CNC (computerized numerical control) combined turning and grinding machine tool for four-linkage enveloping worms and processing method thereof

A technology of compound machine tools and toroidal worms, which is applied in the direction of worms, mechanical equipment, and components with teeth, etc., to achieve the effects of convenient operation, precise transmission and machining accuracy, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

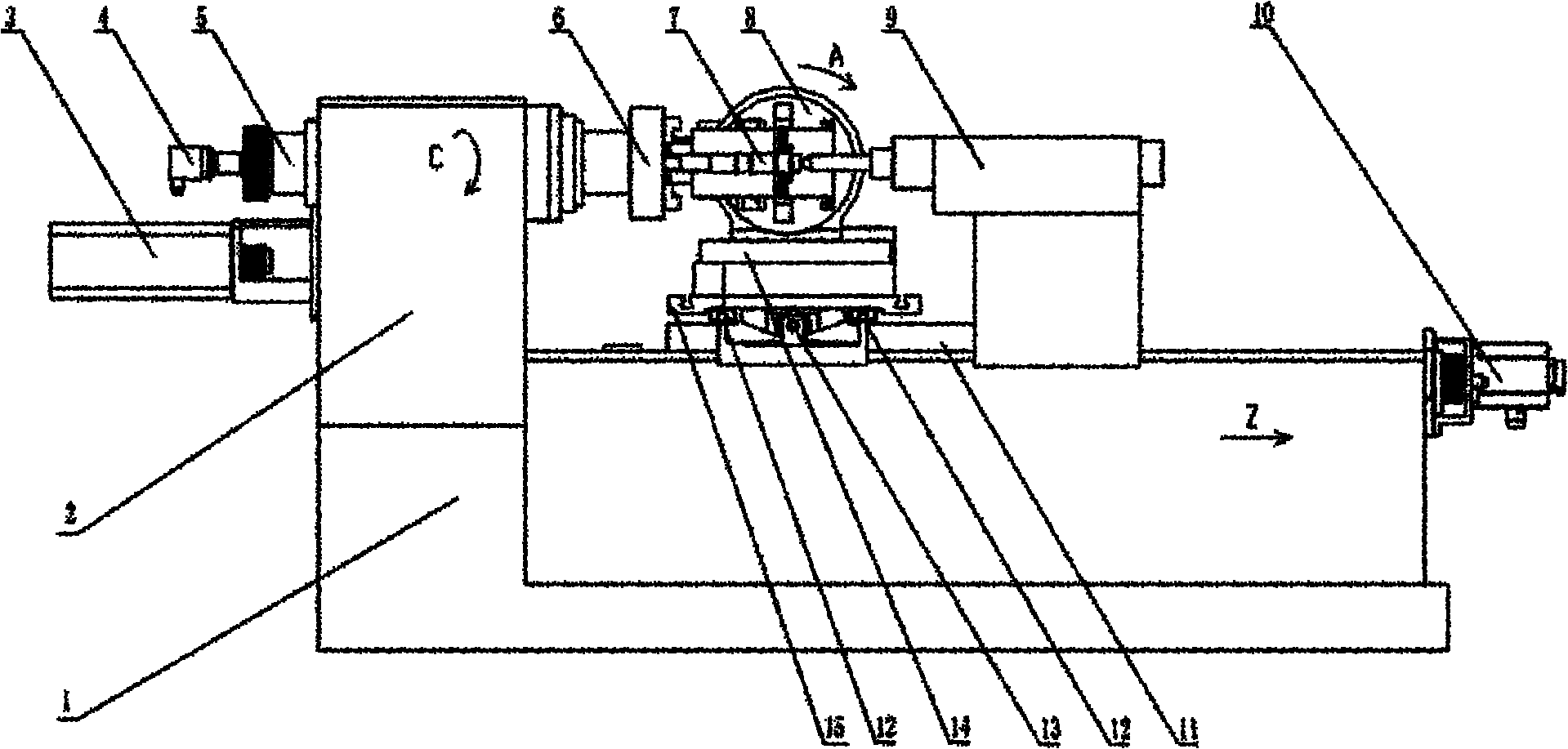

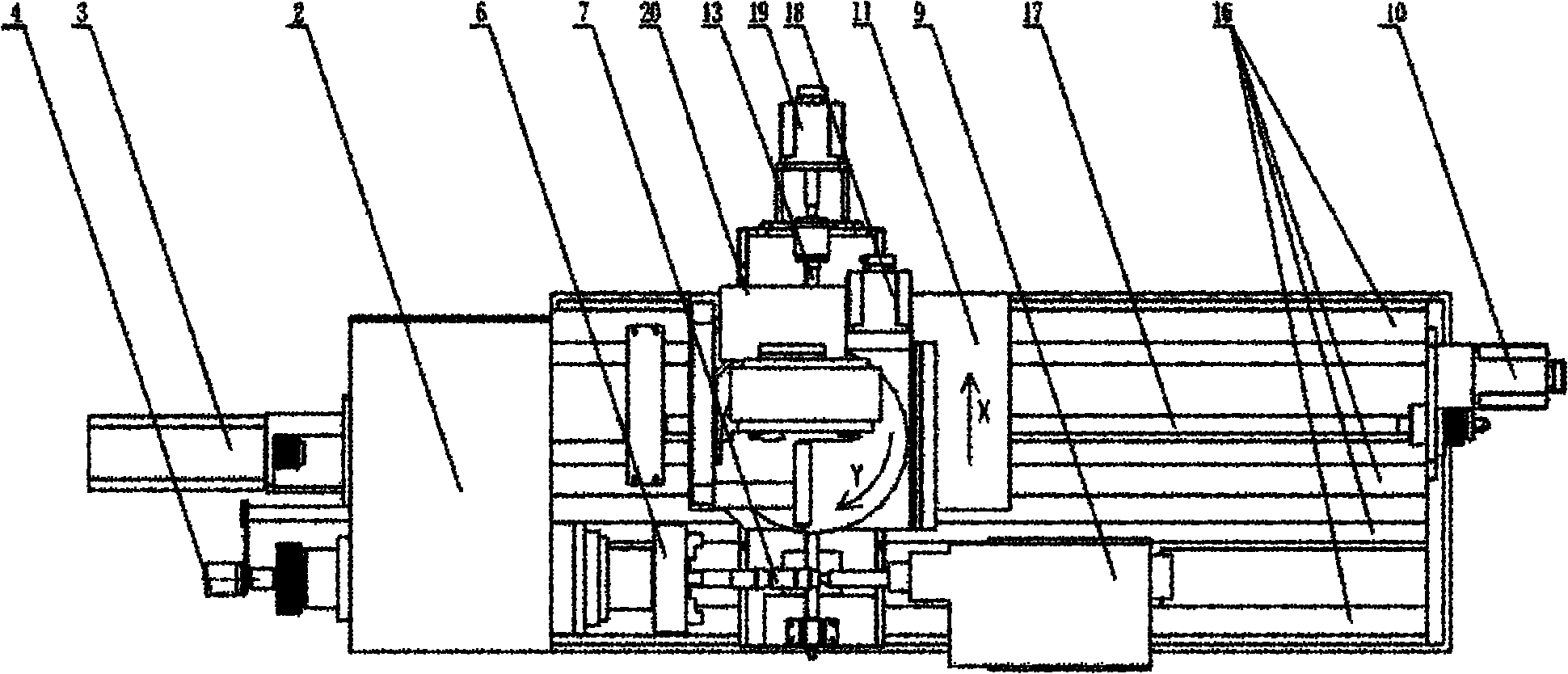

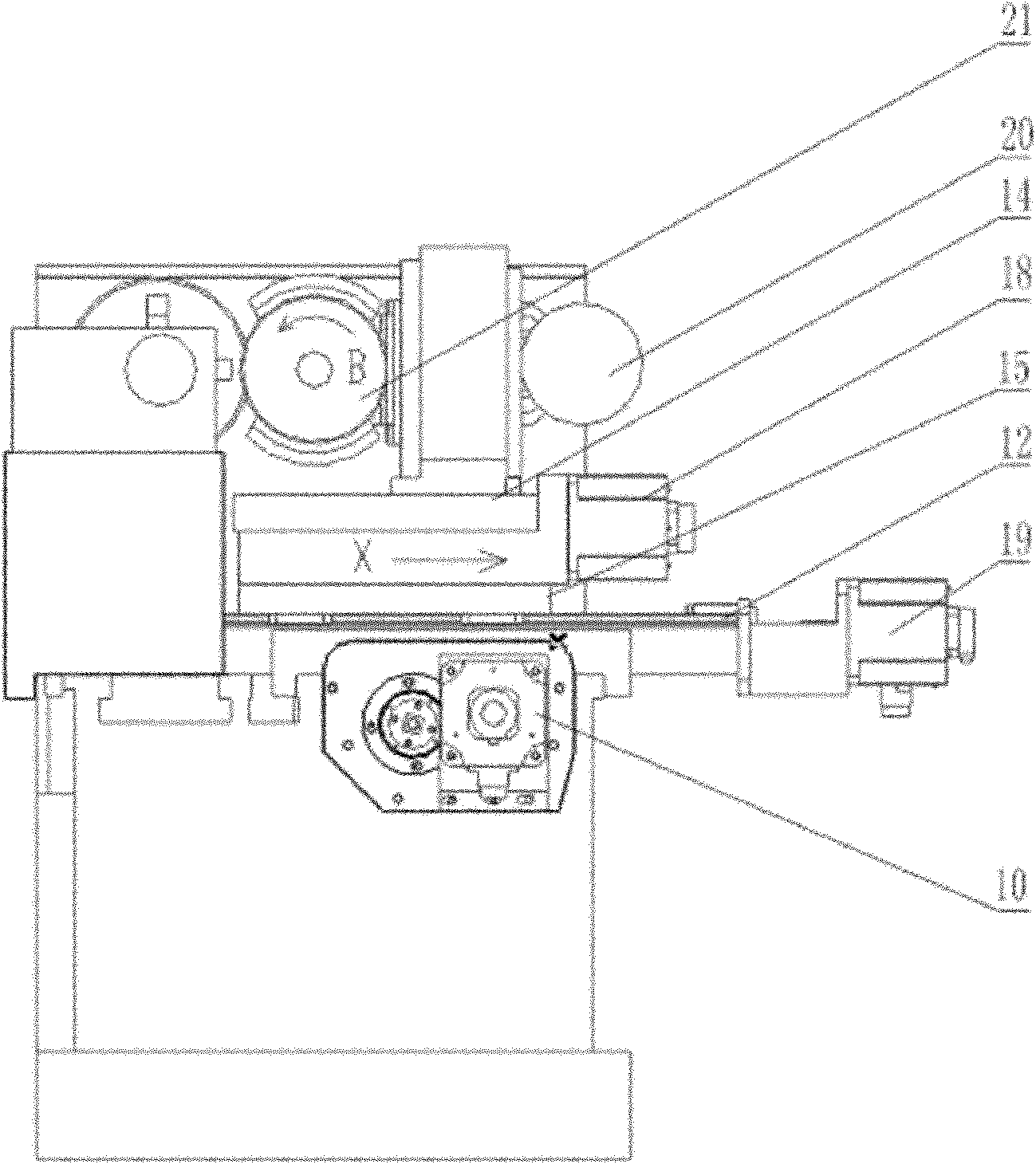

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. This manufacturing technique is very clear to those skilled in the art.

[0026] With the center distance A=125, the number of worm heads is 2, the transmission ratio i=20.5, the number of worm gear teeth surrounded by the worm is 4.5, the axial modulus m=4.927, the arc radius of the worm tooth root is 105.43, the arc radius of the worm tooth top is 97.55, and the length of the working part of the worm 62, a right-handed plane quadratic enveloping toroidal worm with a base circle diameter of 78 and a full tooth height of 7.88 is taken as an example.

[0027] Except for the helical surface of the worm, other dimensions are cut in place first. When rough machining the right side of the spiral surface, the width of the top edge of the cutting tool is 5, which is less than the root groove width of 7.19, and greater than half of the tooth root groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com