Anti-freezing method suitable for polar sailing ship

A sailing ship, electric heating technology, applied in ship components, ship construction, hull ventilation/heating/cooling, etc., can solve the problem of being covered by ice and snow, people cannot enter and exit doors and windows, and cannot start smoothly; mooring equipment is covered by ice and snow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment and accompanying drawing, technical scheme of the present invention is described in further detail:

[0025] The present invention provides an antifreeze method covering pipeline systems, mechanical cabins and liquid tanks, equipment and passages for polar sailing ships, specifically as follows:

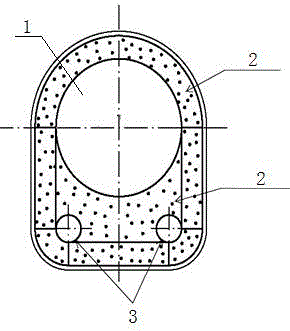

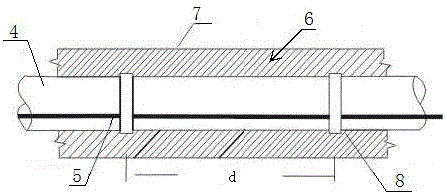

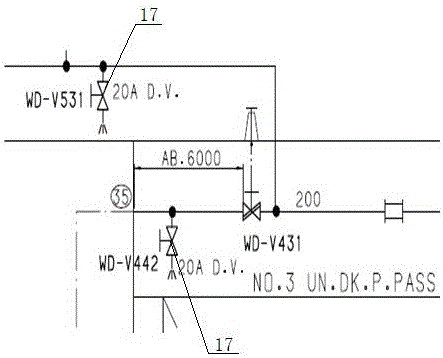

[0026] The liquid medium pipeline of the hull division of the polar navigation ship can adopt the following methods: Figure 1-2 Shown steam heating / electric heating + insulation material, image 3 Anti-freezing method shown in the residual discharge method, the gas medium pipeline can be used Figure 4 Dry gas method shown for freeze protection. The steam heat tracing method relies on the steam heating tube to heat the "target pipeline" and the "medium in the pipeline". figure 1 As shown, heat insulating material 2 is provided at the end and outside of liquid pipeline 1, and a plurality of steam heating pipes 3 are arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com