Pneumatically controlled drain valve

A technology for drain valves and pneumatic switches, applied to valve details, valve devices, steam traps, etc., can solve problems such as damaged membranes, loss of compressor transmission power, and functional reliability limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

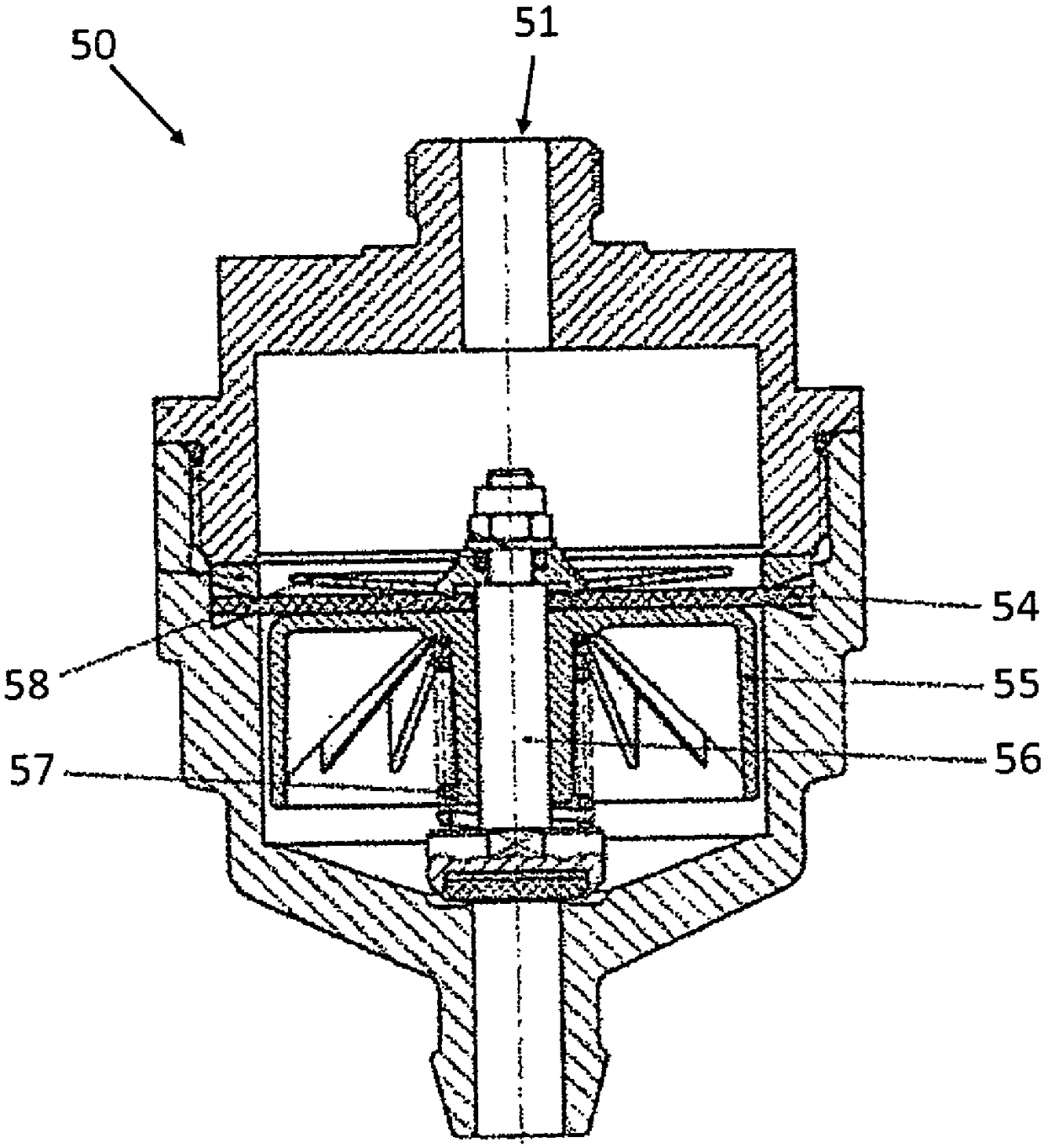

[0026] figure 1 The already described drain valve 50 known from the prior art is shown in the use position in which the connection port 51 is connected to the cooler of an air compressor (not shown). The drain valve 50 has an air bellows 55 which, during compressor operation, is pressed downwards against the force of a spring 57 by the pressure of the air-condensate mixture flowing in via the connection opening 51 . As a result, the inlet valve 58 arranged centrally on the drain valve 50 is opened in order to allow compressed air and condensate to flow into the hood below the membrane 54 . In this case, the valve piston 56 arranged in the lower region seals against the discharge opening of the drain valve 50 . Once the pressure is equalized in the chambers provided above and below the gas shield 55, the gas shield 55 moves upwards due to the upwardly directed force of the spring 57 and closes the inlet valve 58. The pressure in the chamber above the membrane 54 finally drops...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com