Patents

Literature

60results about How to "Accurate machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

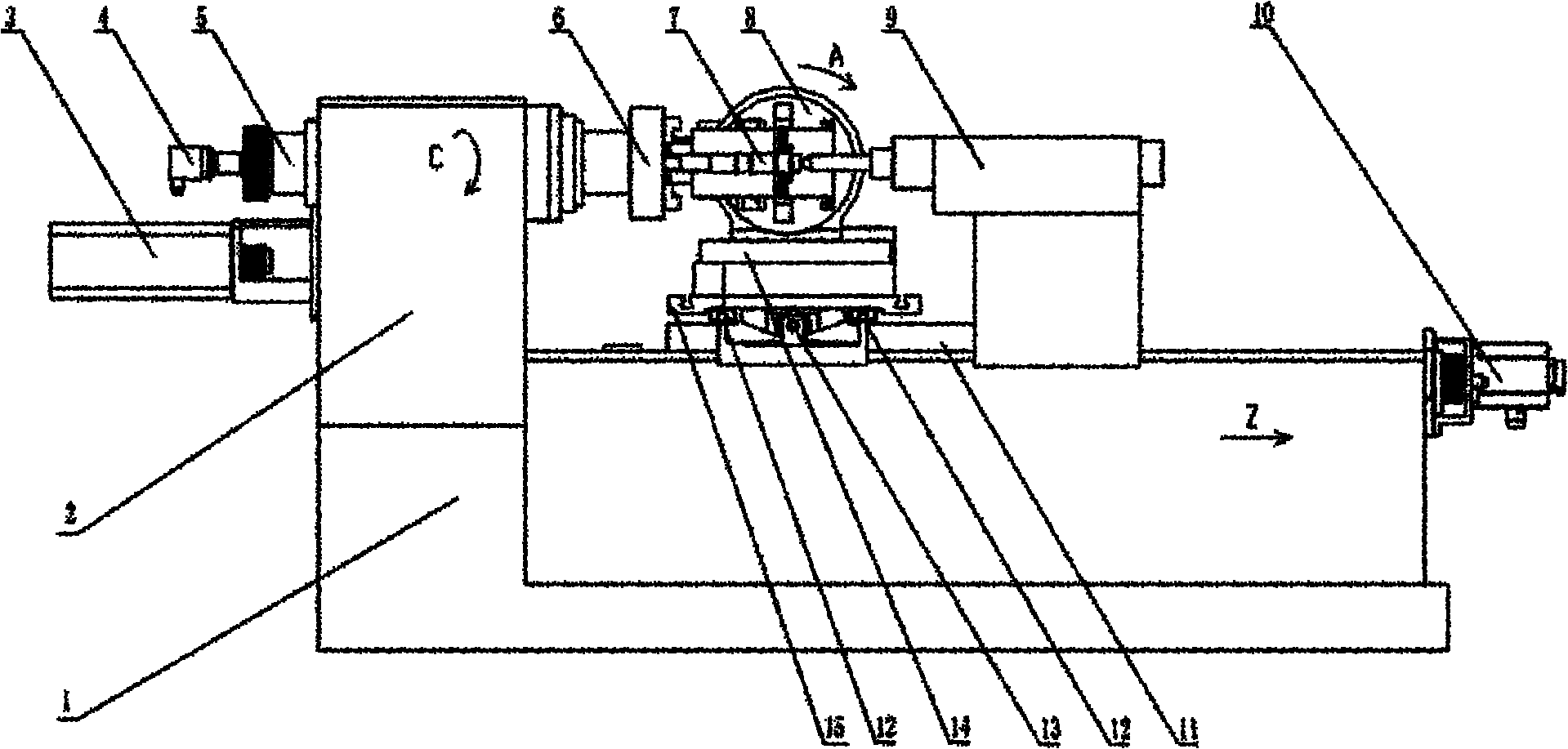

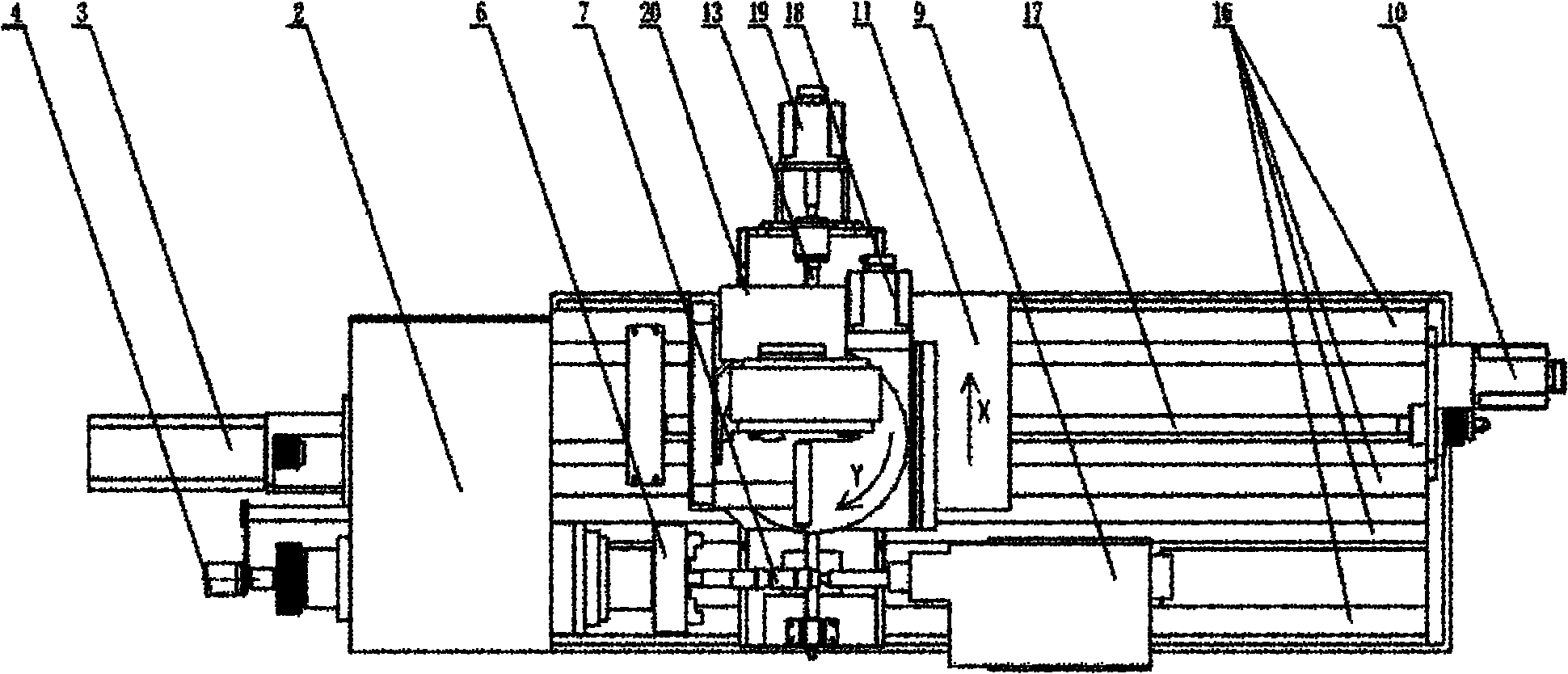

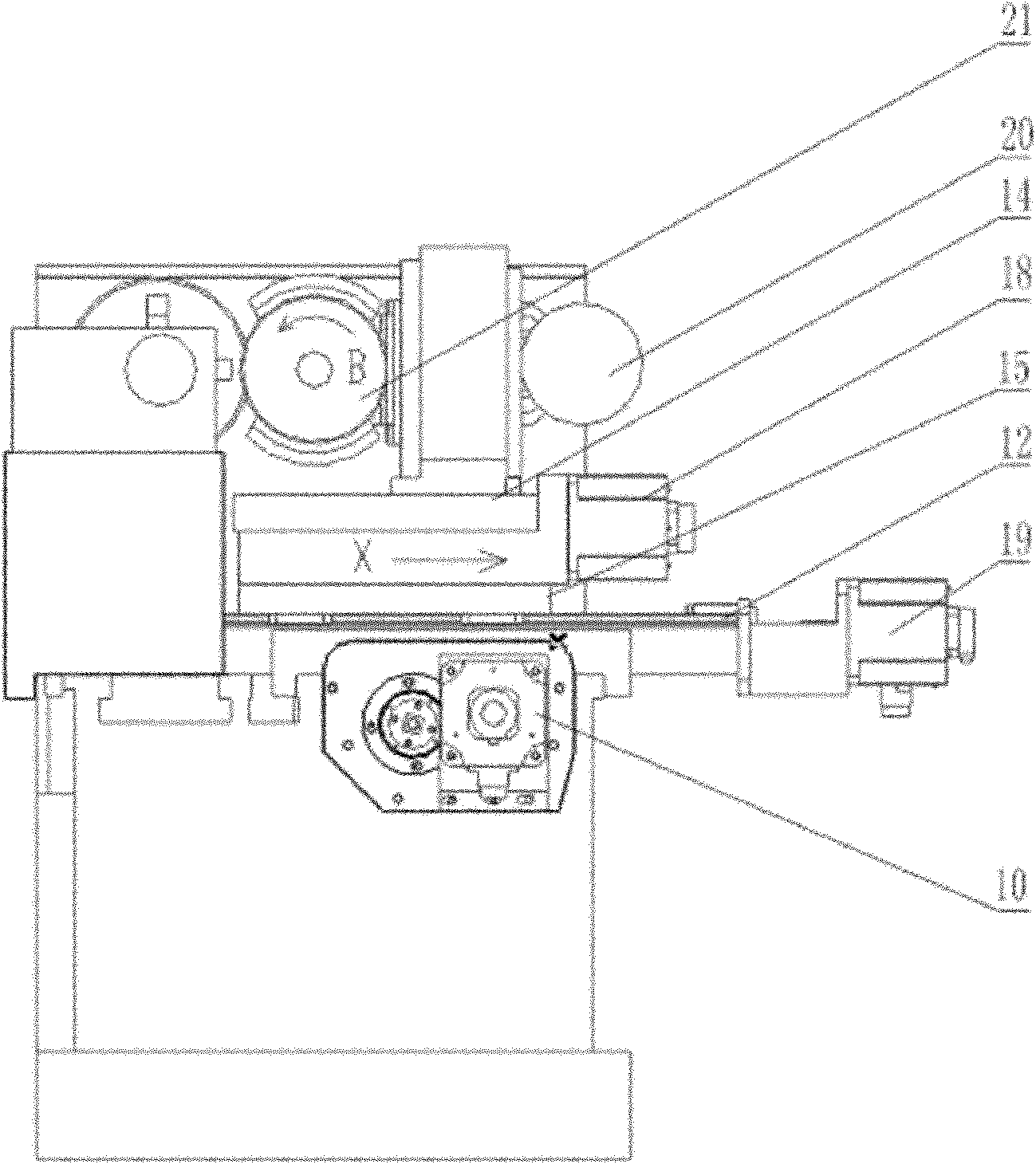

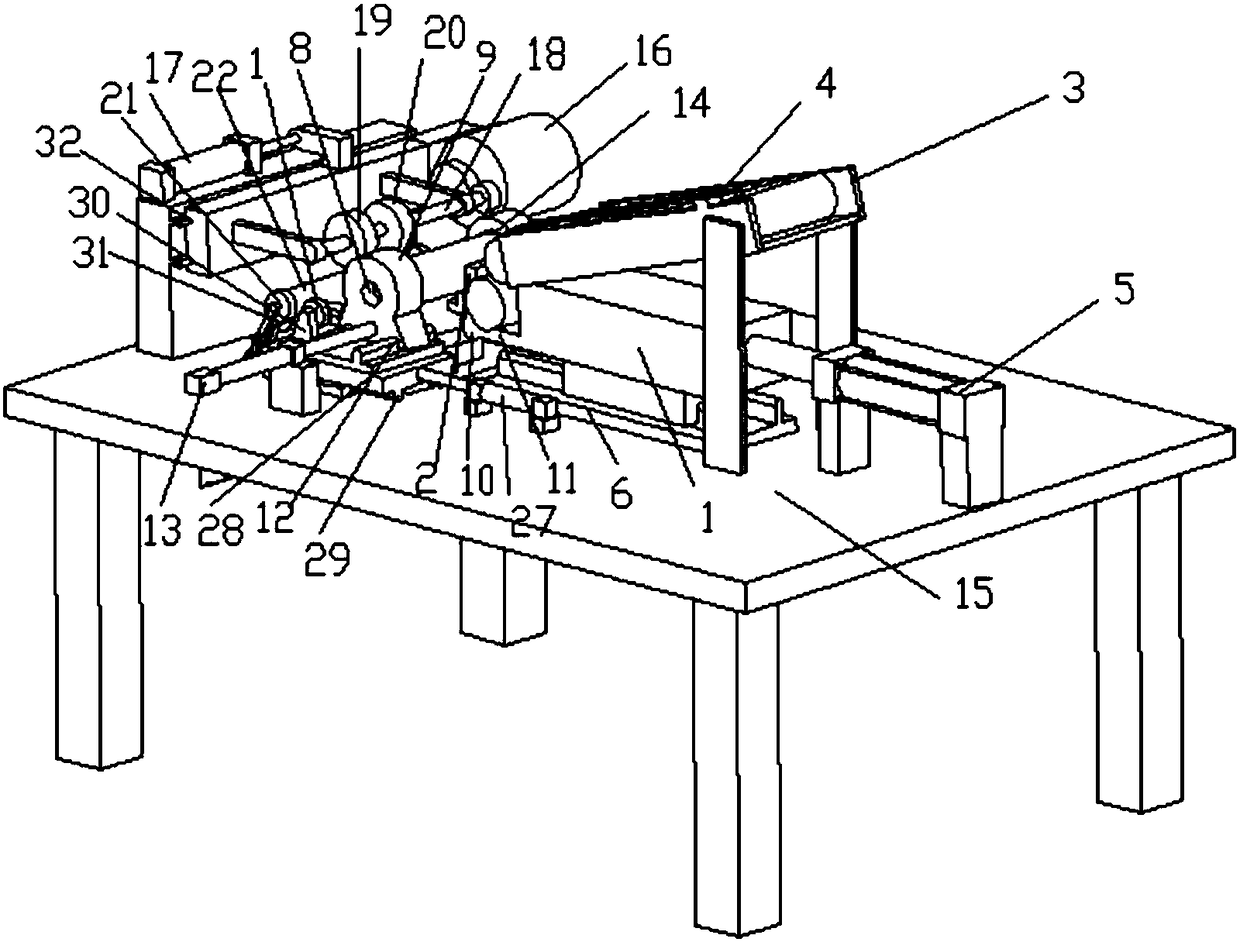

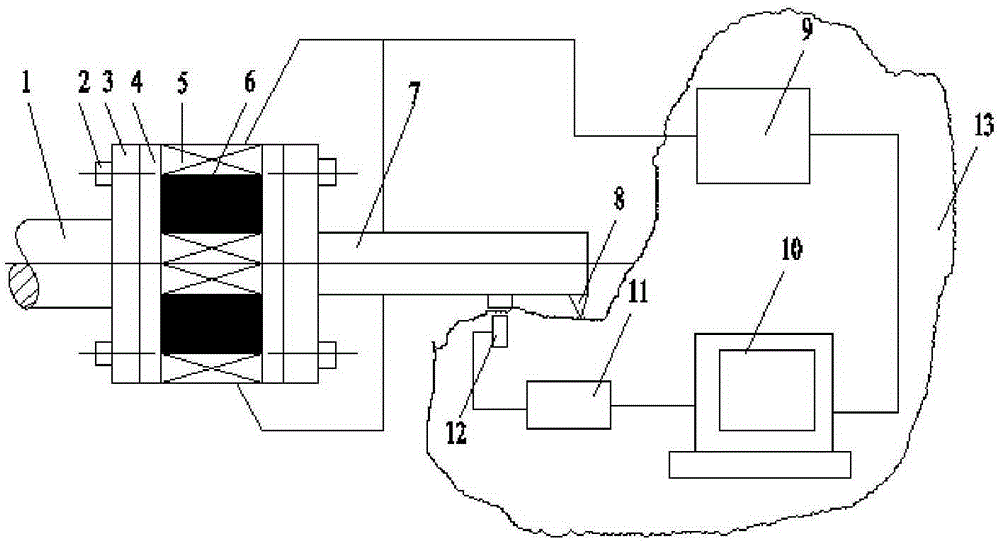

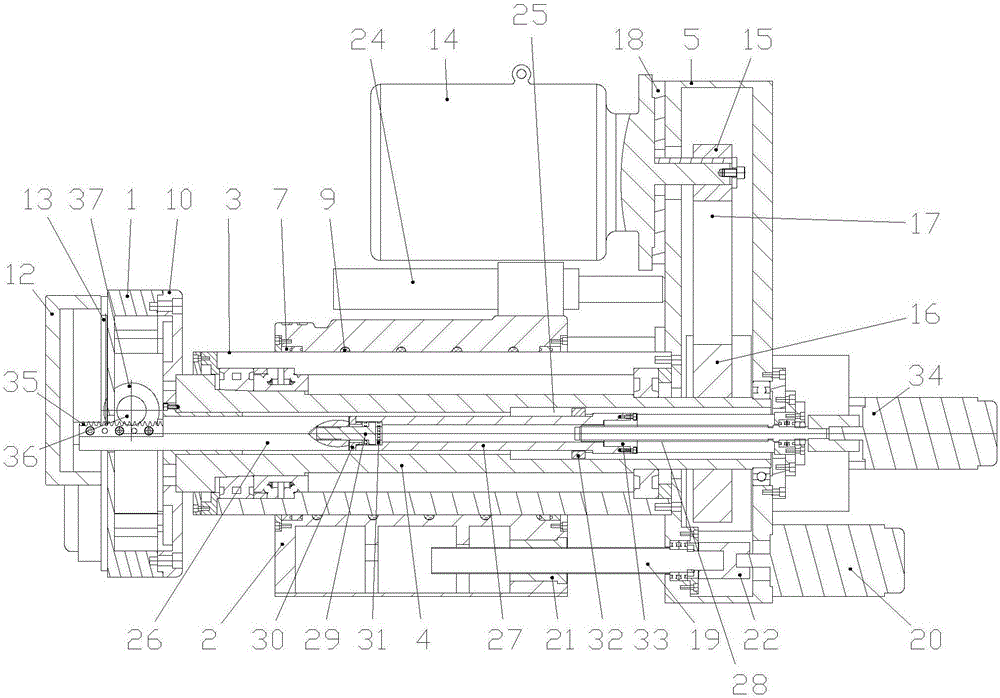

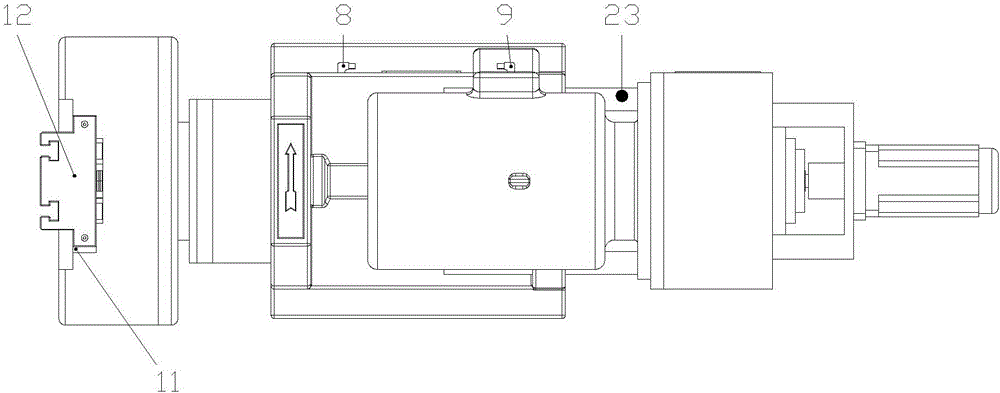

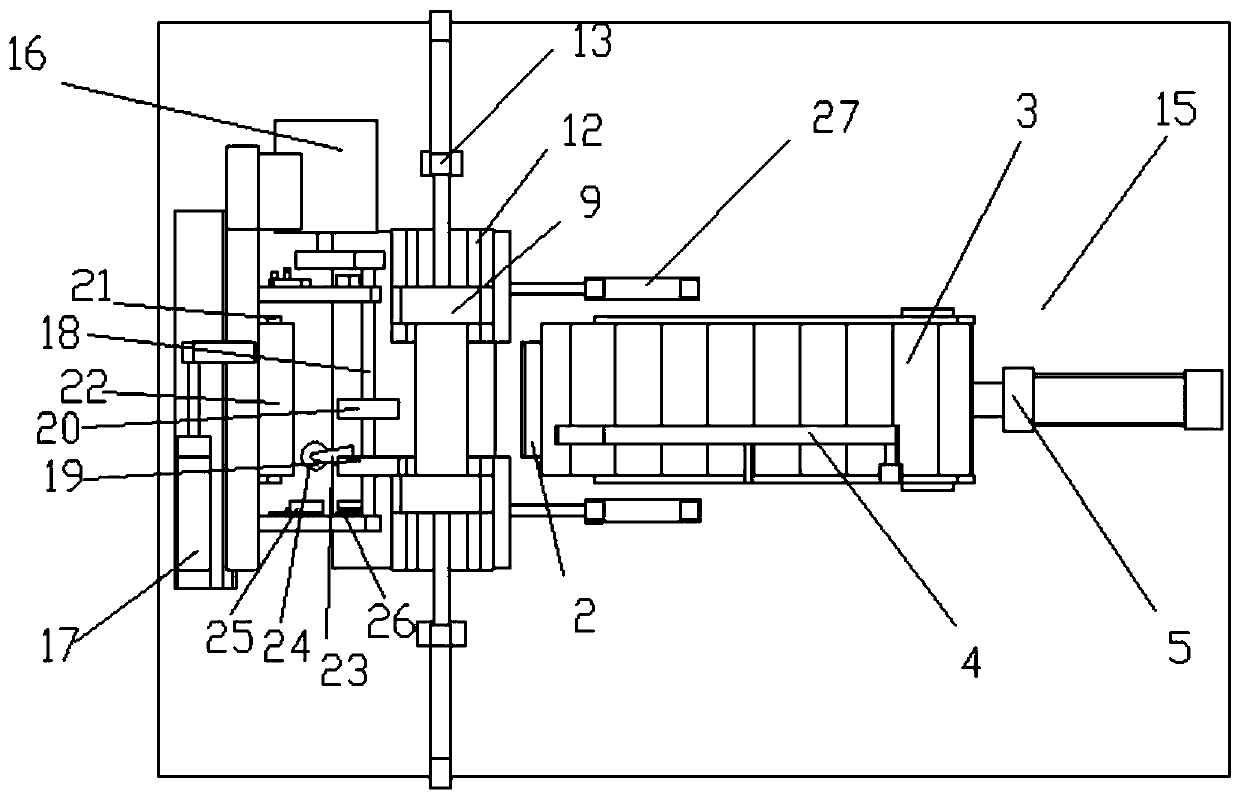

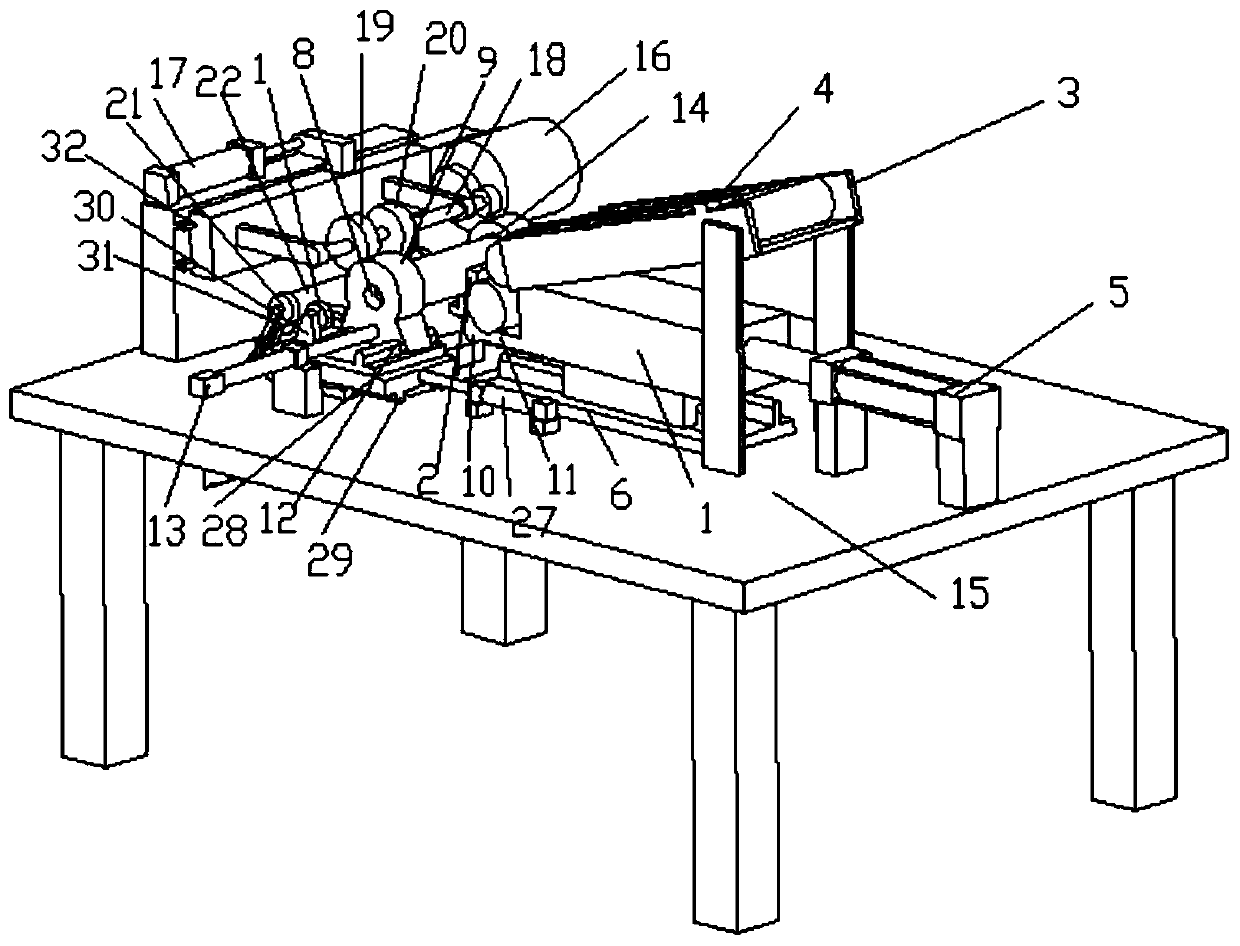

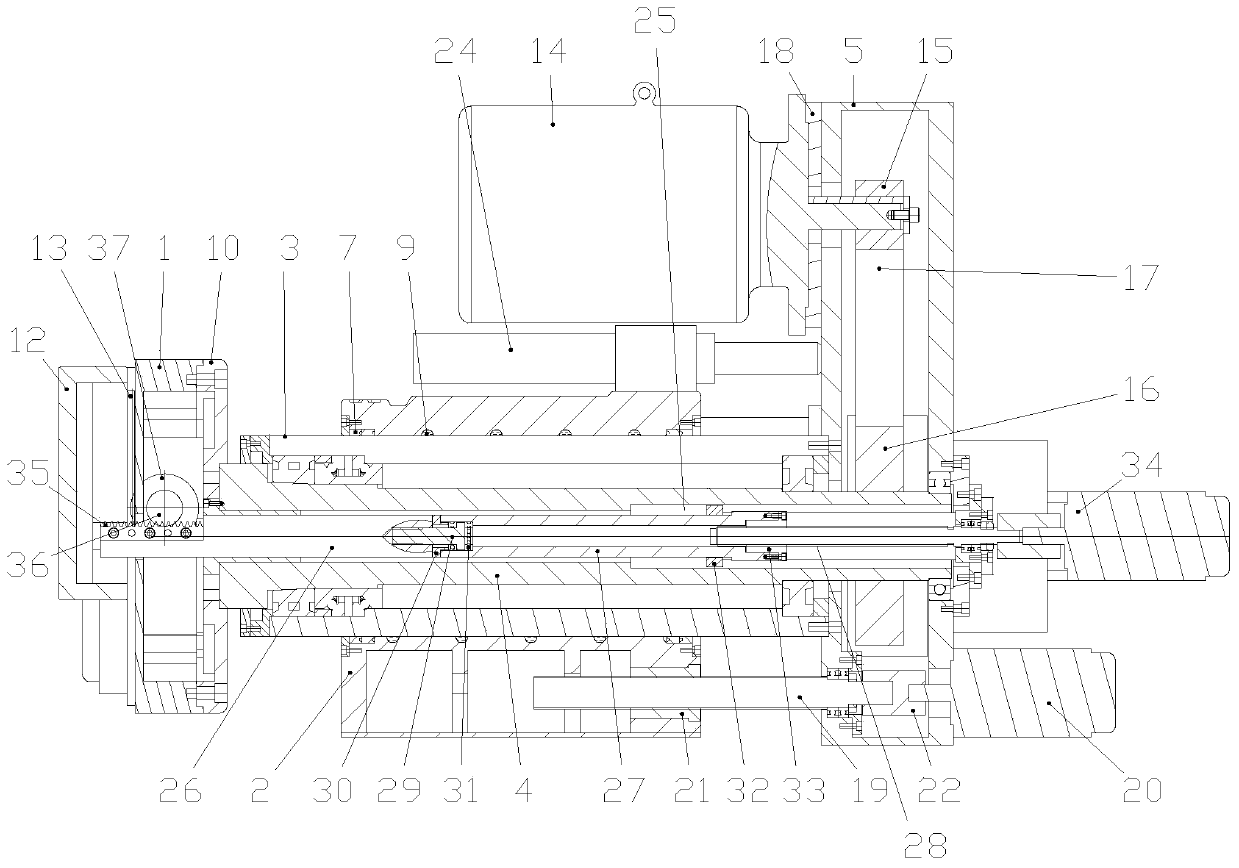

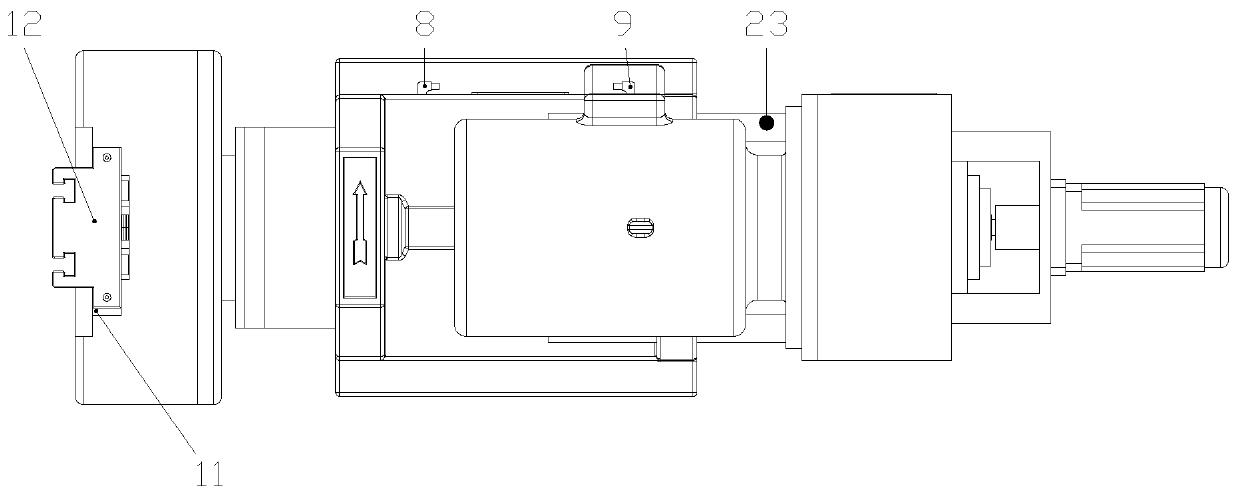

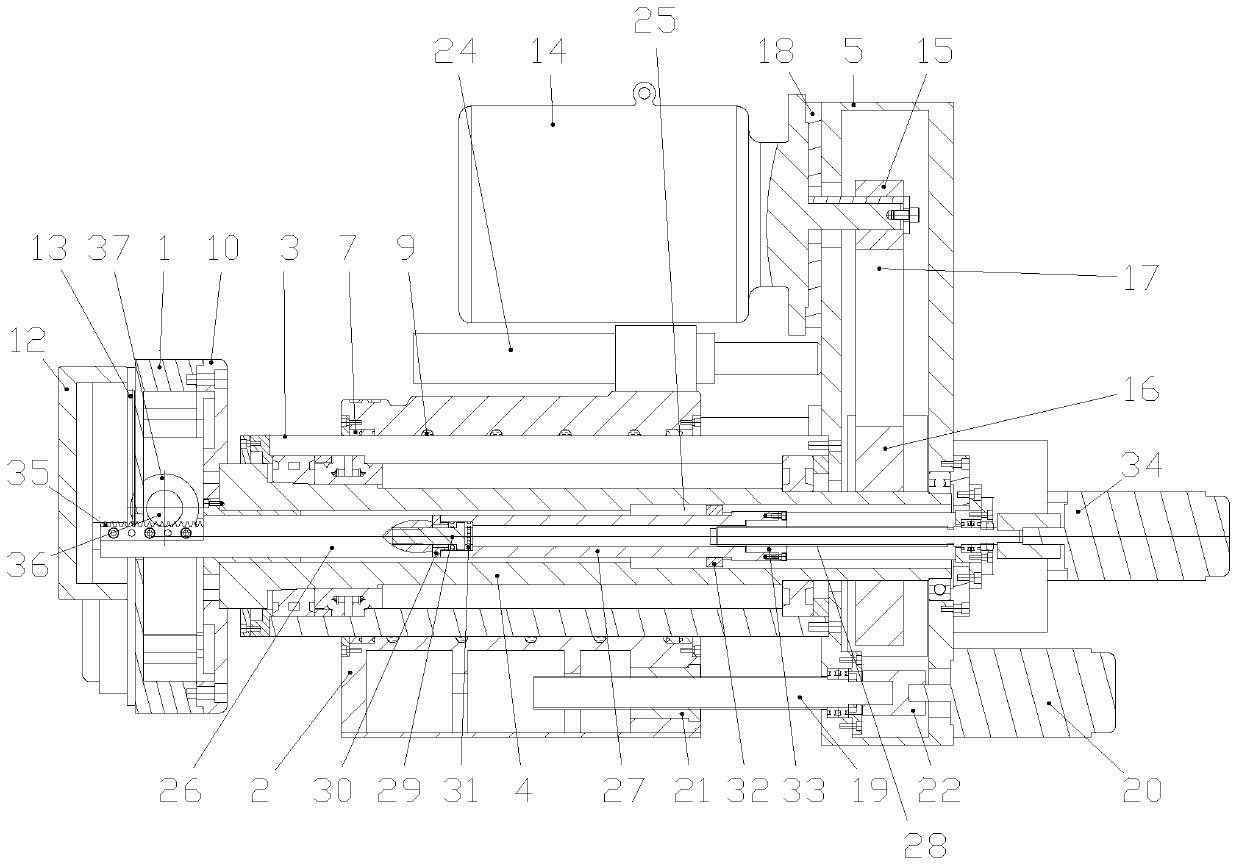

CNC (computerized numerical control) combined turning and grinding machine tool for four-linkage enveloping worms and processing method thereof

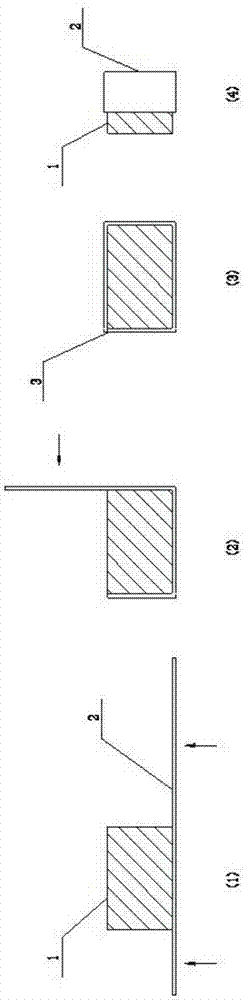

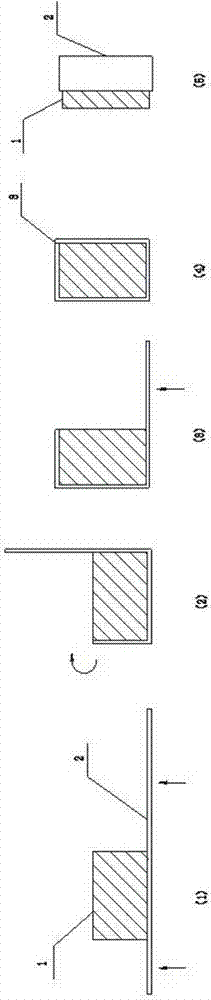

The invention relates to the technical field of machinery, specifically relates to a CNC (computerized numerical control) combined turning and grinding machine tool for four-linkage enveloping worms and a processing method thereof. The machine tool and processing method thereof provided by the invention are characterized in that a main shaft motor 3 drives a main shaft 5 and an enveloping worm 7 to rotate around a C-axis by a synchronous belt, a Z-axis servo motor 10 drives a ball screw 17 to lead a large support plate 11 to move along a Z-direction guide rail 16 by the synchronous belt, an X-axis servo motor 19 drives a ball screw 13 to lead a small support plate 15 to move along an X-direction guide rail 12 by a coupler, a Y-axis servo motor 18 drives a CNC rotary table 14 to rotate around a Y axis by gears, a CNC tool rest or grinding head is fixedly connected to the CNC rotary table, a grinding head motor 20 drives a grinding wheel 21 to rotate around a B-axis by the synchronous belt, and the grinding wheel and the motor synchronously rotate around an A-axis by turning a hand wheel. Compared with the prior art, the machine tool disclosed by the invention is simple and novel instructure, convenient and safe in operation, high in processing efficiency and wide in application range; and in addition, the machine tool can rotate at a high speed, and the operations of turning and grinding are completed on a same machine tool, therefore, the machine tool is complete in function, high in reliability, strong in environment adaptivity, and more accurate in transmission precision and machining precision.

Owner:上海合纵重工机械有限公司

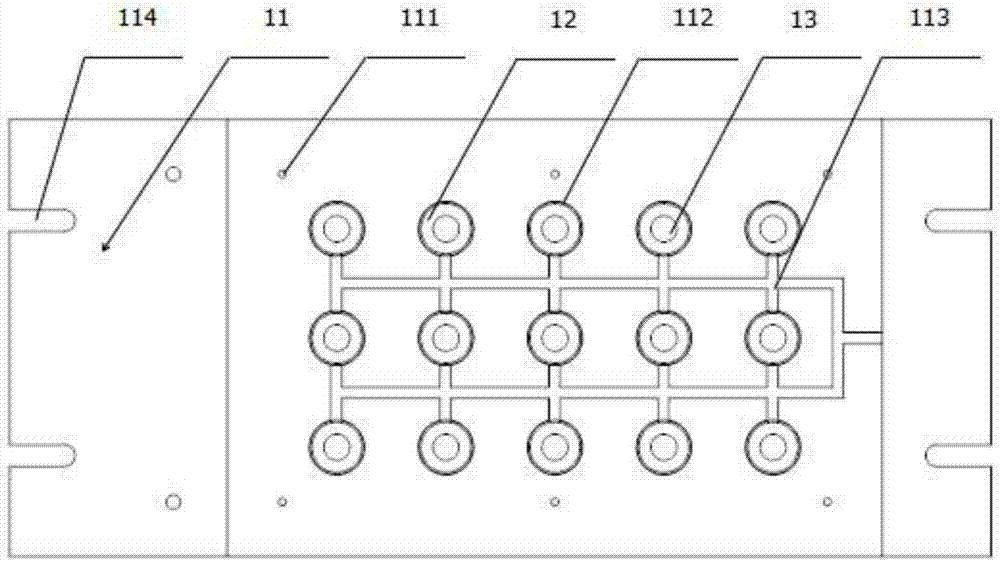

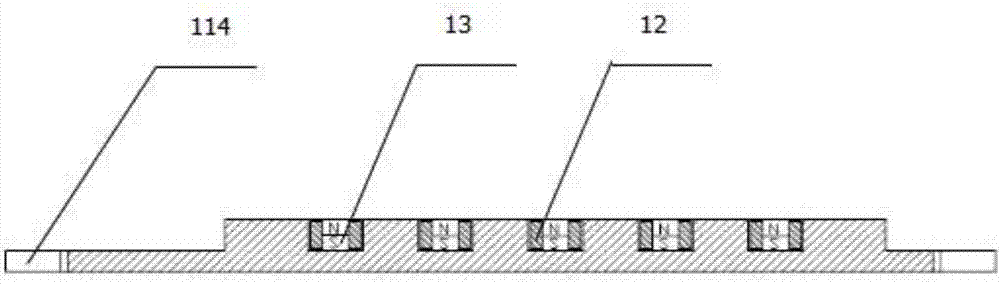

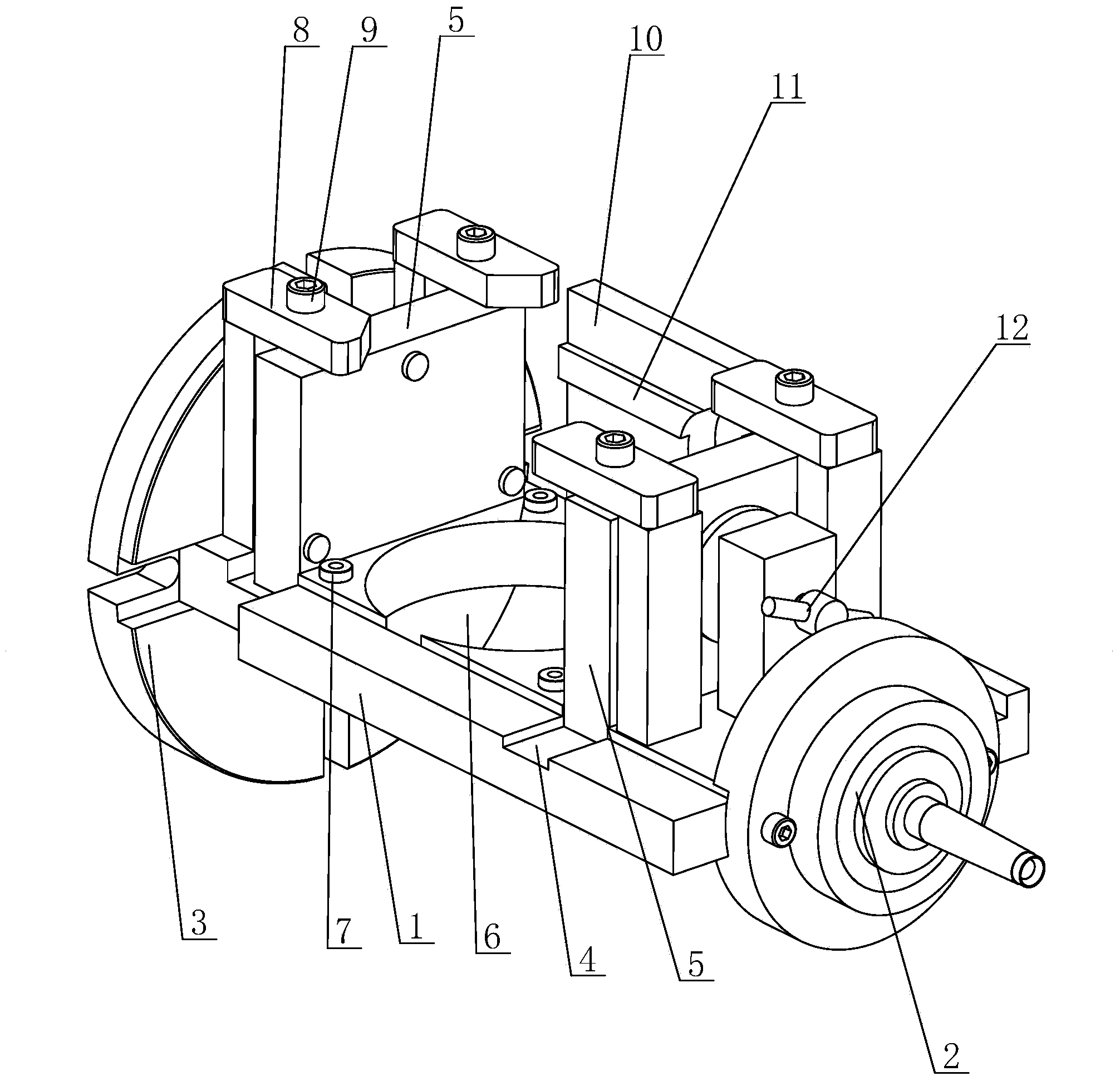

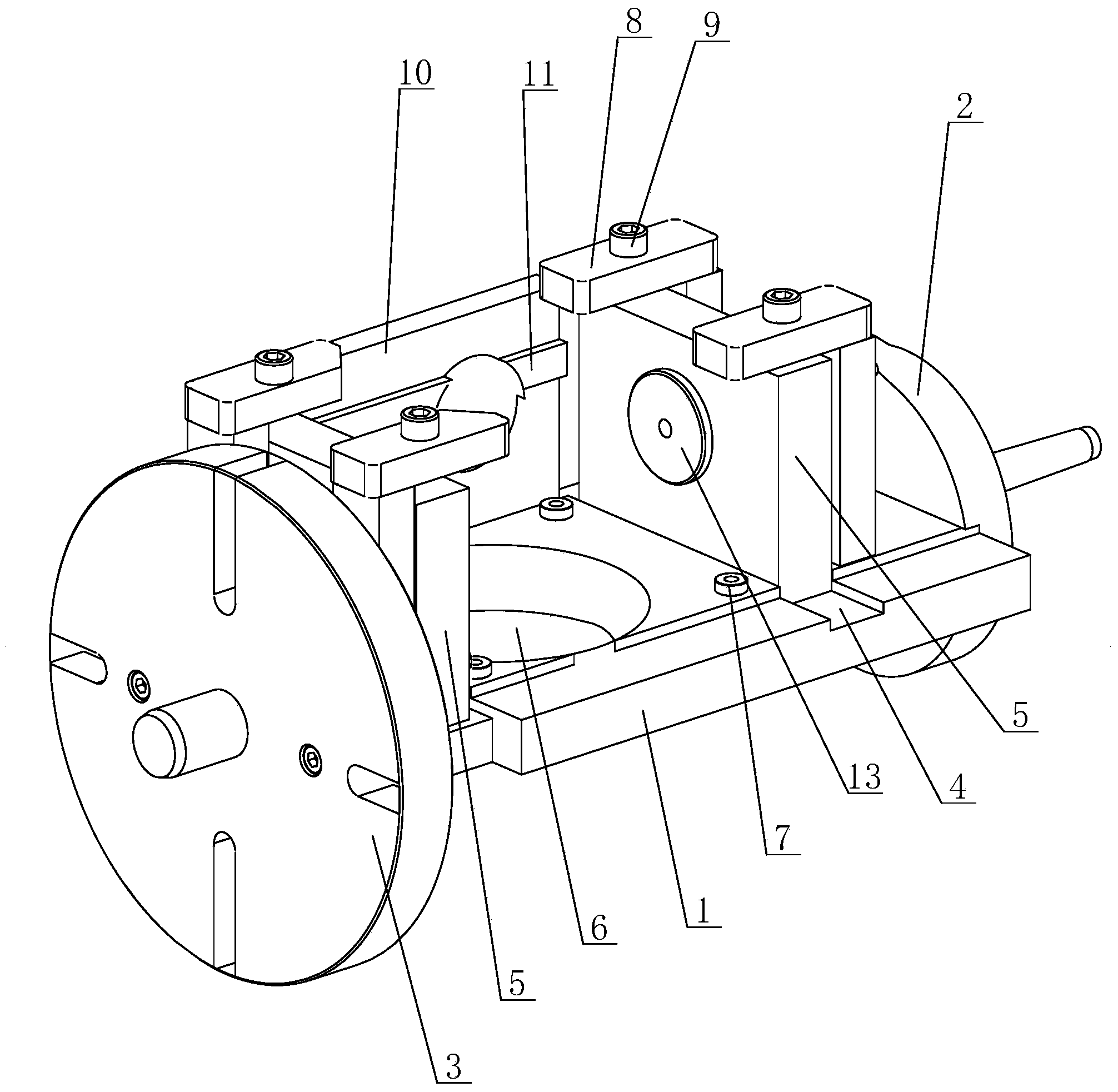

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

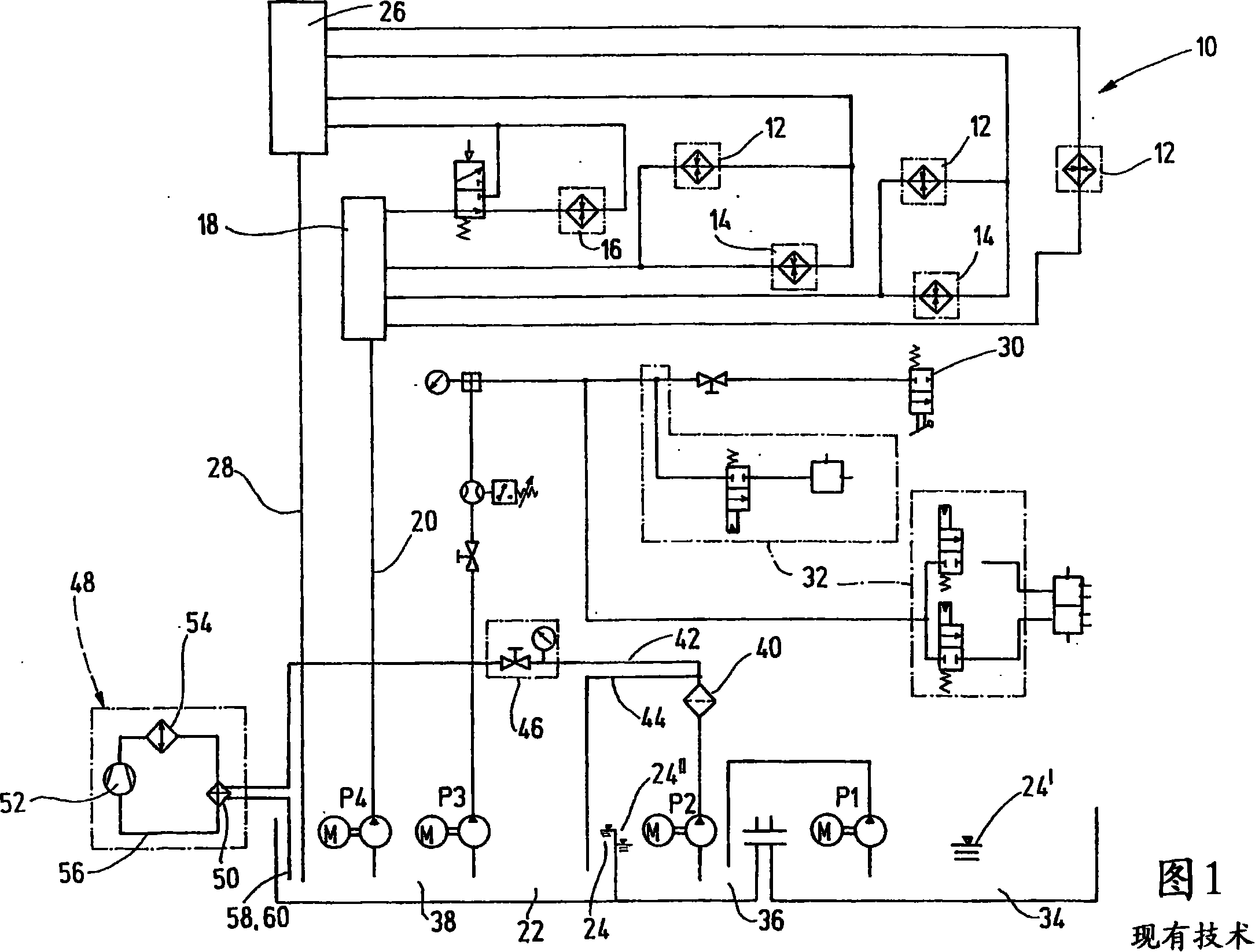

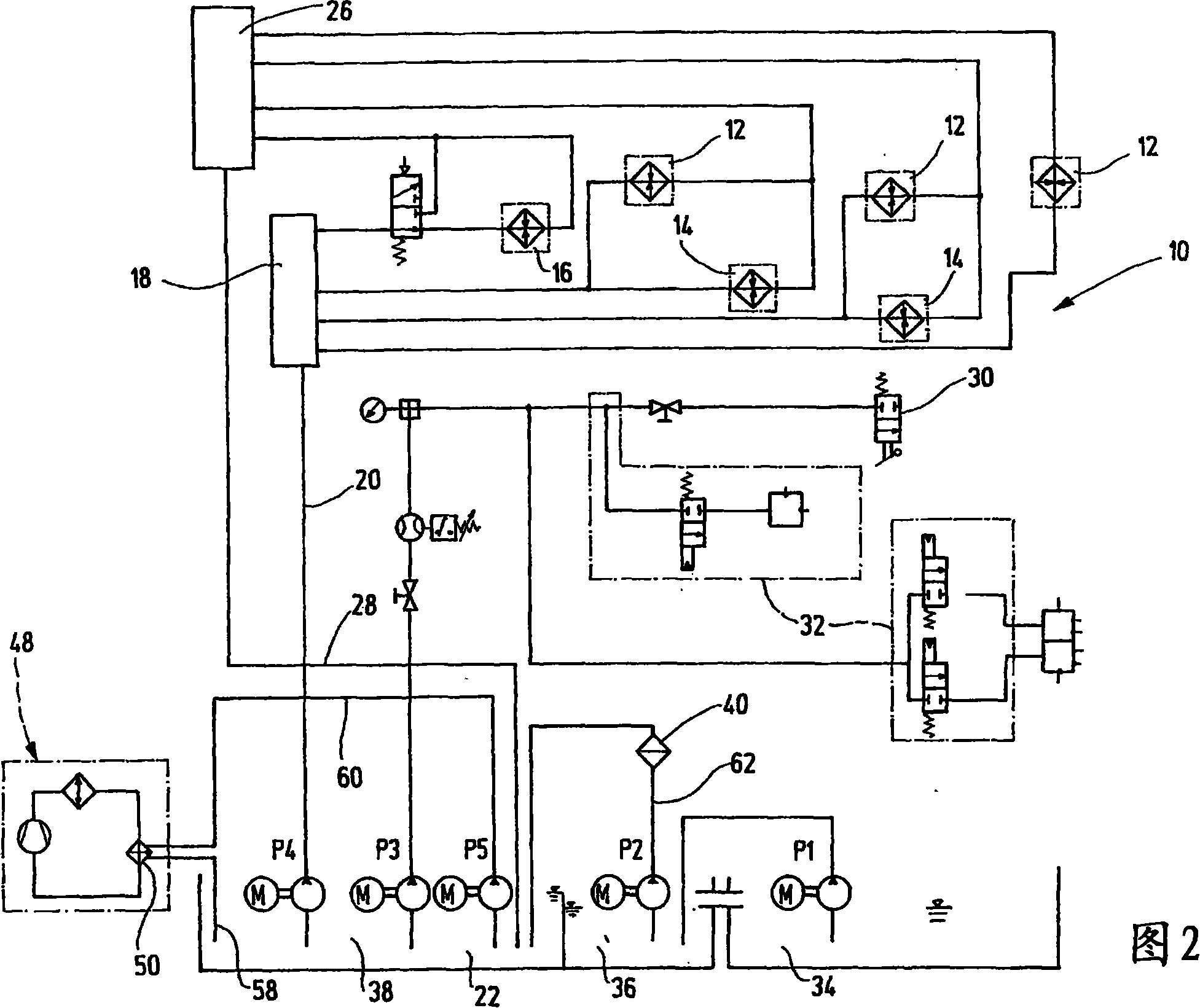

Cooling device

InactiveCN101111346AUniform machining accuracyAccurate machining accuracyMaintainance and safety accessoriesHydraulic pumpEngineering

The cooling device for a working machine (10) for the cooling of a heated fluid such as cooling and lubricating medium has at least one cooling unit (48) which by a pump unit with at least one hydraulic pump (P2) receives fluid filtered by a filter unit (40). A supply tank (38) is divided into a clean tank (22) and a dirty tank (36). The hydraulic pump feeds exclusively filtered fluid from the dirty tank into the clean tank, and an additional independent hydraulic pump (P5) transmits the fluid brought into the clean tank to the cooling unit for circulation.

Owner:HYDAC SYST

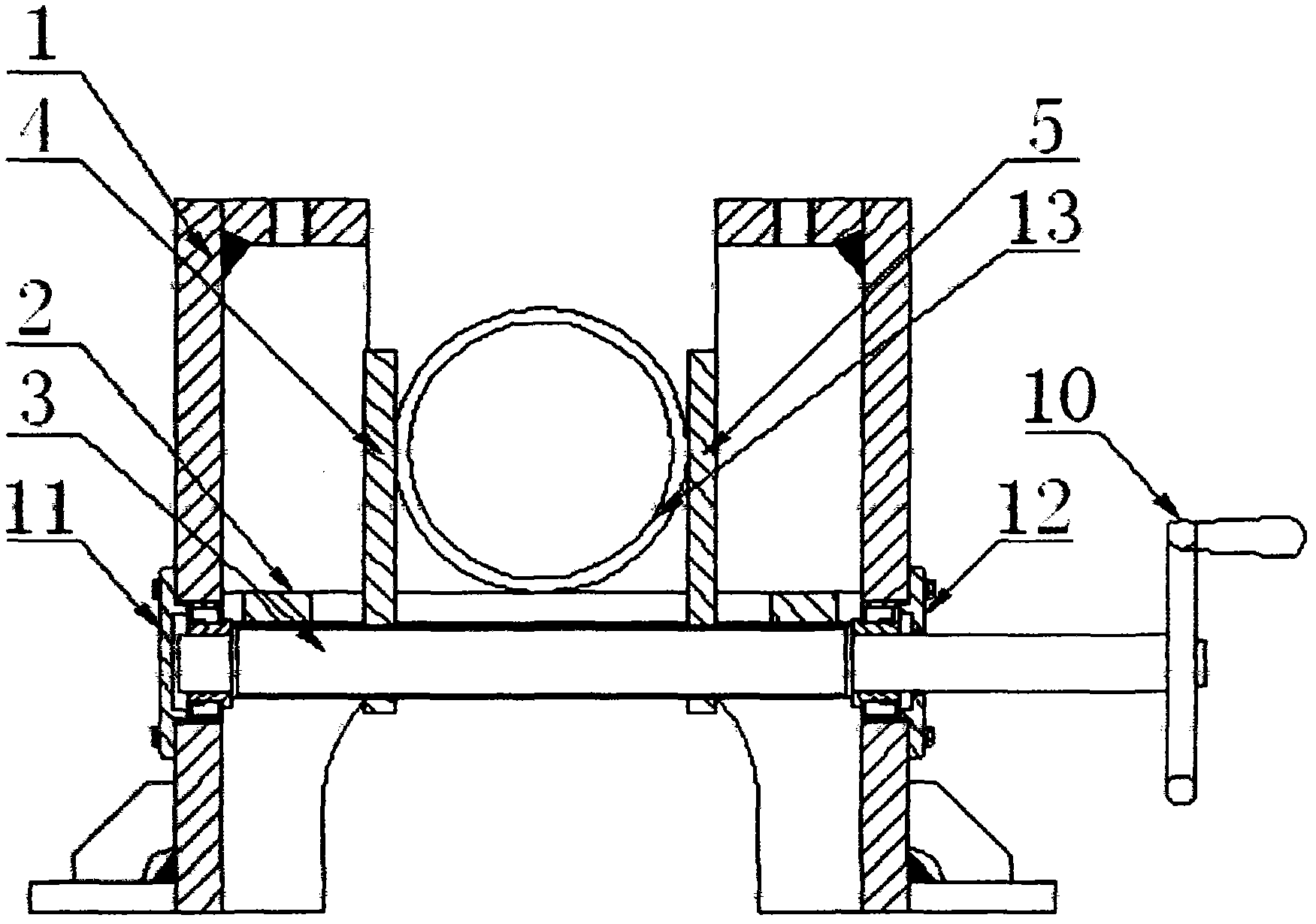

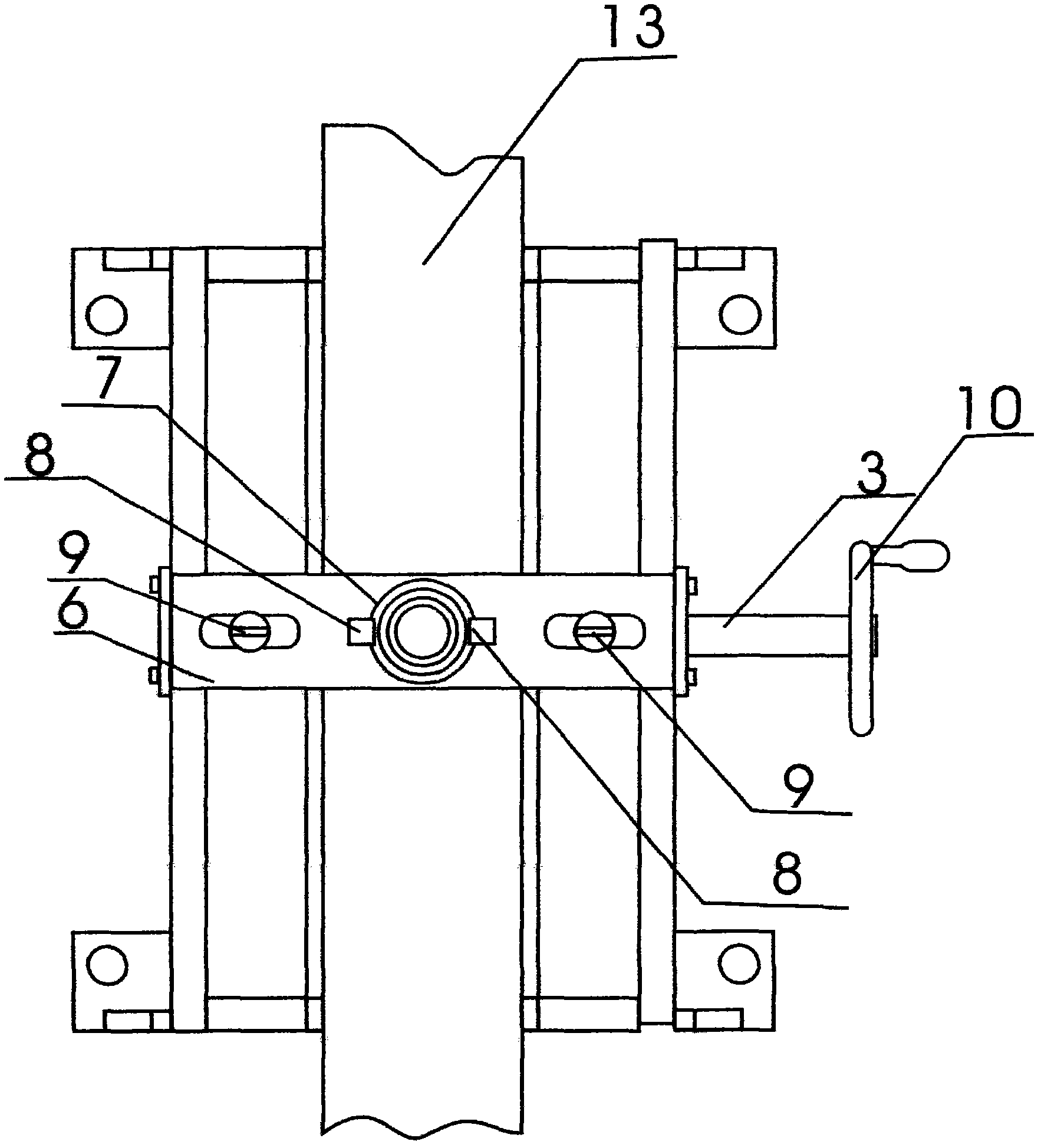

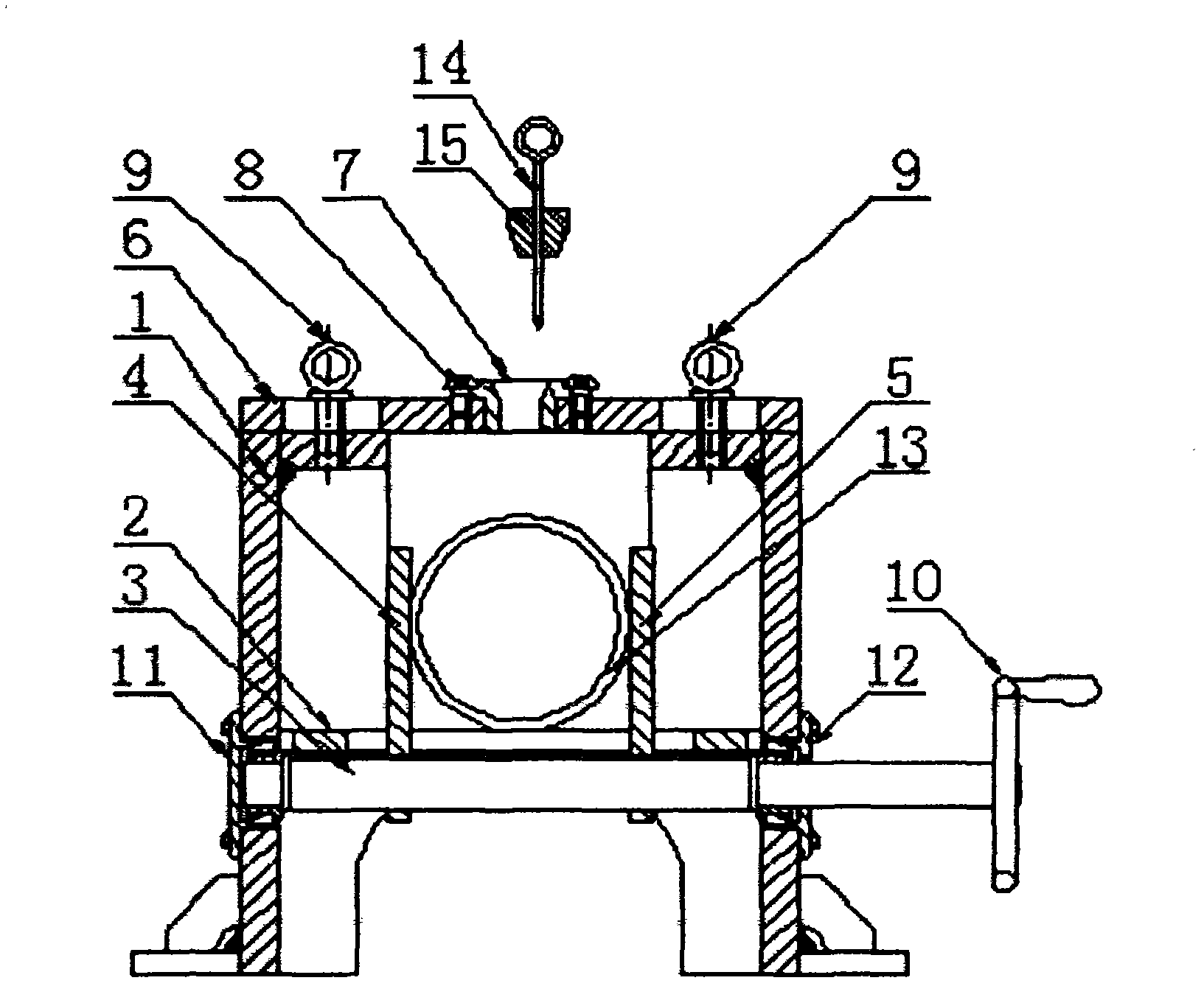

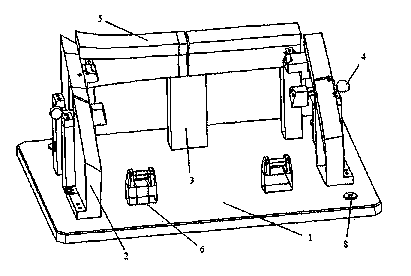

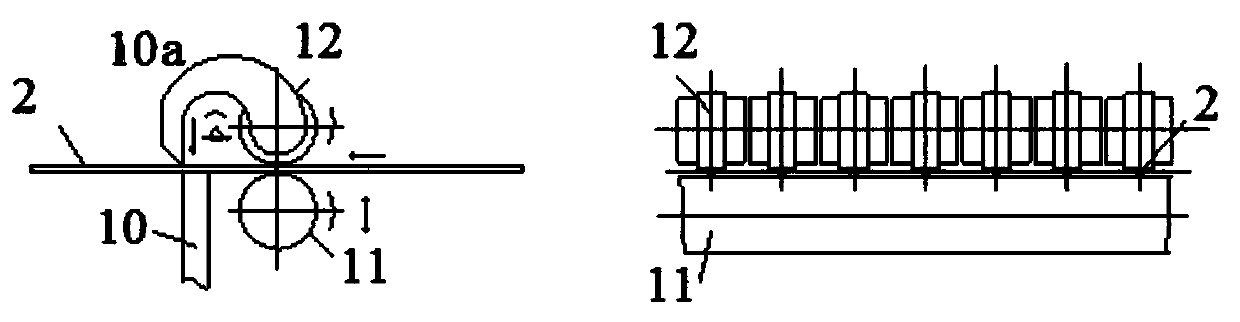

Auxiliary tool for accurate locating drilling

InactiveCN103128574ASimple structureEasy to operatePositioning apparatusDrill jigsEngineeringMachining

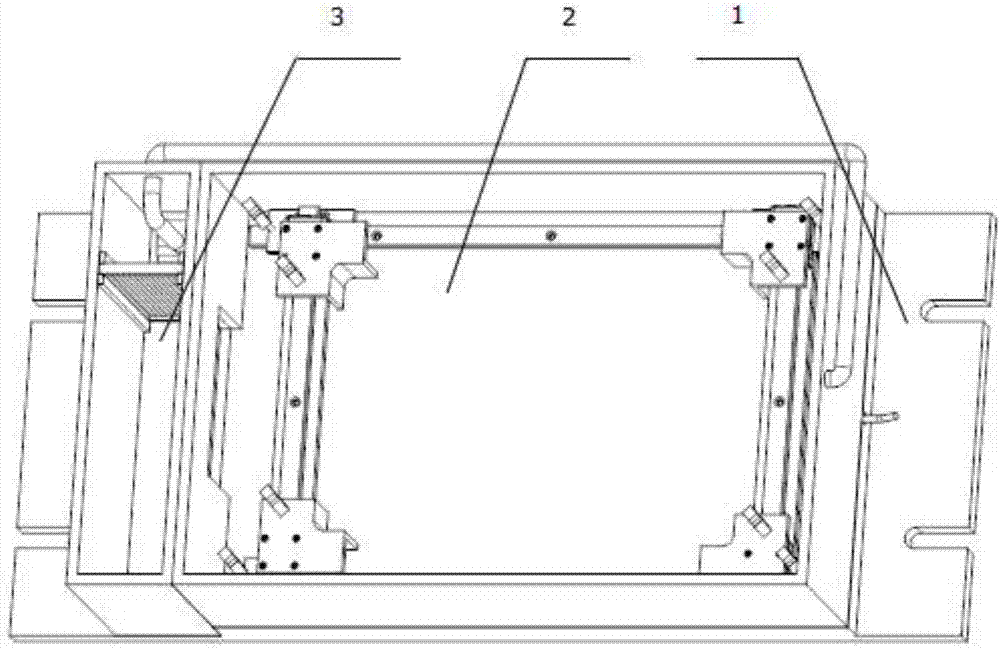

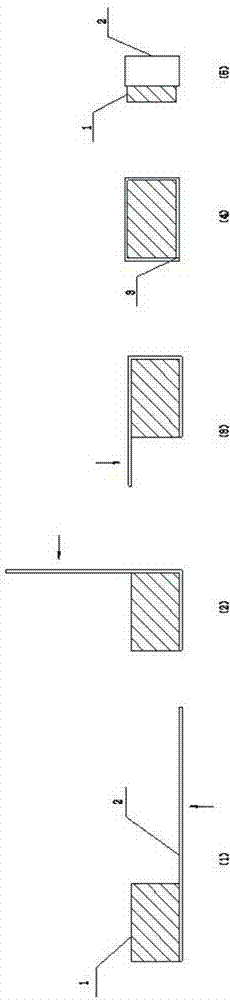

The invention provides an auxiliary tool for accurate locating drilling. The auxiliary tool for the accurate locating drilling is composed of a box body (1), a sliding way (2), a rotary lead screw (3) and the like. The sliding rail (2) is arranged inside the box body (1) and penetrates through the left side wall and the right side wall of the box body (1). A left baffle (4) and a right baffle (5) are respectively arranged inside the sliding rail (2) inside the box body (1) and connected with the rotary lead screw (3) in a threaded mode. A left bearing gland (11) and a right bearing gland (12) fixedly penetrate through the left side wall and the right side wall of the box body (1) and fix the rotary lead screw (3). The end portion of one end, extending out the right side wall in a suspending mode, of the lead screw (3) is not provided with threads and is provided with a hand wheel (10). Due to the fact that the auxiliary tool for the accurate locating drilling is simple in structure, convenient to operate, economic and practical, when used for machining, the auxiliary tool for the accurate locating drilling can not only reduce machining cost, but also improve operational speed and enable machining accuracy to be more accurate.

Owner:天津重钢机械装备股份有限公司

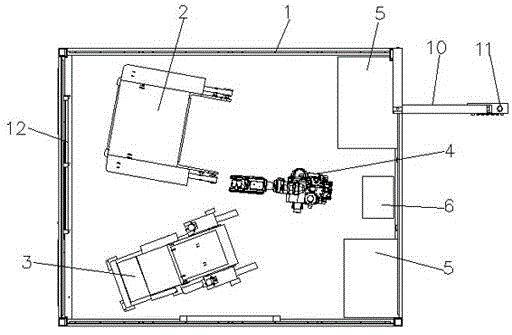

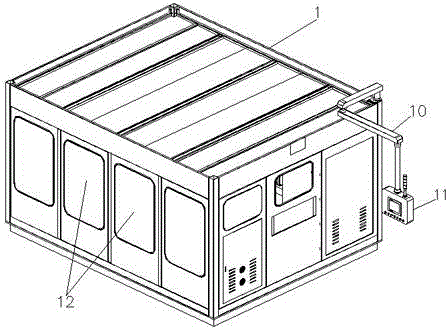

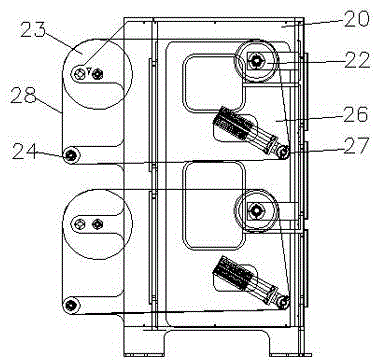

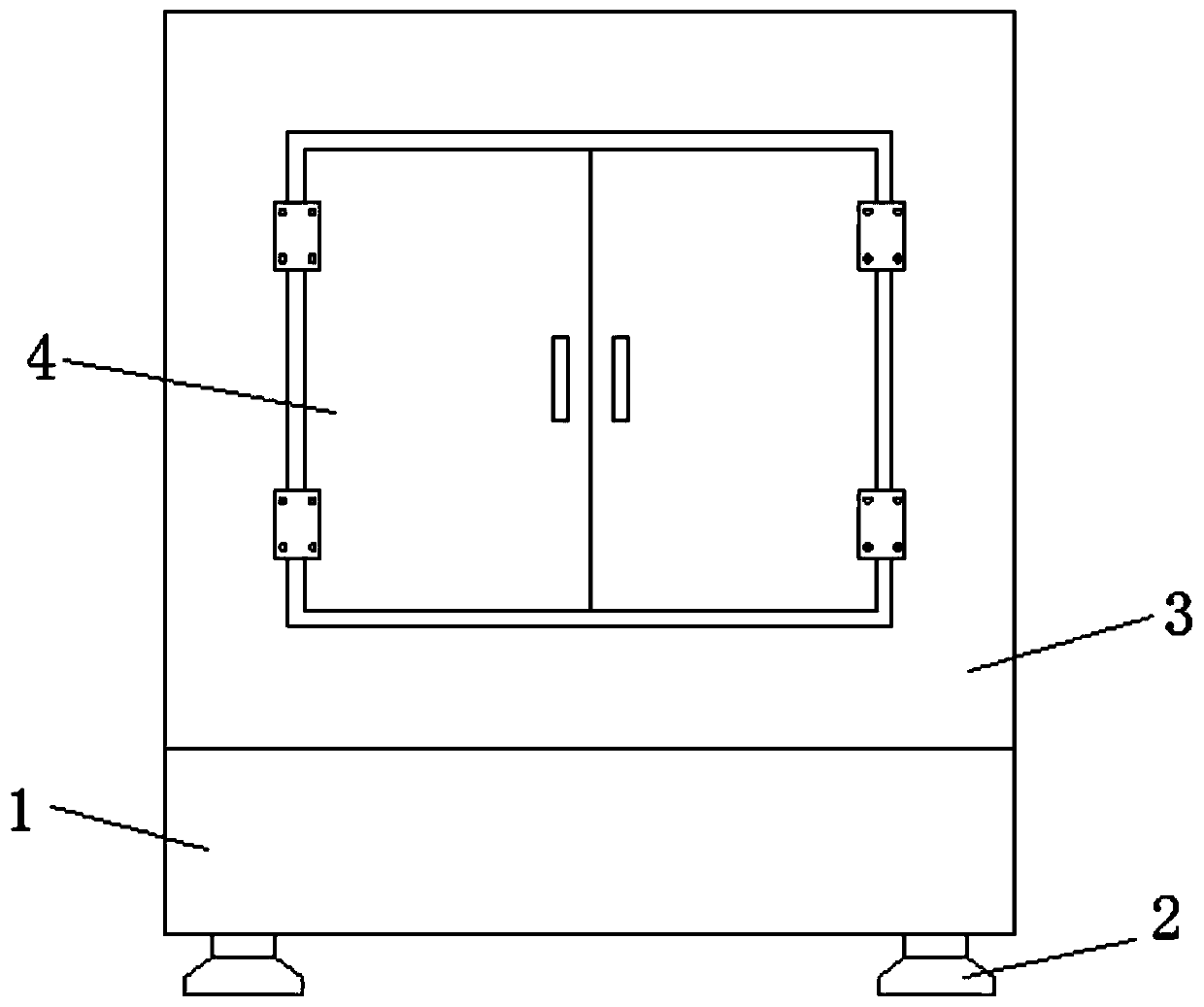

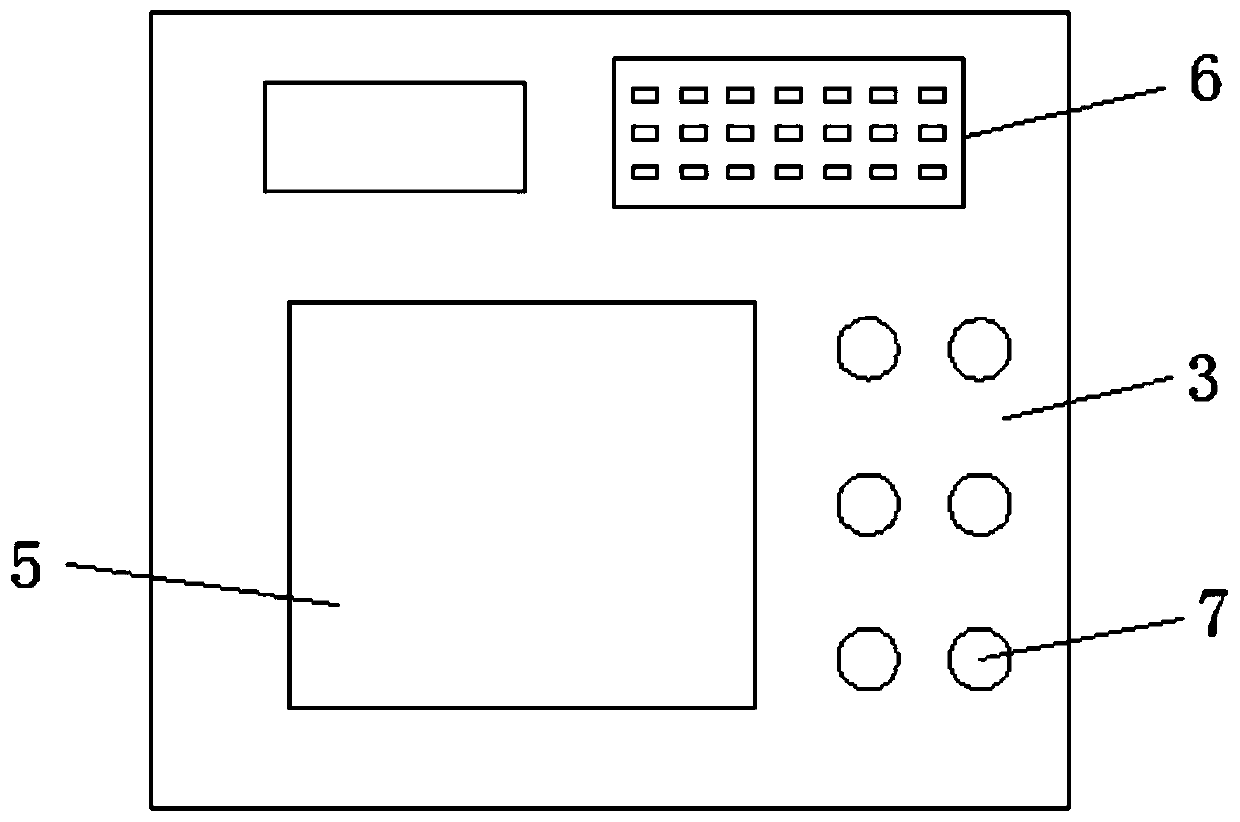

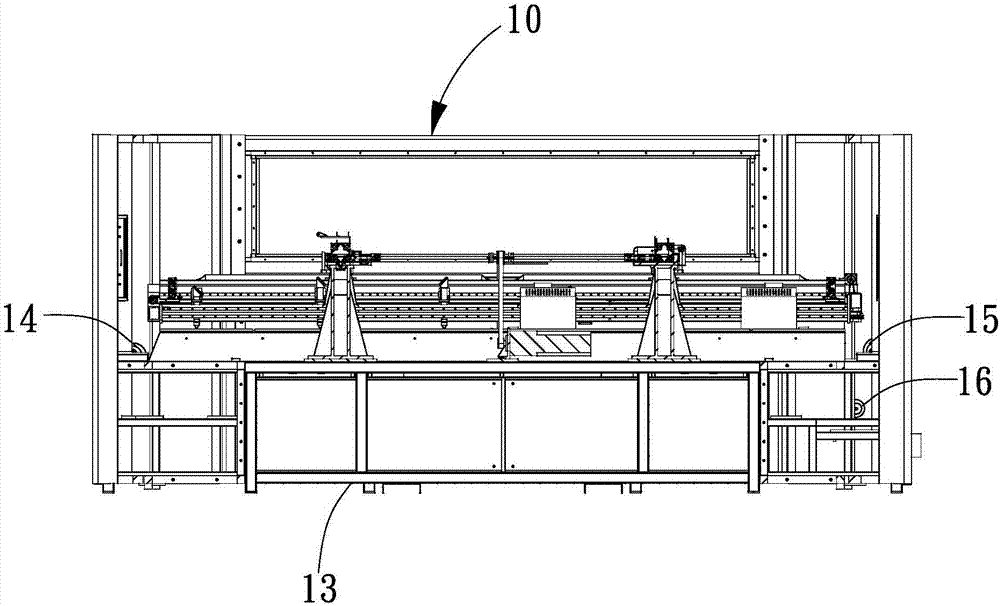

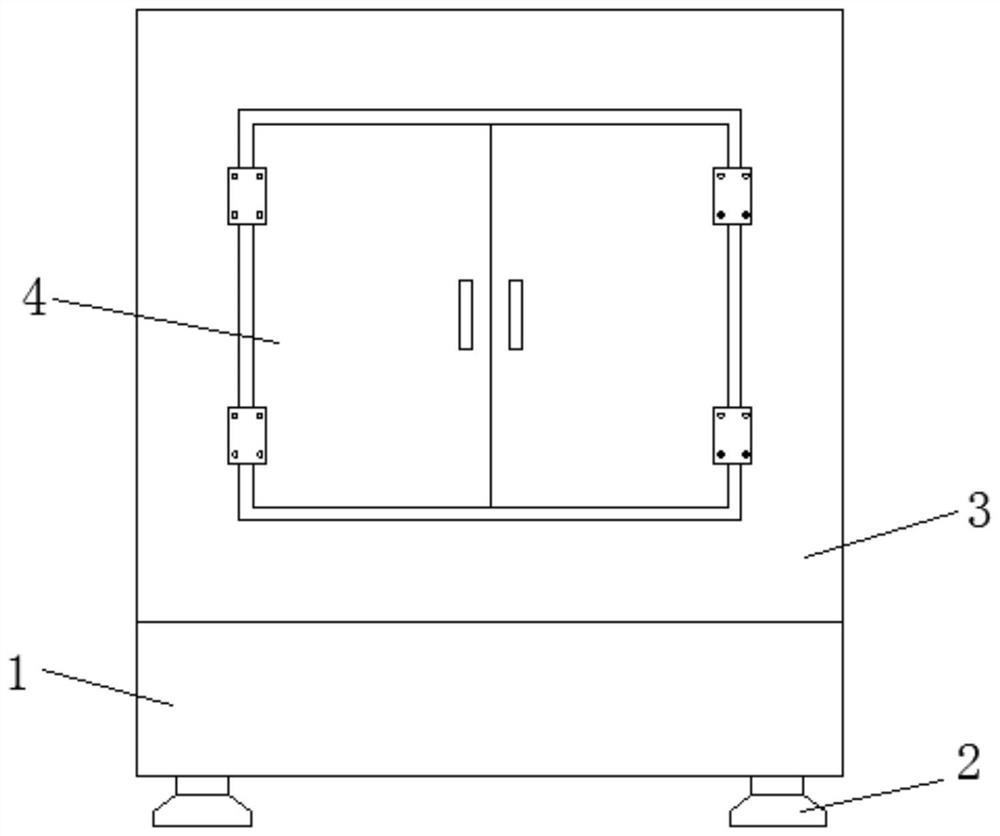

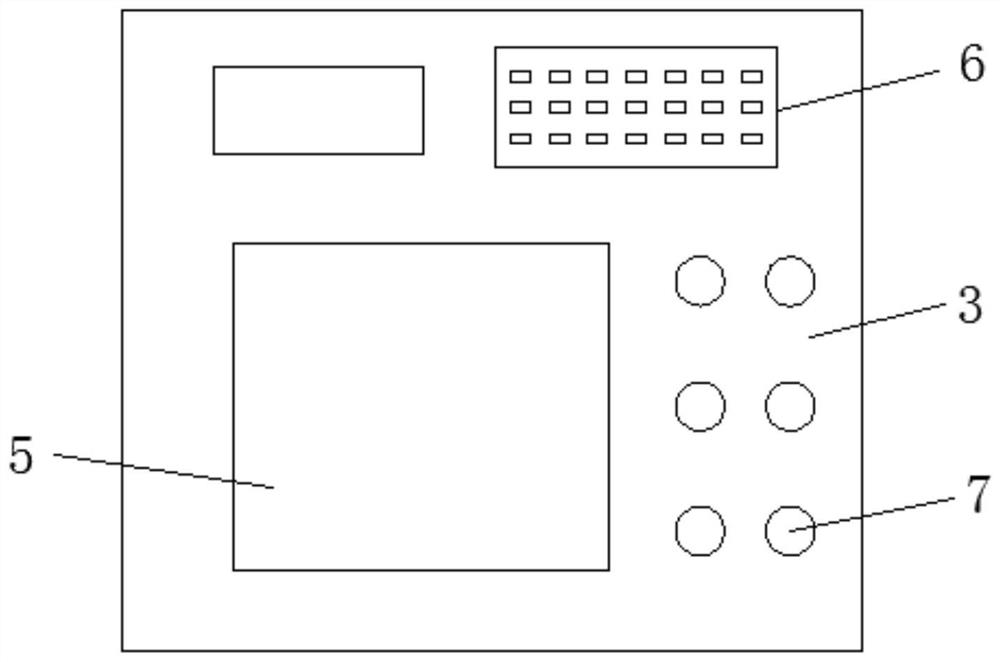

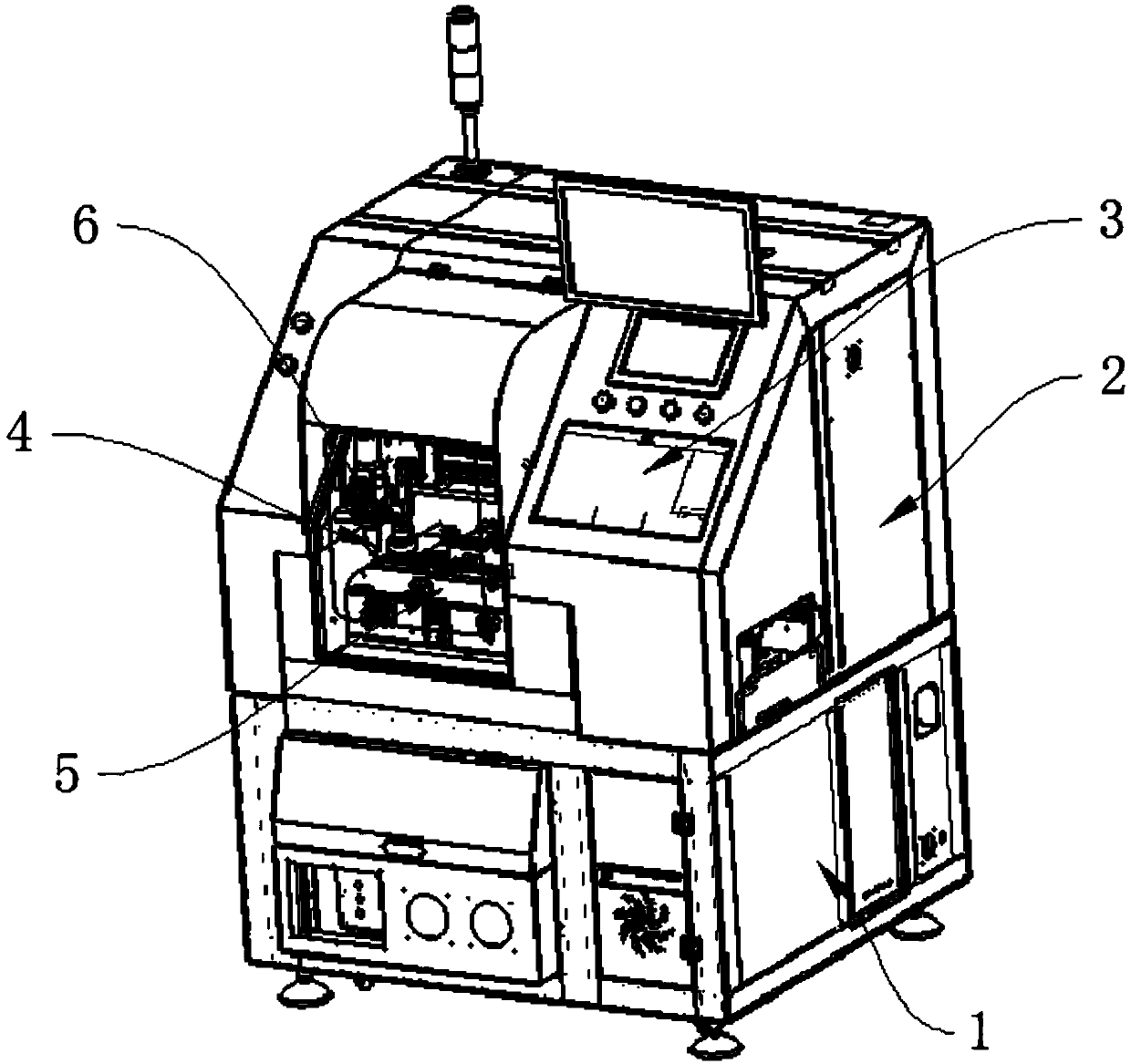

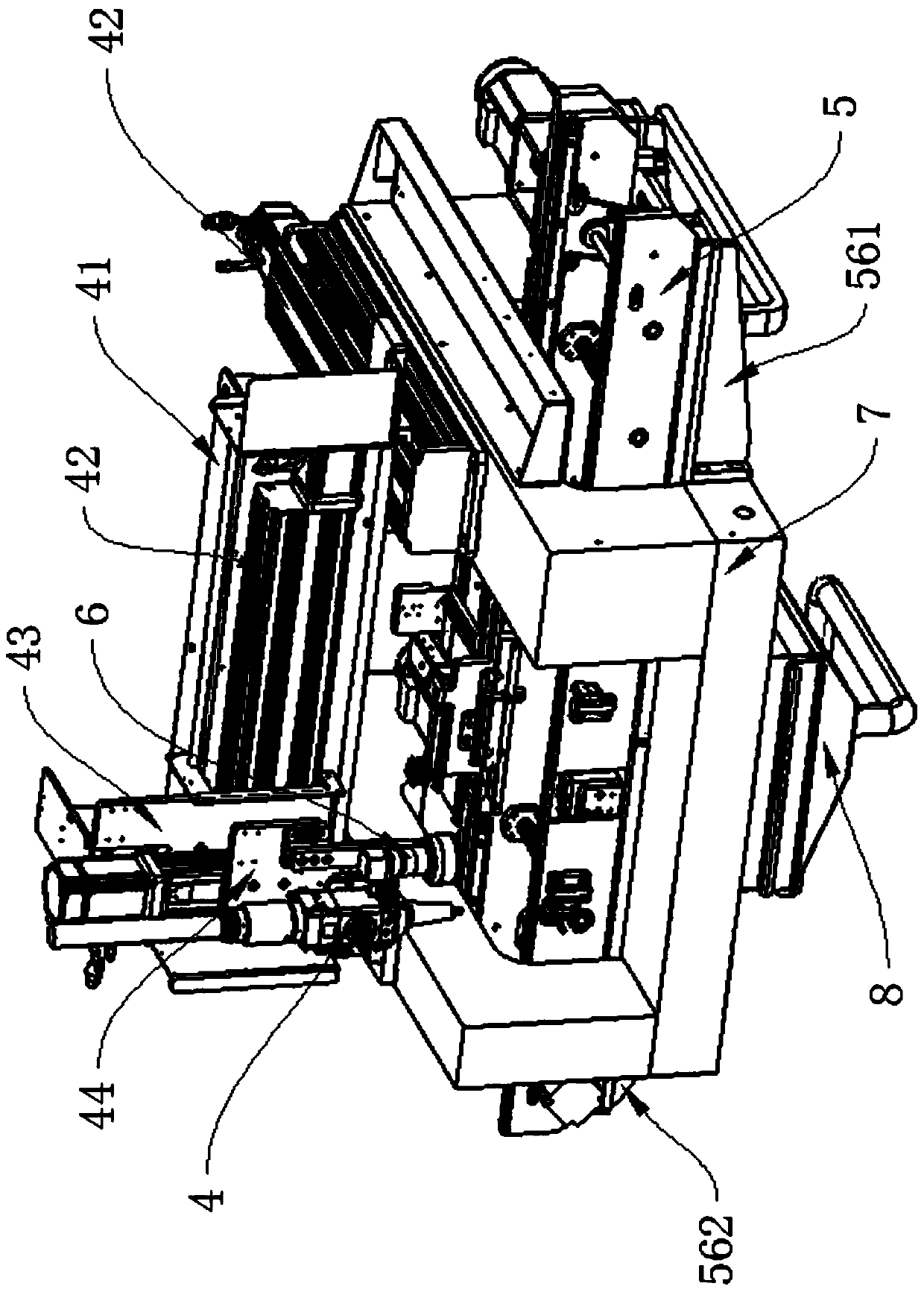

Full-automatic polishing grinding production line

InactiveCN104526507ANo manual operationReduce labor intensityEdge grinding machinesGrinding drivesProduction lineRobot hand

The invention discloses a full-automatic polishing grinding production line which comprises a cover body. A sanding machine, a polishing machine, a manipulator, an electric control box and a feeding table are arranged in the cover body, and an operation panel is fixed outside the cover body through a movable frame. The works of the sanding machine, the polishing machine and the manipulator are controlled through a computer control panel program in the whole machining process, a workpiece is taken and clamped to the sanding machine and the polishing machine to be machined through the manipulator, manual operation is not needed in the whole process, labor intensity is low, machining efficiency is high, machining accuracy is accurate, production cost is low and the like.

Owner:FUJIAN WEILIMU INTELLIGENT EQUIP

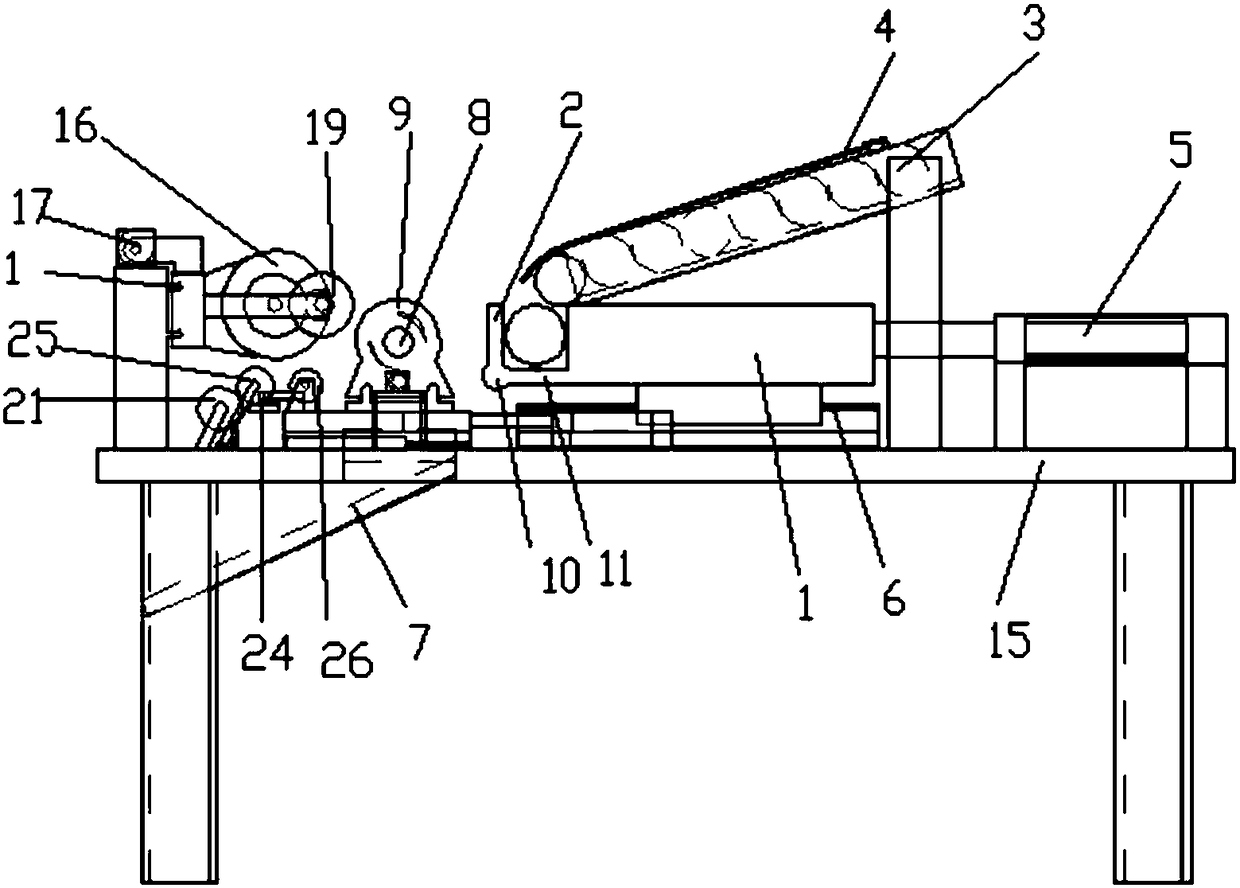

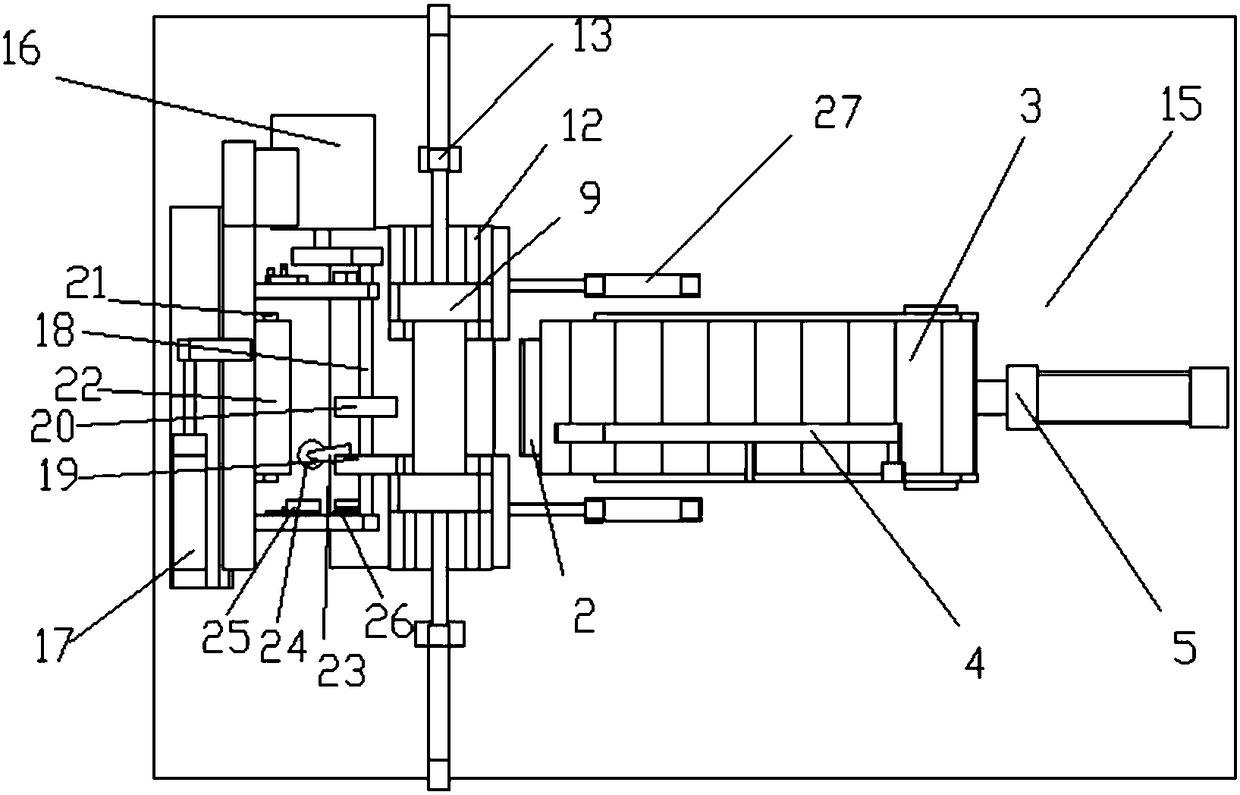

Hammer handle shape machining and polishing device with annular explorator

InactiveCN108311892AImprove processing efficiencyReduce labor costsOther manufacturing equipments/toolsMetal working apparatusExploratorElectric control

The invention relates to the technical field of hammer machining, in particular to a hammer handle shape machining and polishing device with an annular explorator. An electric control box is used forunified control over feeding, clamping, processing and polishing. A blanking device automatically conducts blanking to a conveying device under the effect of the gravity. Automatic conveying, clampingand correction are achieved. A machined hammer handle is conveyed to the position of a machining tool through an explorator cylinder so as to be machined. Meanwhile, the machining distance or the depth is limited through the explorator. A polishing device which coaxially rotates instantly conducts polishing after cutting is completed. Manual operation is not needed in the whole process, so that the machining efficiency is greatly improved, the labor cost is reduced, and the machining precision is high and consistent; and the hammer handle shape machining and polishing device is suitable for large-scale application and popularization.

Owner:SHAODONG HEXIE HARDWARE ELECTROMECHANICAL CO LTD

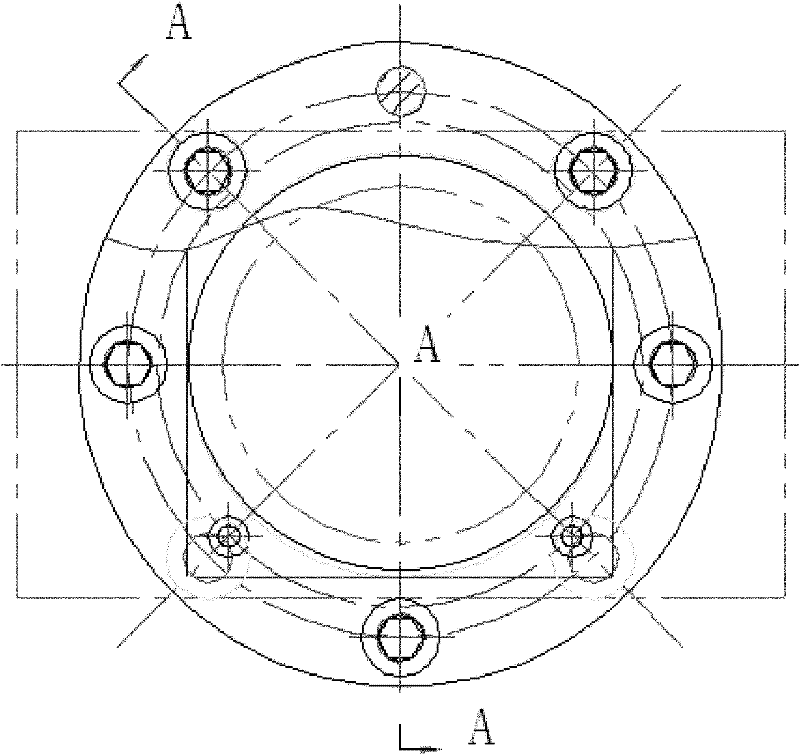

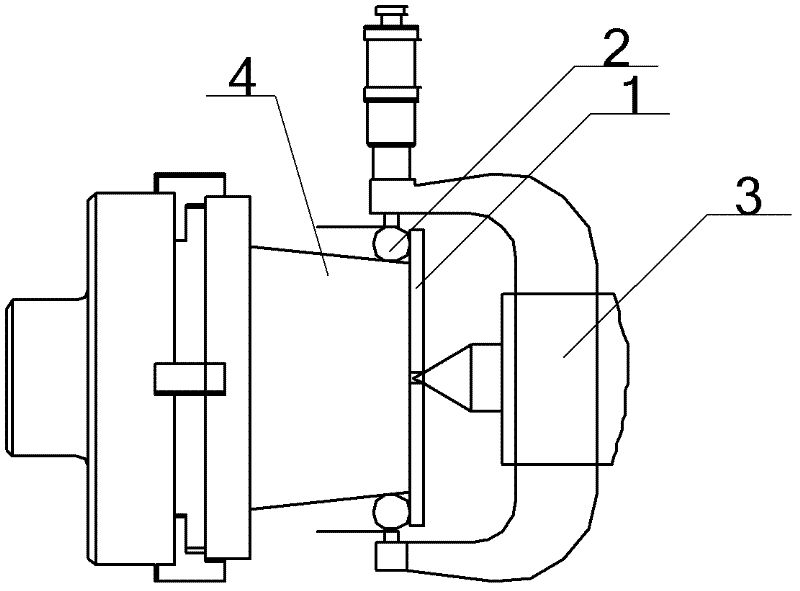

Multi-direction machining clamp for machining center

InactiveCN103978383AGuaranteed verticalityGuaranteed parallelismWork clamping meansPositioning apparatusPulp and paper industryMorse taper

The invention discloses a multi-direction machining clamp for a machining center. The multi-direction machining clamp for the machining center comprises a bottom plate, one end of the bottom plate is connected with a Morse taper shank, and the other end of the bottom plate is connected with a flange plate. The bottom plate is provided with two positioning plates perpendicular to the bottom plate in parallel in a spaced mode, and the bottom plate between the two positioning plates is provided with a hole used for machining parts. The tops of the two positioning plates are respectively provided with a pressing device used for limiting the parts, the position, placed on one sides of the two positioning plates, of the bottom plate is provided with a side plate, and the inner side face of the side plate is provided with a positioning convex edge used for positioning the parts. At lest one of the two positioning plates is provided with a fastening screw, the fastening screw penetrates through the positioning plate, and the end of the fastening screw is connected with a fastening plate. The multi-direction machining clamp for the machining center can achieve the purpose that box body type parts can achieve multi-face machining after one-time clamping, the working strength of workers is reduced, and working efficiency is improved.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

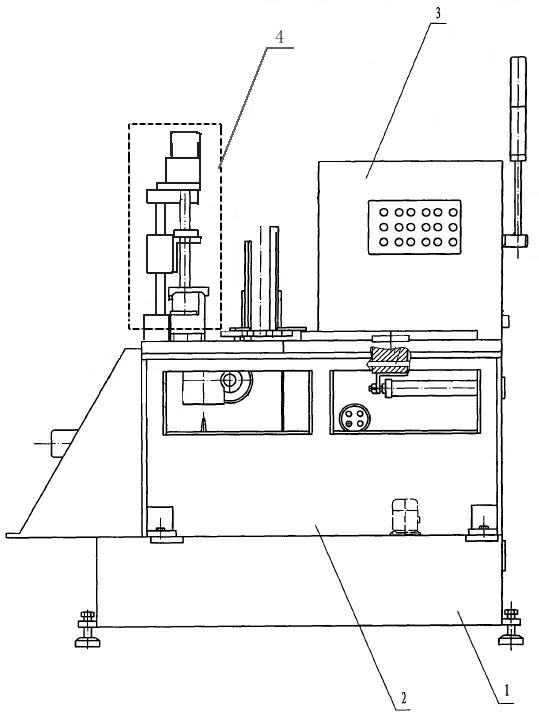

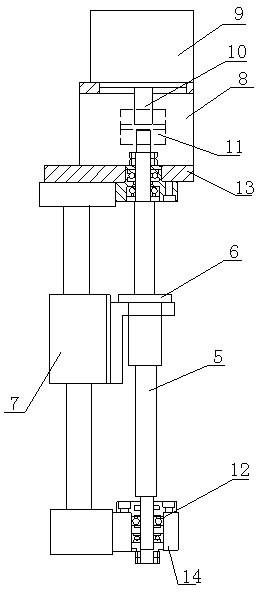

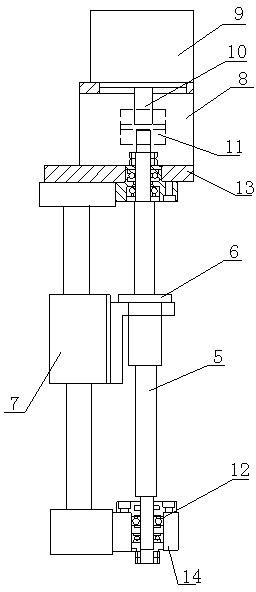

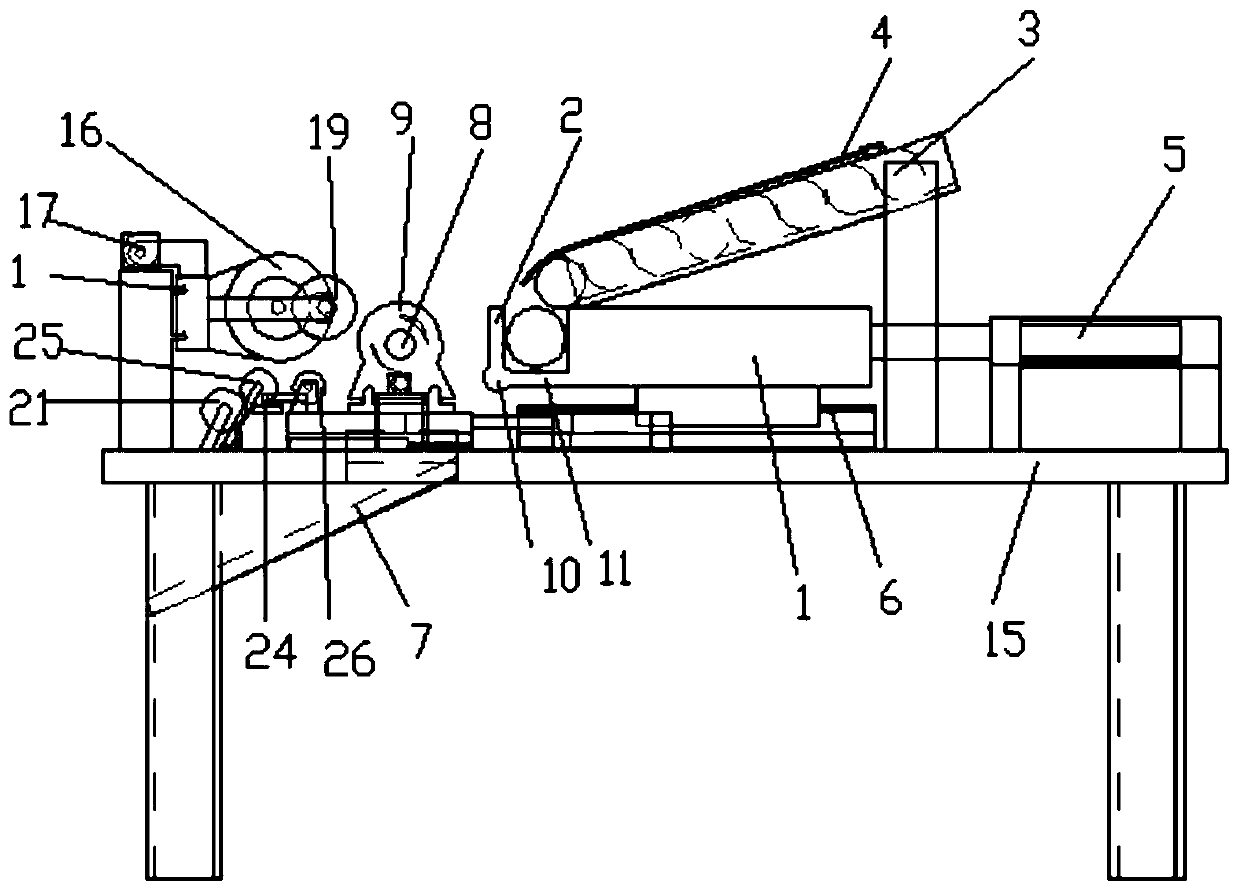

Piston ring automatic repairing machine tool

The invention relates to an automatic piston ring repairing machine tool, comprising a base, a frame fixed on the base, an electric control box fixed on the frame, and a pushing mechanism, characterized in that: the pushing mechanism includes a ball screw and a lead screw sleeve , lead screw bracket, transmission and motor, the motor is connected with the motor connection shaft in the transmission, the motor connection shaft is connected with the upper end of the ball screw through the connection block in the transmission, and the upper end of the ball screw passes through the bearing Fixed on the base of the transmission, the ball screw is sleeved with a screw sleeve, the lower end of the ball screw is fixed on the fixing seat through a bearing, the fixing seat is connected with the bottom of the screw bracket, and the screw bracket The middle part is connected with the lead screw sleeve, and the upper part of the lead screw support is connected with the transmission base. The invention has the advantages that: the original pushing mechanism is driven by hydraulic pressure, but now it is driven by a ball screw, so that the processing accuracy is more accurate, and the pushing progress can be better controlled.

Owner:JIANGSU HUANYANG COMBINATION MACHINE

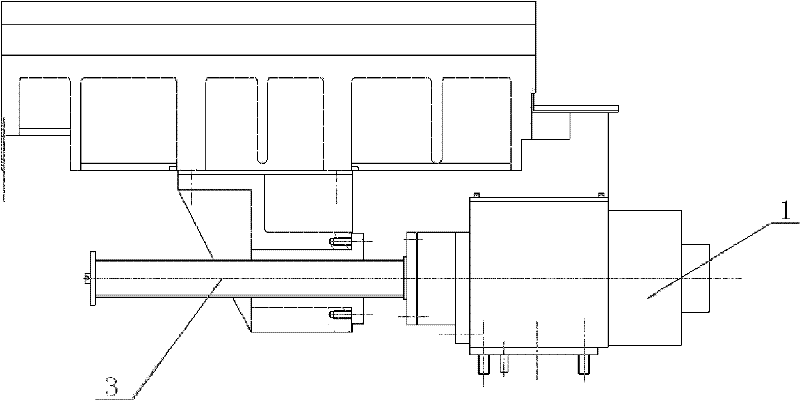

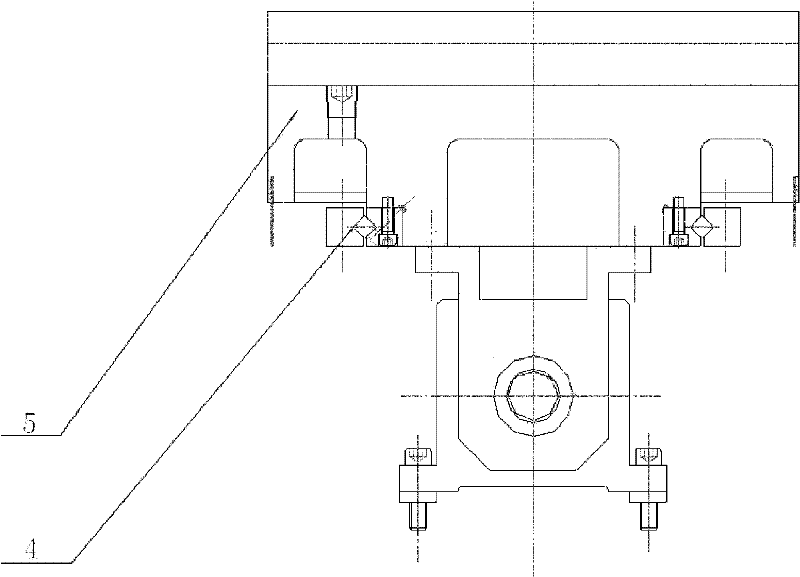

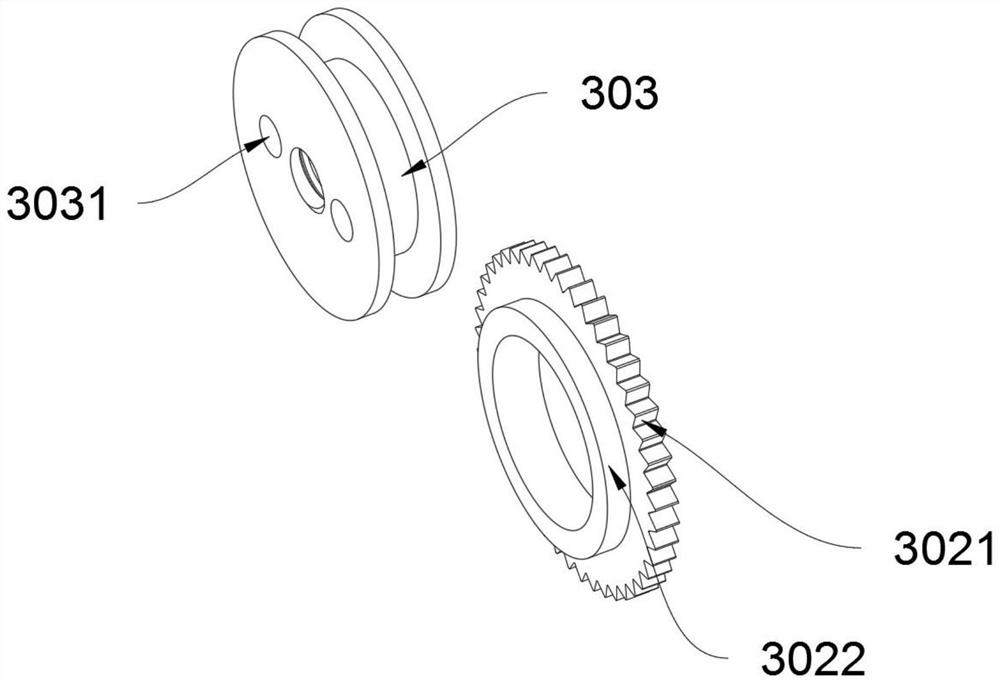

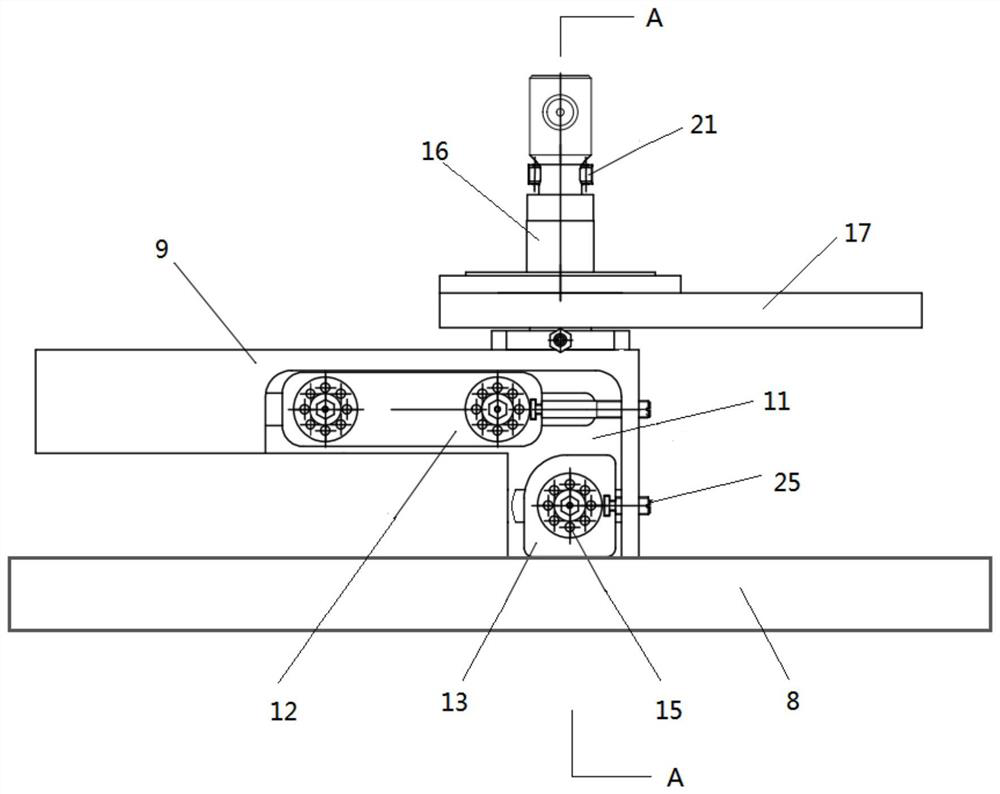

Traverse feeding device of external groove plungecut grinder

InactiveCN102172890AReduce frictional resistanceImprove stabilityGrinding drivesReduction driveReducer

The invention provides a traverse feeding device of an external groove plungecut grinder. The traverse feeding device comprises a roller cross guide rail pair, a traverse feed table and a drive unit, wherein the roller cross guide rail pair comprises guide rails, a roller retainer and a cylindrical roller, and the cylindrical roller is arranged on the guide rails through the roller retainer; the drive unit comprises a stepping motor, a harmonic speed reducer and a ballscrew, wherein the stepping motor drives the harmonic speed reducer to connect the ballscrew, an output shaft of the harmonic speed reducer is fixedly connected with a shaft end of a screw of the ballscrew, a nut of the ballscrew is connected with the transverse feed table, and the nut of the ballscrew can move forth and back on the screw of the ballscrew. By means of the transverse feeding device, the deceleration with large rotation ratio can be carried out through the harmonic speed reducer so that the transverse feeding is more stable, and the transverse feeding precision is improved by controlling the stepping motor through electric programs, thus accurate feeding and reversing are realized, and the machining precision of a bearing ring is accurate; and simultaneously, the stroke of the transverse feeding is also enlarged, the purchase cost of new equipment is reduced, and the purpose of a machine tool is widened.

Owner:HARBIN BEARING GROUP CORP

Vehicle interior decoration glove box checking fixture

InactiveCN103776330ALearned to placeKnow whether the glove box is placed accurately on the inspection fixtureMechanical measuring arrangementsEngineeringGlovebox

The invention discloses a vehicle interior decoration glove box checking fixture which comprises a bottom plate which is provided with a rotating shaft. Two sides of the rotating shaft are provided with first supporting columns. A second support column at the center of the bottom plate is equipped with a simulation piece. One side of the simulation piece is provided with an overturn block. By using the checking fixture of the technical scheme, the processing precision of a glove box can be detected and the glove box is convenient to use, the monitoring of the specification and size of the glove box is realized, and the glove box with high quality is provided. As the preferable technical scheme of the invention, the bottom plate is provided with a plurality of reference holes used for adjusting the position of the glove box, the placement position of the glove box can be rapidly and conveniently adjusted, and accurate detection data is obtained.

Owner:江苏新昌汽车部件有限公司

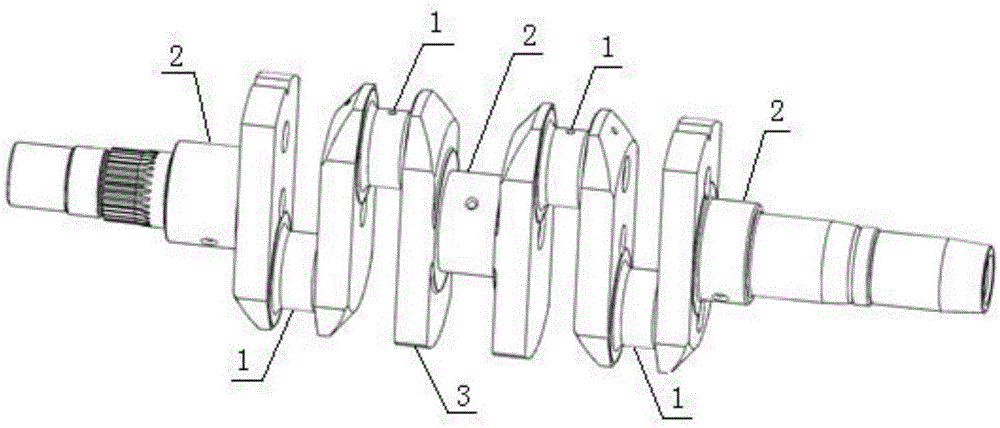

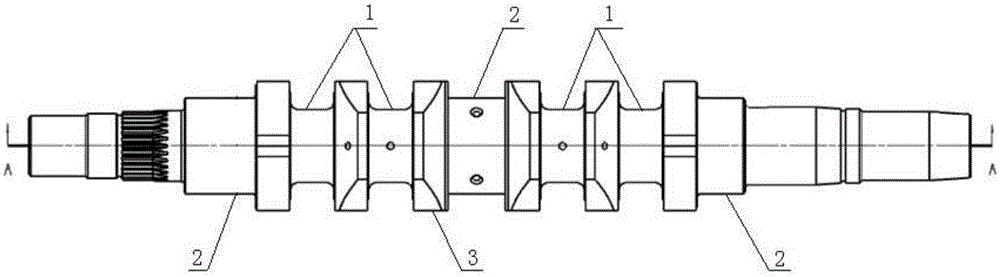

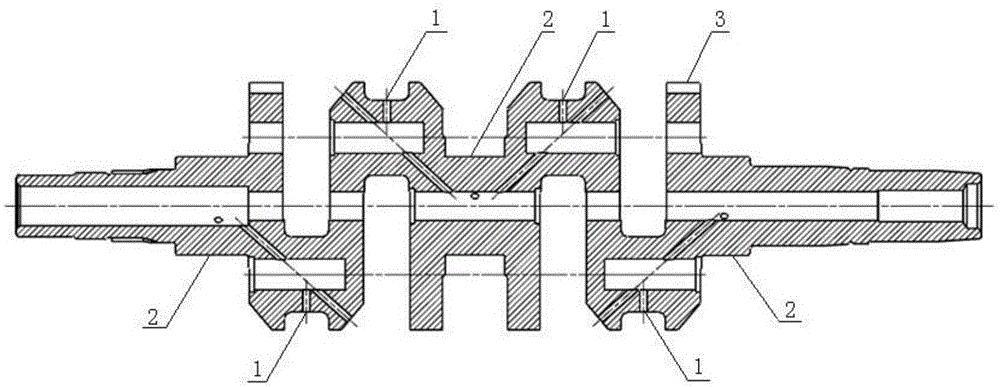

Novel crankshaft used for engine

The invention discloses a novel crankshaft used for an engine. The novel crankshaft comprises a front main shaft bearing and a rear main shaft bearing which are arranged at the two ends of a shaft rod of the crankshaft. At least two crank throw units connected through the main shaft bearings are arranged between the front main shaft bearing and the rear main shaft bearing. Each crank throw unit comprises three cranks which are arranged in parallel. Crank throws are arranged between the cranks. The centers of every two adjacent crank throws are arranged at the upper end and the lower end of the corresponding crank respectively. The novel crankshaft solves the problem that in the prior art, the total length of the crankshaft is too large, so that an engine mechanism can be more compact; and the problem that the bending rigidity and the torsional rigidity are low due to the fact that the crankshaft is too long is solved.

Owner:TIANJIN INTERNAL COMBUSTION ENGINE RES INST

Double-head coaxial boring and milling machining device for machining

PendingCN112589151AAccurate drilling positioningFlexible and convenient operationBoring/drilling componentsBoring/drilling machinesMachine toolMachining

The invention discloses a double-head coaxial boring and milling machining device for machining, relates to the technical field of machining, and solves the problems that an existing machine tool canonly drill one end of a shaft part at a time, the other end of the shaft part can be drilled only by clamping the part again, the steps are tedious, hole sites at the two ends of the part are prone todeviation, and the production precision of parts is influenced. The double-head coaxial boring and milling machining device for machining comprises coaxial machining mechanisms, and the number of thecoaxial machining mechanisms is two. When the device is used for drilling the two ends of the shaft part, drill bits of two drill bit clamps can be coaxially driven to rotate through a transmission shaft, the two coaxial machining mechanisms can independently move, so that operation of drilling the two ends of the shaft part can be completed at the same time, one-time forming is achieved, the part does not need to be clamped again, drilling positioning is accurate, the operation is convenient and flexible, machining efficiency is high, and practicability and flexibility of the device are improved.

Owner:胡天娇

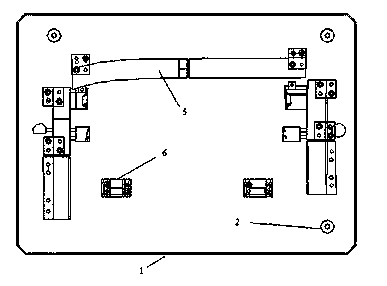

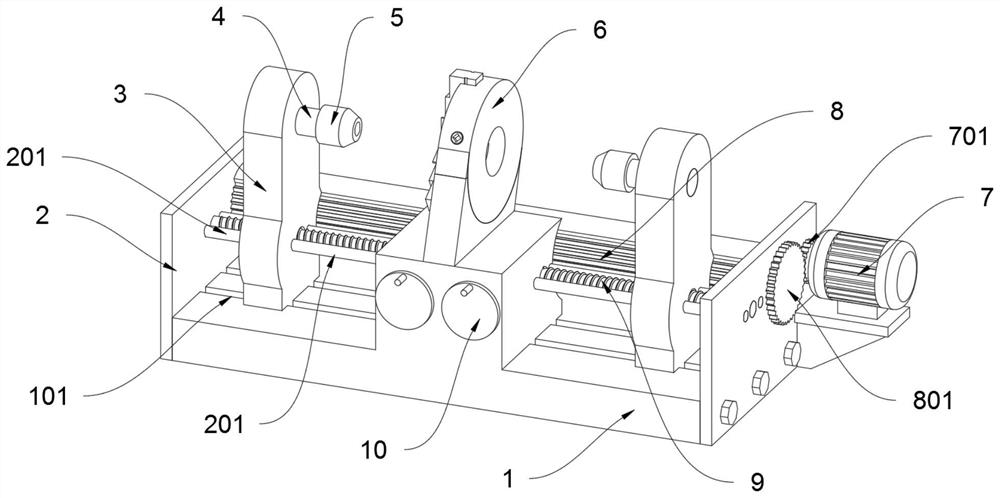

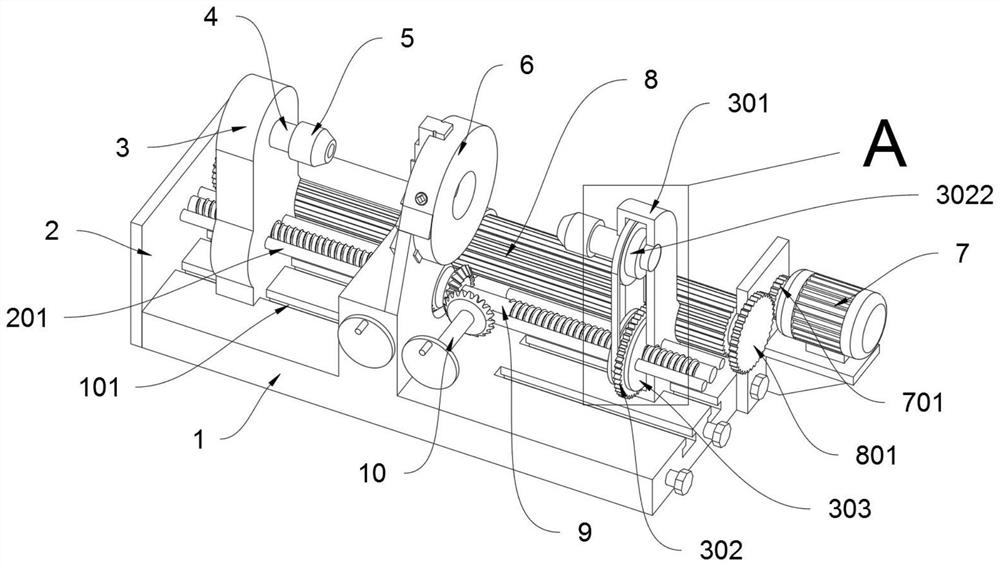

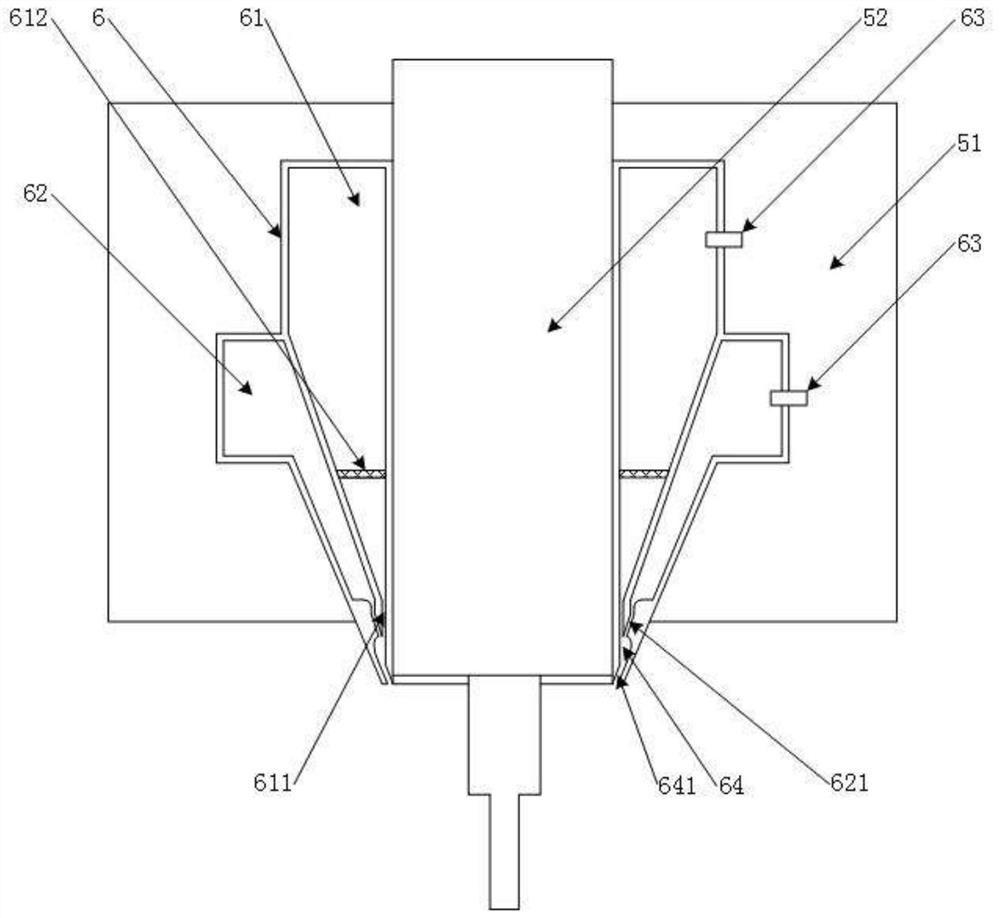

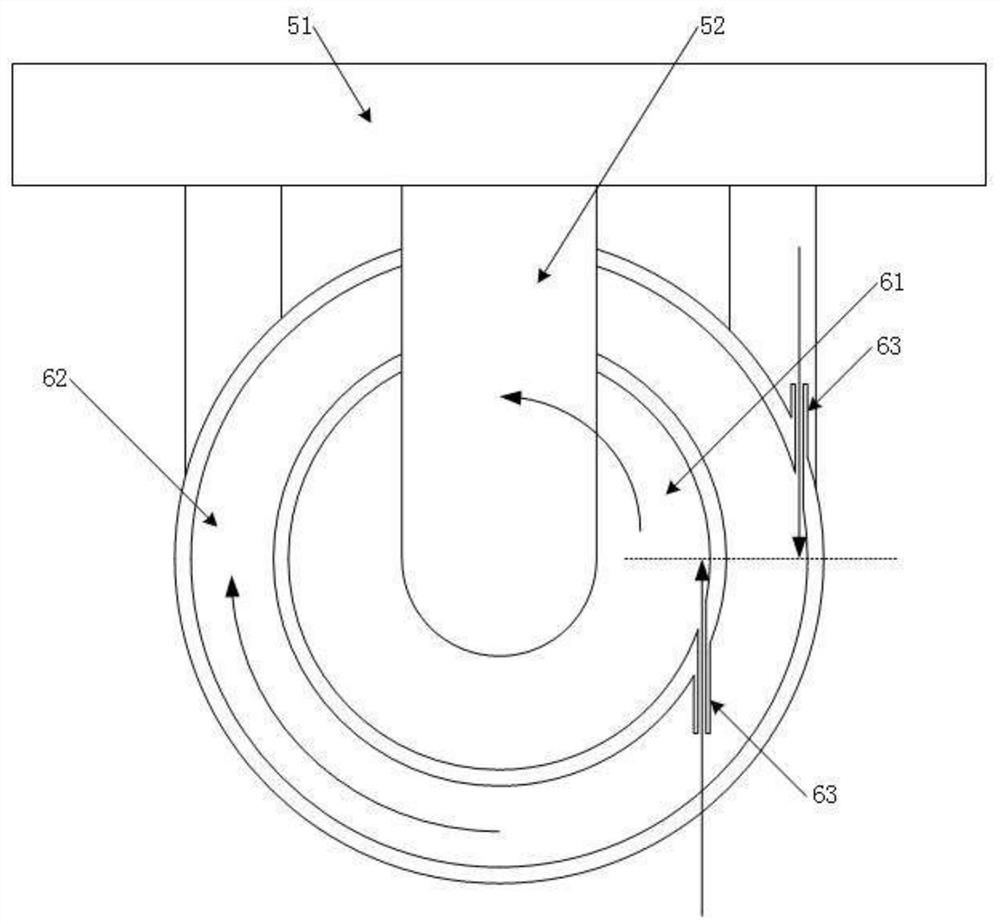

Wire cutting equipment suitable for machining connecting rod expansion stress groove

ActiveCN110170715AEasy and quick processing of stress groovesAccurate machining accuracyElectrical-based machining electrodesWire cuttingEngineering

The invention discloses wire cutting equipment suitable for machining a connecting rod expansion stress groove. The wire cutting equipment comprises a control cabinet, a shell is arranged at the top of the control cabinet, a bottom plate is arranged at the inner bottom of the shell, a vertical plate is arranged at the top of the bottom plate, a mounting groove is formed in the bottom of the vertical plate in a penetrating mode, a first guide wheel seat is arranged at the inner top of the mounting groove, a second guide wheel seat is arranged at the inner bottom of the mounting groove, a secondguide wheel assembly is arranged inside the second guide wheel seat, a wire vertical rod is arranged on one side of the top of the vertical plate, and a connecting rod fixing mechanism matched with the vertical plate is arranged on the top of the vertical plate and located on the outer side of the bottom of the wire vertical rod in a sleeved mode. The equipment has the beneficial effects that through using of the equipment, the groove cutting depth can be freely adjusted according to the expansion effect through the equipment, the quality of the expansion section can be used for adjusting parameters, so that the corresponding effect is achieved, the stress groove is convenient and fast to machine, the machining precision is accurate and safe, and the cost is saved.

Owner:NANGONG JINGQIANG CONNECTING ROD CO LTD

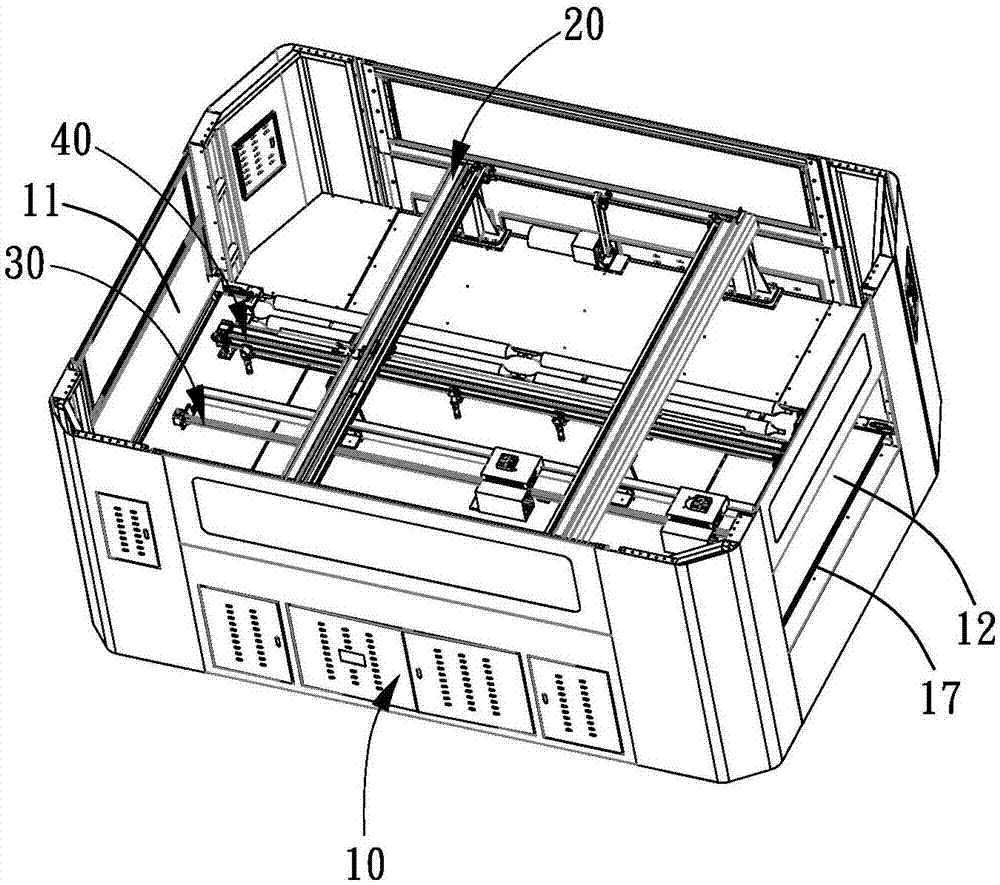

Multifunctional full-automatic leather printing and cutting machine and application method thereof

InactiveCN106944748AAutomatic printingFix workLeather clicking/perforating/clickingLeather surface mechanical treatmentControl systemEngineering

The invention relates to a multi-functional automatic leather printing and cutting machine, which includes a chassis, a Y-axis motion control mechanism installed in the chassis, an automatic printing mechanism vertically arranged with the Y-axis movement control mechanism, and an automatic Automatic laser cutting mechanism with printing mechanism set in parallel. The multifunctional automatic leather printing and cutting machine of the present invention can realize automatic printing, automatic Cutting solves the problem that different jobs need to be completed by different machines or manually, multiple process steps are completed at the same time, and the work efficiency is high; the invention also protects a method of using a multifunctional automatic leather printing and cutting machine.

Owner:DONGGUAN DEL LASER TECH

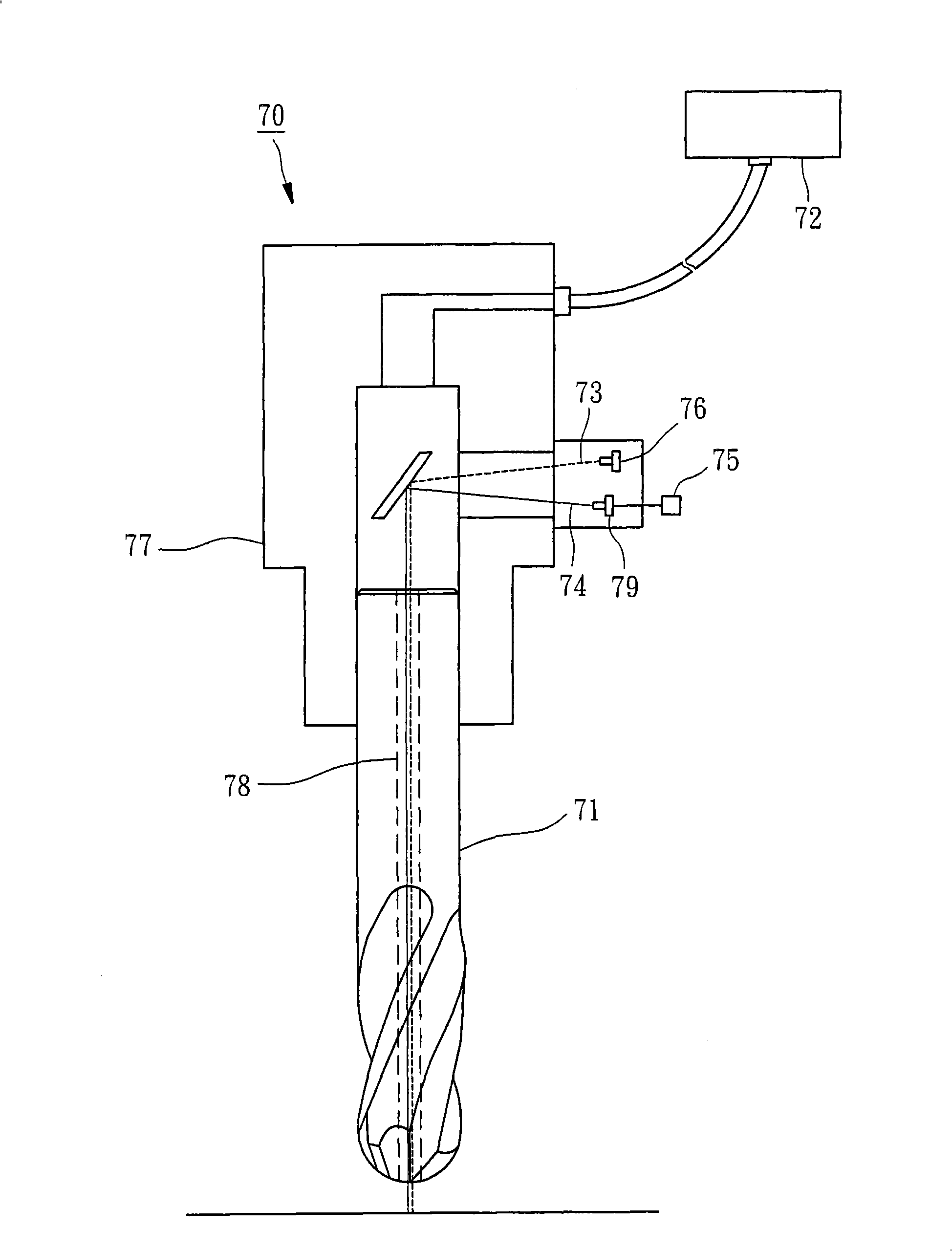

Device of precisely machining special shaped pin hole and machining method

InactiveCN106736252AImprove machining accuracyAccurate machining accuracyOther manufacturing equipments/toolsAutomatic controlControl system

The invention discloses a device of precisely machining a special shaped pin hole and a machining method and relates to the technical field of machining. A fixed bracket is mounted on the right side of a main shaft of a boring mill, a coil bracket is fixed on the fixed bracket, a magnet exciting coil winds the outer side of the coil bracket, an ultra-magnetostrictive rod is fixedly mounted in the coil bracket, a boring bar is fixed at the right end of the coil bracket, a boring cutter is fixed on the right end portion close to the boring bar, an automatic control system is arranged on the side face of the boring bar. The machining method comprises the following steps: S1, casting a workblank; S2, performing quench aging treatment; S3, clamping the workblank; S4, roughly boring; S5, electrifying the magnet exciting coil; S6, adjusting the boring bar to a position of a piston hole; S7, starting the boring mill to feed a piston along the axial direction of the boring hole; S8, finishing hole boring, and retreating the boring bar; and S9, detecting the dimension of the piston hole. According to the device of precisely machining the special shaped pin hole and the machining method disclosed by the invention, the angle of deflection of the boring bar is conveniently adjusted, the precision of the special shaped hole is high, and the degree of automation is high.

Owner:CHIZHOU UNIV

Multifunctional static-pressure type power head

ActiveCN106736793AReduce volumeSmall footprintLarge fixed membersDriving apparatusElectric machineryHigh pressure

The invention discloses a multifunctional static-pressure type power head which comprises a cutter head, a spindle box, a shaft sleeve, a main shaft and a box body, wherein the box body is equipped with a first servo motor and a second servo motor; the main shaft can drive the cutter head to rotate; under action of the first servo motor, the main shaft can drive the cutter head to integrally move front and back relative to the main shaft, so that axial feeding is performed; under action of the second servo motor, the cutter head performs radial feeding; the actions are matched, so that a tool can perform multifunctional processing such as turning, milling and boring; various feeding drive structures are distributed reasonably, the cutter head is small in size, space usage is small and processing precision is accurate; high-pressure oil is filled between the shaft sleeve on which the main shaft is located and the spindle box; locking force of the shaft sleeve can be changed by changing oil pressure, so that control is convenient; and stability after the shaft sleeve is locked is strong, so that the integral power head has good working reliability.

Owner:安徽速诚智能科技有限公司

Forming method of iron core for movable iron unit

The invention discloses a forming method of an iron core for a movable iron unit. The forming method of the iron core for the movable iron unit comprises the following steps: a strip material and at least one mould core are prepared, the length of the strip material is equal to the outer circle perimeter of at least one iron core needing to be machined, the width of the strip material is at least equal to the axial length of the iron core, the outer circle perimeter, the height and the axial length of the mould core are respectively equal to the inner circle perimeter, the height and the axial length of the needed iron core, the strip material is arranged between two moulds of punching equipment, the mould core is arranged on the strip material, a punch of the punching equipment punches the strip material in one or multiple directions along the outer circle of the mould core, the mould core is taken out of the punched iron core through manual work or a machine, and the mould core is fixedly connected at a breaking position of the punched iron core. By means of the forming method of the iron core for the movable iron unit, the machining cost and the machining difficulty can be lowered, and the machining accuracy is further guaranteed.

Owner:SUZHOU YICHUAN TECH CO LTD

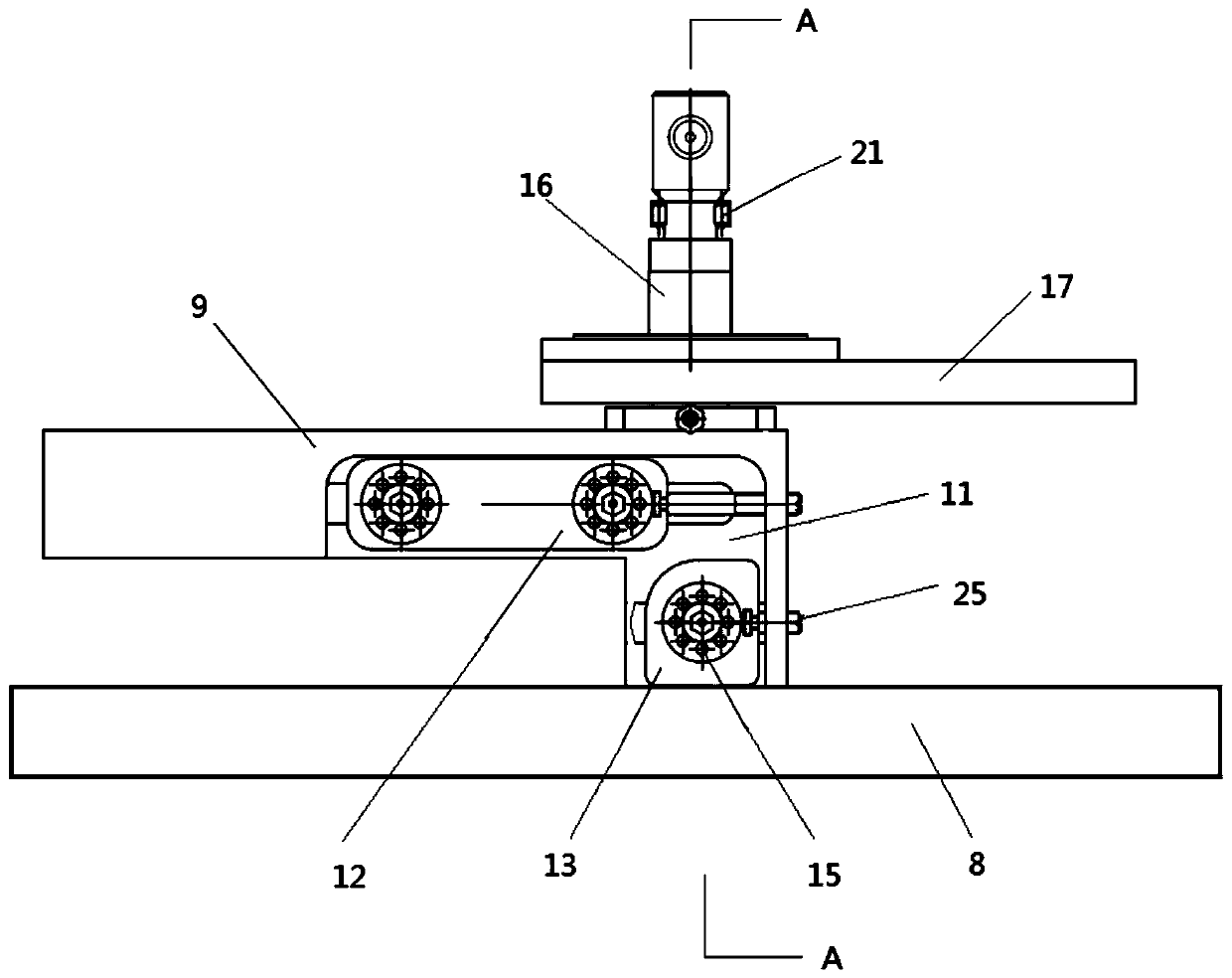

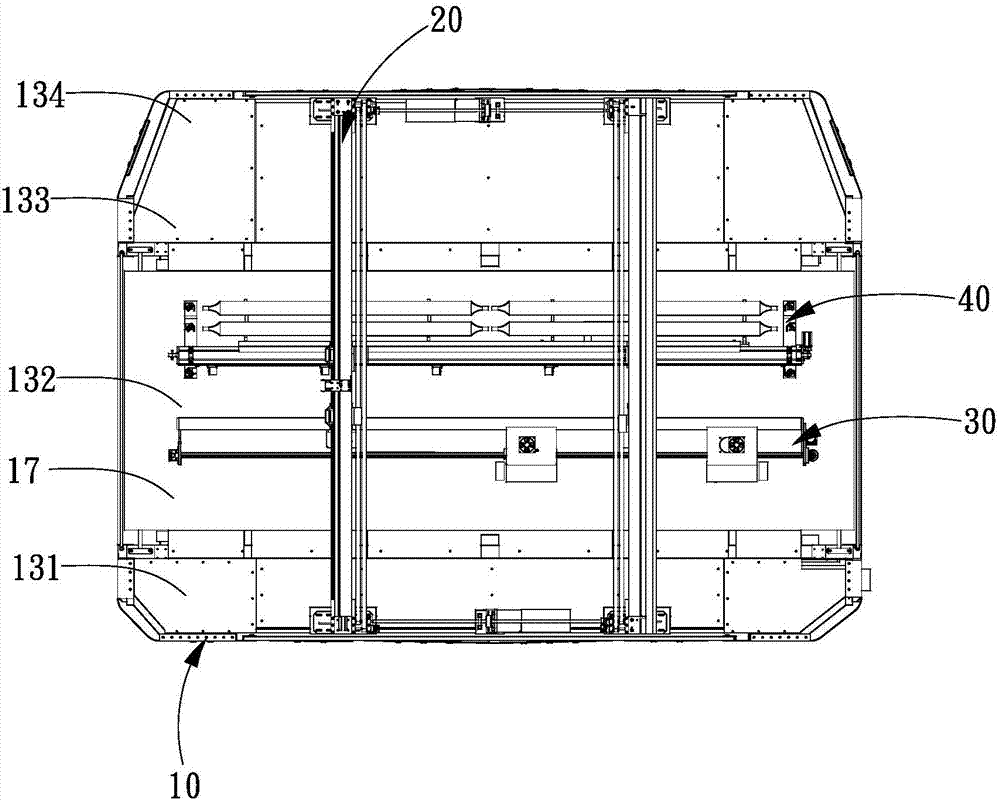

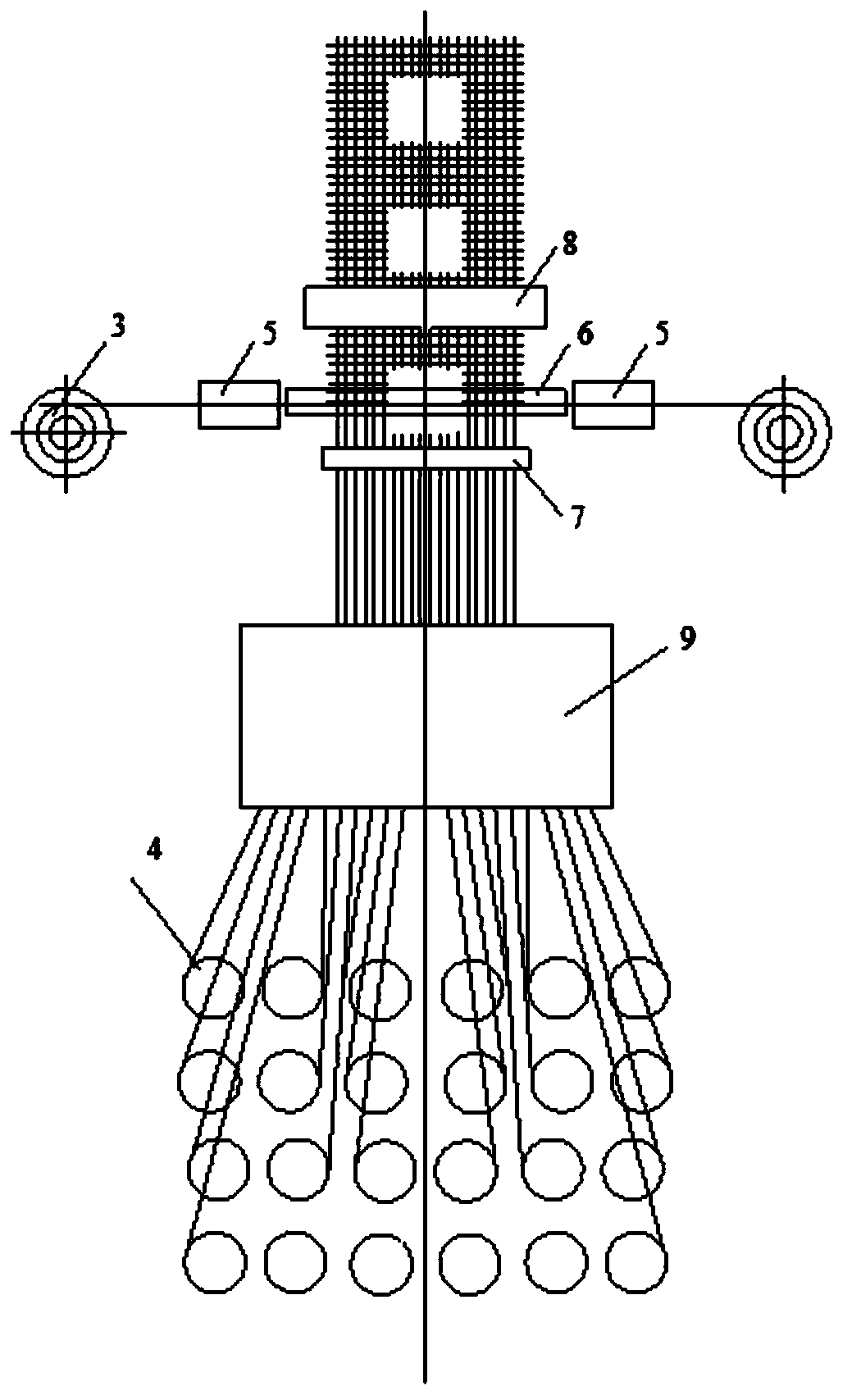

Numerical control hinge drilling machine

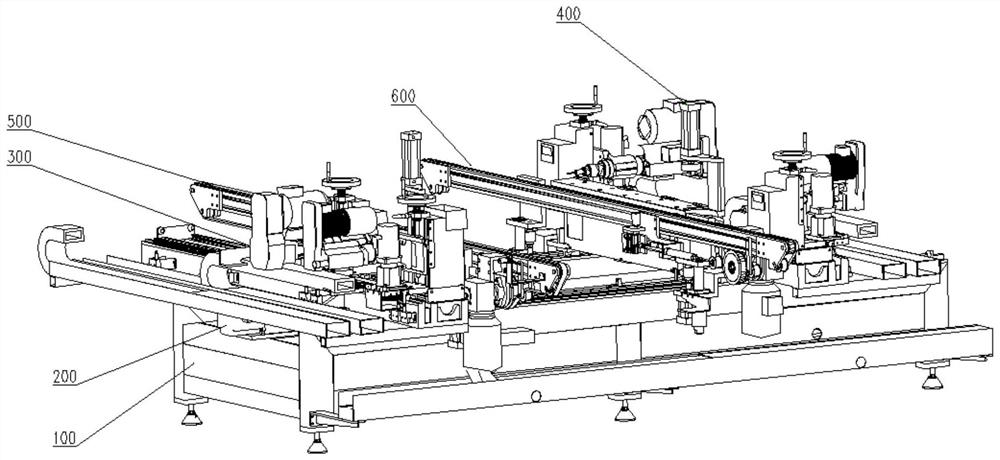

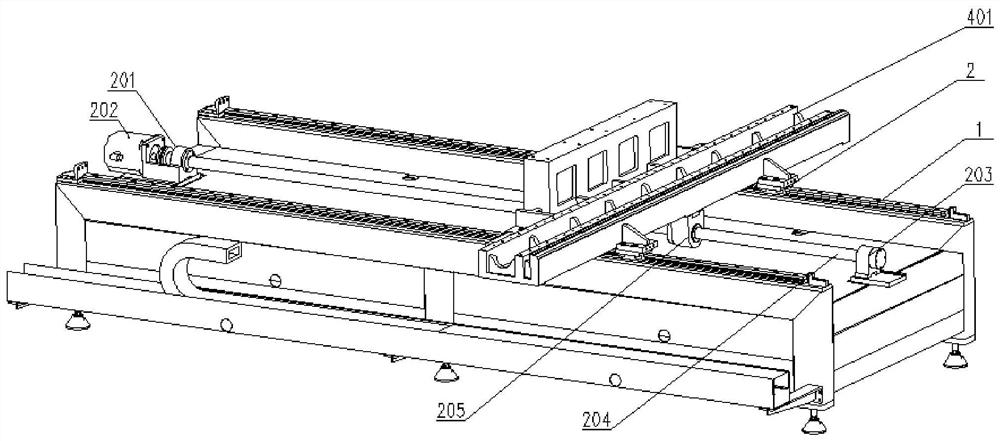

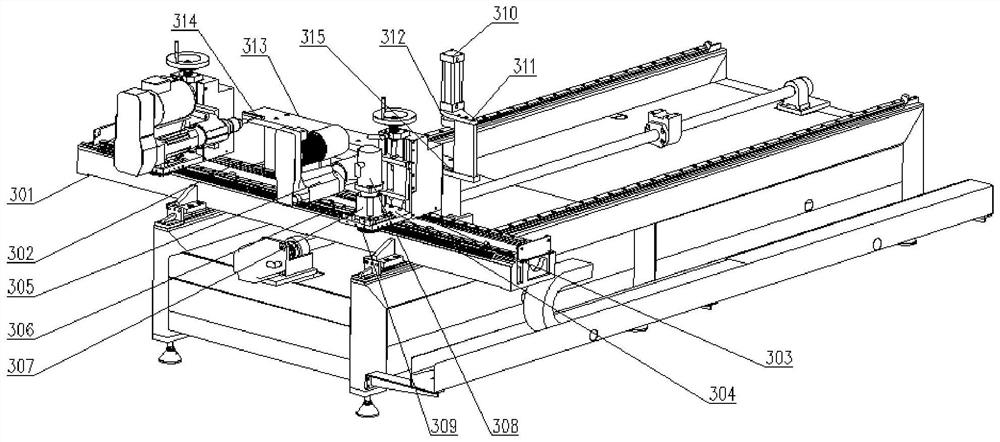

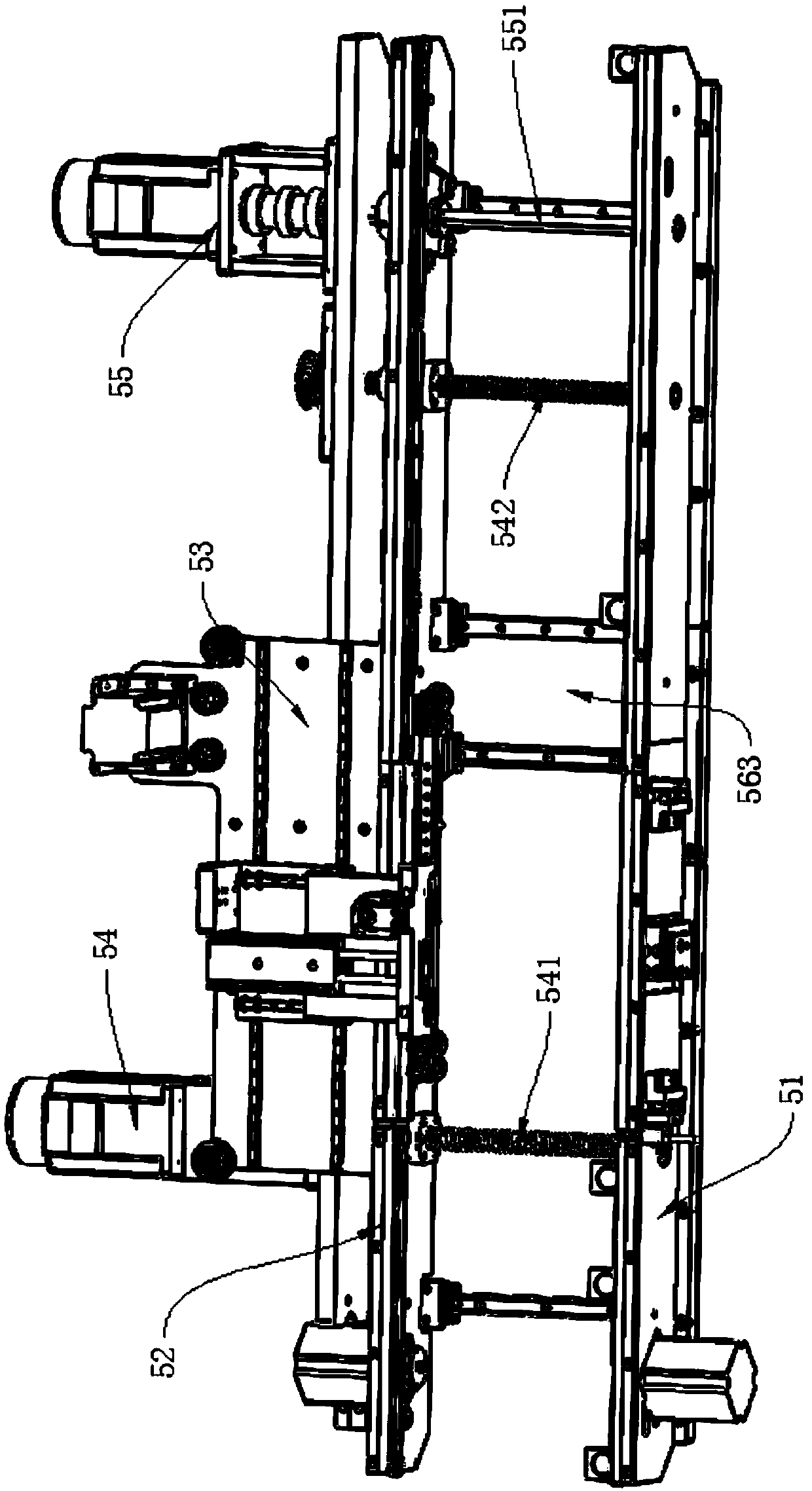

PendingCN113231665AImprove processing efficiencyAccurate machining accuracyWork clamping meansPositioning apparatusProcessing accuracyServo

The invention discloses a numerical control hinge drilling machine. The numerical control hinge drilling machine comprises a rack, an X-direction servo mechanism, a left fixed drilling and milling mechanism, a right movable drilling and milling mechanism, a left lifting conveying mechanism and a right lifting conveying mechanism; the X-direction servo mechanism is arranged on the upper portion of the rack, the left fixed drilling and milling mechanism is fixed to one side of the rack, and the right movable drilling and milling mechanism is arranged on the other side of the rack, driven by the X-direction servo mechanism and matched with the left fixed drilling and milling mechanism; and the left lifting conveying mechanism is arranged on one side of the left fixed drilling and milling mechanism, and the right lifting conveying mechanism is arranged on the right movable drilling and milling mechanism. The numerical control hinge drilling machine has the advantages of being high in machining efficiency and accurate in machining precision.

Owner:济南天辰智能装备股份有限公司

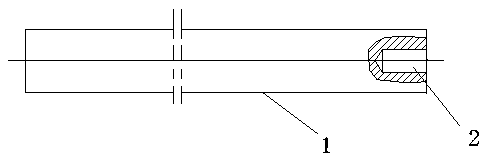

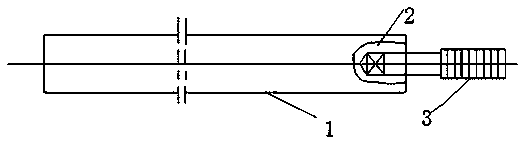

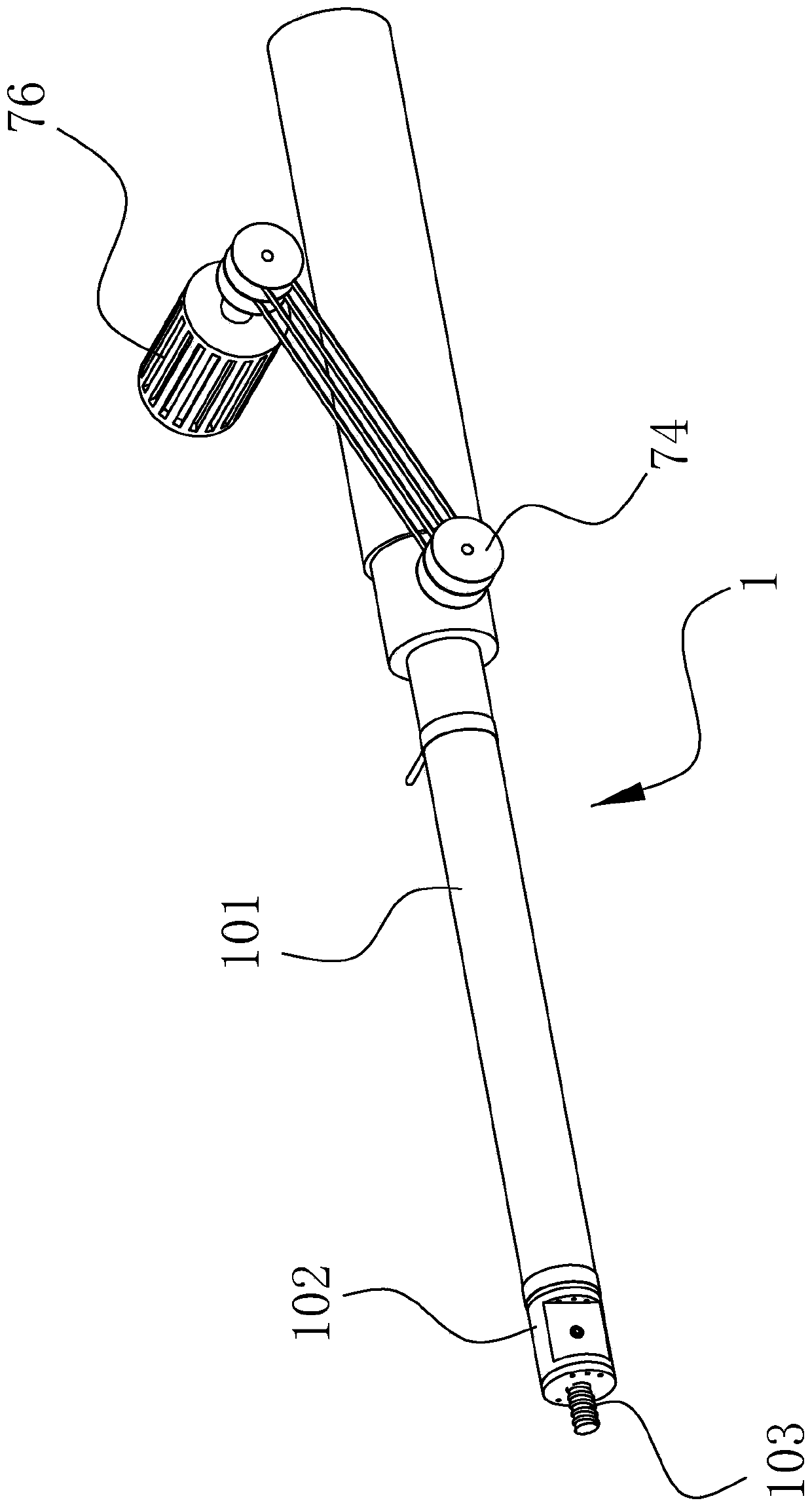

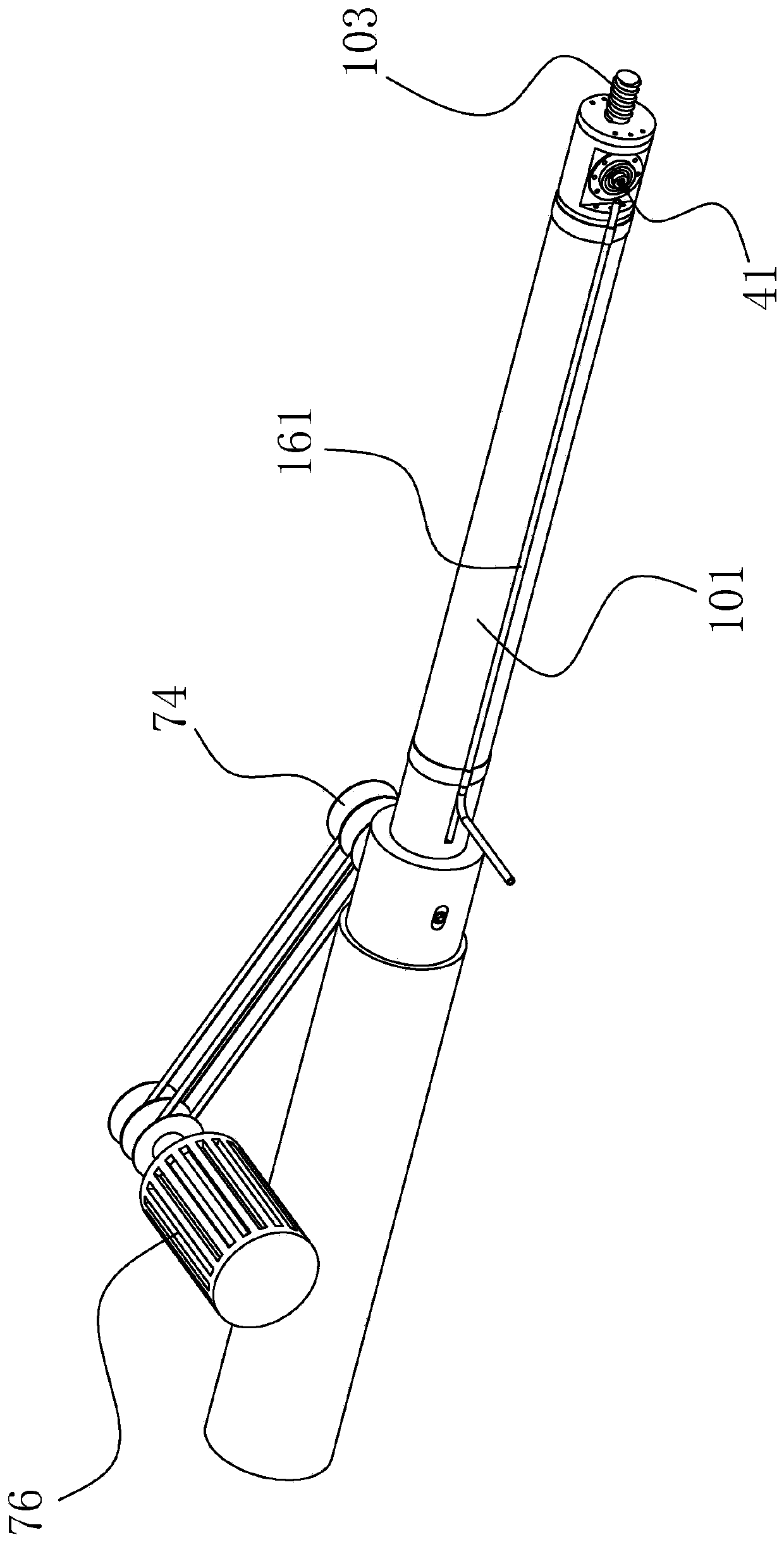

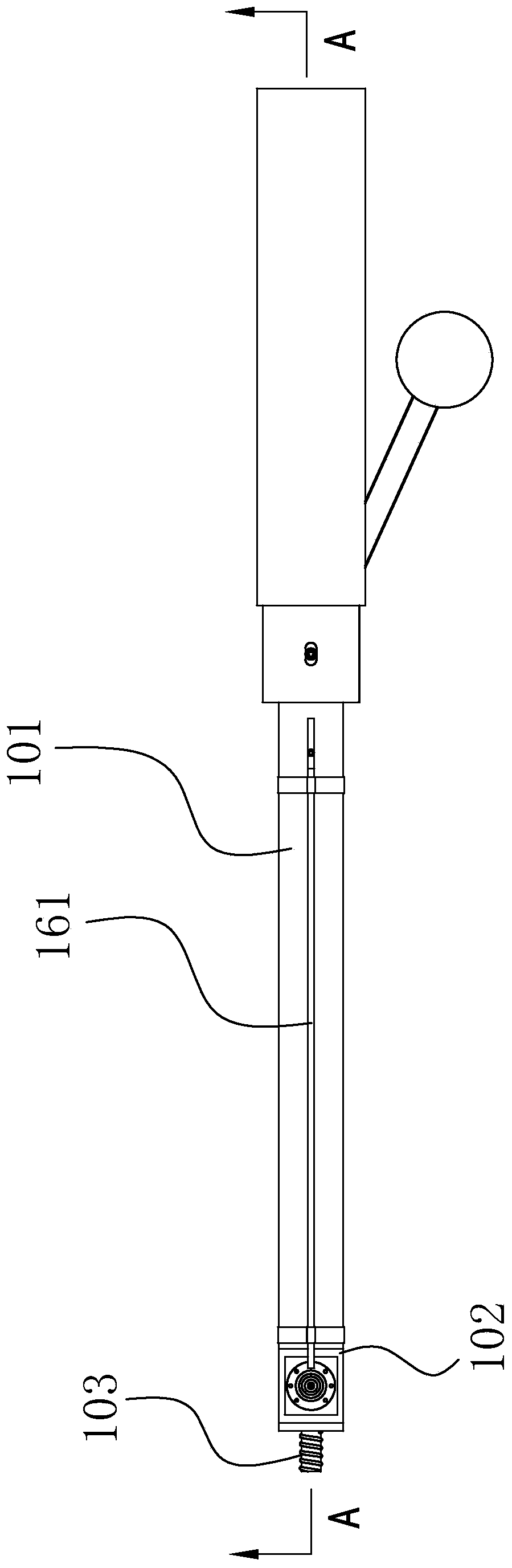

Lengthening bar

The invention provides a lengthening bar, which comprises a bar body (1), a screw tap hole (2) and a screw bolt (3), wherein the bar body (1) is in a rectangular shape, and the length of the bar body (1) is 180mm. The lengthening bar has the advantages that the structure is compact, the processing precision is accurate, the use is convenient, and the like.

Owner:KUNSHAN ETEK METAL IND

A kind of wire cutting equipment suitable for processing the stress groove of connecting rod expansion

ActiveCN110170715BEasy and quick processing of stress groovesAccurate machining accuracyElectrical-based machining electrodesWire cuttingStructural engineering

Owner:NANGONG JINGQIANG CONNECTING ROD CO LTD

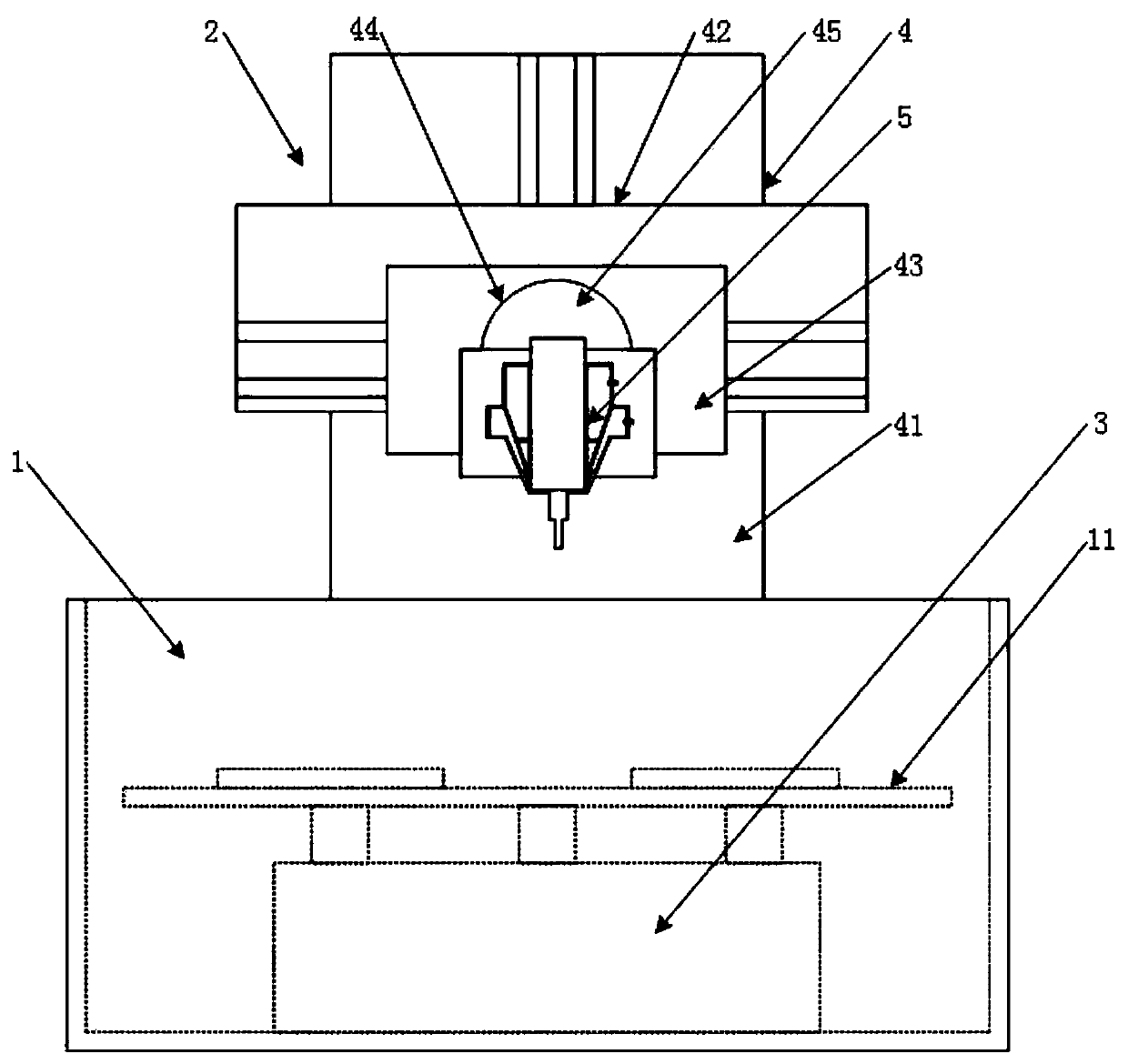

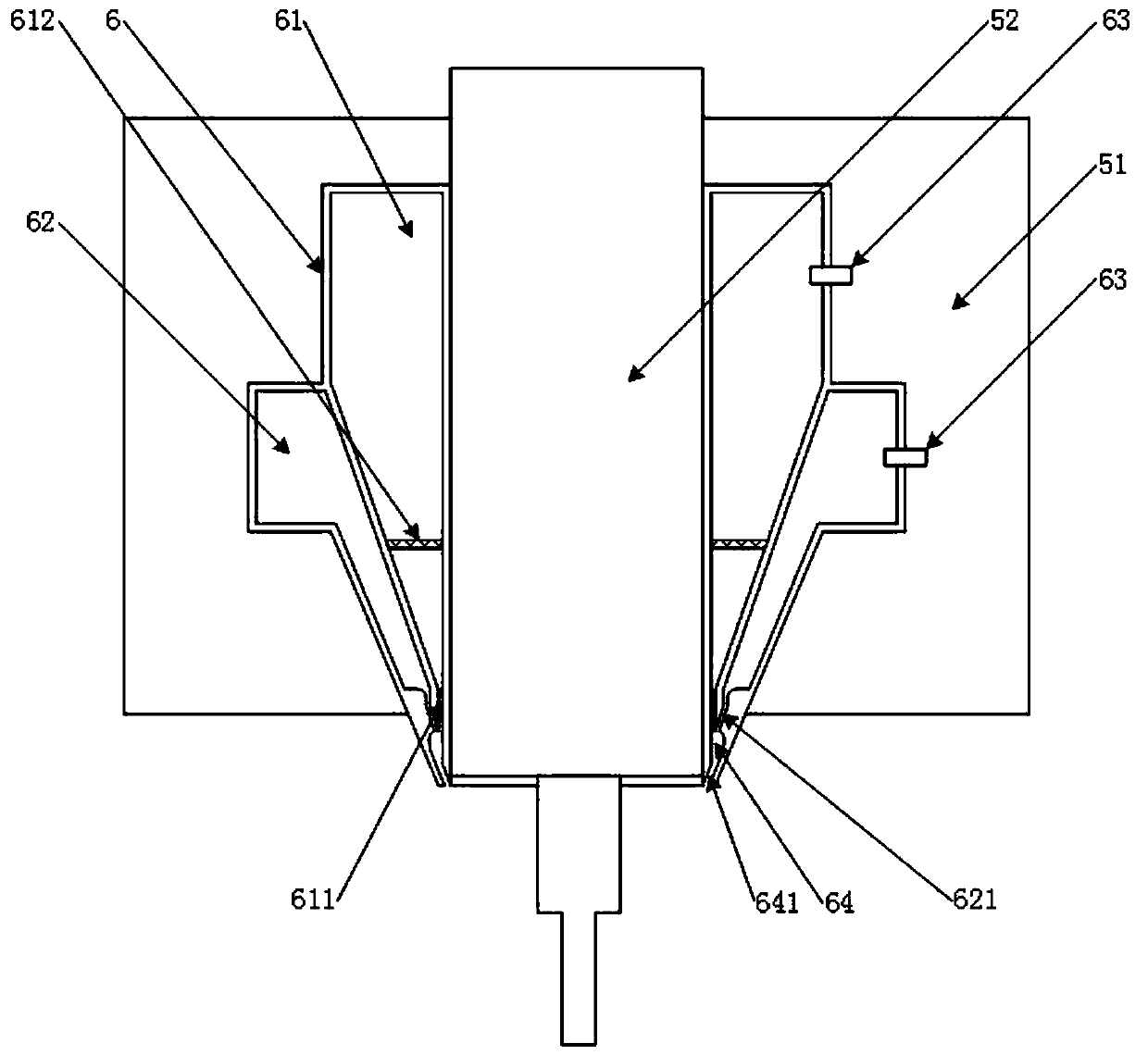

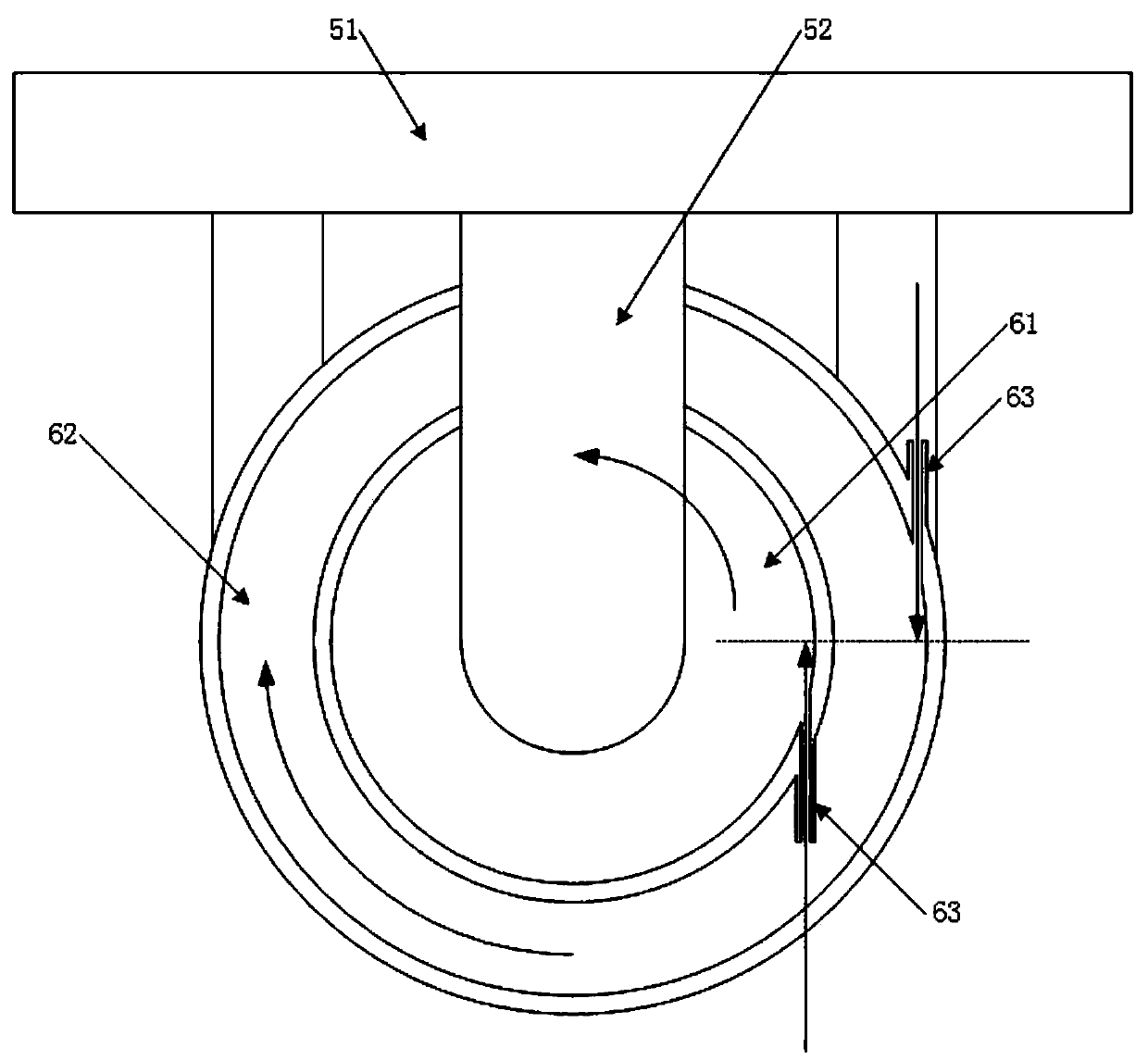

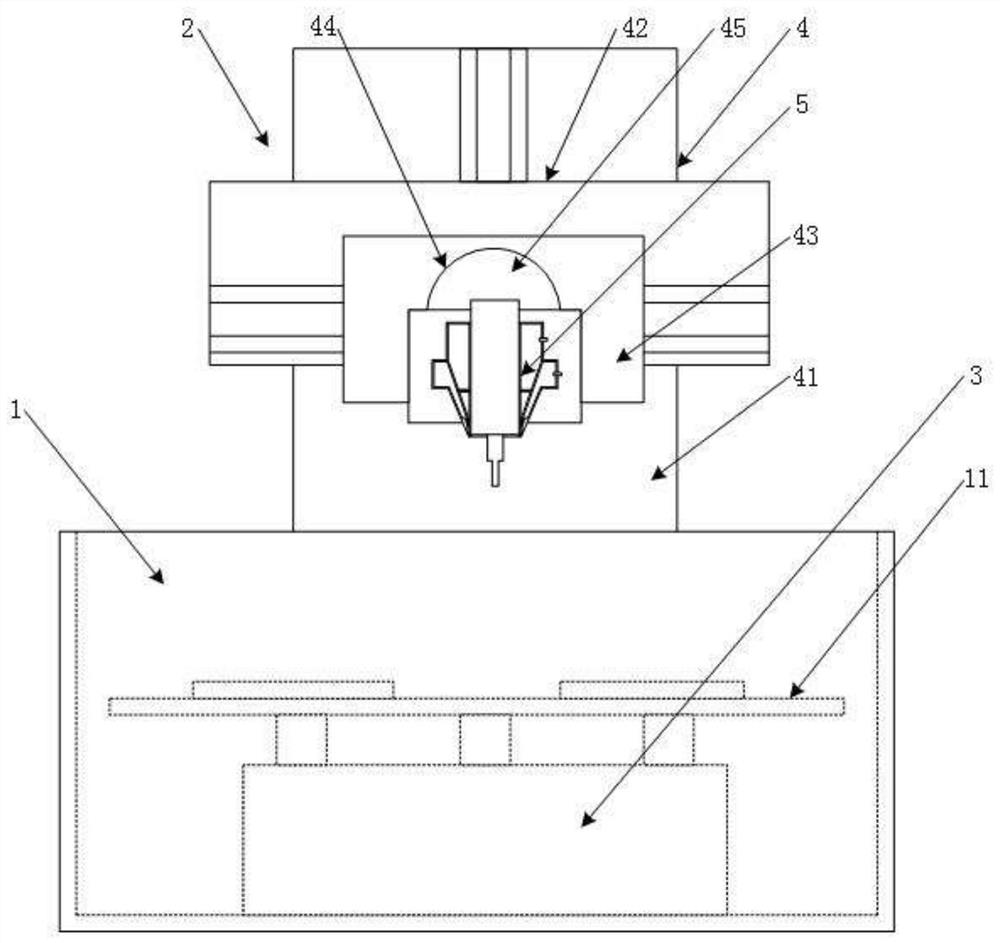

Spark erosion equipment with ultrasonic assistance

ActiveCN111390307ASatisfied with exact configurationMeet the needs of efficient removalElectrical-based auxillary apparatusThermodynamicsEngineering

The invention discloses spark erosion equipment with ultrasonic assistance. The spark erosion equipment comprises a material carrying cabin and an electrode base table, wherein a material plate and anultrasonic generating device are arranged in the material carrying cabin, the electrode base table comprises a displacement driving source and an electrode device, the electrode device comprises a base plate, an electrode base and an oil atomizing spraying mechanism, the oil atomizing spraying mechanism comprises an annular oil storage chamber and an annular air spraying chamber, circular tangential feeding pipe openings are formed in the peripheral wall of the annular oil storage chamber and the peripheral wall of the annular air spraying chamber, a material mixing chamber is formed in the bottom of the annular air spraying chamber, a conical spraying channel is formed in the bottom of the material mixing chamber, an annular feeding channel communicating with the mixing chamber is arranged at the bottom of the annular oil storage chamber, and an annular accelerating channel communicating with the mixing chamber is arranged in the annular air spraying chamber. According to the spark erosion equipment, the mode that jet electric spark media are matched with ultrasonic amplitude is adopted, the requirements for accurate discharge channel configuration and efficient removal of electric corrosion products are met, the workpiece machining quality is improved, and the equipment is particularly suitable for deep hole forming.

Owner:昆山正多荣五金机械有限公司

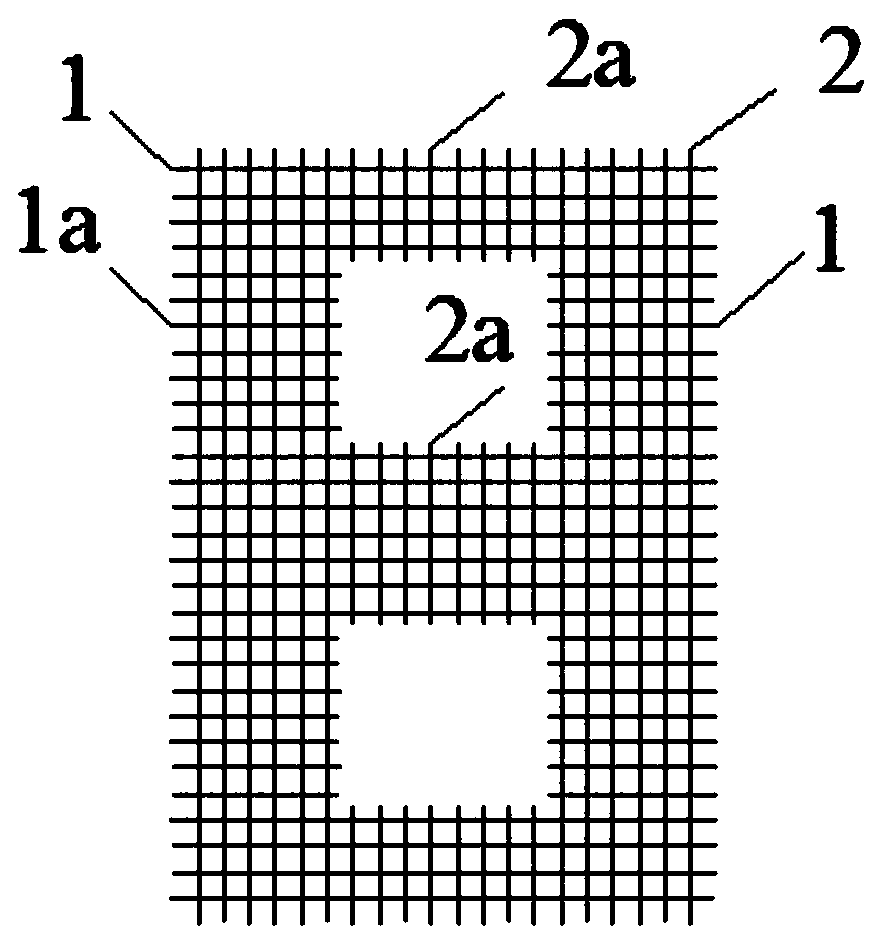

Machining equipment of hollow welding net

InactiveCN110102678ARealize mechanical operationIncrease productivityWire networkWire rodLeft direction

The invention discloses machining equipment of a hollow welding net. The machining equipment comprises a welding net main machine, a longitude line conveying device, a longitude line straightening mechanism and a net shearing device, wherein the two ends of the welding net main machine are correspondingly provided with two latitude line straightening and cutting-off devices, the longitude line conveying device can independently control the stepping of longitude lines, and meanwhile, each longitude line is provided with a longitude line cutting off device; when perforating is not needed, only the latitude line straightening and cutting-off devices on one end is started, meanwhile, longitude line steel wire rods enter the longitude line conveying device after being straightened through the longitude line straightening mechanism, and whole row welding is carried out at the main machine; when a position needing to be perforated is met, the stepping of the stepping longitude lines at a perforated port is stopped, and cut-off is carried out at the corresponding positions, and the rest of the longitude lines continuously step; and when the longitude lines step to a welding position of themain machine, the latitude line straightening and cutting-off devices at the two ends of the main machine work at the same time, stepping latitude lines with corresponding sizes are correspondingly conveyed from the left direction and the right direction according to the position of the perforated port, and holes meeting the requirements can be produced along with performing of the stepping. By adopting the method, the production efficiency is greatly improved, and the product precision is high.

Owner:ANHUI BRC & MA STEEL WELDMESH

Circuit board laser cutting equipment and application method

PendingCN109604843AAchieve positioningGuaranteed cutting needsPrinted circuitsLaser beam welding apparatusEngineeringLaser cutting

The invention provides circuit board laser cutting equipment and an application method thereof and belongs to the field of laser cutting equipment. The equipment comprises a workbench, a conveying assembly and a laser cutting gun. The laser cutting gun is arranged on the workbench and reciprocates relative to the workbench in the directions of the X-axis, Y-axis and the Z-axis. The conveying assembly is arranged above the workbench and arranged along the X axis. The conveying assembly comprises a front plate group and a rear plate group which are same in structure and arranged symmetrically. The front plate group and the rear plate group are arranged in parallel along the X axis. A first conveying belt arranged symmetrically and a second conveying belt arranged symmetrically are arranged on the inner sides of the front plate group and the rear plate group correspondingly. A push manipulator used for achieving circuit board transfer is arranged between the first conveying belt and the second conveying belt, arranged on the side, away from the front plate group, of the rear plate group and located in the middle of the workbench. The circuit board laser cutting equipment is high in cutting precision, high in efficiency, stable in performance, long in service life and low in subsequent maintenance cost.

Owner:天津镭恒自动化科技有限公司

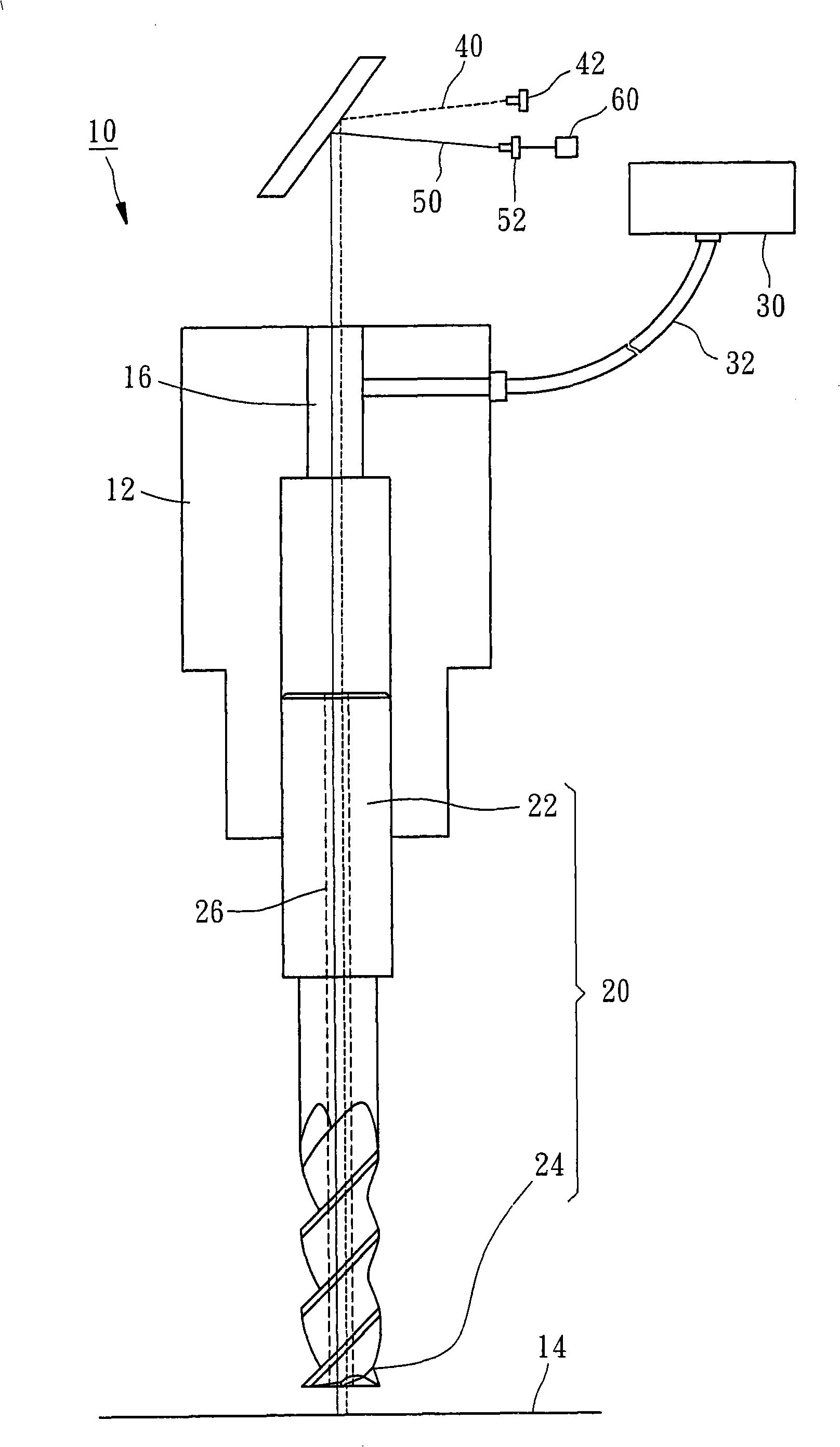

Cutting composite processor with function of measuring processing depth

InactiveCN101513715AFast processingAccurate machining accuracyMeasurement/indication equipmentsOther manufacturing equipments/toolsDepth functionAcoustics

The invention relates to a cutting composite processor, which comprises a cutter, a supply device, a first detecting light wave, a second detecting light wave and a detection control device. The cutter is provided with a through channel; the supply device is used for supplying gas or liquid into the channel; the first detecting light wave and the second detecting light wave are projected to a workpiece along the channel and towards a cutting end of the cutter; and the detection control device is used for receiving light waves which are reflected after the second detecting light wave is projected to the workpiece. Because of the components, not only the processing speed is higher, but also the processing precision is more accurate.

Owner:CONTREL TECH CO LTD

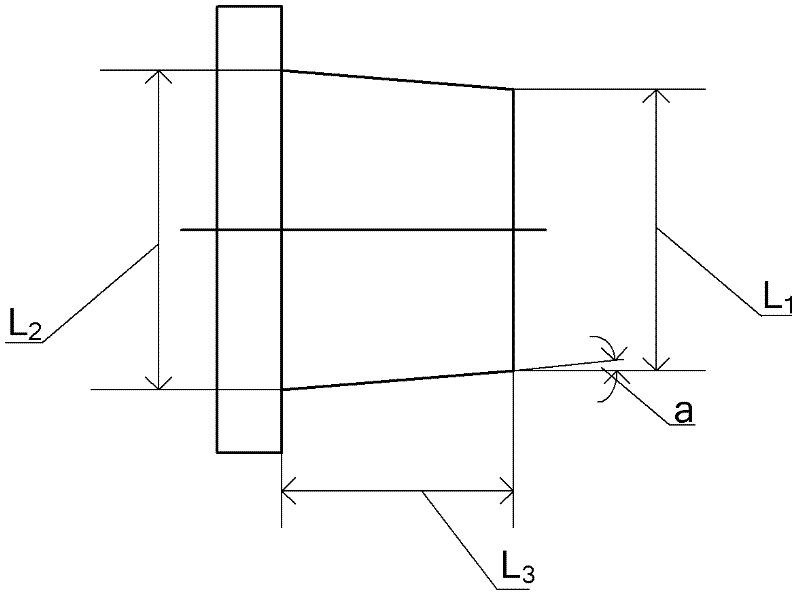

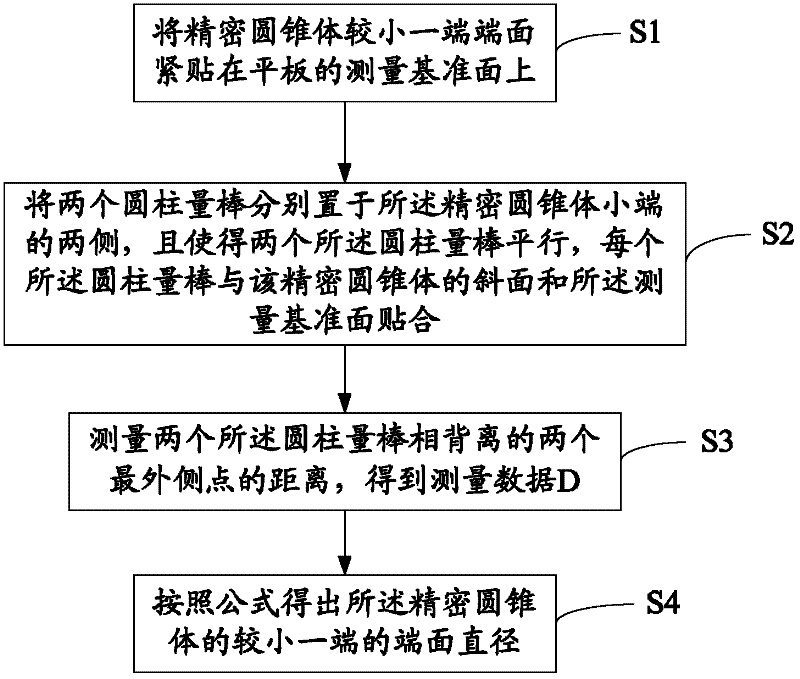

Method for measuring precision cone

InactiveCN102538633AAvoid the problem that the two ends of the diameter of the smaller end face of the precision cone cannot be stuck exactlyAccurate machining accuracyMechanical diameter measurementsOptoelectronicsVertical distance

The invention discloses a method for measuring a precision cone. The method comprises the following specific steps of: clinging the end face of one smaller end of the precision cone on a measurement reference surface of a flat plate; respectively arranging two cylindrical measuring rods at the two sides of the smaller end of the precision cone, and leading the two cylindrical measuring rods to be parallel to each other, wherein each cylindrical measuring rod clings to the tilt surface of the precision cone and the measurement reference surface; measuring a vertical distance between two outermost side points departed from each other in the two cylindrical measuring rods to obtain measurement data D; and according to a formula, obtaining the diameter of the end face of the smaller end of the precision cone. According to the method for measuring the precision cone, the diameter of the end face of the smaller end of the precision cone is not directly measured but is obtained by using indirect measurement and calculation of the cylindrical measuring rods, so that the diameter of the end face of the smaller end of the precision cone can be more accurately obtained; and therefore, the processing precision of the diameter of the end face of the smaller end of the precision cone can be accurately obtained.

Owner:LAIWU IRON & STEEL GRP

Milling cutter structure for cylinder inner hole groove milling

InactiveCN110976989AEasy to processReduce replacement costsMilling cuttersMilling equipment detailsTool bitMilling cutter

The invention discloses a milling cutter structure for cylinder inner hole groove milling. The milling cutter structure comprises a cutter head for milling a groove in an inner hole of a cylinder, a rotating part capable of detachably fixing a tool bit, a transmission part capable of being linked with an output shaft of a driving motor, and a cutter bar capable of extending into the inner hole ofthe cylinder. The rotating part is rotatably arranged at the head part of the cutter bar; the transmission part is arranged at the rear part of the cutter bar; a cavity capable of containing a transmission belt is formed in the cutter bar in the axial direction; the rotating part is in linkage with the transmission part through the transmission belt; when the milling cutter works, the tool bit canmake contact with the inner wall of the cylinder along with movement of the cutter bar in the inner hole of the cylinder to rotate; and a conveying pipe capable of conveying cooling water to the cutter bit is arranged on the cutter bar in the axial direction. The milling cutter structure has the advantages that the groove penetrating through the inner hole of the cylinder can be milled in the inner wall of the inner hole of the cylinder; the tool bit is convenient to replace after being abraded; a spiral groove can be machined in the inner hole of the cylinder; and the groove milling depth ofthe tool bit on the inner wall of the inner hole of the cylinder can be changed.

Owner:舟山市金塘山舟机械厂

A ring profiling hammer handle shape processing and polishing equipment

InactiveCN108311892BImprove processing efficiencyReduce labor costsOther manufacturing equipments/toolsMetal working apparatusPolishingEngineering

The invention relates to the technical field of hammer machining, in particular to a hammer handle shape machining and polishing device with an annular explorator. An electric control box is used forunified control over feeding, clamping, processing and polishing. A blanking device automatically conducts blanking to a conveying device under the effect of the gravity. Automatic conveying, clampingand correction are achieved. A machined hammer handle is conveyed to the position of a machining tool through an explorator cylinder so as to be machined. Meanwhile, the machining distance or the depth is limited through the explorator. A polishing device which coaxially rotates instantly conducts polishing after cutting is completed. Manual operation is not needed in the whole process, so that the machining efficiency is greatly improved, the labor cost is reduced, and the machining precision is high and consistent; and the hammer handle shape machining and polishing device is suitable for large-scale application and popularization.

Owner:SHAODONG HEXIE HARDWARE ELECTROMECHANICAL CO LTD

EDM equipment with ultrasonic assistance

ActiveCN111390307BSatisfied with exact configurationMeet the needs of efficient removalElectrical-based auxillary apparatusElectric dischargeEngineering

The invention discloses an electric spark processing equipment with ultrasonic assistance, which includes a material loading cabin and an electrode base. The material loading cabin is provided with a material plate and an ultrasonic generating device. The electrode base includes a displacement driving source and an electrode device. The electrode device It includes a seat plate, an electrode seat, and an oil atomization injection mechanism. The oil atomization injection mechanism includes an annular oil storage chamber, an annular air injection chamber, and the outer peripheral wall of the annular oil storage chamber and the annular air injection chamber. The outer peripheral wall is respectively provided with a circular tangential feeding nozzle, the bottom of the annular air injection chamber is provided with a mixing chamber, the bottom of the mixing chamber is provided with a tapered injection channel, and the bottom of the annular oil storage chamber is provided with There is an annular feeding channel connected to the material mixing chamber, and an annular acceleration channel connected to the material mixing chamber is arranged in the annular air injection chamber. The invention adopts the method of matching the injection electric spark medium and the ultrasonic amplitude, meets the requirements of accurate discharge channel configuration and efficient removal of electric corrosion products, improves the processing quality of workpieces, and is especially suitable for deep hole forming.

Owner:昆山正多荣五金机械有限公司

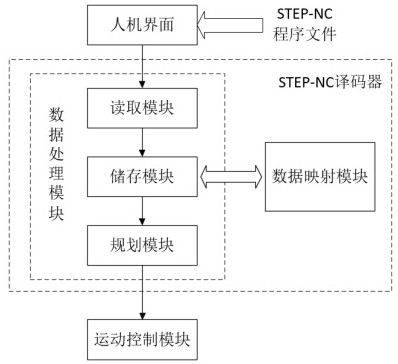

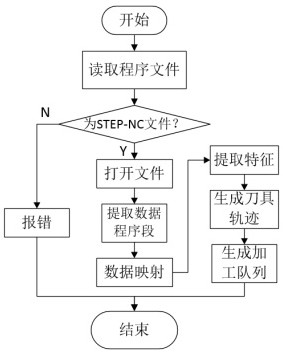

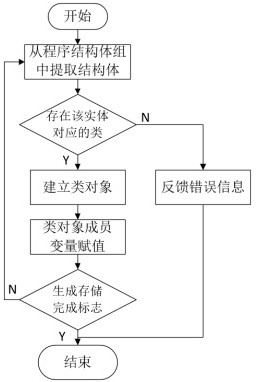

A Step-NC Decoder Development Method for Open CNC System Based on Linux

ActiveCN113296475BAvoid lossIncrease profitProgramme controlComputer controlDecoding methodsFeature extraction

The invention relates to a STEP-NC decoder development method of an open numerical control system based on Linux. Through the analysis of STEP‑NC data model structure, the decoding method of STEP‑NC code based on Linux-based open CNC system is studied, the decoding workflow of STEP‑NC decoder is designed, and the STEP‑NC decoding is developed Functional modules such as the reader module, data mapping module, storage module and planning module, etc., integrate the STEP‑NC decoder into the Linux-based open CNC system to realize the configurable NC decoding method. The STEP-NC decoder developed by this method can recognize 2.5D manufacturing features defined in the ISO 14649 standard, extract geometric information and machining information, and generate tool paths that can be used in actual machining.

Owner:FUZHOU UNIV

A multifunctional hydrostatic power head

ActiveCN106736793BReduce volumeSmall footprintLarge fixed membersDriving apparatusHigh pressureControl theory

The invention discloses a multifunctional static-pressure type power head which comprises a cutter head, a spindle box, a shaft sleeve, a main shaft and a box body, wherein the box body is equipped with a first servo motor and a second servo motor; the main shaft can drive the cutter head to rotate; under action of the first servo motor, the main shaft can drive the cutter head to integrally move front and back relative to the main shaft, so that axial feeding is performed; under action of the second servo motor, the cutter head performs radial feeding; the actions are matched, so that a tool can perform multifunctional processing such as turning, milling and boring; various feeding drive structures are distributed reasonably, the cutter head is small in size, space usage is small and processing precision is accurate; high-pressure oil is filled between the shaft sleeve on which the main shaft is located and the spindle box; locking force of the shaft sleeve can be changed by changing oil pressure, so that control is convenient; and stability after the shaft sleeve is locked is strong, so that the integral power head has good working reliability.

Owner:安徽速诚智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com