Full-automatic polishing grinding production line

A polishing and production line technology, used in grinding/polishing equipment, grinders, abrasive belt grinders, etc., can solve the problems of high scrap rate, high labor cost, hidden dangers in product quality and safety, and achieve accurate processing accuracy and processing. The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

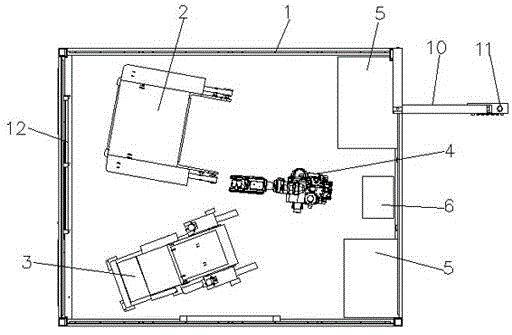

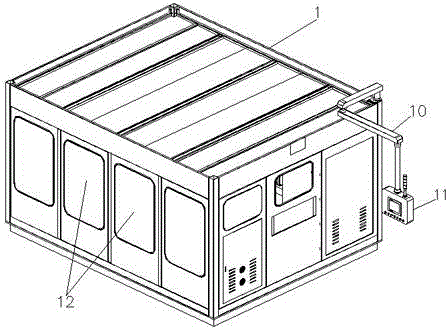

[0020] refer to Figure 1 to Figure 6 As shown, the full-automatic polishing and grinding production line includes a cover body 1, and the cover body is provided with a sanding machine 2, a wheel cloth machine 3, a manipulator 4, an electric control box 5 and a feeding table 6, and the cover body 1 passes through a The movable frame 10 is fixed with an operation panel 11, and the cover body 1 is provided with a plurality of visible windows 12 through which the processing status of the workpiece in the cover can be observed for easy operation.

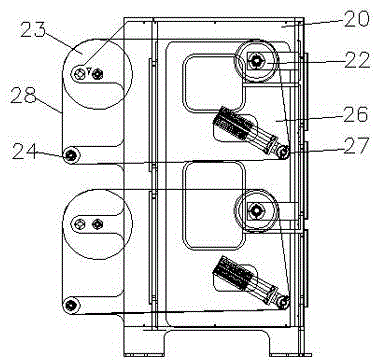

[0021] Above-mentioned sand-beating machine 2 comprises sand-beating frame 20, and described sand-beating frame 20 is provided with at least two groups of sand-beating mechanisms, and desired sand-beating mechanism is composed of sand-beating motor, driving wheel 22, beating emery wheel 23, support wheel 24, Sanding belt 25, tensioning cylinder 26 and tensioning wheel 27 are formed, and the output end of sanding motor is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com