Structural laying layer for unmanned ship and preparation method of structural laying layer

A layering and boating technology, which is applied in the field of structural layering and preparation of unmanned boats, can solve the problems of poor structural strength of the hull, and achieve the effects of ensuring safe navigation, reducing weight, and eliminating electronic control disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The second aspect of the present application provides a method for preparing a structural layup for an unmanned boat, comprising the following steps:

[0040] S01. Laying the first fabric layer, the second fabric layer, the third fabric layer and the fourth fabric layer sequentially according to the composite fabric layer of the structure lay-up provided in the first aspect;

[0041] S02. Under negative pressure and vacuum conditions, introducing resin into the composite fabric layer, the resin penetrates into the composite fabric layer, and forms a solid glue after curing treatment to obtain the layered structure.

[0042] In the preparation method for the structural layup of unmanned boats provided in the embodiment of the present application, four layers of fabric are firstly laid up, and then the resin is introduced under vacuum and negative pressure conditions, and the laminated structure is obtained after curing. In this case, the vacuum negative pressure is not o...

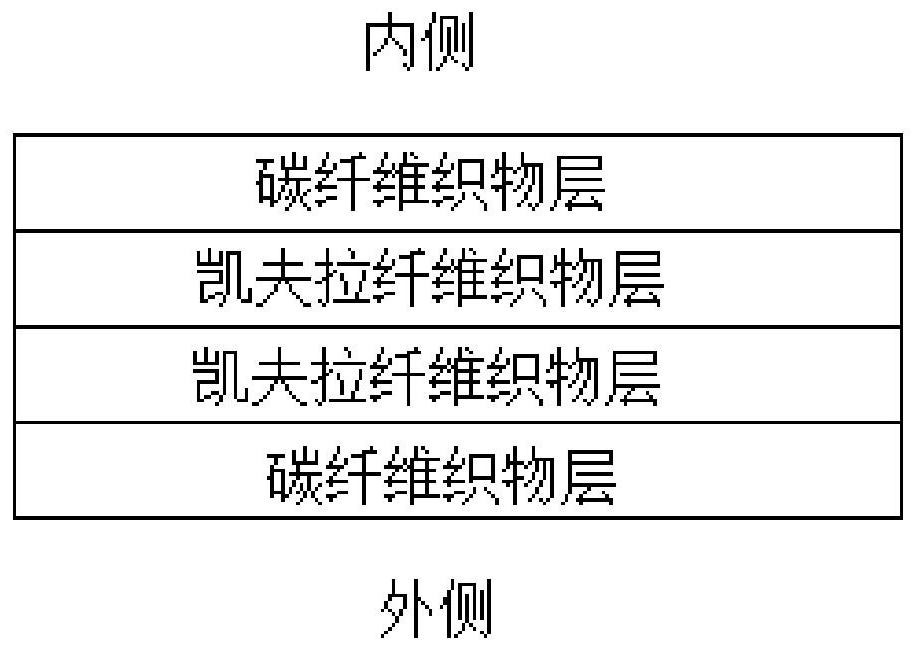

Embodiment 1

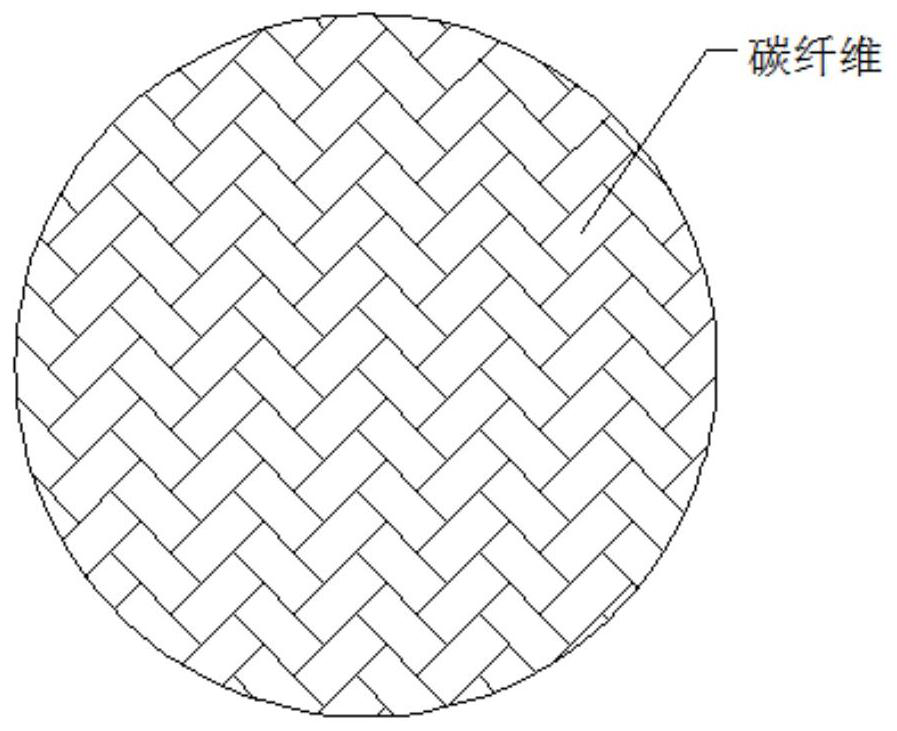

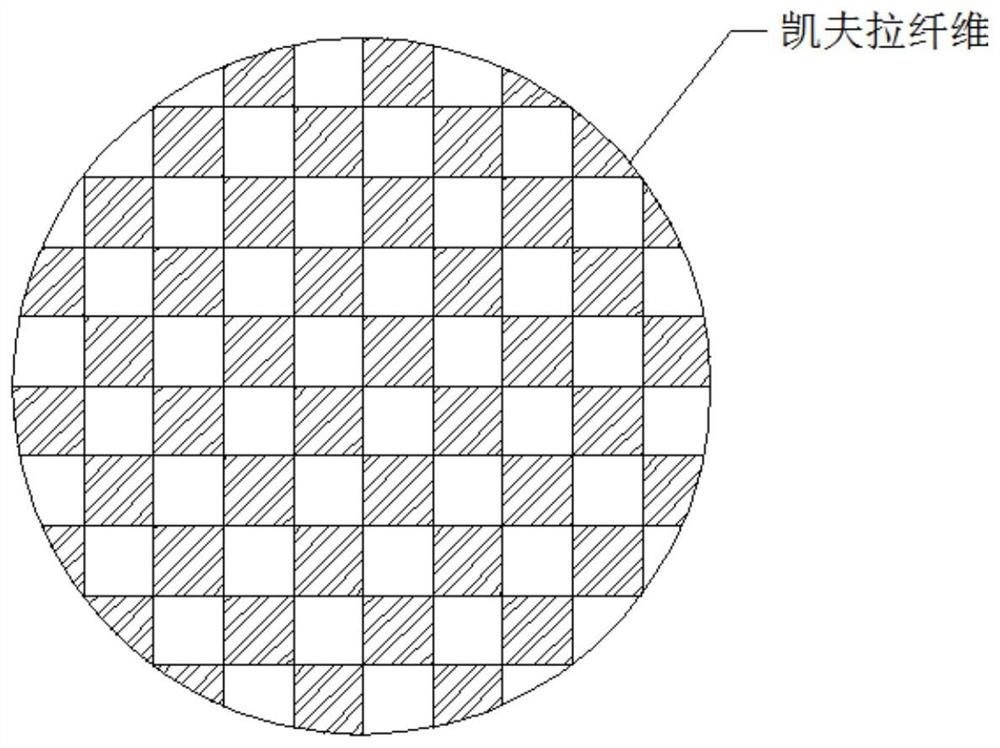

[0047] A hull lay-up structure of an unmanned ship, comprising a composite fabric layer and a cured glue infiltrated into the composite fabric layer, wherein, from the outside to the inside, the composite fabric layer includes a first fabric laid in sequence and arranged in a single layer layer, the second fabric layer, the third fabric layer and the fourth fabric layer, the angle between the weft of the second fabric layer and the weft of the first fabric layer is 90°, the third fabric layer The angle between the weft and the weft of the first fabric layer is 45°, the angle between the weft of the fourth fabric layer and the weft of the first fabric layer is 135°, and the fourth fabric The angle between the weft of the layer and the weft of the third fabric layer is 90°, and the fibers in the first fabric layer and the fourth fabric layer are carbon fibers, the second fabric layer and the The fibers in the third fabric layer are Kevlar fibers; the curing glue is epoxy resin. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com