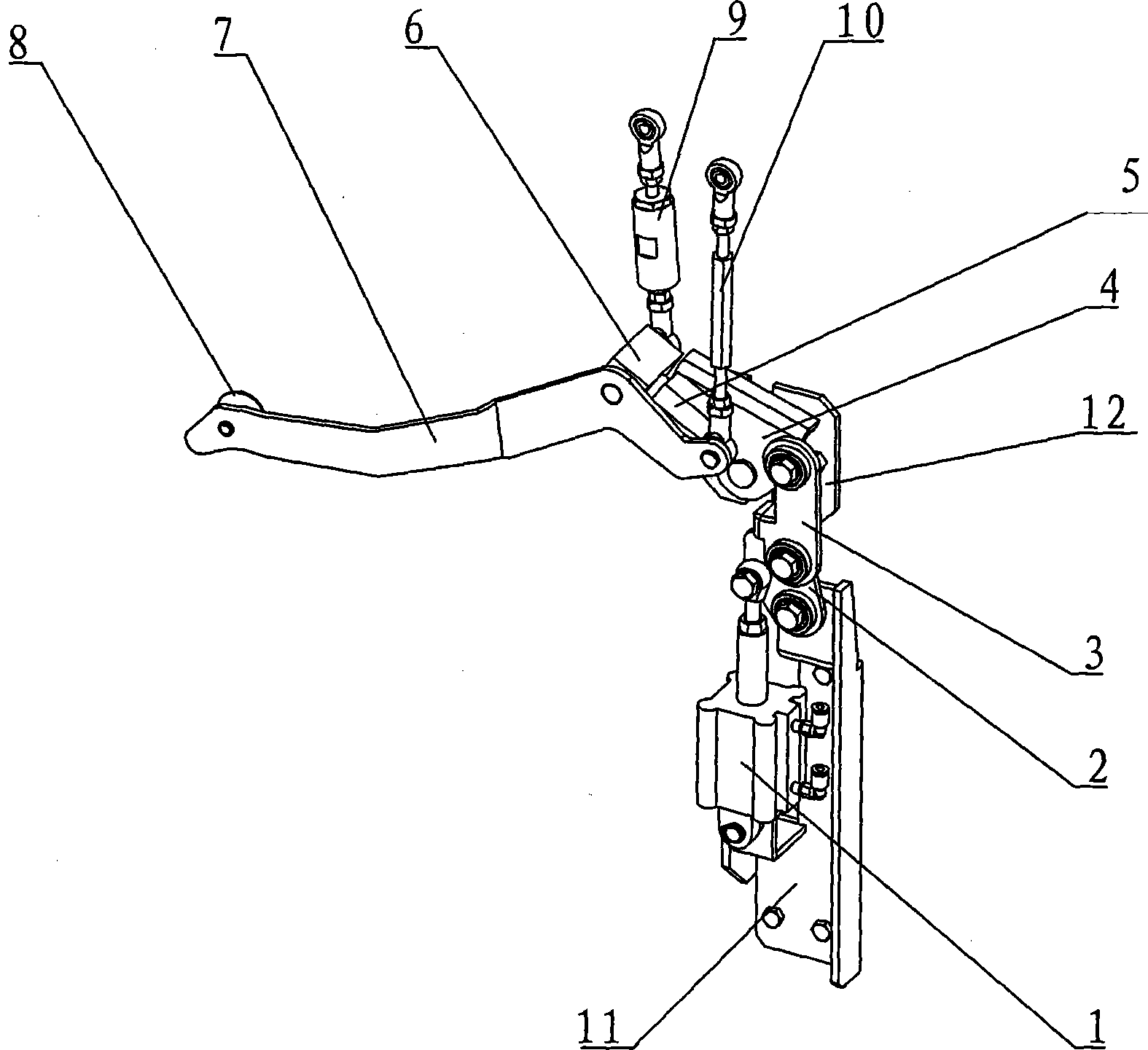

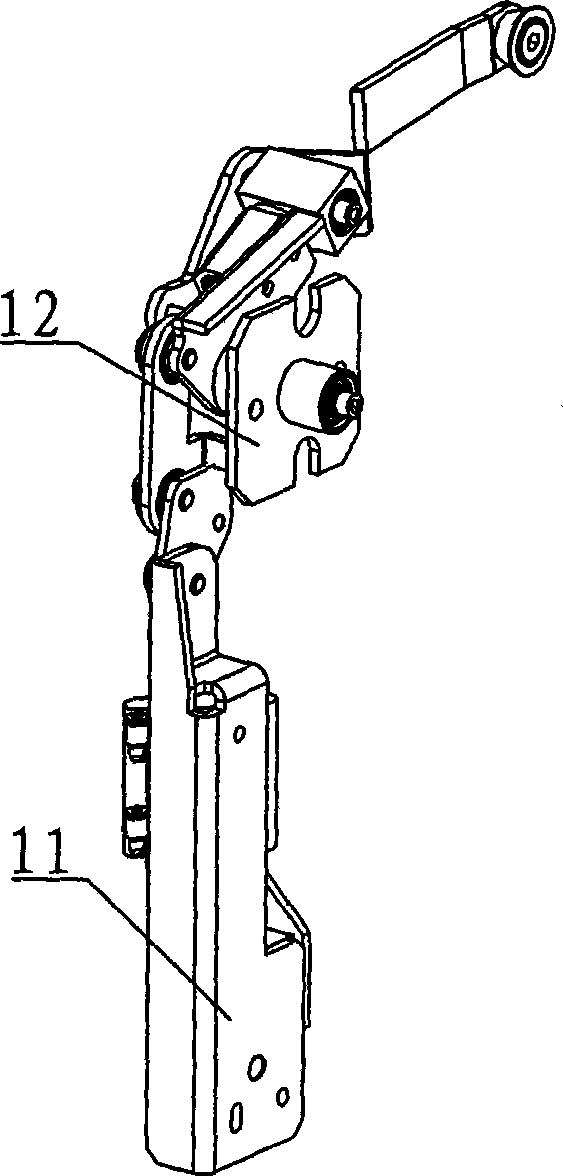

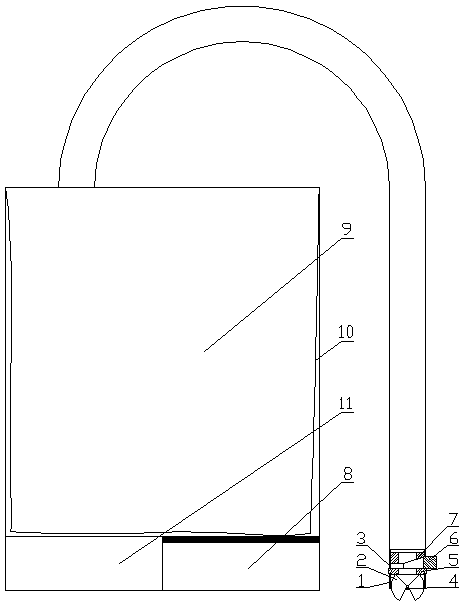

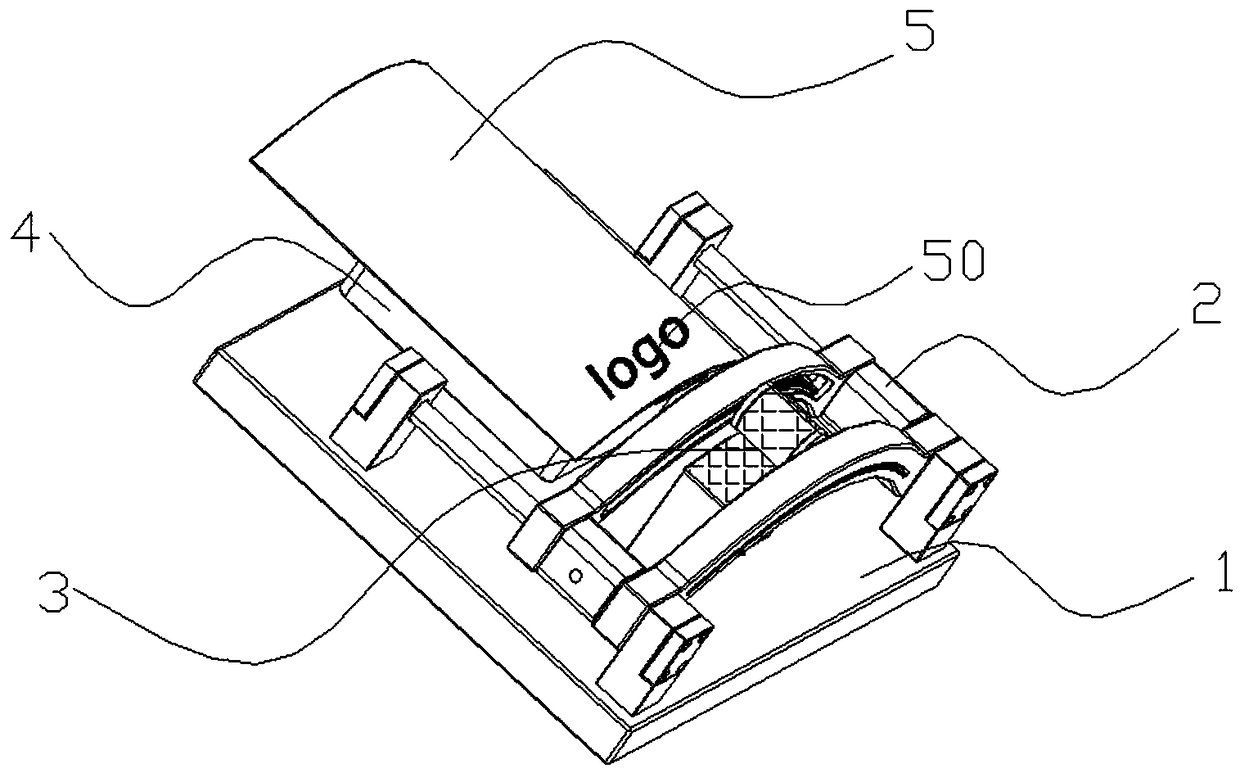

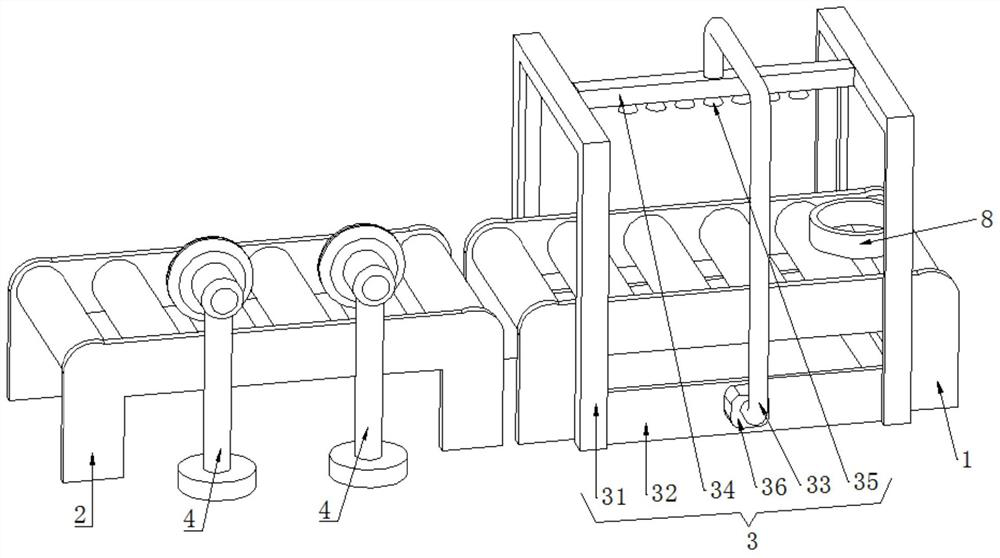

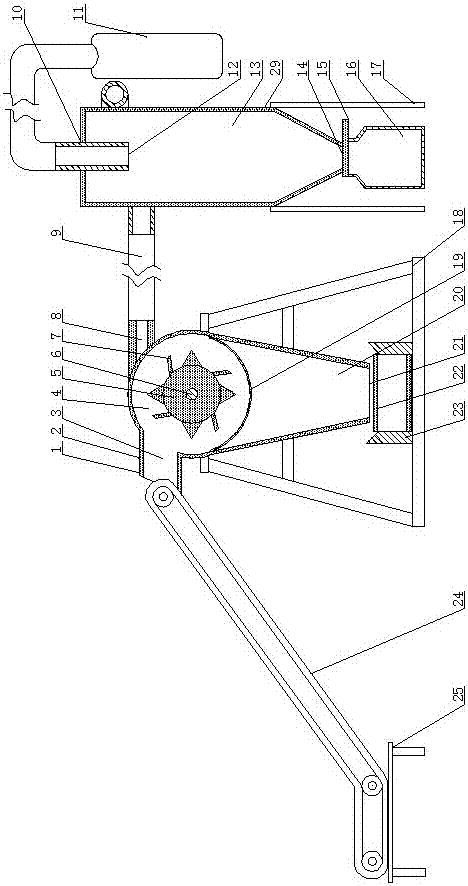

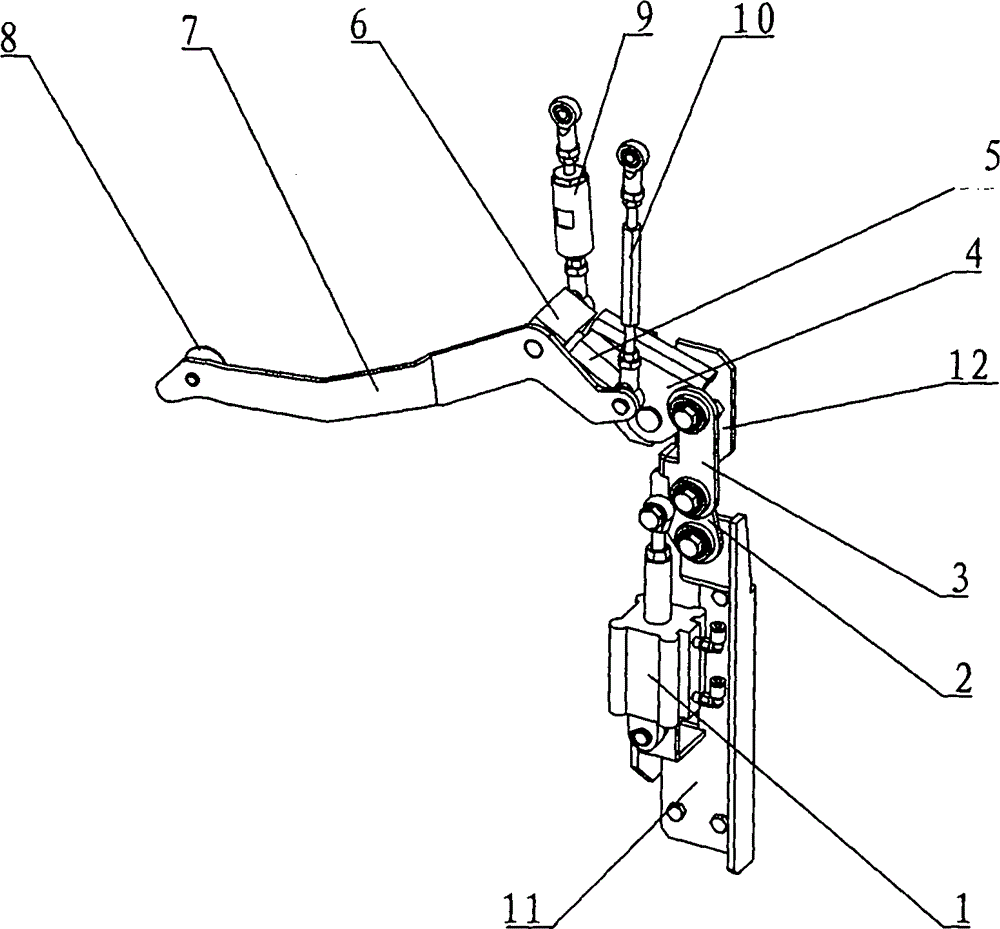

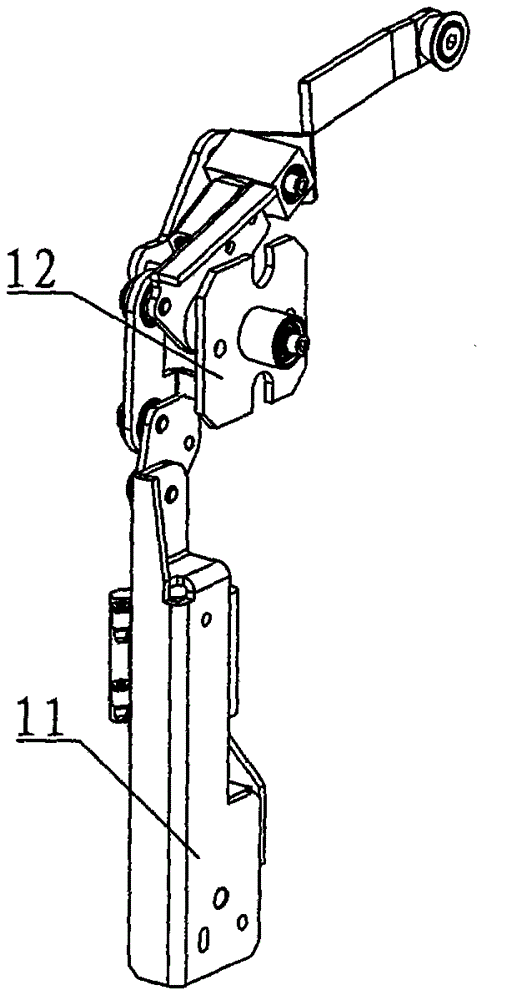

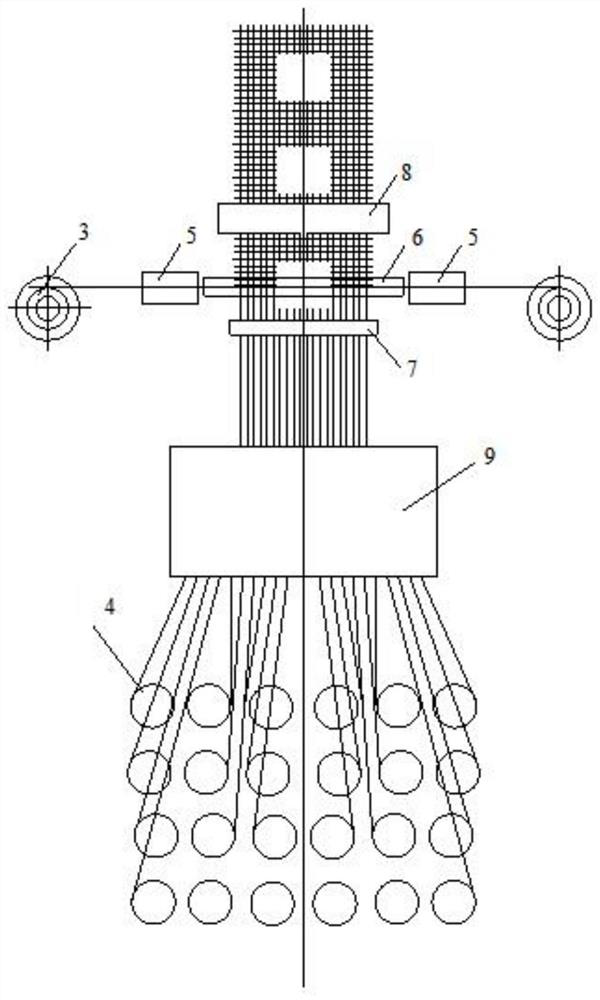

Doffing mechanical arm

ActiveCN103526364ARealize mechanical operationImprove work efficiencyTextiles and paperAutomatic controlEngineering

The invention discloses a doffing mechanical arm on a spinning machine. The doffing mechanical arm comprises a drive device, a transmission assembly and a holding assembly. The drive device is connected with the lower end of a first lever of the transmission assembly. The upper end of the first lever is hinged to the lower end of a second lever through a transition plate. The upper end of the second lever is fixed with a cross-shaped shaft seat. A lengthwise shaft of a cross-shaped shaft is connected in a hole of the cross-shaped shaft seat in an inserted mode to form clearance fit. A horizontal shaft is fixed to the tail end of a swing arm, and the horizontal shaft penetrates through a horizontal axial hole in the cross-shaped shaft and is connected with the drive device through a horizontal joint pull rod. The tail end of the swing arm is connected with the drive device through a lengthwise joint pull rod. The holding part is arranged at the head end of the swing arm. As the drive device is controlled by an automatic control system, after the holding part is connected with a moving arm of a creel in a clamped mode, the holding part can move in three dimensions, namely in lengthwise direction, in horizontal direction and in a front-and-back mode under the drive of the transmission assembly. The reel will be driven along with the holding part to finish all actions needed in doffing. Thus, mechanical operation of automatic doffing is achieved and the working efficiency of the spinning machine is improved.

Owner:AVIC SHAANXI HUAYAN AERO INSTR

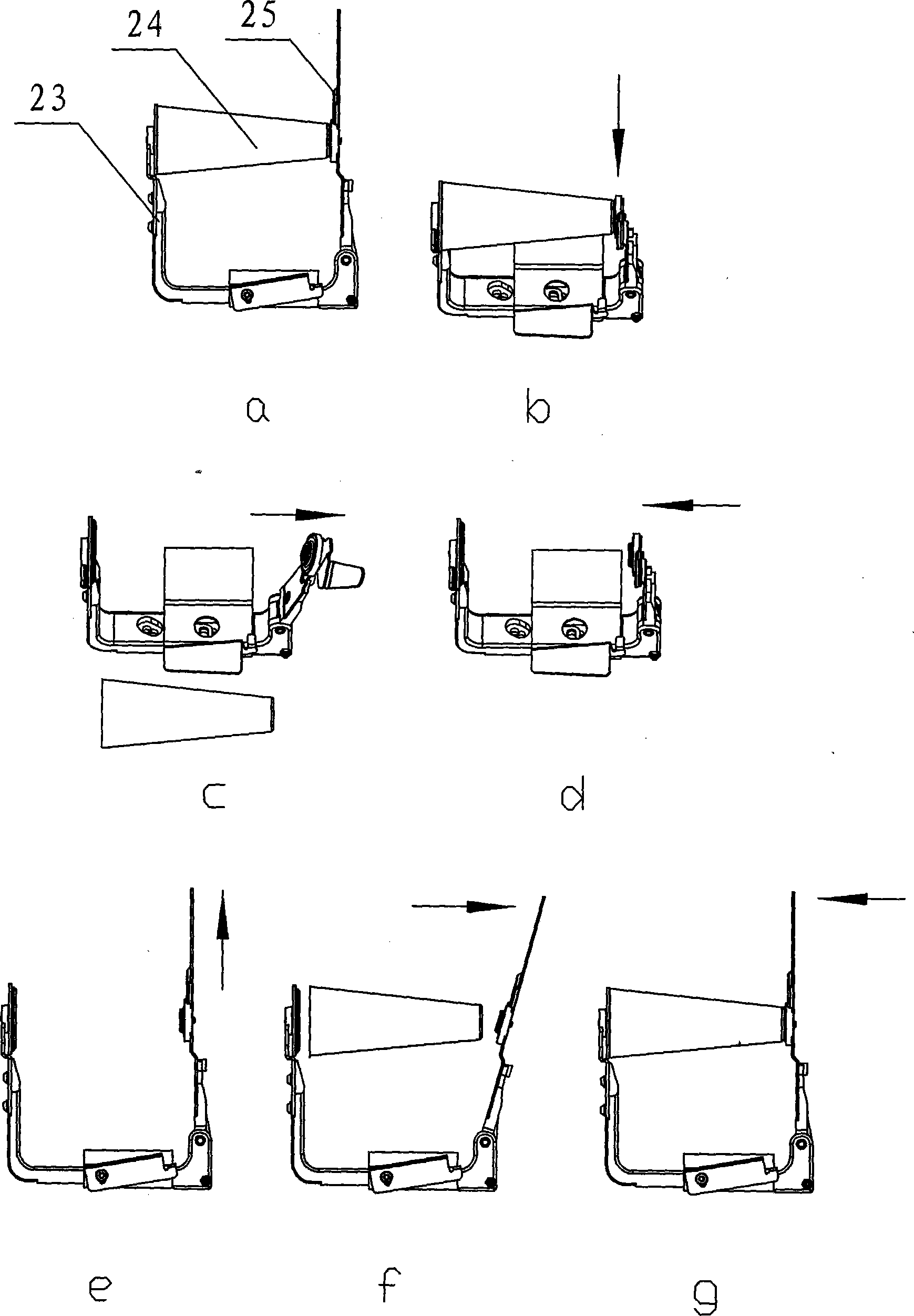

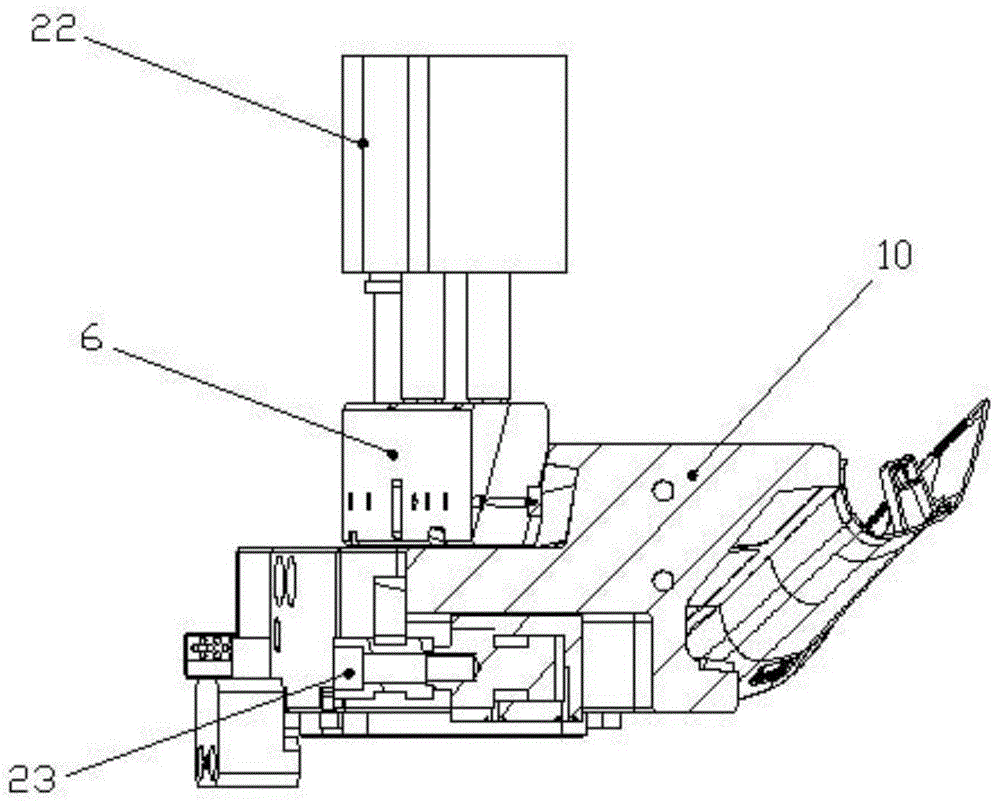

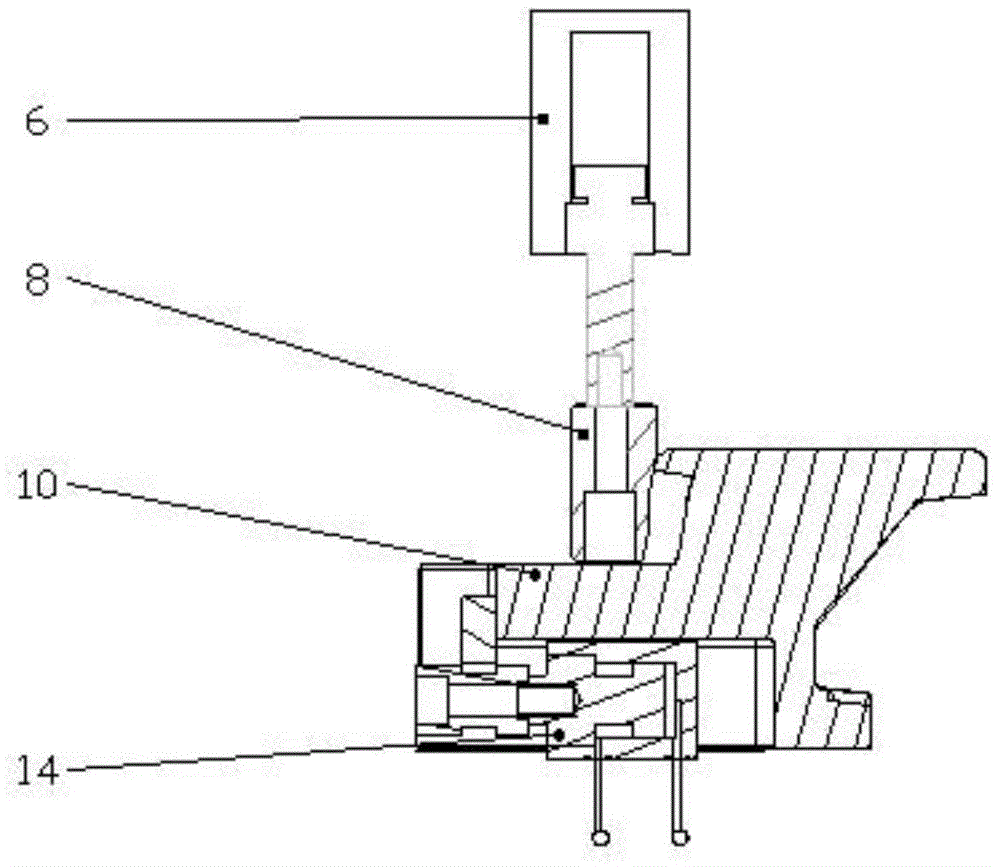

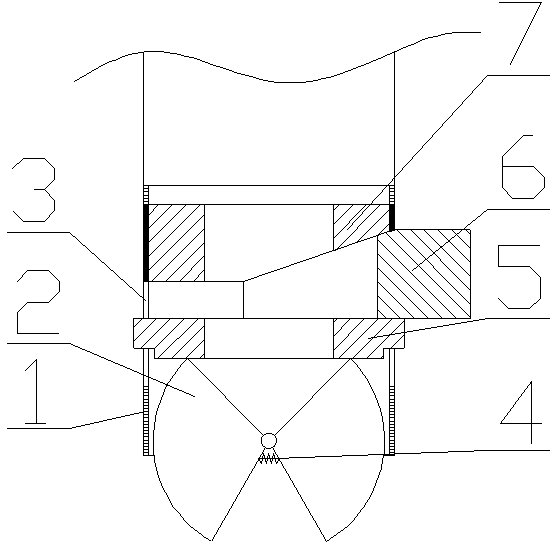

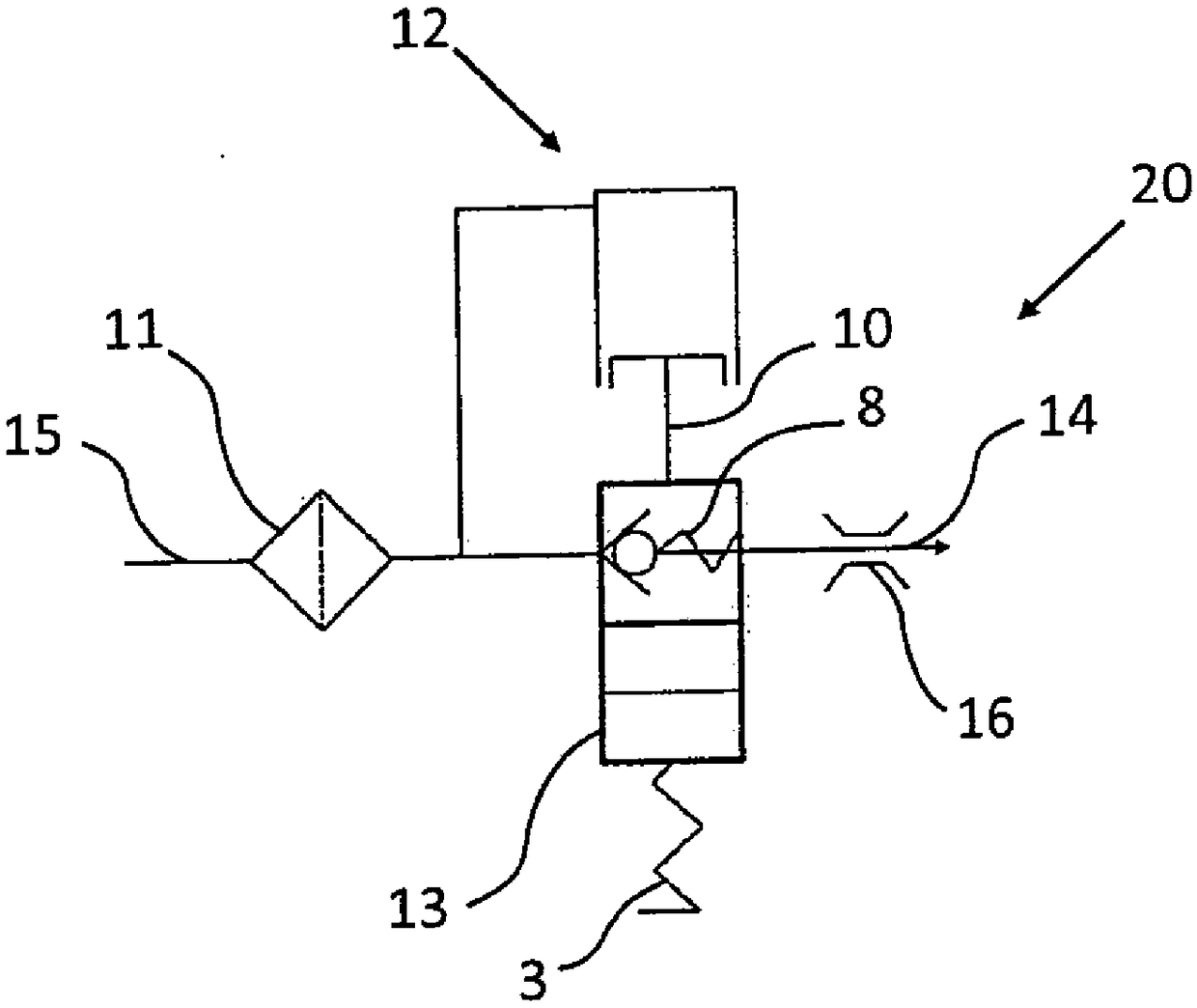

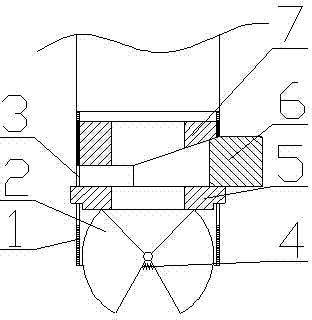

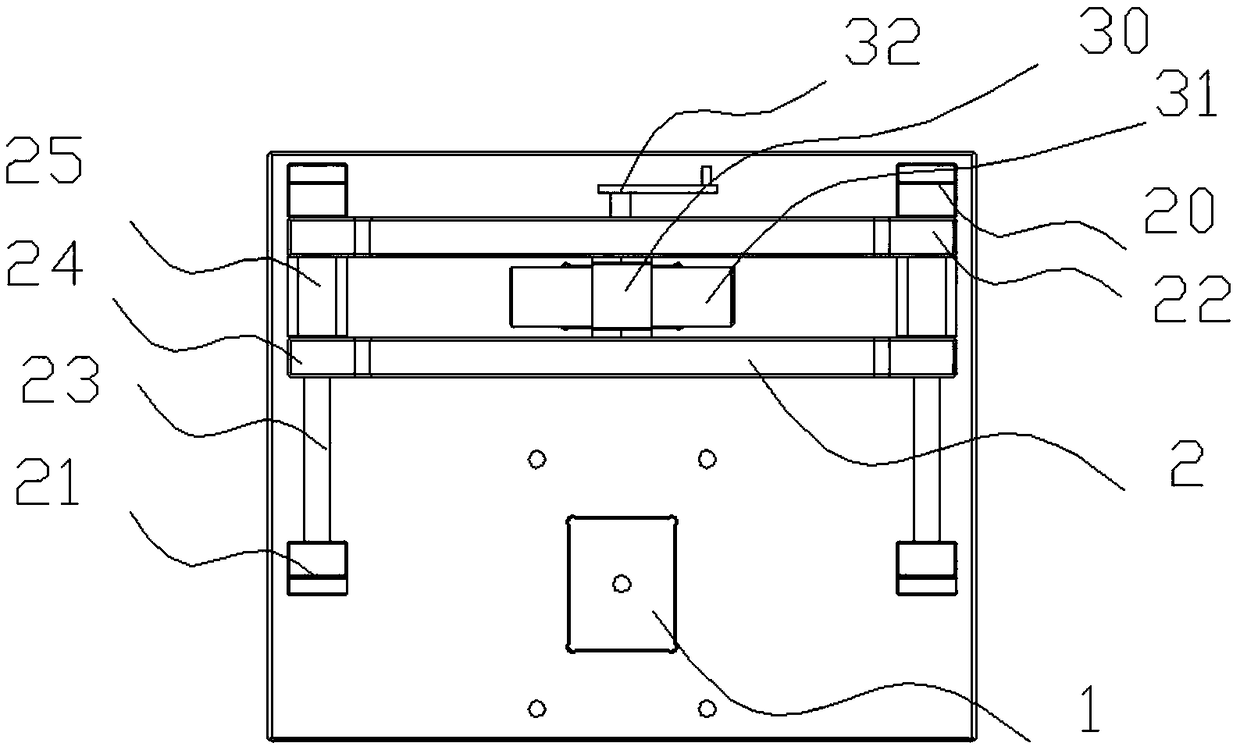

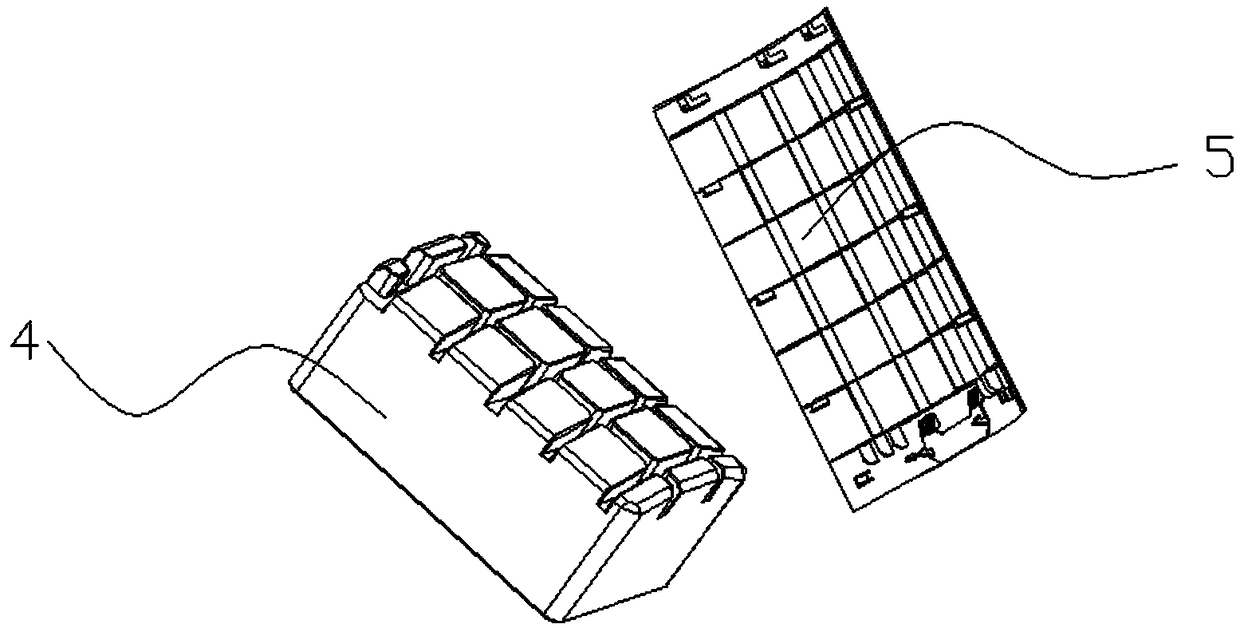

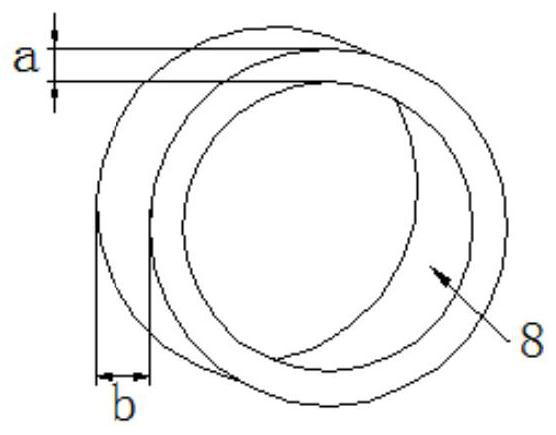

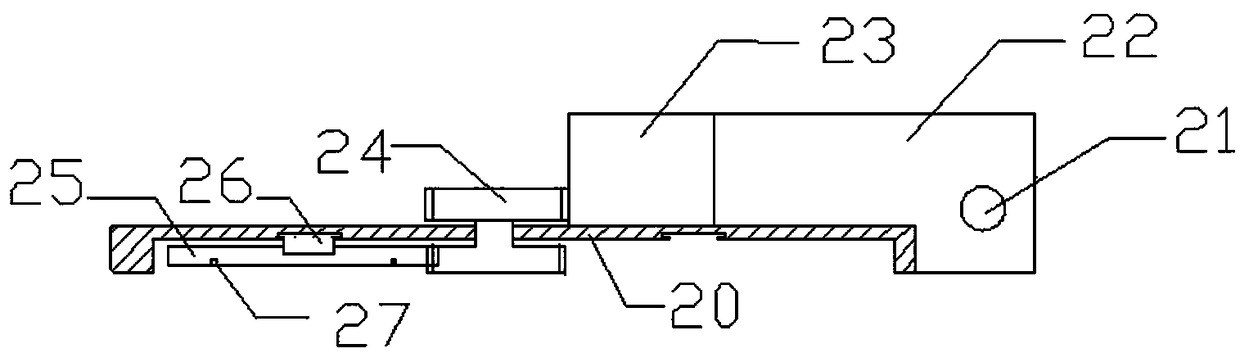

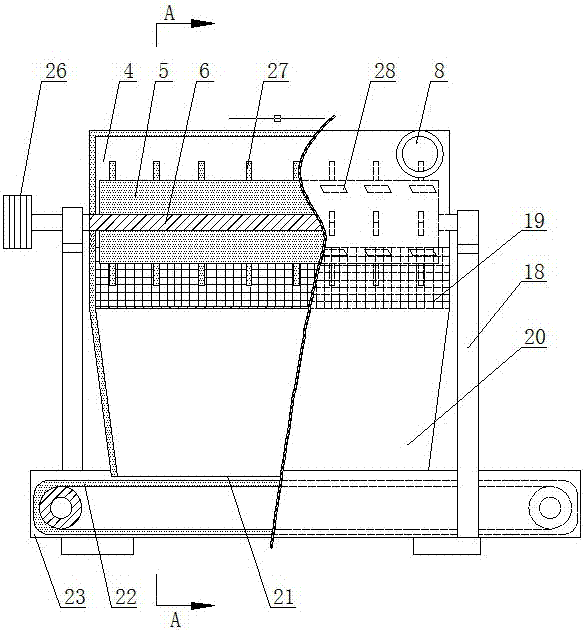

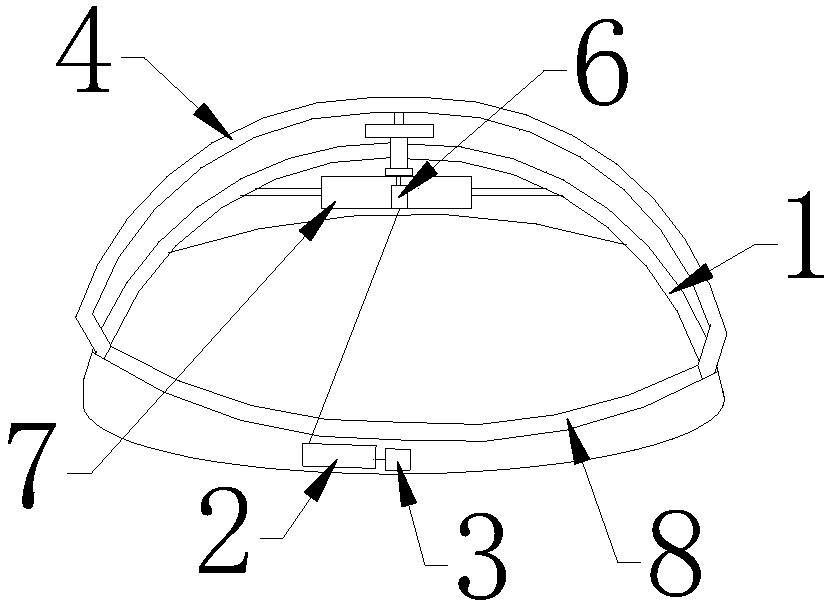

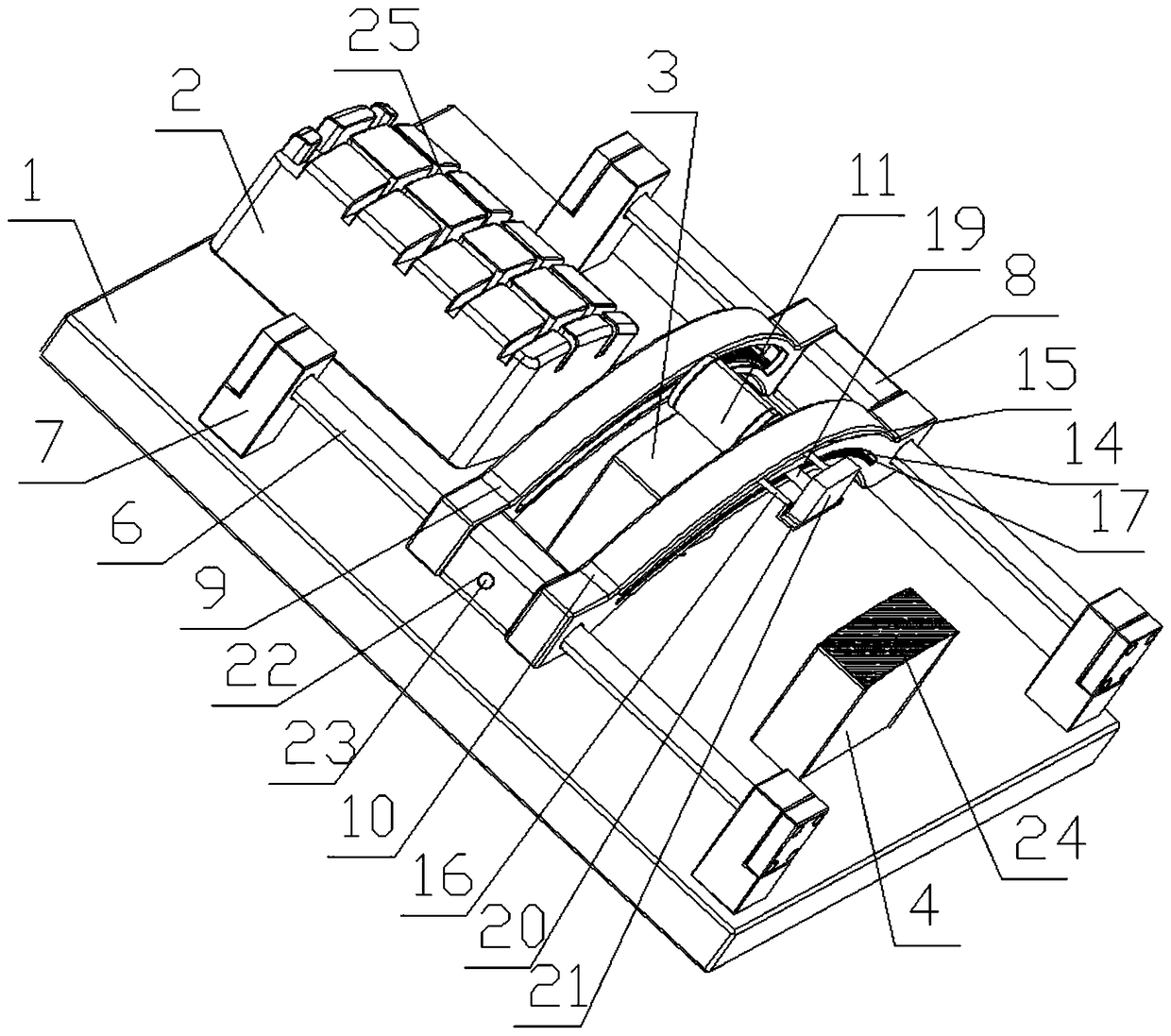

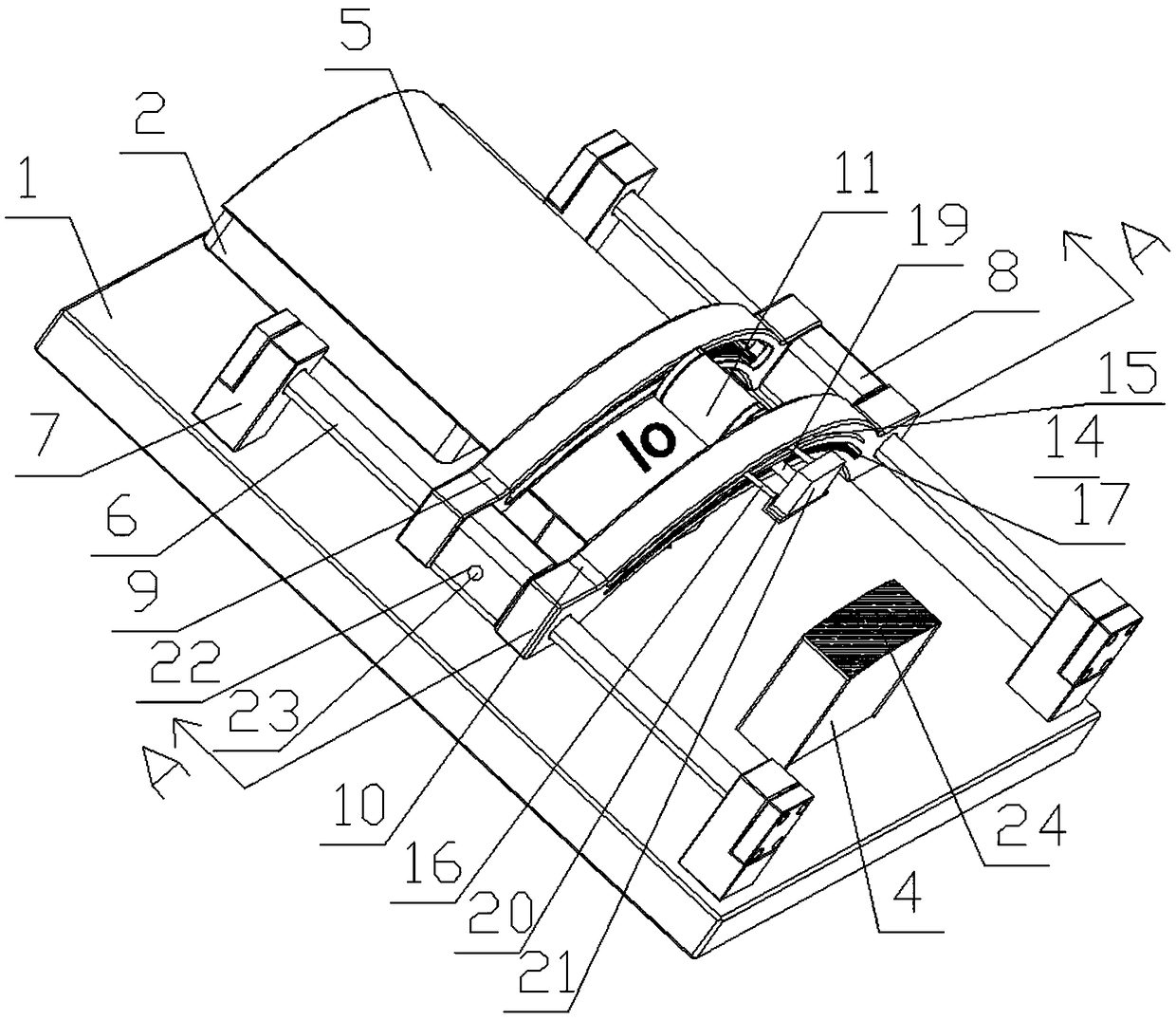

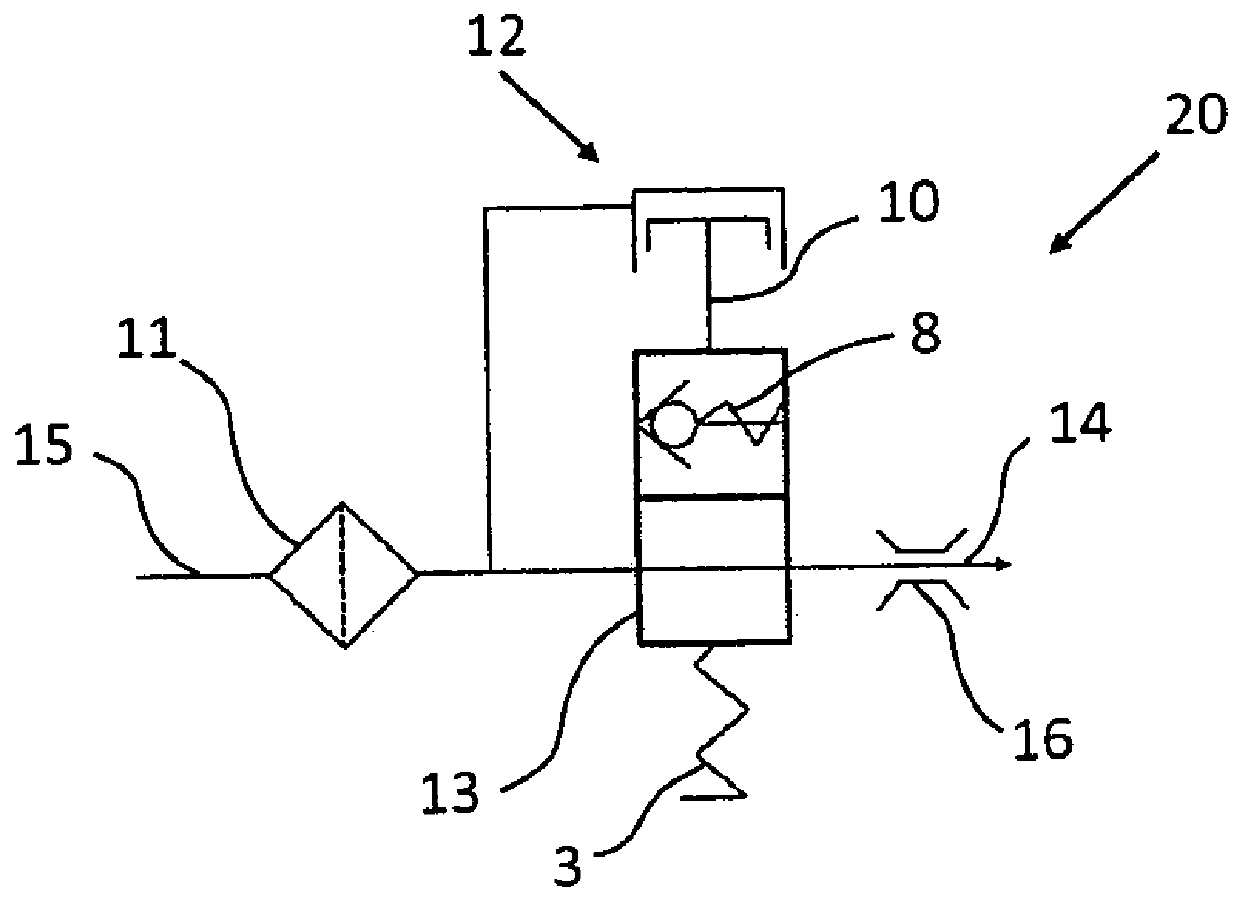

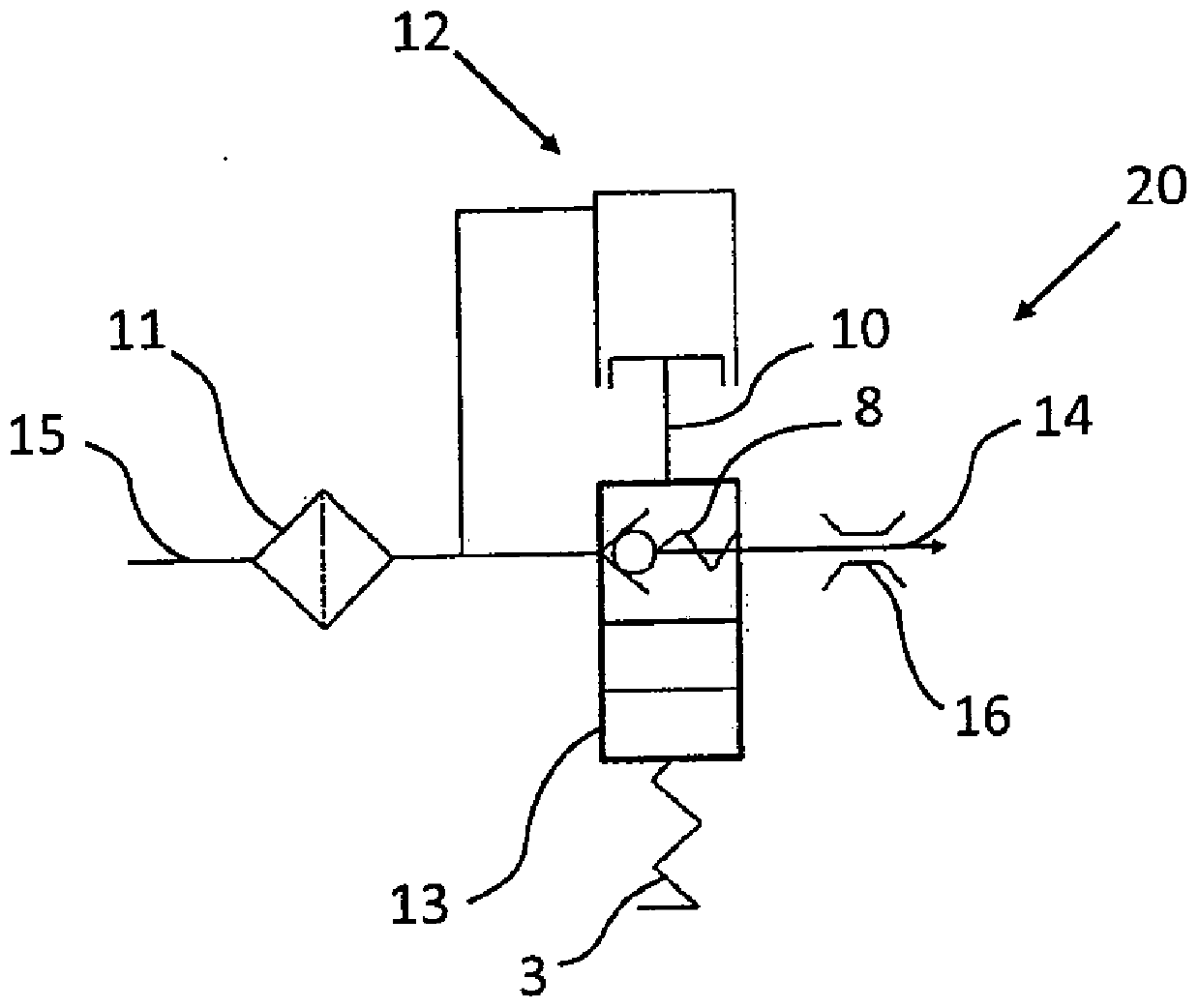

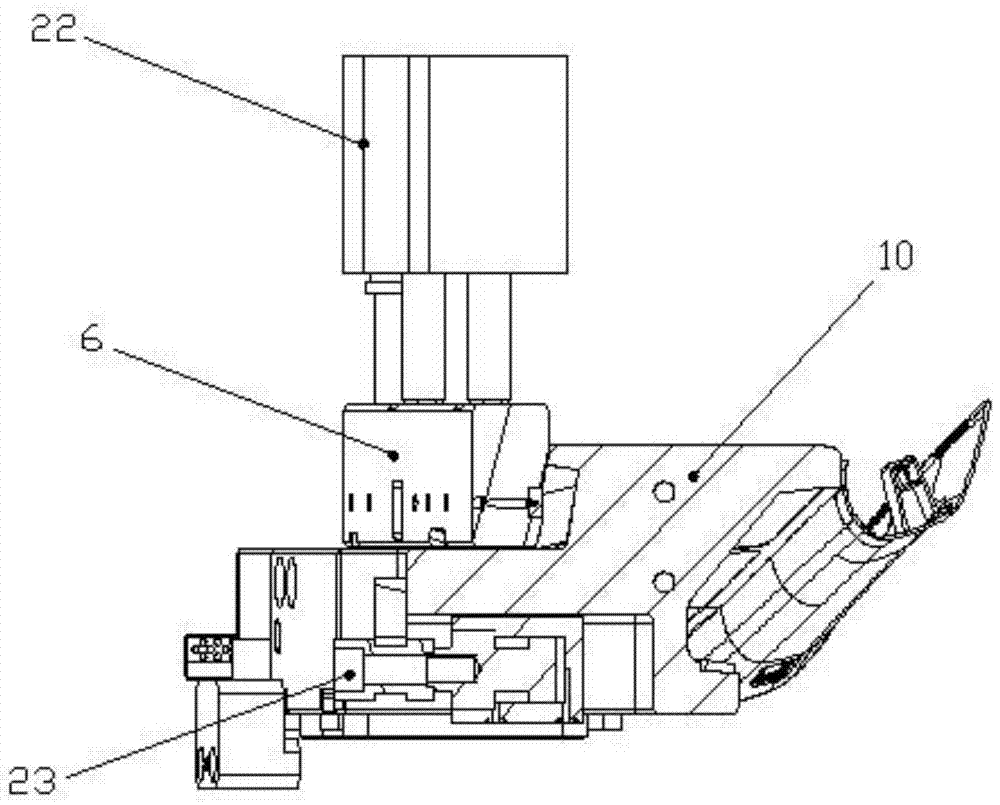

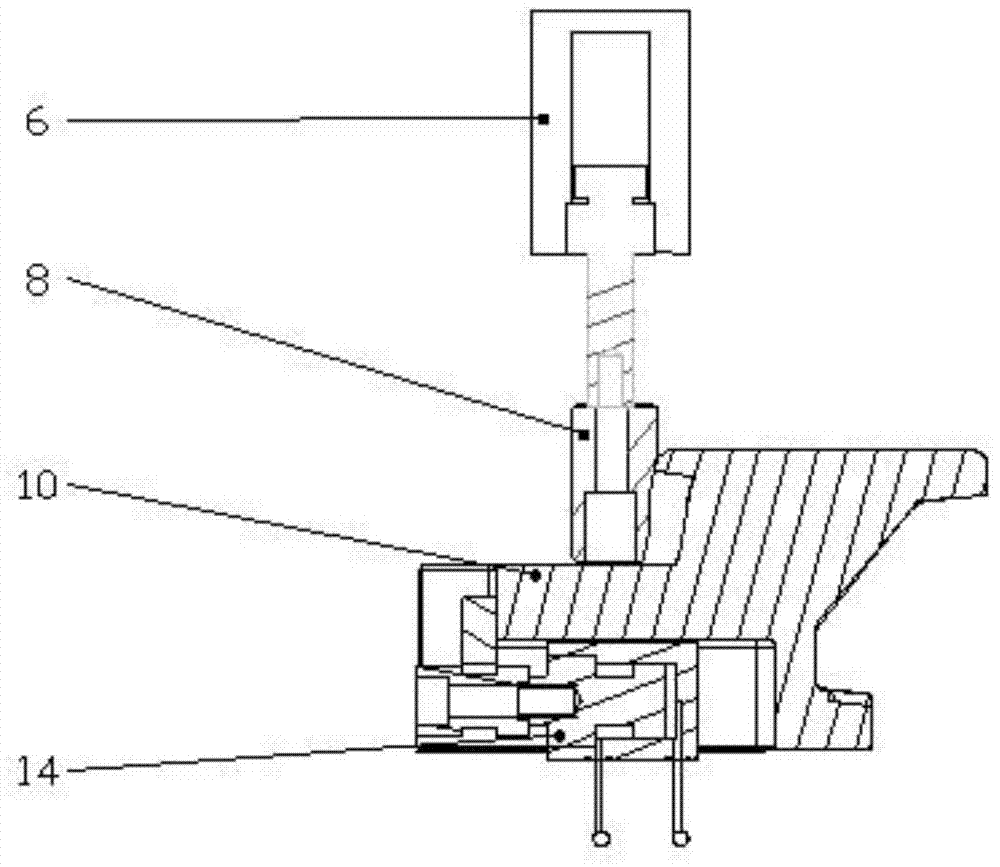

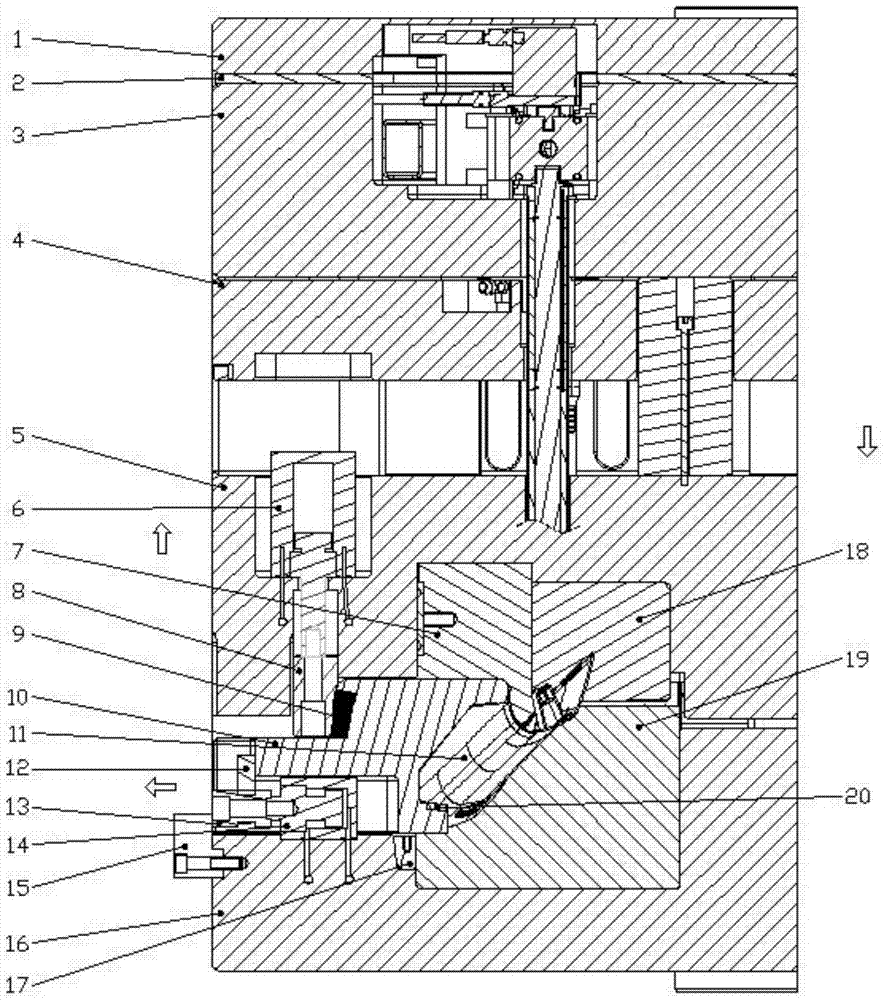

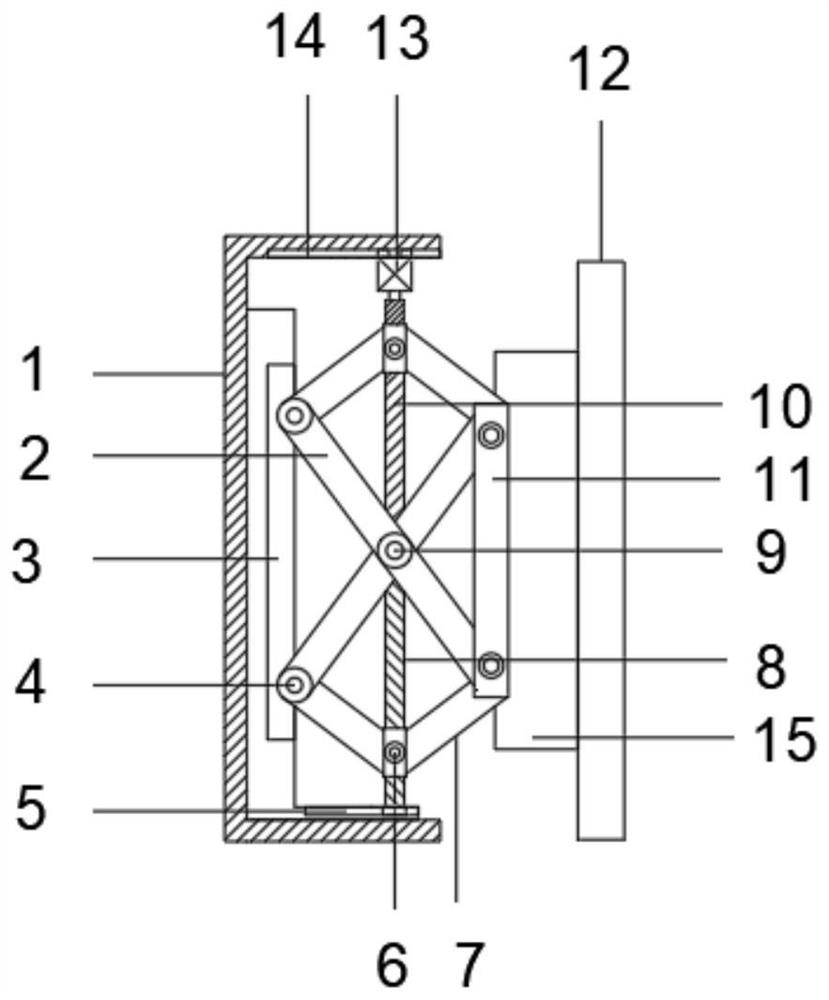

Slide demoulding mechanism for injection mould

ActiveCN105196499ARealize mechanical operationReduce one mold openingEngineeringMechanical engineering

The invention relates to the field of injection moulds, in particular to a slide demoulding mechanism for an in-mould lamination injection mould. The slide demoulding mechanism comprises a slide (10) which forms a mould cavity of the injection mould jointly with a fixed mould core and a movable mould core and is further provided with a heel block (8) used for limiting the position of the slide (10) in the injection mould, a first power mechanism (22) which can drive the heel block (8) to move to relieve limiting of the heel block (8) on the position of the slide (10) in the injection mould and a second power mechanism (23) which can drive the slide (10) to be far away from the mould cavity of the injection mould. According to the slide demoulding mechanism for the in-mould lamination injection mould, the heel block and the slide in the injection mould can be driven by the power mechanisms to be adjusted, so that separation and backoff between the slide and a moulded product can be achieved; compared with the traditional mode that the mould is artificially opened to take the slide out, mechanical operation in the injection mould is achieved, one-time mould opening in the injection process can be reduced, the injection cycle is effectively shortened, and the production efficiency in the injection process is improved.

Owner:KUNDA MOLD SHENZHEN

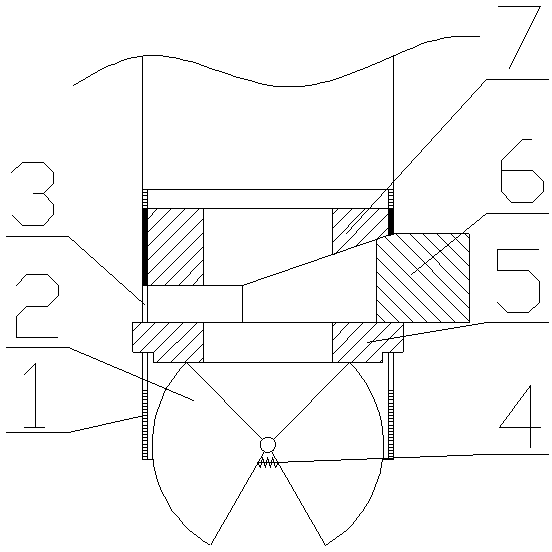

Single portable tea leaf picker

InactiveCN104272924AIn line with operating habitsEasy to operatePicking devicesAgricultural engineeringStructural engineering

The invention discloses a single portable tea leaf picker comprising a backpack (9). An accumulator (11) and a vacuum pump (8) are arranged at the bottom of the backpack (9). Filtering cloth is arranged between the vacuum pump (8) and the backpack (9) which is connected with a pipe (1). A slide slot (3) is formed in the side wall of the pipe (1) and internally provided with a compressing slide block (5) in the fixed manner. Left and right spherical cutters (2) are arranged under the pipe (1) and provided with the compressing slide block (5). A spring (4) is arranged between the spherical cutters (2). The compressing slide block (5) is provided with a movable slide block (6) provided with a limiting slide block (7). A face, in contact with the movable slide block (6), of the limiting slide block (7) is a slope. The single portable tea leaf picker can be operated by single hand and has operational simplicity and no harm to hands or tea leaves. The single portable tea leaf picker is convenient to operate, labor saving and high in picking efficiency.

Owner:马世龙

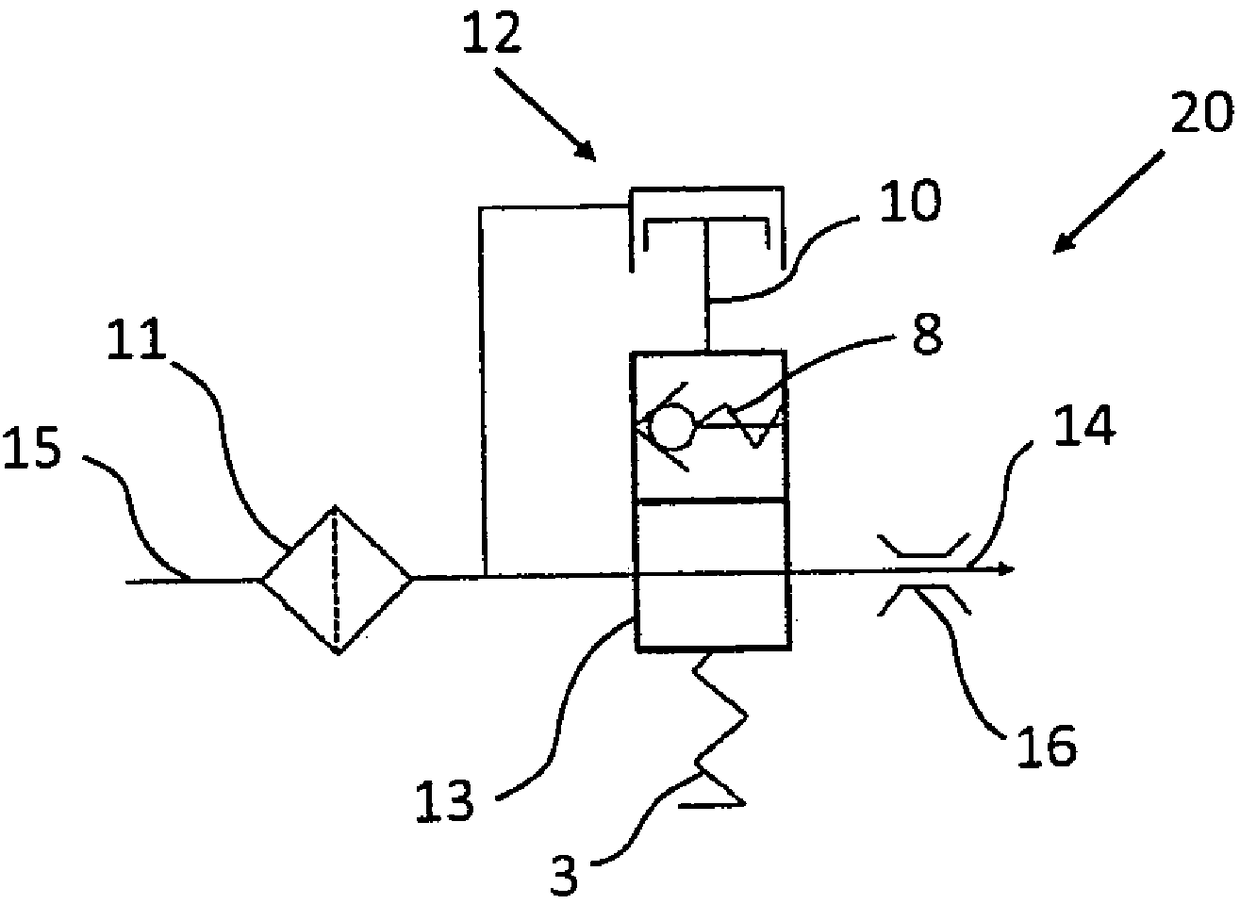

Pneumatically controlled drain valve

ActiveCN108474372AFunctionality is not affectedSmall cross sectionOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringMechanical engineering

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

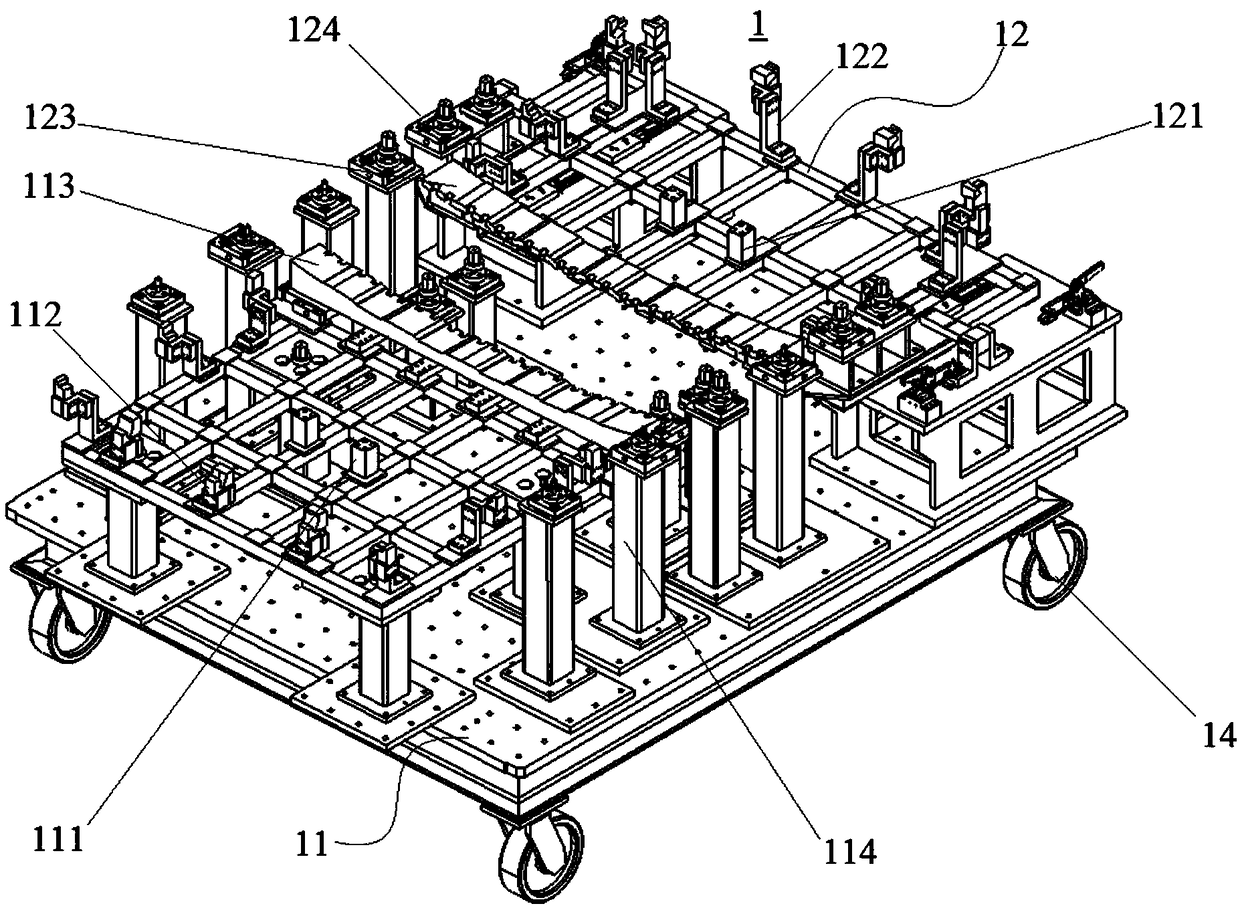

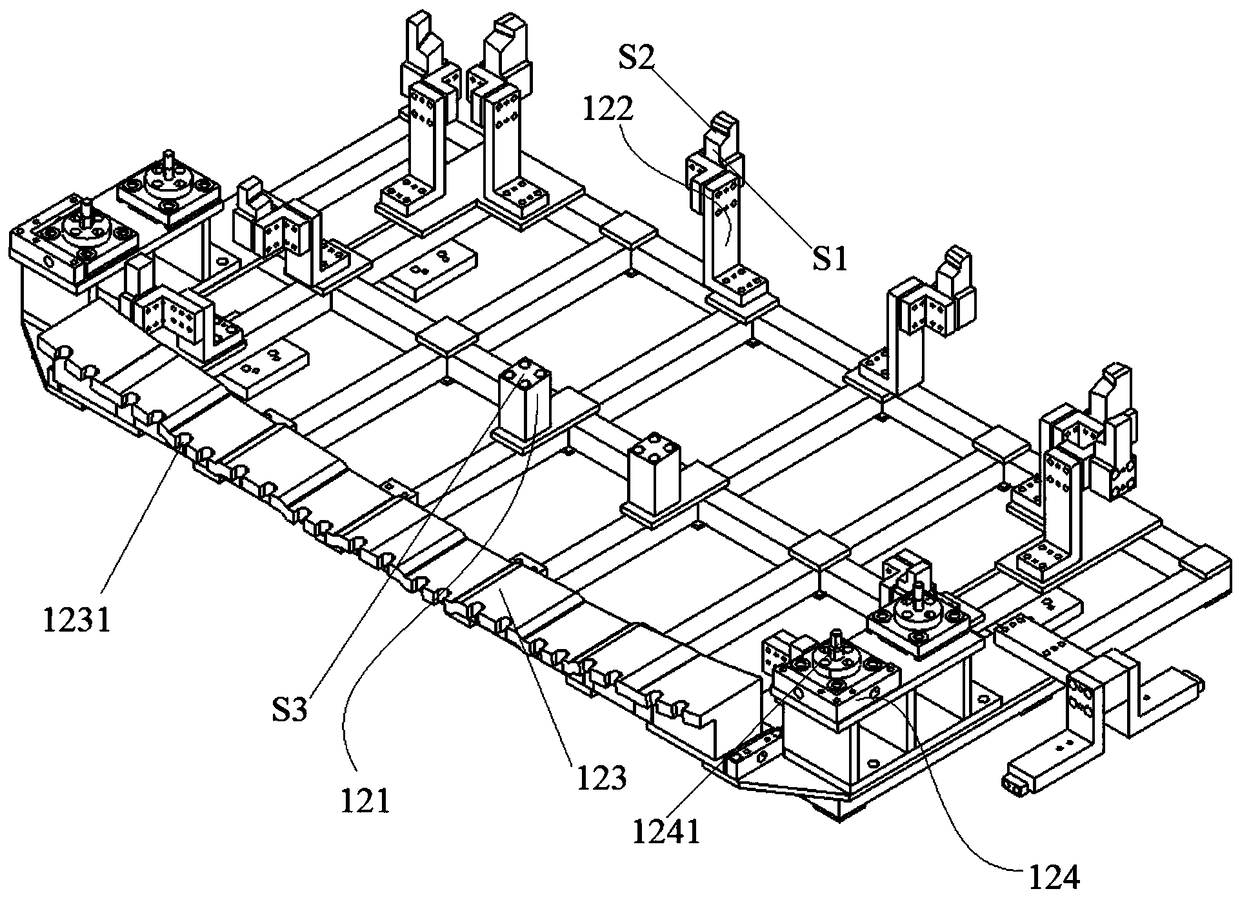

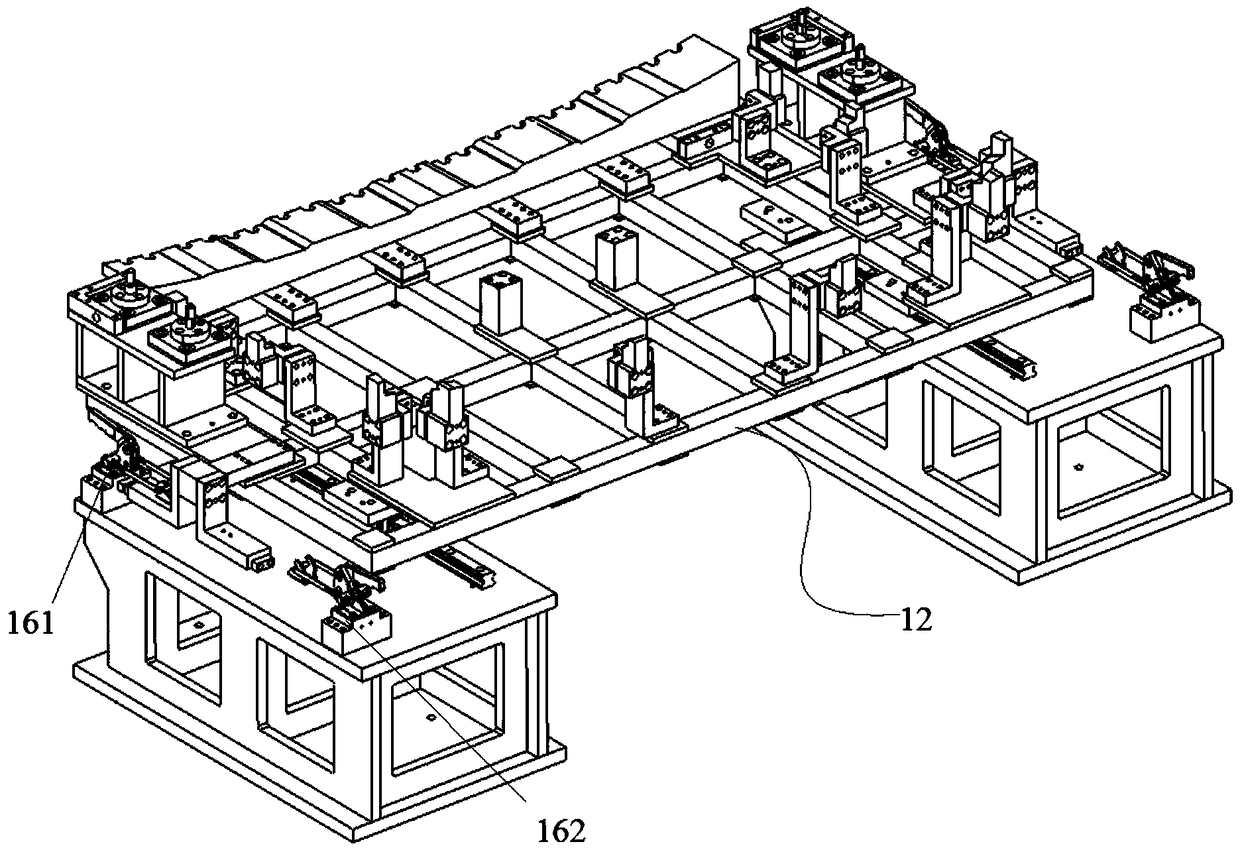

Clamp mechanism for cutting and splicing car body pieces

PendingCN108907561ARealize mechanical operationQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a clamp mechanism for cutting and splicing car body pieces. The clamp mechanism comprises a base, a sliding table arranged on the base and capable of sliding in the length direction of the base, a first supporting block arranged on the base and providing a bottom support for the car body pieces, a first limiting supporting block vertically arranged on one edge of the base in the length direction, a second supporting block providing a bottom support for the car body pieces and vertically arranged on the sliding table, a second limiting supporting block vertically arranged on the sliding table and getting close to the other edge of the base in the length direction, a support block supporting face upwards extending in the width direction of the base, a first support block and a second support block, wherein the first limiting supporting block and the second limiting supporting block are each provided with a supporting face and a limiting face, each limiting face faces the interior of the base so as to limit movement of the car body pieces in the length direction of the base, the first support and the second support are oppositely arranged, the first support block is arranged on the base, the second support block is arranged on the sliding table, and therefore supporting is provided for to-be-cut positions or to-be-spliced positions of the car body pieces.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

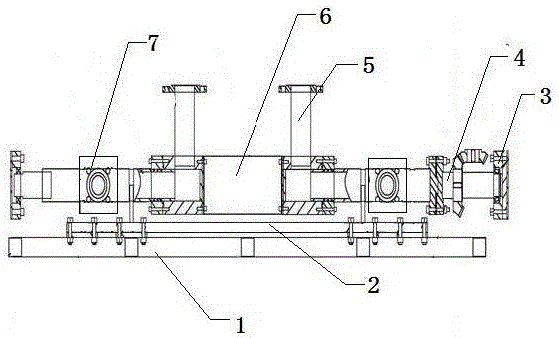

Special rotating shaft

The invention provides a special rotating shaft. The special rotating shaft is characterized by comprising a mounting support, a converting frame, a bearing pedestal, a shaft weldment, a rotating joint weldment, a joint fixing seat and a static liquid medium interface, wherein the shaft weldment is broken from the center and is cooperated and connected with the converting frame; the central part of the shaft weldment is suspended, and the upper and lower ends of the shaft weldment are both provided with a connection port; the rotating joint weldment is a fluid medium dynamic-static conversion sealing member and is cooperated and connected with one of the connection ports of the shaft weldment; the other connection port of the shaft weldment is provided with the bearing pedestal; and the rotating joint weldment is provided with the rotating joint fixing seat. The special rotating shaft provided by the invention is simple and reasonable in structure, reliable in performance, high in applicability, good in energy saving effect, long in service life, convenient for maintenance, suitable for mass production and strong in market competitiveness, and can realize flexible rotation and actual mechanical operation.

Owner:陈洪厚

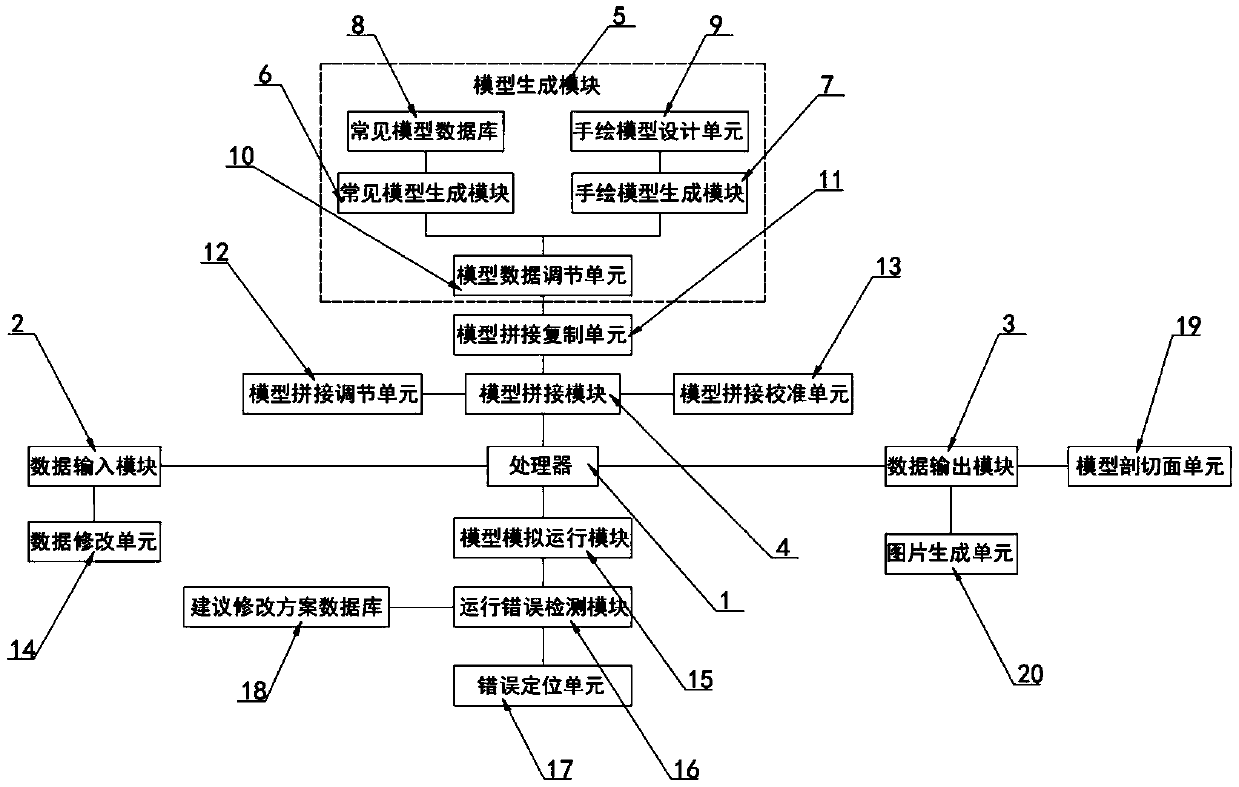

Artificial intelligence computer aided design system and application

PendingCN110414105AImprove combination effectSimple designSpecial data processing applicationsMechanical modelsData information

The invention discloses an artificial intelligence computer aided design system and application. The invention specifically relates to the technical field of aided design systems. The system comprisesa processor for data processing, the input end of the processor is connected with a data input module for inputting model design data; the output end of the processor is connected with a data outputmodule used for outputting model design finished product data and a model splicing module used for model design combination, and the output end of the model splicing module is connected with a model generation module used for constructing sub-models required by design model combination. According to the invention, a common sub-model is rapidly generated through data information input by the commonmodel database and the input module; the hand-painted model design unit is used for drawing the structural shapes of the design sub-models, the model splicing module is used for splicing and combining the models, common sub-models are generated quickly, time and labor are saved, the matching degree of the common sub-models and the design sub-models is high, the model quality is high, and design of a mechanical model is facilitated.

Owner:杜艳阳

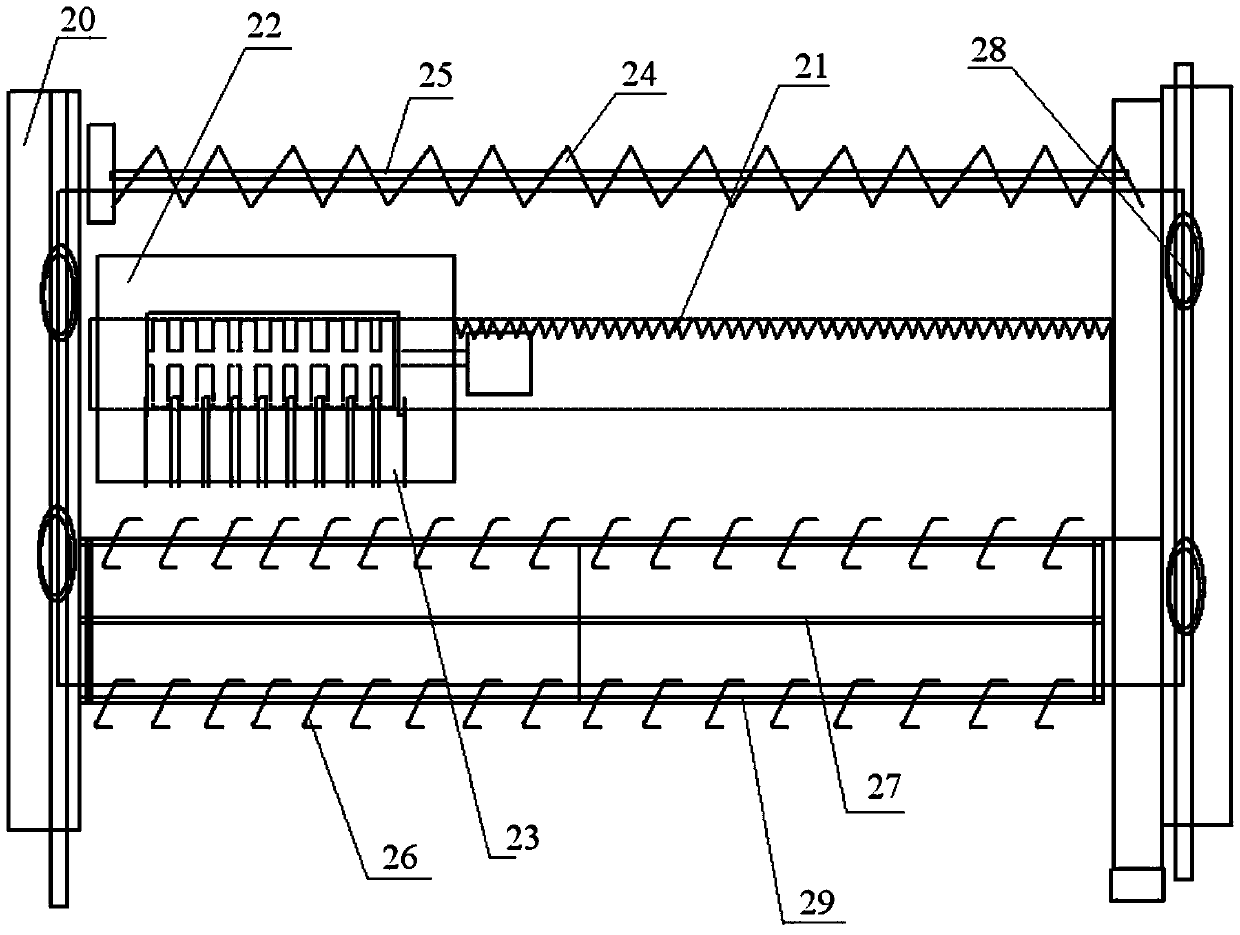

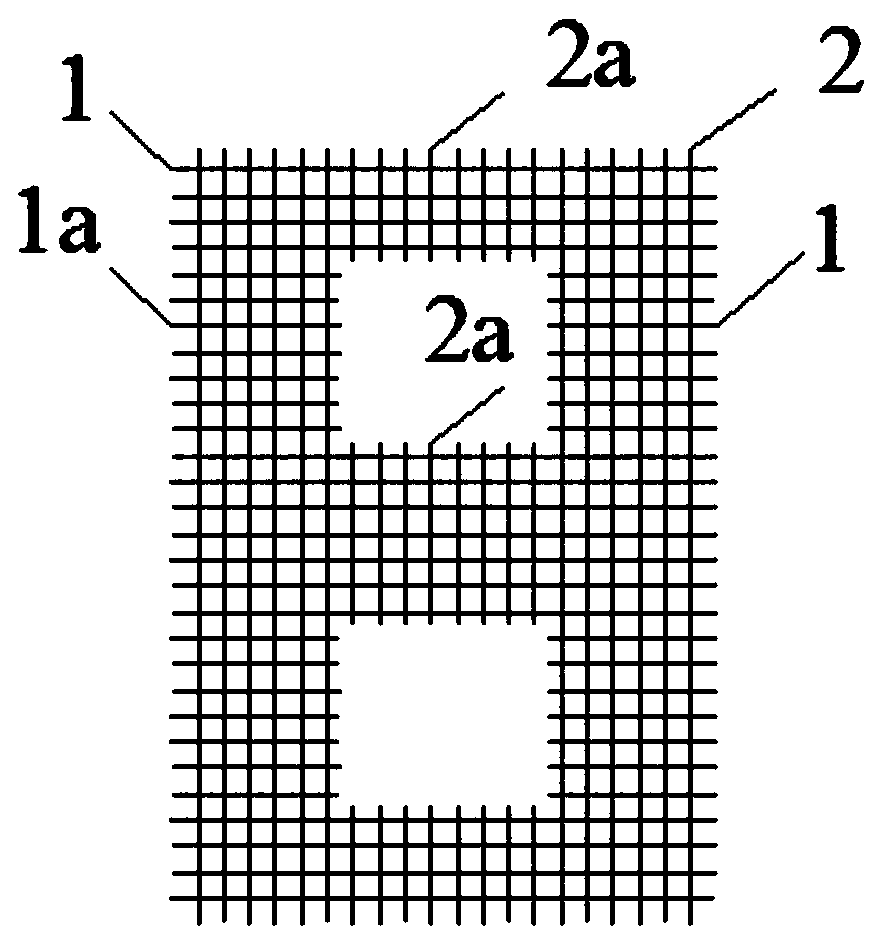

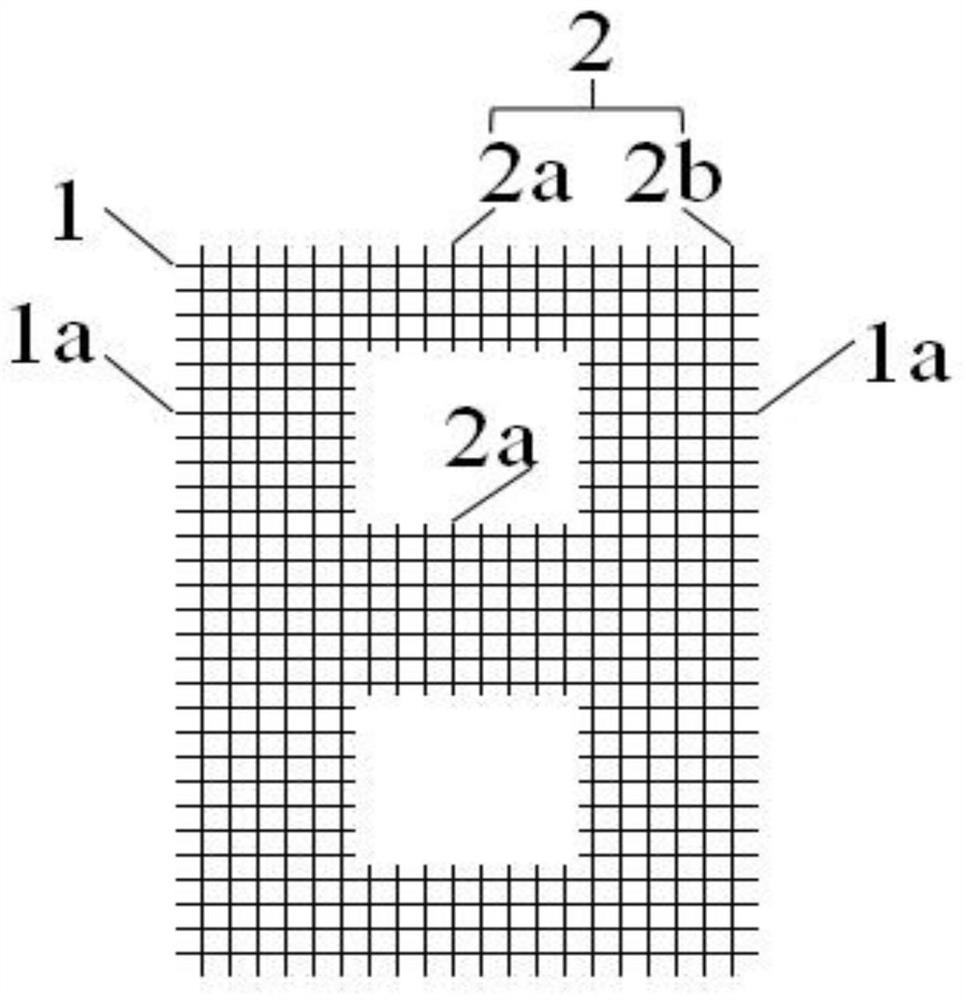

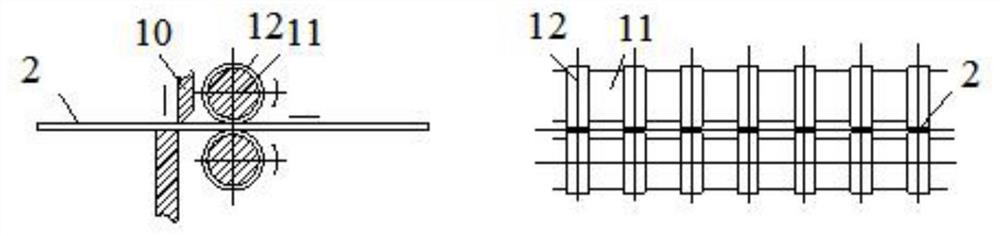

Machining equipment of hollow welding net

InactiveCN110102678ARealize mechanical operationIncrease productivityWire networkWire rodLeft direction

The invention discloses machining equipment of a hollow welding net. The machining equipment comprises a welding net main machine, a longitude line conveying device, a longitude line straightening mechanism and a net shearing device, wherein the two ends of the welding net main machine are correspondingly provided with two latitude line straightening and cutting-off devices, the longitude line conveying device can independently control the stepping of longitude lines, and meanwhile, each longitude line is provided with a longitude line cutting off device; when perforating is not needed, only the latitude line straightening and cutting-off devices on one end is started, meanwhile, longitude line steel wire rods enter the longitude line conveying device after being straightened through the longitude line straightening mechanism, and whole row welding is carried out at the main machine; when a position needing to be perforated is met, the stepping of the stepping longitude lines at a perforated port is stopped, and cut-off is carried out at the corresponding positions, and the rest of the longitude lines continuously step; and when the longitude lines step to a welding position of themain machine, the latitude line straightening and cutting-off devices at the two ends of the main machine work at the same time, stepping latitude lines with corresponding sizes are correspondingly conveyed from the left direction and the right direction according to the position of the perforated port, and holes meeting the requirements can be produced along with performing of the stepping. By adopting the method, the production efficiency is greatly improved, and the product precision is high.

Owner:ANHUI BRC & MA STEEL WELDMESH

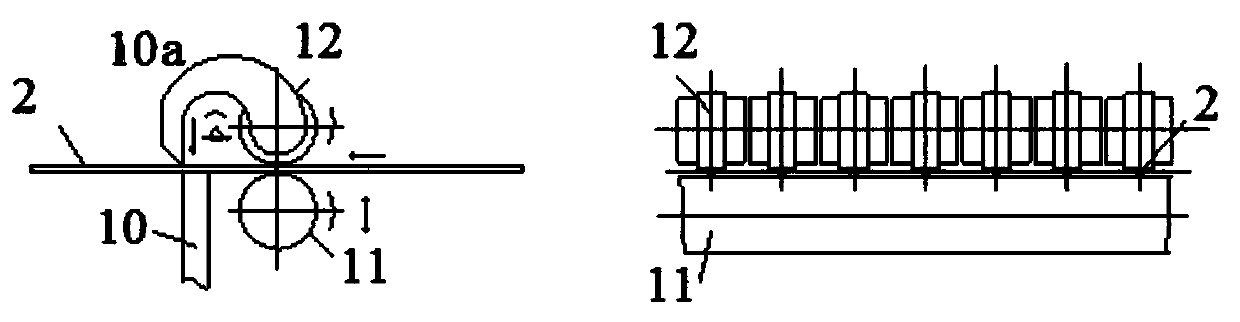

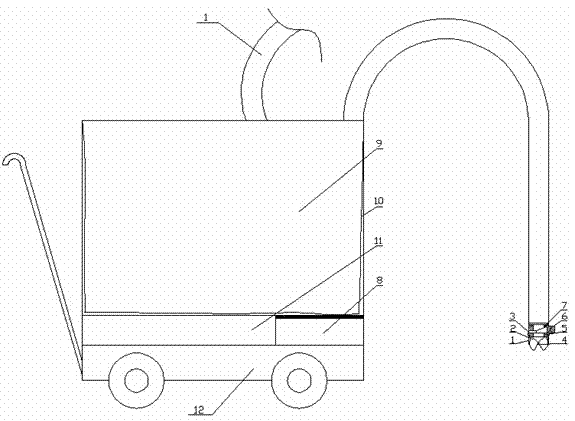

Movable tea picking machine

InactiveCN104255189AIn line with operating habitsEasy to operatePicking devicesStructural engineeringVacuum pump

The invention discloses a movable tea picking machine. The movable tea picking machine comprises a box body (9), a storage battery (11) and a vacuum pump (8) are arranged at the bottom of the box body (9), a piece of filter cloth is arranged between the vacuum pump (8) and the box body (9), the box body (9) is arranged on a cart (12) and connected with more than one pipe body (1), a chute (3) is formed in the side wall of each pipe body (1), a press slide block (5) is fixed in the chute (3), a left semi-spherical cutter and a right semi-spherical cutter (2) are arranged below the pipe body (1), a spring (4) is arranged between the left and right semi-spherical cutters (2), the left and right semi-spherical cutters (2) are provided with a press slide block (5), the press slide block (5) is provided with a movable slide block (6), the movable slide block (6) is provided with a limit slide block (7), and contact surfaces of the limit slide block (7) and movable slide block (6) are inclines. The movable tea picking machine can be operated by multiple users, and the movable tea picking machine is featured with convenience in operation, labor saving and high picking efficiency.

Owner:马世龙

Rolling printing device for plastic products

InactiveCN108859400AGuaranteed uniformityEnsure the uniformity of plastic products in printingRotary pressesEngineeringMechanical engineering

Owner:芜湖精益达模塑股份有限公司

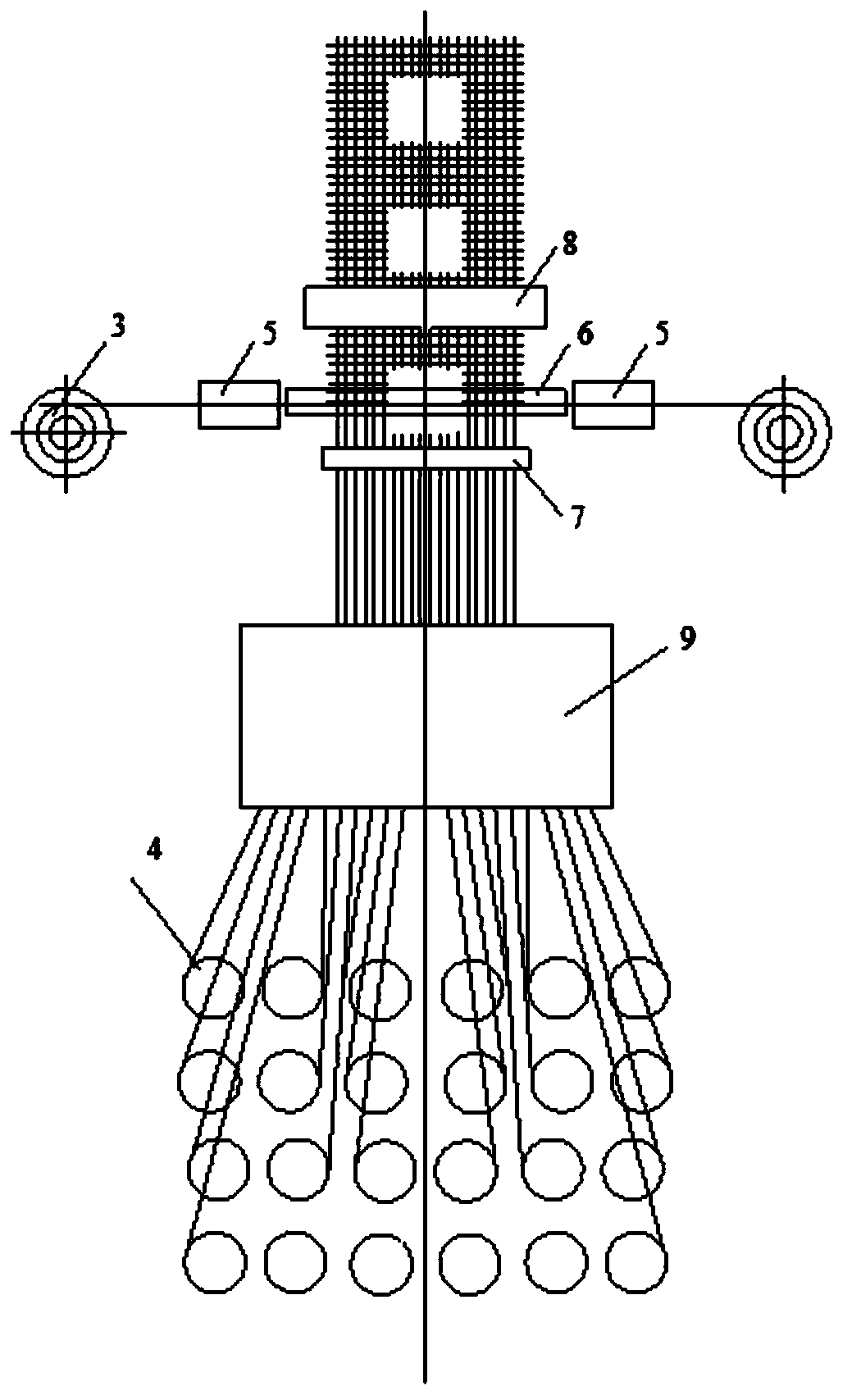

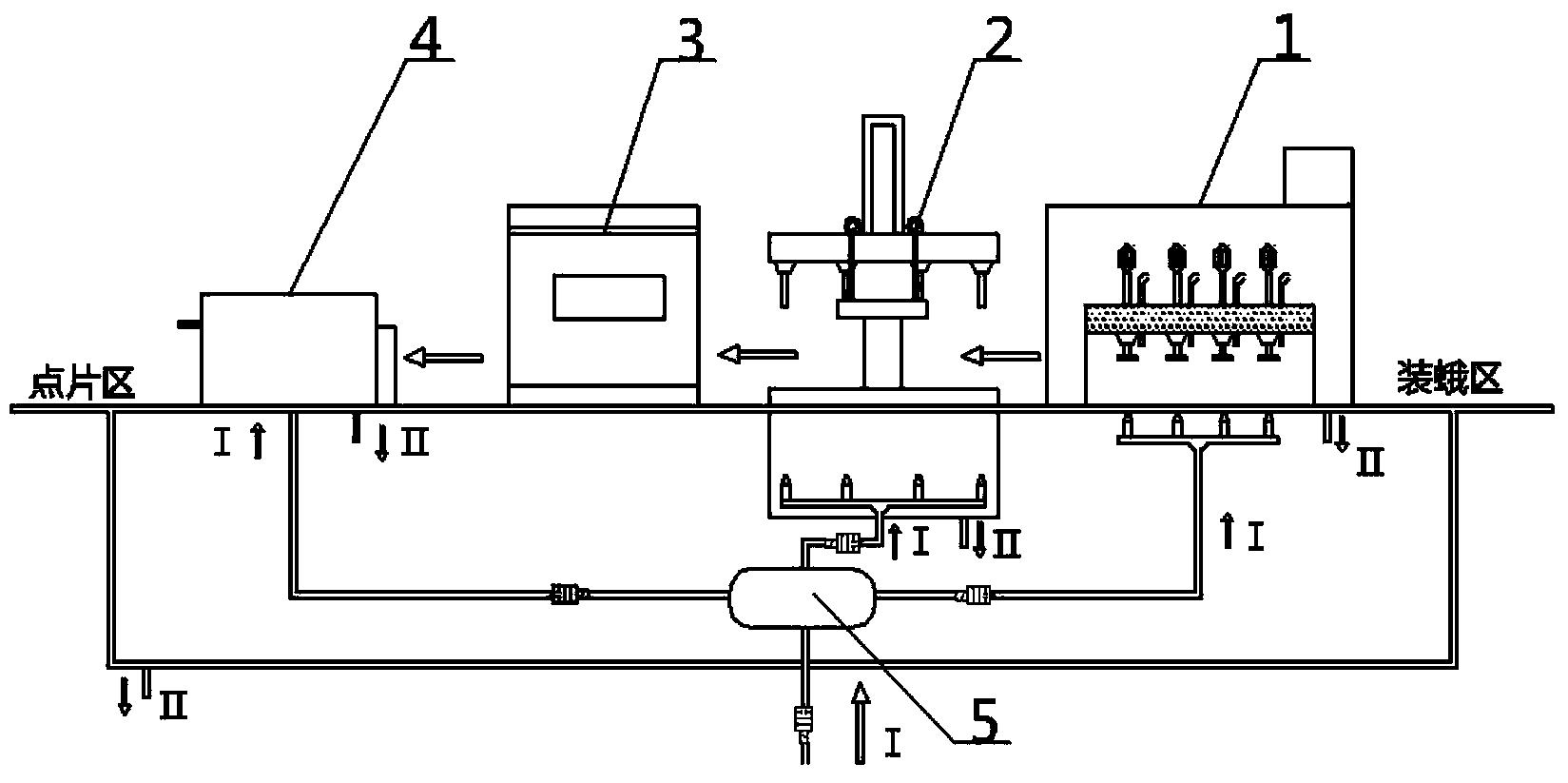

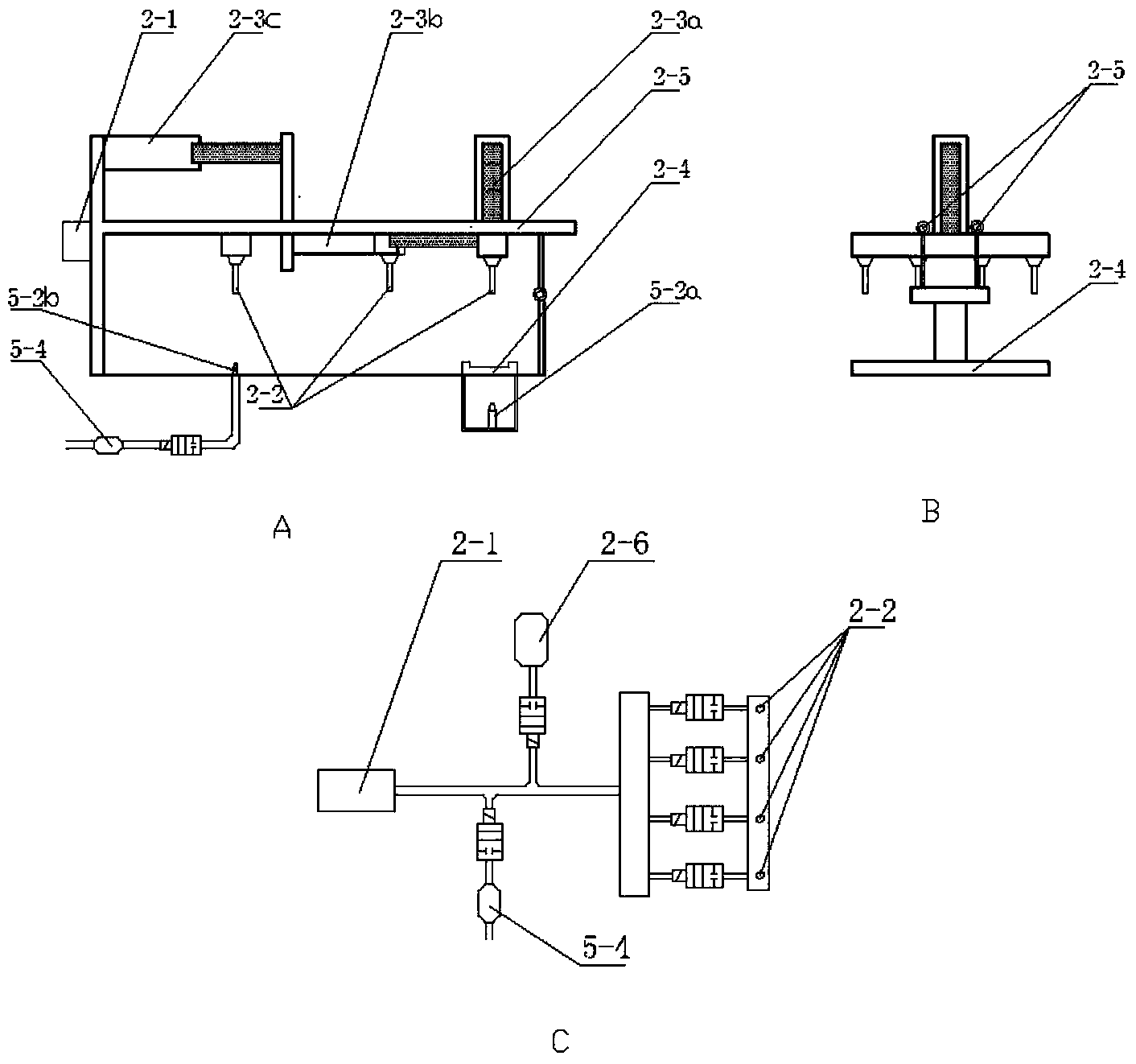

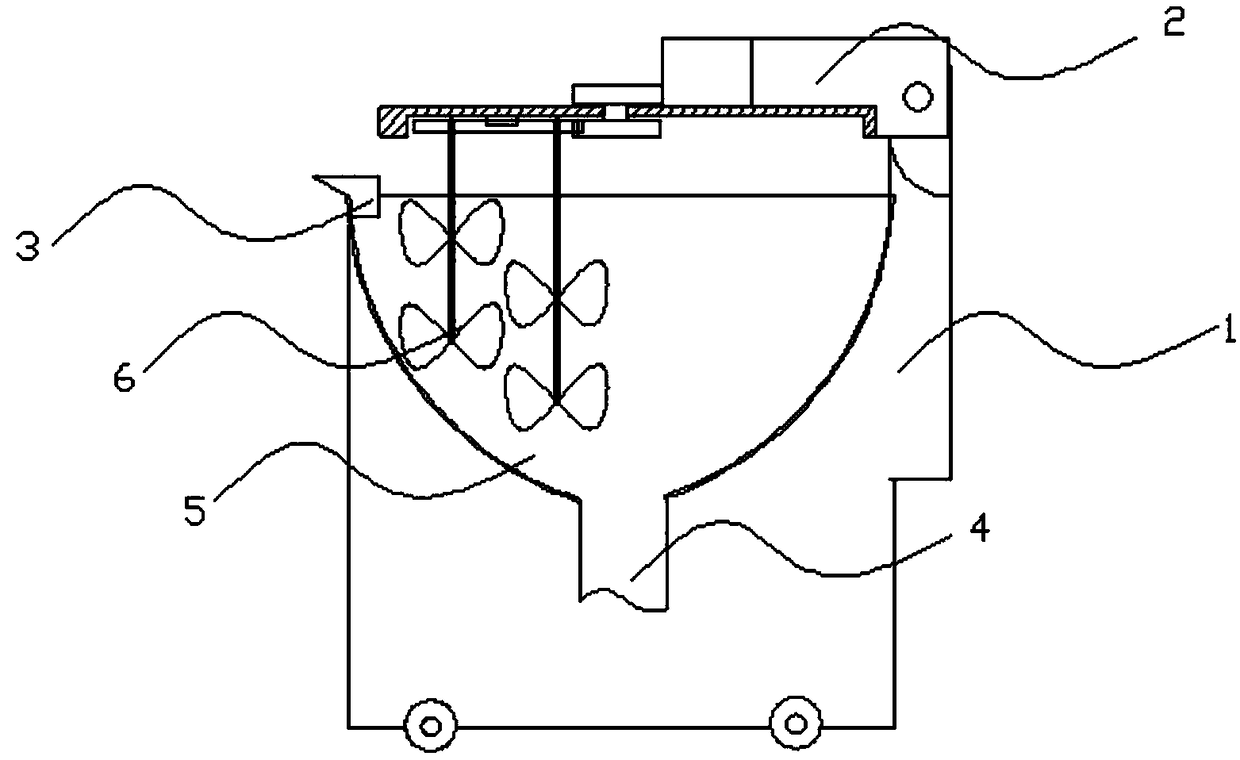

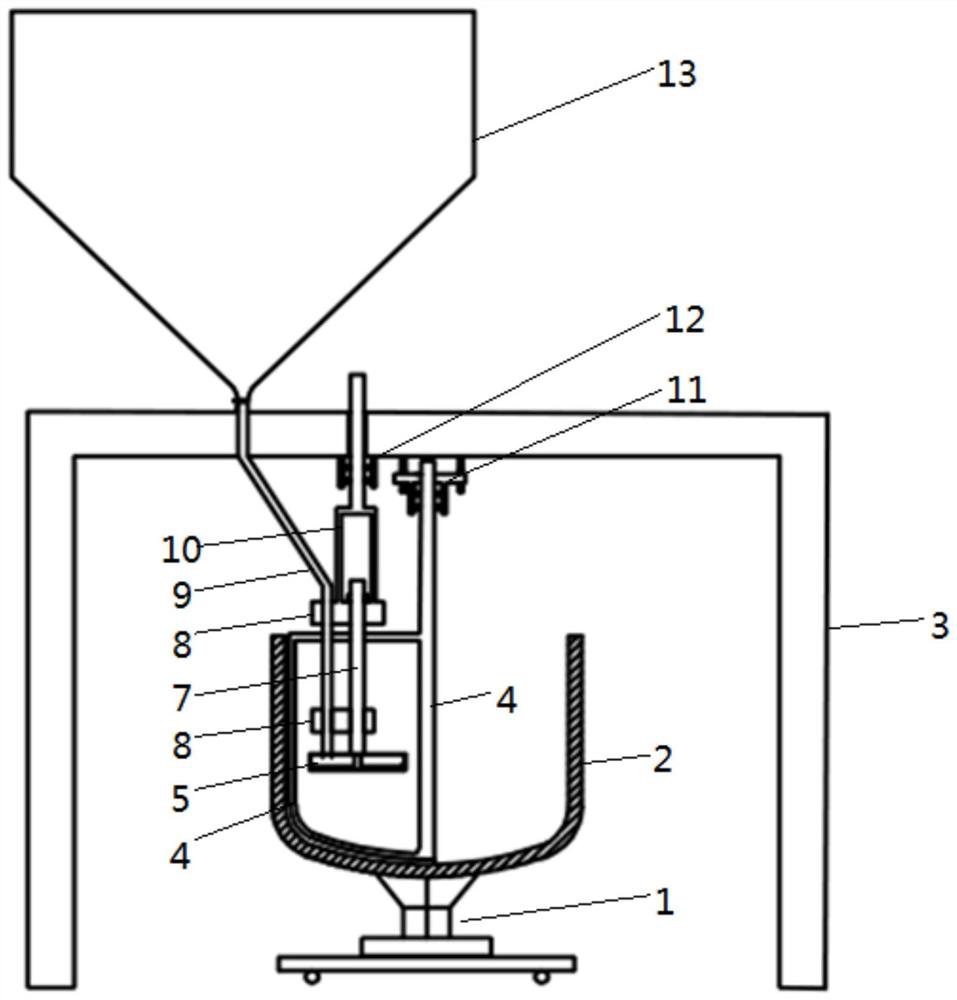

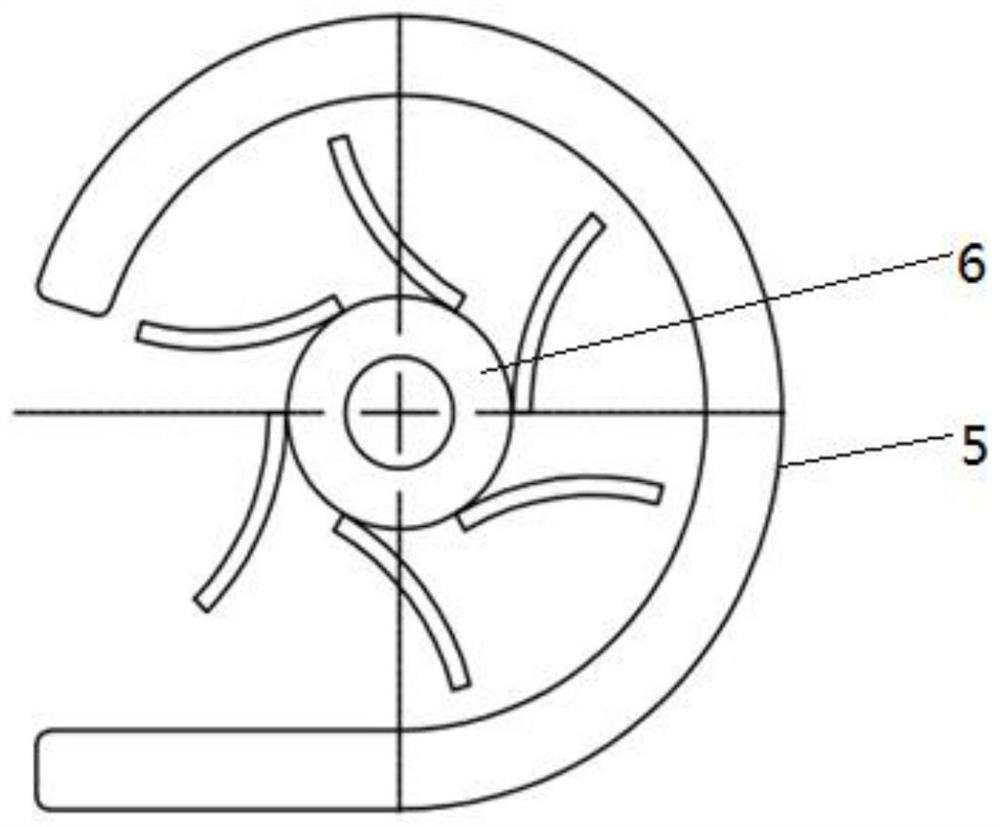

Moth grinding sample preparation system for detecting silkworm female moth corpuscule pathogeny spore

InactiveCN102706717BRealize mechanical operationIncrease exposurePreparing sample for investigationSporelingAnimal science

The present invention relates to a moth grinding sample preparation system for detecting microparticle pathogenic spores of Bombyx moth moth, which consists of moth grinding system 1, automatic liquid transfer system 2, centrifugal enrichment device 3, centrifugal tube washing device 4 and automatic cleaning system 5 components, and in turn integrated in a worktop. The present invention basically realizes the mechanical operation of each link of grinding moth sample preparation, saving labor and labor; the liquid injection and the grinding moth are carried out synchronously, which increases the chance of contact between the material and the blade, and the material is more thoroughly ground; the electromagnetic automatic pipetting (suction liquid return), the liquid return volume is uniform and accurate; the automatic transmission spray washing device is used to wash the centrifuge tube, covering the grinding moth, suction liquid return, centrifuge tube washing, and automatic spray washing is realized. Using high-pressure automatic flushing appliances, the water-saving effect is very significant, and 80% of water consumption can be saved. It has the advantages of fast work rate, water saving, good safety performance and high sample clarity. It can be used in silkworm egg production units and silkworm egg quality inspection departments to quickly prepare large batches of samples when microscopic detection of microscopic pathogenic spores of silkworm female moths.

Owner:重庆市蚕业管理总站 +1

A cooling device for bearing forgings

ActiveCN113385633BReduce hindrancePromote circulationEngine componentsHeating/cooling devicesCooling effectMachine

The invention discloses a bearing forging cooling device, which relates to the technical field of bearing processing, including a water-cooling conveyor, an air-cooling conveyor, a water-cooling device, an air-cooling device, a turning mechanism, the water-cooling conveyor and the air-cooling conveyor are connected, and the water-cooling conveyor There is a water-cooling device on the machine, and an air-cooling device on the air-cooled conveyor. The turning mechanism is located between the water-cooling conveyor and the air-cooling conveyor. The seat is connected with the air-cooled conveyor, the lower end of the flipping fixed plate is connected with the flipping seat, the lower end of the flipping movable plate is hinged with the flipping seat, the flipping telescopic rod is arranged on the side of the flipping movable plate away from the flipping fixed plate, and the lower end of the flipping telescopic rod is connected with The flipping seat is connected, and the upper end of the flipping telescopic rod is hinged with a flipping slider, and the flipping slider is slidably connected with the flipping movable plate. The invention can improve the air cooling effect on the bearing forging.

Owner:临清市同兴轴承锻造有限公司

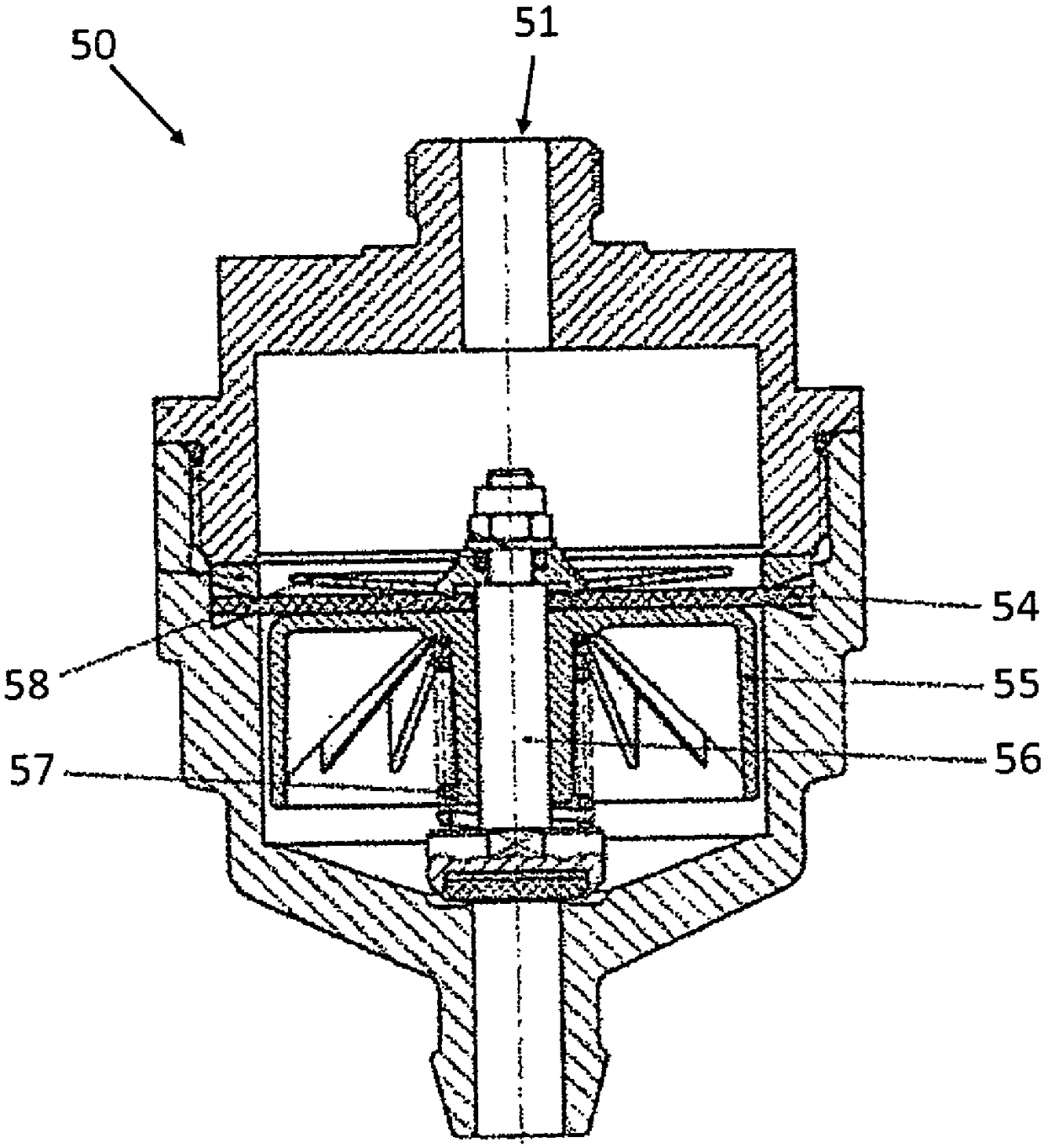

Feeding barrel of pharmaceutical tablet press

InactiveCN108854743AStir wellSimple structureRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a feeding barrel of a pharmaceutical tablet press. The feeding barrel comprises a barrel body, an agitation barrel in a bowl-typed structure is made from stainless steel and arranged in the barrel body, a feed port is arranged at the upper edge of the agitation barrel and connected with the upper edge of the agitation barrel, a discharge outlet is arranged at the bottom ofthe agitation barrel, the discharge outlet is communicated and connected with the bottom of the agitation barrel, an agitation mechanism is arranged at the upper end of the barrel body and is rotatively connected with the upper end of the barrel body by bolts, a mounting panel is arranged under a motor and a reducing mechanism and is fixedly connected with the motor and the reducing mechanism, gears is devided into an upper gear and a lower gear in a co-axial connection, the upper gear is meshed with the reducing mechanism, the lower gear is meshed with a gear 2, the gear 2 is arranged under amounting table, and a mounting hole of an agitation rod is arranged on the gear 2. The feeding barrel of the pharmaceutical tablet press rotates and agitates the agitation rod to make an even agitation, wherein a gear structure drives motion of a rotation mechanism. The feeding barrel of the pharmaceutical tablet press is simple in structure and high in working efficiency and fulfills efficient mechanical operation as a whole.

Owner:WUHU KANGQI PHARMA

Method for preparing air strainer by using environment-friendly TPE (thermoplastic elastomer)

InactiveCN102167880BGood flexibilityImprove plasticityDispersed particle filtrationAntioxidantPolypropylene

The invention provides a biodegradable TPE (thermoplastic elastomer) and a preparation method thereof. The TPE comprises the following components in parts by weight: 100 parts of SEBS (styrene-ethylene-butadiene-styrene), 5-380 parts of white mineral oil, 5-200 parts of PP (polypropylene), 5-100 parts of polyurethane, 0-80 parts of EVA (ethylene-vinyl acetate), 0-100 parts of calcium carbonate, 0-3 parts of calcium stearate, 0.2-1 part of antioxidant, 1-100 parts of maleic anhydride grafted polypropylene, 0-10 parts of titanium dioxide and 1-15 parts of ethylene propylene diene monomer. The TPE provided by the invention has favorable flexibility and high preparation efficiency, is an ideal material for preparing an air strainer, and can be used for mechanical operation, and the scraps can be recycled and reutilized, thereby having an important meaning for saving resources.

Owner:欧瑞喜(福州)塑胶科技有限公司

A ceramic fiber waste slag cotton mixing and shearing separator

The invention discloses a shearing and separating machine for mixed materials of waste slag and waste cotton of ceramic fibers and belongs to the field of shearing and separating machines. The shearing and separating machine aims at achieving separation and recycle of mixed materials of the waste slag and waste cotton of the ceramic fibers. The shearing and separating machine comprises a support I, a feeding conveyor, a shearing and separating machine body, a discharging conveyor, a collecting device, a motor unit and an electric cabinet; the shearing and separating machine body is fixed to the support I; the shearing and separating machine body comprises a shell, a rotor, a rotating shaft, a plurality of blades and a screen; the shell forms a shearing and separating cavity and a slag bin which are communicated with each other; a feeding port and a discharging port are formed in the shearing and separating cavity; a slag discharging port is formed in the slag bin; the shearing and separating cavity is isolated from the slag bin located below the shearing and separating cavity through the screen; the rotating shaft is arranged inside the shearing and separating cavity; the rotor is arranged on the periphery of the rotating shaft; the blades are arranged on the outer side face of the rotor; the motor unit is connected with and drives the feeding conveyor, the discharging conveyor and the rotating shaft; the feeding conveyor is communicated with the feeding port; the discharging conveyor is located below the slag discharging port; the discharging port is communicated with the collecting device.

Owner:山东红阳高温节能材料股份有限公司

Bearing forge piece cooling device

ActiveCN113385633AReduce hindrancePromote circulationEngine componentsHeating/cooling devicesPhysicsAir cooling

The invention discloses a bearing forge piece cooling device, and relates to the technical field of bearing machining. The bearing forge piece cooling device comprises a water-cooling conveyor, an air-cooling conveyor, a water-cooling device, an air-cooling device and a turnover mechanism, the water-cooling conveyor is connected with the air-cooling conveyor, the water-cooling device is arranged on the water-cooling conveyor, the air-cooling device is arranged on the air-cooling conveyor, the turnover mechanism is arranged between the water-cooling conveyor and the air-cooling conveyor and comprises a turnover seat, a turnover fixed plate, a turnover movable plate and a turnover telescopic rod, the turnover seat is connected with the air-cooling conveyor, the lower end of the turnover fixed plate is connected with the turnover seat, the lower end of the turnover movable plate is hinged to the turnover seat, the turnover telescopic rod is arranged on the side, away from the turnover fixed plate, of the turnover movable plate, the lower end of the turnover telescopic rod is connected with the turnover seat, and a turnover sliding block is hinged to the upper end of the turnover telescopic rod and is in sliding connection with the turnover movable plate. The air cooling effect on a bearing forge piece can be improved.

Owner:临清市同兴轴承锻造有限公司

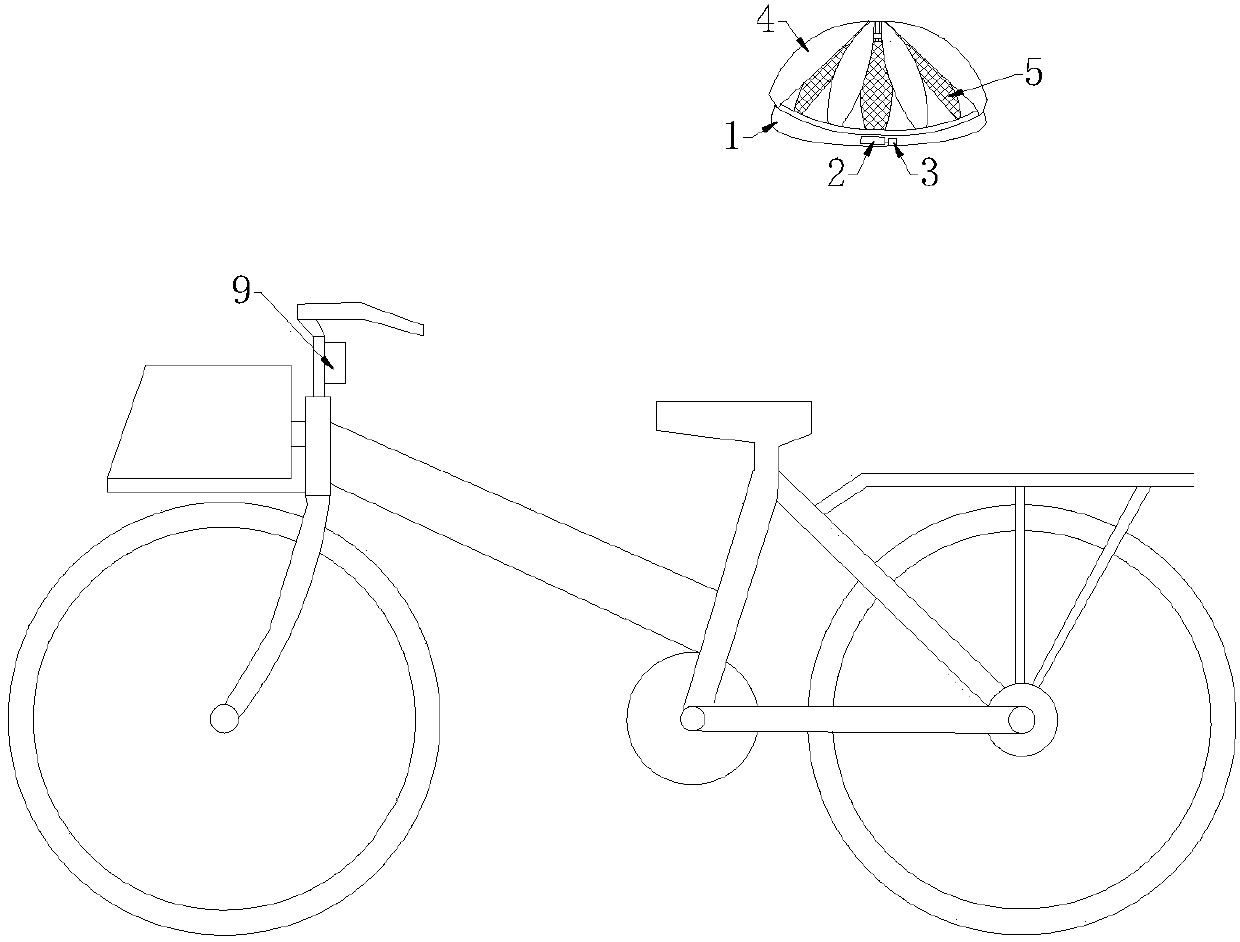

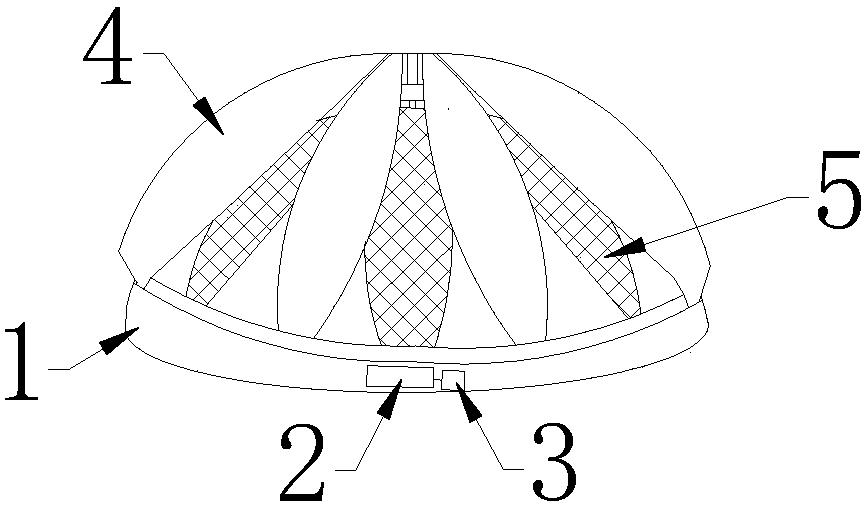

Novel breathable vehicle helmet

InactiveCN109691721ARealize mechanical operationNo manual operation requiredHelmetsHelmet coversEngineeringEnergy converter

A novel breathable vehicle helmet comprises an inner shell and an outer shell, the outer shell covers the inner shell, a fixing base is arranged at the top of the inner shell, a rotating motor is arranged in the fixing base, a connecting rod is arranged at the upper end of the rotating motor, the top end of the connecting rod is connected with the outer shell, and the outer shell is covered with asolar absorbing film. An energy converter is arranged in the fixing base and connected with a solar film plate, and an auxiliary controller is connected with the rotating motor. The helmet is dividedinto the inner shell and the outer shell, the two shells are connected together through the connecting rod, the rotating motor is arranged at the tail end of the connecting rod, ventilation meshes are formed in the inner shell, blades of the outer shell can cover the ventilation meshes when the helmet is not used, when ventilation is needed, the motor rotates the blades, the angle of the blades is changed, and the ventilation meshes are opened for ventilation. Mechanical operation is completely achieved in the process, manual operation is not needed, and riding is not affected.

Owner:TIANJIN BEIJIAQI TECH DEV CO LTD

Doffing robot

ActiveCN103526364BRealize mechanical operationImprove work efficiencyTextiles and paperAutomatic controlAutomated control system

The invention discloses a doffing mechanical arm on a spinning machine. The doffing mechanical arm comprises a drive device, a transmission assembly and a holding assembly. The drive device is connected with the lower end of a first lever of the transmission assembly. The upper end of the first lever is hinged to the lower end of a second lever through a transition plate. The upper end of the second lever is fixed with a cross-shaped shaft seat. A lengthwise shaft of a cross-shaped shaft is connected in a hole of the cross-shaped shaft seat in an inserted mode to form clearance fit. A horizontal shaft is fixed to the tail end of a swing arm, and the horizontal shaft penetrates through a horizontal axial hole in the cross-shaped shaft and is connected with the drive device through a horizontal joint pull rod. The tail end of the swing arm is connected with the drive device through a lengthwise joint pull rod. The holding part is arranged at the head end of the swing arm. As the drive device is controlled by an automatic control system, after the holding part is connected with a moving arm of a creel in a clamped mode, the holding part can move in three dimensions, namely in lengthwise direction, in horizontal direction and in a front-and-back mode under the drive of the transmission assembly. The reel will be driven along with the holding part to finish all actions needed in doffing. Thus, mechanical operation of automatic doffing is achieved and the working efficiency of the spinning machine is improved.

Owner:AVIC SHAANXI HUAYAN AERO INSTR

Automatic roll printing device for plastic products

ActiveCN109454987AAvoid offsetPrevent crushingRotary pressesOther printing apparatusEngineeringElectrical and Electronics engineering

Owner:芜湖精益达模塑股份有限公司

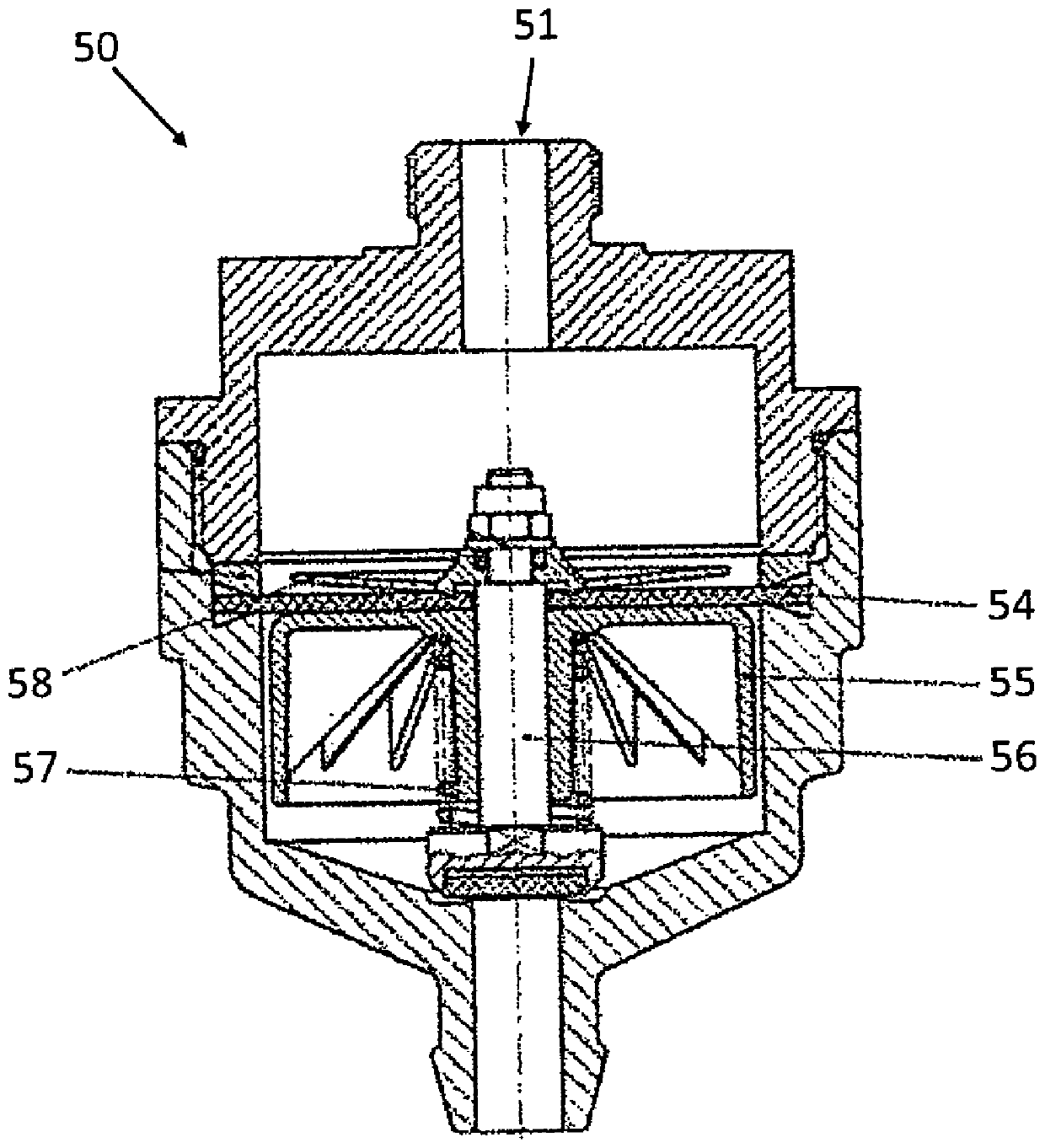

Pneumatically controlled drain valve

ActiveCN108474372BFunctionality is not affectedSmall cross sectionOperating means/releasing devices for valvesPositive displacement pump componentsControl theoryVALVE PORT

The invention relates to a drain valve for a cooler of a compressor, comprising a pressure chamber which can be connected to the interior of the cooler via a connection port and which has a drain for draining condensate. The proposed valve has a pneumatic switching device and a non-return valve, which are operatively connected to the pressure chamber, wherein there is an operative connection between the switching device and the non-return valve, by means of which the non-return valve can be switched from the switching device actuation to open position. When the compressor is not in operation, the non-return valve can be actuated into an open position by means of the switching device, so that condensate can be drained from the connection via the non-return valve through the discharge port.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Environment friendly thermoplastic elastomer used as fire-retardant sealing strip and preparation method thereof

The invention provides a fire-retardant thermoplastic elastomer (TPE) capable of being used as a sealing strip of a bus and a preparation method thereof. The TPE contains the following components in parts by weight: 100 parts of segmented styrene copolymer, 50-180 parts of mineral oil, 40-80 parts of polypropylene PP, 50-80 parts of EVA, 50-100 parts of calcium carbonate, 50-100 parts of decabromodiphenyl oxide, 20-50 parts of antimony trioxide, 0.1-3 parts of calcium stearate and 0.2-1 part of antioxidant. The TPE provided by the invention has good flexibility, fire retardancy and high manufacturing efficiency, is an ideal material for manufacturing the sealing strip of the bus, and can be mechanically operated. The leftover material can be recycled, which is significant to save resources.

Owner:GUANGDONG KINGREAT HITECH

Crucible forming device

ActiveCN114474310AImprove quality and efficiencyIncrease productivityAuxillary shaping apparatusGlass productionCrucibleMechanical engineering

The invention discloses a crucible forming device. The crucible forming device comprises an automatic feeding module and an automatic forming module. The automatic forming module comprises a crucible mold and is used for receiving fed materials of the automatic feeding module; the mold rotation driving part is arranged below the crucible mold, is fixedly connected with the crucible mold and is used for driving the crucible mold to rotate; the fixing frame is arranged above the crucible mold; the forming rod comprises a vertical fixing section and an arc-shaped forming section connected with the vertical fixing section, the vertical fixing section is connected to the fixing frame, and the arc-shaped forming section and the inner wall of the crucible mold are arranged at a preset interval. According to the crucible forming device, automatic operation of the feeding stage and raw material forming can be achieved, the labor cost is reduced, the consistency of crucible forming is improved, and the production efficiency is improved while the quality of the crucible is improved.

Owner:浙江美晶新材料股份有限公司

A system for drying sludge using diversified thermal energy

InactiveCN103992019BEasy to retractFull transmissionSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentThermal energyToxic gas

Owner:宋雷震

Tealeaf picker

InactiveCN104272923AIn line with operating habitsEasy to operatePicking devicesMechanical engineeringEngineering

The invention discloses a tealeaf picker. The tealeaf picker comprises a pipe (1), the side wall of the pipe (1) is provided with a slide groove (3), a press slider (5) is fixed in the slide groove (3), a left hemispherical cutter (2) and a right hemispherical cutter (2), a spring (4) is arranged between the left hemispherical cutter (2) and the right hemispherical cutter (2), the press slider (5) is arranged on the left and right hemispherical cutters (2), a movable slider (6) is arranged on the press slider (5), a limit slider (7) is arranged on the movable slider (6), and a contact surface of the limit slider (7) and the movable slider (6) is an inclined surface. The tealeaf picker can be operated with one hand, is simple to operate and has no damage to hands and tealeaves. The tealeaf picker has the advantages of convenience in operation, labor saving and high picking efficiency.

Owner:马世龙

A row-position ejection mechanism for an injection mold

ActiveCN105196499BRealize mechanical operationReduce one mold openingEngineeringMechanical engineering

The invention relates to the field of injection moulds, in particular to a slide demoulding mechanism for an in-mould lamination injection mould. The slide demoulding mechanism comprises a slide (10) which forms a mould cavity of the injection mould jointly with a fixed mould core and a movable mould core and is further provided with a heel block (8) used for limiting the position of the slide (10) in the injection mould, a first power mechanism (22) which can drive the heel block (8) to move to relieve limiting of the heel block (8) on the position of the slide (10) in the injection mould and a second power mechanism (23) which can drive the slide (10) to be far away from the mould cavity of the injection mould. According to the slide demoulding mechanism for the in-mould lamination injection mould, the heel block and the slide in the injection mould can be driven by the power mechanisms to be adjusted, so that separation and backoff between the slide and a moulded product can be achieved; compared with the traditional mode that the mould is artificially opened to take the slide out, mechanical operation in the injection mould is achieved, one-time mould opening in the injection process can be reduced, the injection cycle is effectively shortened, and the production efficiency in the injection process is improved.

Owner:KUNDA MOLD SHENZHEN

An automatic forming method for hollow welded mesh

ActiveCN110125290BRealize mechanical operationIncrease productivityWire networkWire rodIndustrial engineering

The invention discloses an automatic forming method of a hollow welding net. The automatic forming method comprises the following steps that when holes are not needed, only a weft straightening and cutting device at one end is opened to produce wefts, meanwhile warp wire rods enter a warp conveying device after being straightened by a warp straightening mechanism, and each warp runs at a normal step distance and is welded in a whole row at a main machine; when a position which needs to be opened is met, step-by-step warps at the opening stop stepping at the warp conveying device, and are positioned and cut off at the corresponding position, and the rest warps continuously step, when stepping to a welding part of the main machine, the weft straightening and cutting devices at the two ends of the main machine work at the same time and respectively convey step-by-step wefts of corresponding sizes from the left direction and the right direction according to the position of the hole, and with the progress of stepping, the holes meeting the requirements can be produced; and then, the step-by-step warps that stop working are started, and mesh production continues to repeat the above processes continuously and circularly in sequence. The production efficiency of the hollow weld net produced by the automatic forming method is greatly improved, and the machining precision of the productis accurate.

Owner:ANHUI BRC & MA STEEL WELDMESH

Adjustable wall-mounted support for liquid crystal display television

The invention provides an adjustable wall-mounted support for a liquid crystal display television, the adjustable wall-mounted support comprises a recycling cabinet and a connecting plate, a first sliding groove is formed in the middle of the inner side of the recycling cabinet, the two ends of the first sliding groove are in sliding fit with first rotating sliding blocks, and one side of each first rotating sliding block is rotationally connected with a supporting rod; a rotating shaft is rotationally connected between the supporting rods; a hanging opening is formed in the middle of the front side of the connecting plate, a plurality of limiting blocks are arranged on the two sides of the hanging opening correspondingly, the limiting blocks are fixedly connected with the connecting plate, grooves are formed in the middles of the top ends of the limiting blocks correspondingly, protruding blocks are inserted into the grooves correspondingly, and one ends of the protruding blocks are fixedly connected with fixing frames correspondingly. And the rotating shaft and the connecting plate are rotationally connected, angle rotation of the liquid crystal display television is adjusted after rotation, and the rotating effect of the connecting plate is adjusted while a user watches the television at different angles.

Owner:TAIZHOU HUIJIN ELECTRONIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com