A ceramic fiber waste slag cotton mixing and shearing separator

A ceramic fiber and separator technology, which is applied in the field of shear separator, can solve the problems of affecting cotton fiber quality, unreasonable structure, and low production effect, and achieve the effects of saving labor, improving production efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

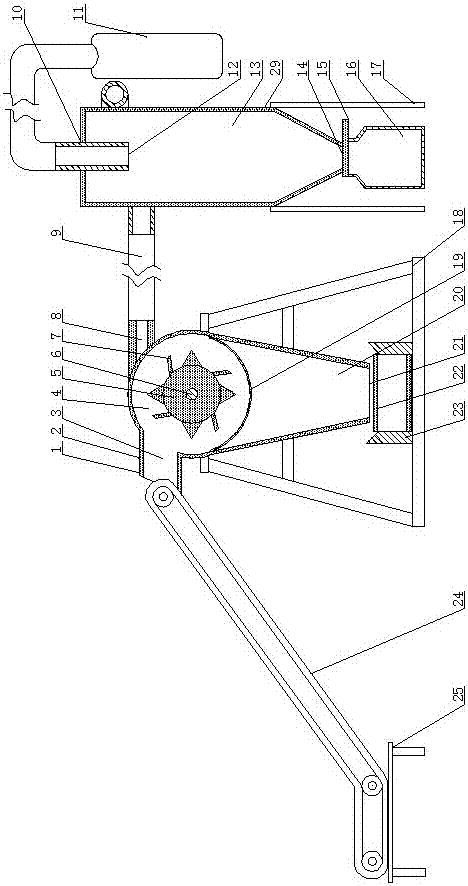

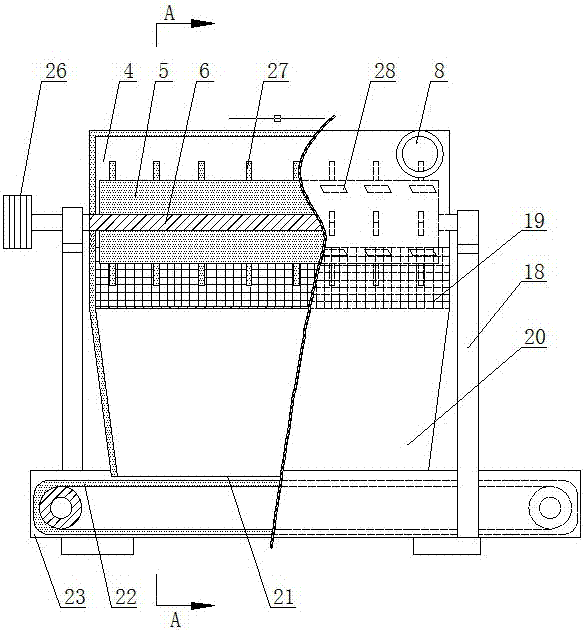

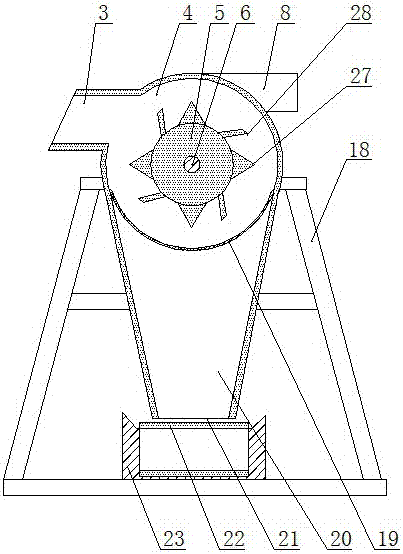

[0031] The ceramic fiber waste slag cotton blending shearing separator of the present invention includes a bracket I18, a feeding conveyor 24, a shearing separator 1, a discharge conveyor 22, a collecting device 29, a charging bag 5, a motor unit, The electric control box, the shearing separator 1 is fixed on the bracket I18. The shearing separator 1 includes a casing 2, a rotor 5, a rotating shaft 6, a number of blades 7, and a screen 19. The casing 2 forms a connected shearing separation chamber 4, The slag bin 20, specifically, the cross section of the shear separation chamber 4 is arc-shaped, the shear separation chamber 4 and the side wall of the slag bin 20 intersect tangentially, and the shear separation chamber 4 is provided with a feed port 3 and a discharge port 8. The slag bin 20 has a slag outlet 21, the shear separation chamber 4 and the lower slag bin 20 are separated by a screen 19, and the rotating shaft 6 is located in the shear separation chamber 4 and is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com