Method for preparing air strainer by using environment-friendly TPE (thermoplastic elastomer)

An air filter, an environment-friendly technology, applied in the field of air filter preparation, can solve the problems of resource waste, non-environmental protection, low efficiency, etc., and achieve the effects of improving production efficiency, saving resources, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

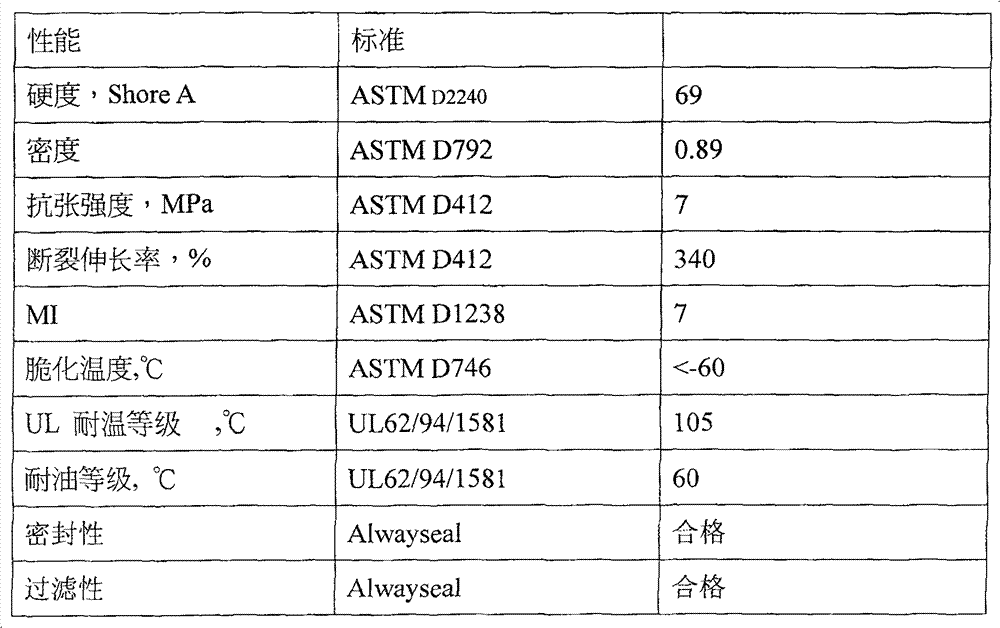

Embodiment 1

[0037] 1. Raw material preparation: including each ingredient according to the following weight ratio:

[0038] SEBS 100 copies;

[0039] 5 parts white mineral oil;

[0040] 5 parts of polypropylene PP;

[0041] 5 parts of polyurethane;

[0042] 1 part of EPDM rubber;

[0043] Antioxidant 0.2 parts;

[0044] 5 parts of maleic anhydride grafted polypropylene.

[0045] 2. Preparation equipment: twin-screw extrusion granulator, injection molding machine, and prefabricated molds for manufacturing air filter nets.

[0046] 3. Preparation steps:

[0047] Step 20, first pour SEBS into the mixer;

[0048] Step 30, put the white mineral oil into the blender, and stir for 1 minute;

[0049] Step 40, put other raw materials together, and stir for 1 minute to fully mix;

[0050] Step 50, putting the mixed materials into a twin-screw granulator to extrude and granulate at 150°C to obtain environment-friendly TPE particles;

[0051] Step 60. Put the prepared environmentally friend...

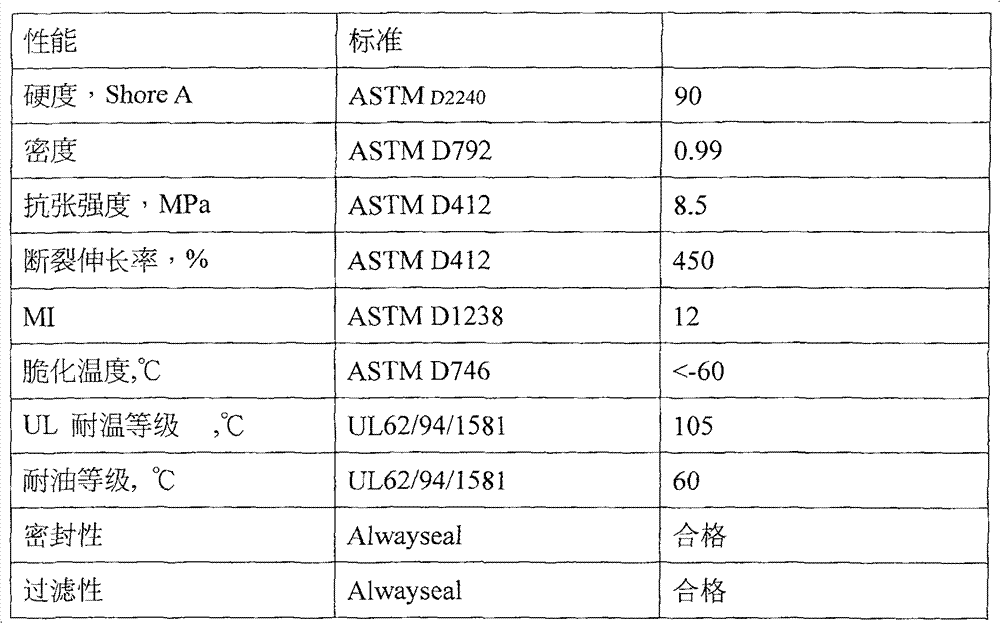

Embodiment 2

[0055] 1. Raw material preparation: including each ingredient according to the following weight ratio:

[0056] SEBS 100 copies;

[0057] 380 parts of white mineral oil;

[0058] Polypropylene PP 200 parts;

[0059] 100 parts of polyurethane;

[0060] 80 copies of EVA;

[0061] 100 parts of calcium carbonate;

[0062] 3 parts calcium stearate;

[0063] 15 parts of EPDM rubber;

[0064] 3 parts of titanium dioxide;

[0065] Antioxidant 1 part;

[0066] 5 parts of maleic anhydride grafted polypropylene;

[0067] 2. Preparation equipment: twin-screw extrusion granulator, injection molding machine, and prefabricated molds for manufacturing air filter nets.

[0068] 3. Preparation steps:

[0069] Step 20, first pour SEBS into the mixer;

[0070] Step 30, put the white mineral oil into the blender, and stir for 5 minutes;

[0071] Step 40, put other raw materials together, and stir for another 5 minutes to fully mix;

[0072] Step 50, putting the mixed materials into a ...

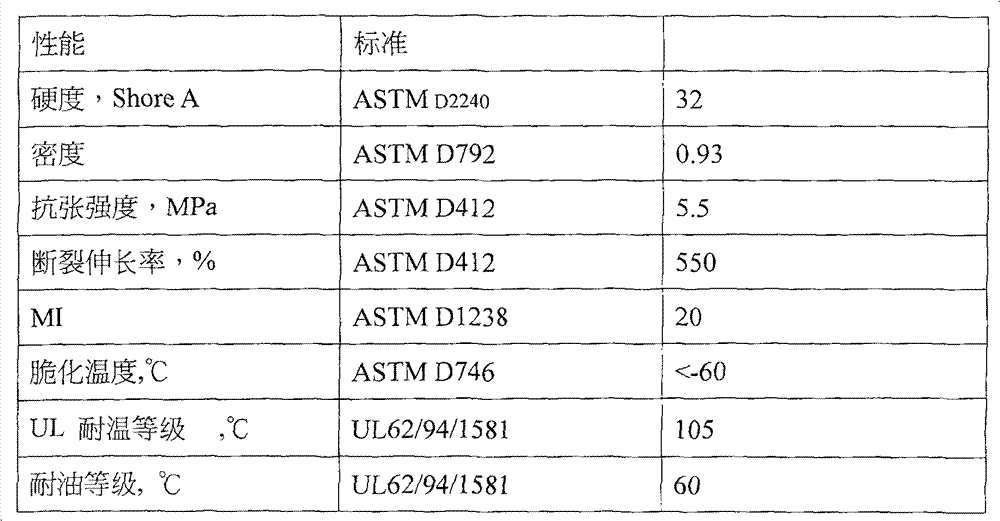

Embodiment 3

[0077] 1. Raw material preparation: including each ingredient according to the following weight ratio:

[0078] SEBS 100 copies;

[0079] 200 parts of white mineral oil;

[0080] 80 parts of polypropylene PP;

[0081] 50 parts of polyurethane;

[0082] 30 copies of EVA;

[0083] 50 parts of calcium carbonate;

[0084] 2 parts calcium stearate;

[0085] 8 parts of EPDM rubber;

[0086] 5 parts of titanium dioxide;

[0087] Antioxidant 0.6 part;

[0088] 3 parts of maleic anhydride grafted polypropylene.

[0089] 2. Preparation equipment: twin-screw extrusion granulator, injection molding machine, and prefabricated molds for manufacturing air filter nets.

[0090] 3. Preparation steps:

[0091] Step 20, first pour SEBS into the mixer;

[0092] Step 30, put the white mineral oil into the blender, and stir for 3 minutes;

[0093] Step 40, put other raw materials together, and stir for another 3 minutes to fully mix;

[0094] Step 50, putting the mixed materials into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com