Machining equipment of hollow welding net

A technology for processing equipment and welded wire mesh, which is applied to the processing field of hollow welded wire mesh, can solve the problems of low production efficiency, poor economy, and can not meet the continuous production of equipment, and achieve the effect of precise processing accuracy and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

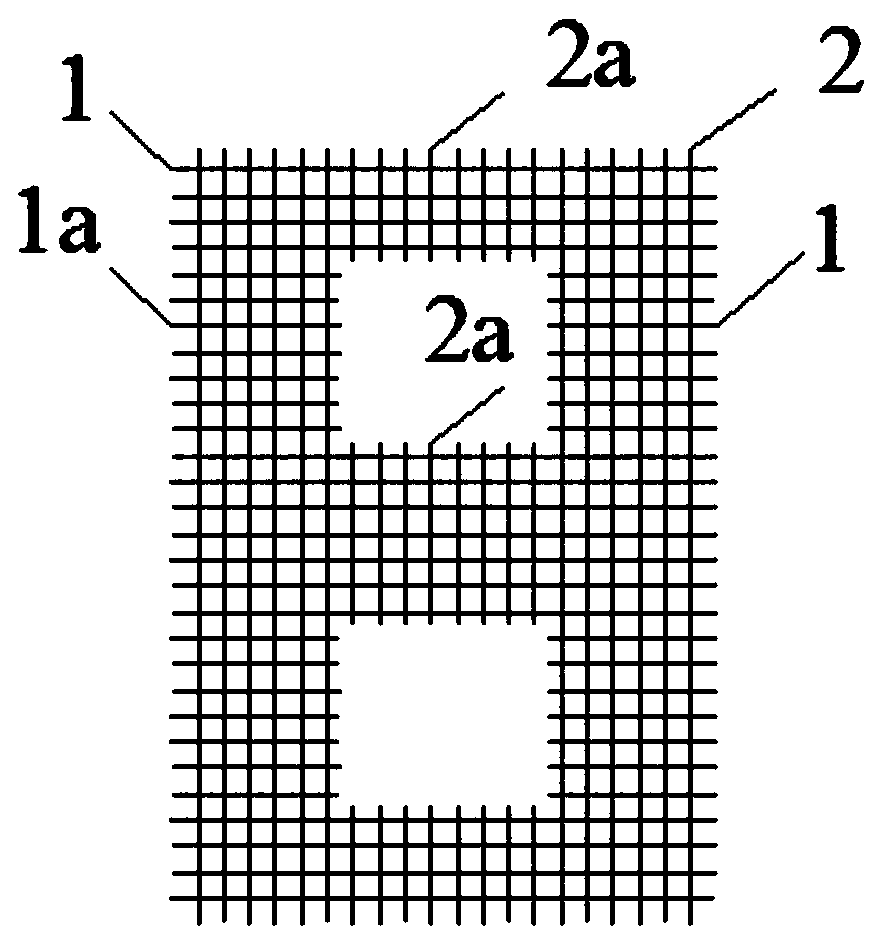

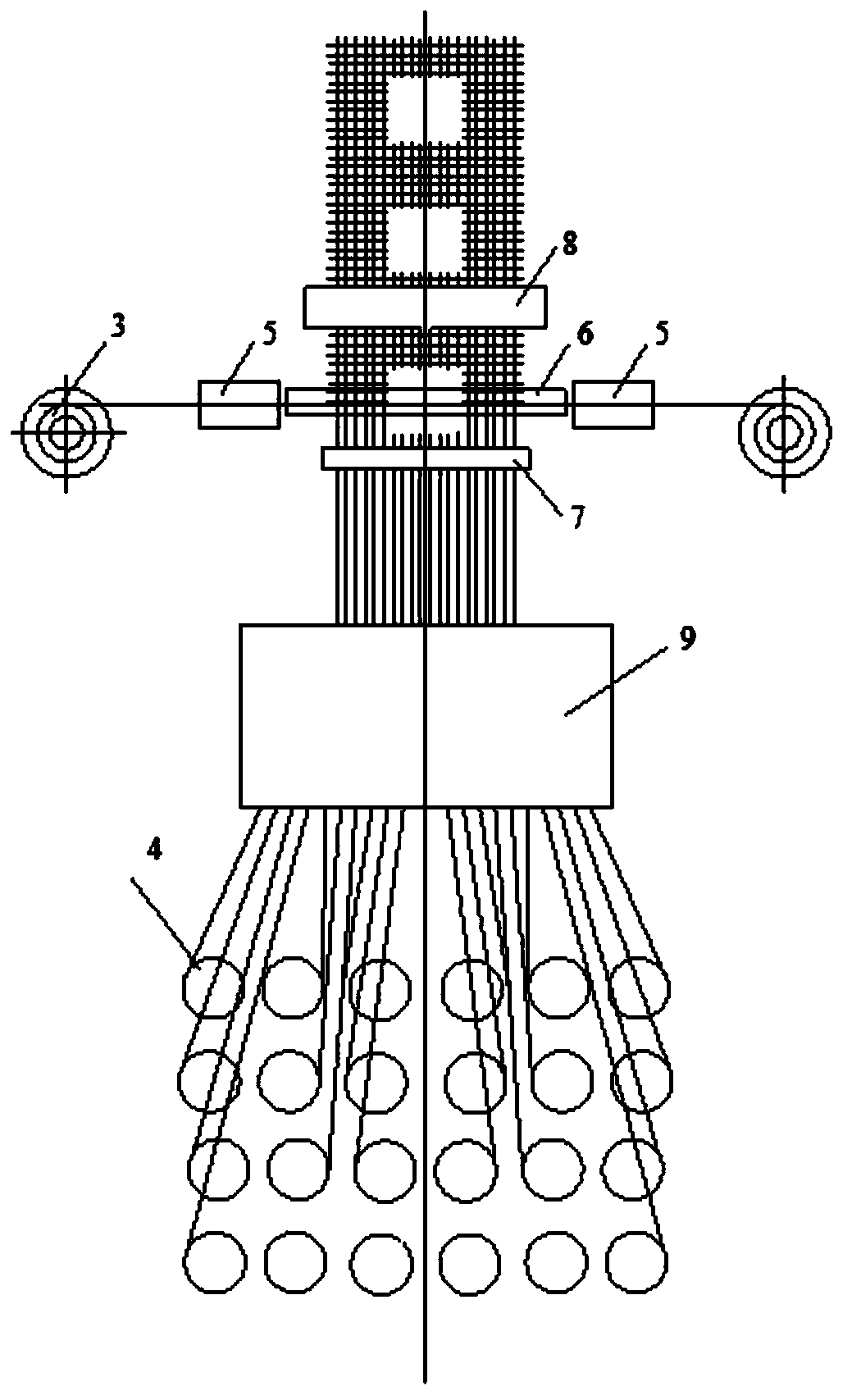

[0010] From figure 2 It can be seen that a hollow welded mesh processing equipment includes a welded mesh host 6, a warp conveying device 7 at the front end of the welded mesh host 6, a warp straightening mechanism 9, and a shearing net at the rear end of the welded mesh host 6. Device 8, two weft thread straightening and cutting devices 5 are respectively installed at the two ends of the welding net main machine 6, the warp thread conveying device 7 can control the step of each warp thread independently, and each warp thread is equipped with a warp thread cutting device 10 at the same time.

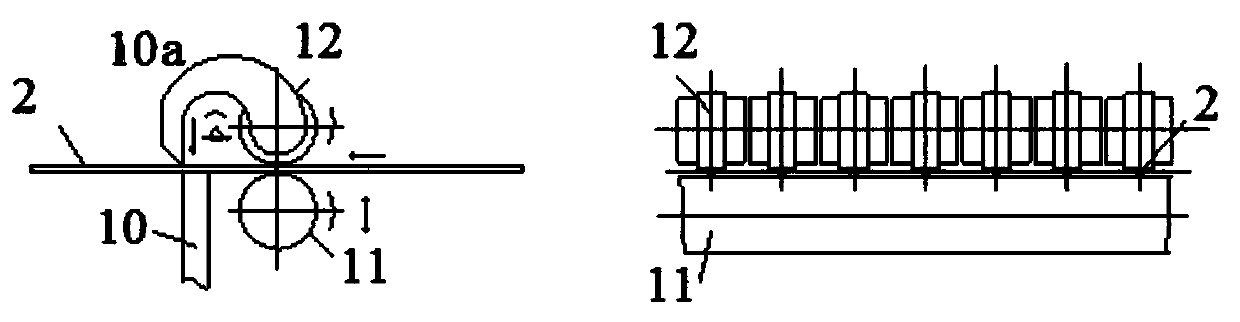

[0011] From image 3 It can be seen that the warp conveying device 7 is composed of a driving wheel 11 and a driven wheel 12. The driving wheel 11 is connected to the power unit to be driven to rotate as an integral structure. sports. The driven wheel 12 in the conveying device 7 is integrated with the cutting knife 10a in the cutting device, and the driven wheel 12 breaks away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com