Soldered condenser

a condenser and braze technology, applied in the field of soldered/brazed condensers, can solve the problems of reducing manufacturing costs, simple and uncomplicated mounting, etc., and achieve the effect of satisfying functions, reducing manufacturing costs, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

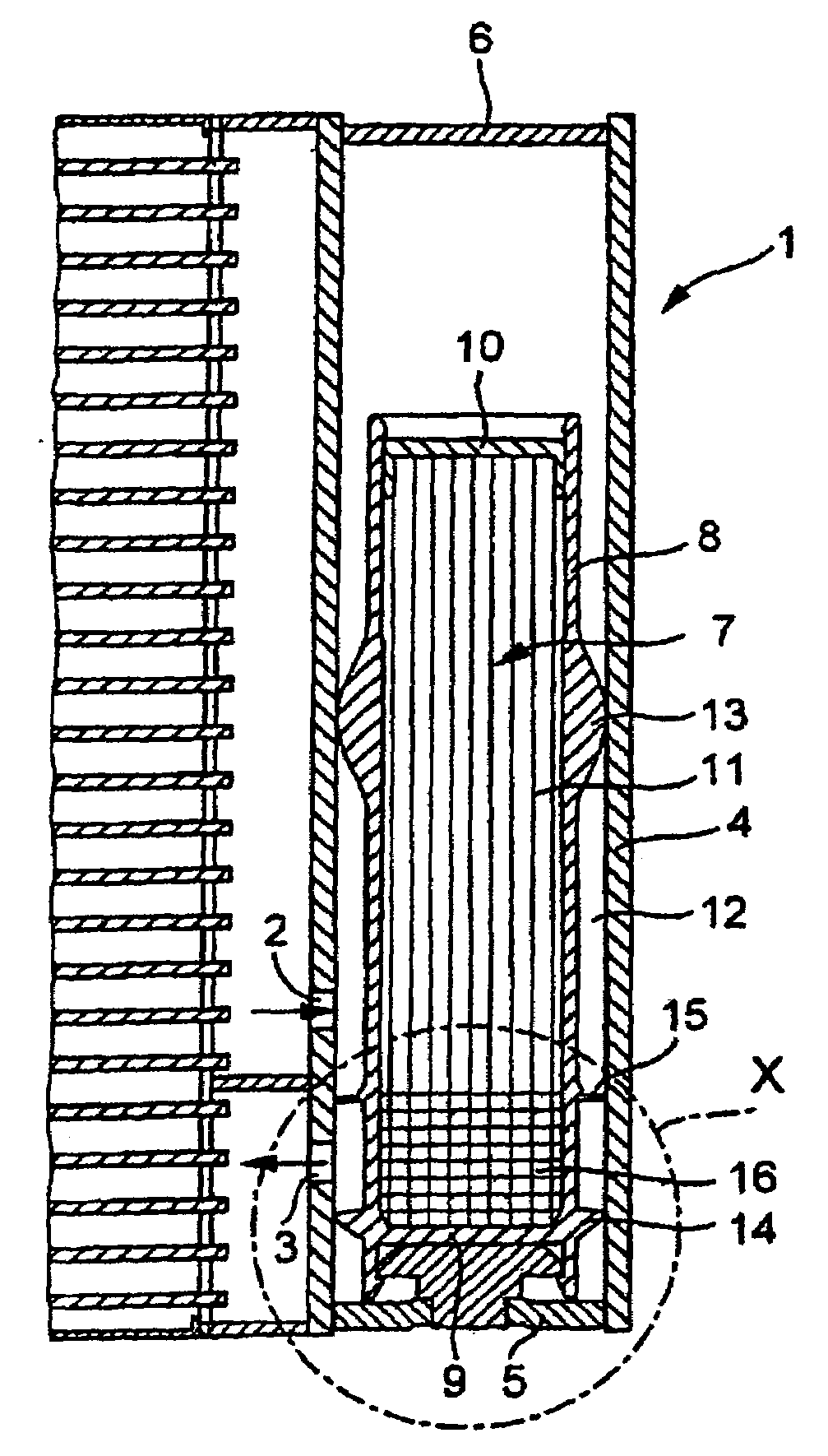

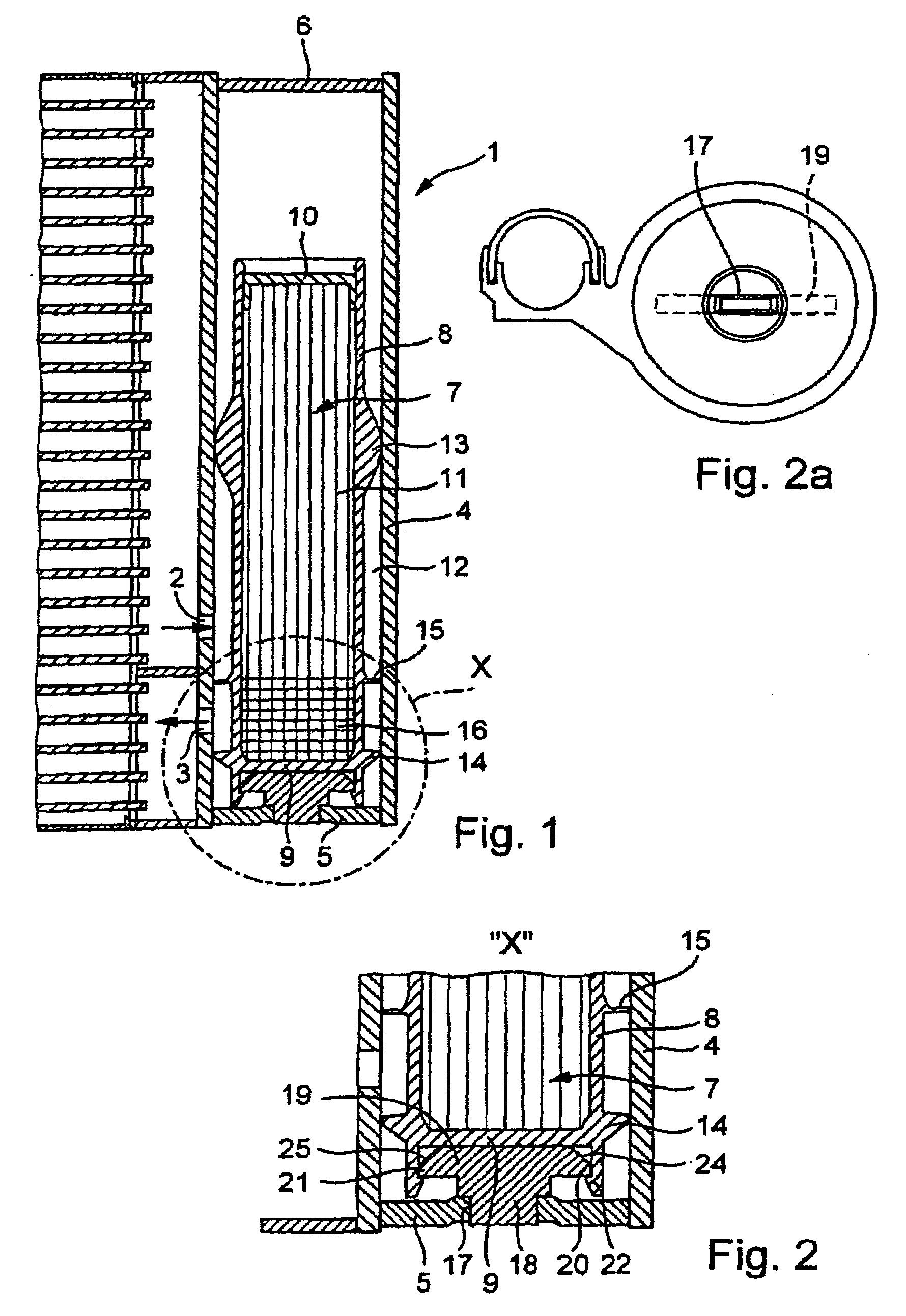

[0012]FIG. 1 shows a collector 1 for a coolant condenser (not completely illustrated) according to the prior art, for example, in accordance with DE-A 42 38 853. Such condensers are referred to as a condenser module because the collector is structurally integrated into the condenser, i.e., it is arranged in parallel with one of the two collector or header tubes and is connected to it in a manner permitting refrigerant communication between the two components. The collector or header 1 therefore has a refrigerant inflow opening 2 and a refrigerant outflow opening 3. Via these two openings, the collector is therefore connected at the refrigerant side to a collector tube of a condenser. The collector 1 is composed of an aluminum tube 4 which is matched in terms of its wall thickness and strength to the operating pressure of the condenser. The tube 4 is closed at the ends by a disk 5 at the bottom and a disk 6 at the upper end. In the interior of the tube 4, there is a dryer / filter cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com